- Efficient Tobacco & Nicotine Powder Packaging

- Automatic Snus Tobacco Complete Packing Line

- Continuous Packing Machine For Granule

ALLPACK Snus Packing Machine

ALLPACK snus packing machine is mainly used to pack 0.2g to 1g snus in small portions made of non woven fabric. The machine could realize fully automatic forming, filling and sealing machine for small sachets, and then some sachets are packed into the bag by the snus bag packing machine. The machine adopts correcting system controlled by microcomputer, owing to a response signal is handle and set pass through microcomputer. The snus packing machine can accomplish whole set to synchronization, sack length, position fixing, voluntarily follow the tracks of light-mark and voluntarily diagnose trouble and show to screen. It is suitable for package of foodstuff, seasoning, medicine (For example: puffed, fried fresh chip, cracknel, moon cake and so on.)

Snus Packing Machines

4-Lanes Dry/Wet Granule Small Back-Seal Packaging Machine Snus Packing Machine

ALLPACK 4-lanes snus packing machine is designed and manufactured according to GMP pharmaceutical standards for a stylish appearance and intelligent operation. It is specialized for quantitatively filling and packaging granular materials using dry/wet process technology. This snus packing machine can be the pianeered reverse blow filling device for materials with 3%-40% humidity, achieving up to 180 bags per minute.

Smooth and elegant bag shape

High efficiency and durability

High-Speed Packaging

10-Lanes Dry/Moist Ultrasonic Sealing Packing Machine Snus Packing Machine

ALLPACK 10-lanes snus packing machine is a state-of-the-art, fully automated solution designed for the efficient and hygienic packaging of snus products. This machine is ideal for manufacturers in the tobacco industry looking to streamline their production process, ensure consistent packaging quality, and meet high-volume demands. Equipped with advanced sensors and control systems to ensure accurate filling, sealing, and labeling of snus pouches.

User-Friendly Interface

Built with high-quality components

PLC intelligent control, stable operation

20-lanes Heat-seal Dry/Moist Packing Machine Snus Packing Machine

ALLPACK 20-lanes snus packing machine is equipped with a microcomputer control system with english dispaly and a smart temperature controller to ensure beautiful and smooth seal. The machine can automatically complete such discontinuous operations as measuring,filling,bag marking,counting,printing etc. Lower consumption,high efficiency, safety and cleanness,it's an ideal equipment which can be used for packing wheat flour,paper powder,yeast powder,instant powder,spices,cocoa powder etc.

Compact size and movable for limited space

With HMI and PLC control system for easy parameter setting

Simple basic structure,easy for daily maintenance

High-speed single-lane wet powder Snus Packing Machine Nicotine Pouch Packing Machine

ALLPACK high-speed snus packing machine mainly consists of volumetric cup filling system and the main bagging machine. It is suitable for fined granule products like salt, sugar, seeds, granular spices, deoxidizer, snus powder, ect. automatic metering, filling, sealing and packing into pouches.Customized volumetric cups are available for choice to meet different kinds of granule tea packing in a certain filling range. Simple roll film structure enable film running in stable and unhindered condition.

Super-efficient Full Automatic

Chewing Nicotine Snus Sachet Packaging Machine

Easy to Operate Automatic

Snus Labeling Machine

ALLPACK snus labeling machine is a customized non-standard upper and lower plane plus spoke round bottle labeling machine. It is mainly used to organize reliable in operation.The main machine uses a serve motor to put out labels, PLC program control, and a touch screen to realize a human machine dialogue interface. There is no bottle falling phenomenon, and it has a photoelectric control device. When the bottle is detected, the label is stopped after one label is put out, and the cycle repeats.

Advanced servo drive

Fast speed and high poisioning accuracy

High stability and accurate detection

Fully Automatic Sleeve Style Heat-Shrink Wrapping Machine

ALLPACK fully automatic sleeve style heat-shrink wrapping machine is a fully automatic PE film shrink wrapping machine that automatically organizes materials and is suitable for automatic shrink wrapping of combination products without bottom trays. The shrink wrapping achine allows combination shrink wrapping of snus/snus pouch-in-box products , etc.

Convenient operation

Photoelectric automatic detection

High automation program

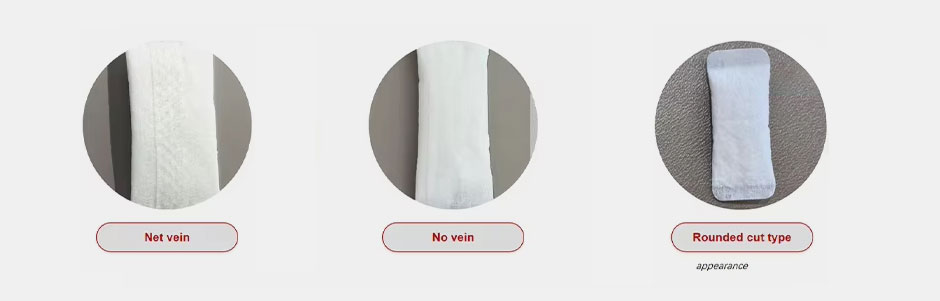

Experimental Single-Row Wet-Process Granule Small Back-Seal Snus Packing Machine

ALLPACK experimental single row snus packing machine is suitable for non-woven packaging film, and the bag width specifications can be selected from 13mm, 14mm, and 15mm. The machine adopts the inner and outer lap seal/twisted edge sealing structure, and the finished bag is longitudinally sealed without flanges, and the chewing taste is better. The main machine adopts a servo heat-sealed bag pulling structure,with high bag pulling accuracy and more convenient to change the bag length on the touch screen.

GMP standards

Quantiative filing and back-sealing

High intelligent operation

Automatic Lidding Machine

ALLACK automatic lidding machine adopts an inclined ramp type lid pressing method and automatically removes reverse lids. It utilizes a wire chute for lid feeding, equipped with photoelectric lid detection, and programmatically controls automatic lid supplementation. With continuous turnable structure, the automatic lidding machine has a maximum lid pressing speed of up to 45 boxes per minute.

PLC touch screen control

Safety door&warning signs

Intelligent control

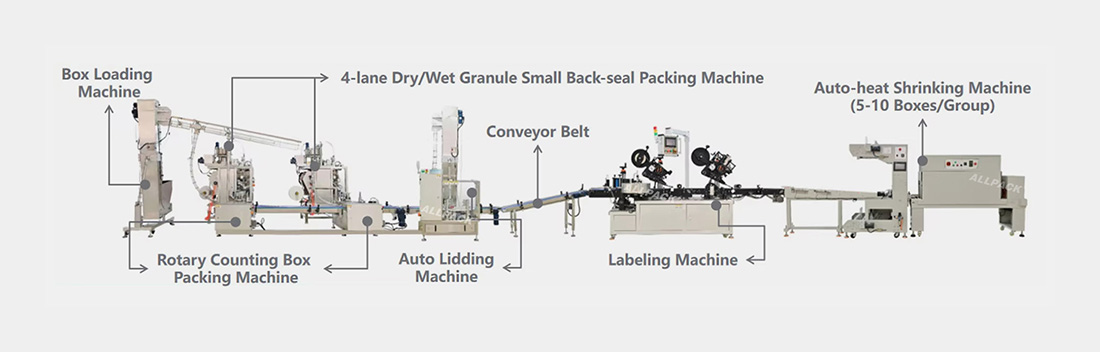

4-Lanes Snus Packing Machine Snuff Powder Chewing Tobacco Can Filling Packing Machine Line

ALLPACK 4-lanes snus packing machine can filling production line involves automatic filling, automatic cartoning, automatic labeling and automatic heat shrink wrapping. The whole production line can realize 5-10 boxes per pack. The whole production speed could be 40 box per minutes, 800 packs per minute. The whole snus packing machine production line is suitable for all kinds of snus, snuff, nicotine pouches, tabacco pouches, dip pouches and other similiar shape products.Big capacity to meet your growing market demand.

Automatic operation saving labor

Simple and convenient operation

Provide customized solutions

10-Lanes Feibin Mouth Tobacco Pouch Snus Packing Machine Production Line

ALLPACK 10-lanes snus packing machine automatic production line can complete the production processes of snus packaging, canning, capping, round bottle labeling,flat labeling, coding, etc., saving labor costs. The whole production line has the functions of self-diagnosis and fault prompt. With PLC intelligent control, stable operation, adjustable speed, parameter setting via touch screen, support for multiple languages, simple operation.

Suitable for different bag types

PLC intelligent system

High efficiency&low energy consumption

Snus Packing Machine Videos

The Buyer's Guide

Snus Packaging Machine: A Complete FAQ Guide in 2025

Do you have any idea which machine is used to package snus? Well, a snus packaging machine is used to pack a smokeless tobacco, snus. As in the young generation, the demand of snus is increasing. So, attractive packaging to appeal to the customers is one of the top priorities. For industries like tobacco, pharmaceutical and many more, a machine with high -quality, dependable, and guaranteed packaging is necessary.

There are various models of snus packaging machines. Your mind will jumble with a lot of questions about machine quality, benefits, and many more as buying a snus packaging machines requires deep information. If you are looking machine for snus packaging, then snus packaging machine is the best choice for you.

This complete FAQ guide is about snus packaging machine. You will get detail information that will help you to make the best decision to choosing a packaging machine. Get ready to step in.

1.What is snus?

Snus

Snus is smokeless, powdered tobacco that is placed under the lips. Over time, the nicotine is absorbed by oral mucosa. They are not chewed like traditional tobacco, so you don’t need to spit as it is socially acceptable. It comes in various size pouches with easy- to- carry quality. Snus is pasteurized and heated rather than fermented which retard bacteria growth and provides a long shelf life. It is the alternative to smoking with less harmful effects and it produces no smoke and has no odor.

2.Do you know what is snus packaging machine?

ALLPACK snus packaging machine

The snus packaging machine is designed to package the snus- a smokeless tobacco. Not only packaging is done by this machine, but it can do multitasks such as loading, filling, sealing, and packaging of snus. It can handle different packaging from mini to standard pouches with different products other than snus. A snus packaging machine ensures perfect packaging with accurate and precise dosing and high-speed production. To prevent products from moisture and contamination, it extends product shelf life.

3.Enlist the benefits of snus packaging machine?

Snus packaging machine is in high demand due to various benefits. Here are the following benefits.

Versatility

Versatility- Picture courtesy: stoptobac.com

One of the important features of this machine is that it can handle a wide variety of packaging such as small or large pouches, and round packs. It can also handle biodegradable materials such as paper -made snus pouches.

Labor cost

Due to the automation mode, filling, sealing and packaging are done by the machine itself. There is less need for labor to handle the process. This will not put on burden on your industry accessit to give laborers wages. This encourages efficiency with fewer human errors.

High production

High production-Picture courtesy: theroyalsnusonline.com

This machine makes the snus pouches at a very high speed, making hundreds of packs or pouches in a minute. This range varies, depending on the model of machine. It can meet high demand by increasing product efficiency and boosting output overall.

Enhance brand

Elevate brand

To make your product a unique and eye catchy, this machine full fill your demand. It enables different businesses to customize packaging using different styles and formats. Snus packaging machine forms snus packs of various sizes and designs.

Cost-effective

Another benefit is cost-effectiveness. You do not have to buy a separate machine to load and fill snus packs because it operates filling and packaging in one production line. If your hands are tight and have a small business, a manual snus packaging machine is the best option, and then upgrade to a highly efficient automated snus packaging machine.

4.What industries can get benefits from snus packaging machine?

Followings are the industries that can get benefits from the snus packaging machine.

Herbal pouch industry

A lot of people look for nicotine-free snus. The herbal industry makes an alternative to snus by adding other herbal ingredients. Snus packaging machine is used to pack these herbal mimic products.

Pharmaceutical industry

Pharmaceutical industry

For pharmaceutical products, sterile and hygienic packaging is necessary. Some of the oral medicines filled with the pharmaceutical products for fast absorption are packed in snus like format. Therefore, the pharmaceutical industry gets benefits from this machine this way.

Food industry

Food industry

Food products are also packed in pouches. Products like mouth fresheners and others are packaged using a snus packaging machine. This ensures the protection of the product and resealable options.

Tobacco industry

Tobacco industry

A snus packaging machine is used in the tobacco industry to pack tobacco -containing products. This machine is demandable, where tobacco use is in high demand, due to its automation and high production level.

Chemical industry

Chemical industry

Chemical industry also uses snus packaging machine to pack chemicals in powdered or granules form in pouches or sachets. These provides a stable and moist resistance sealing.

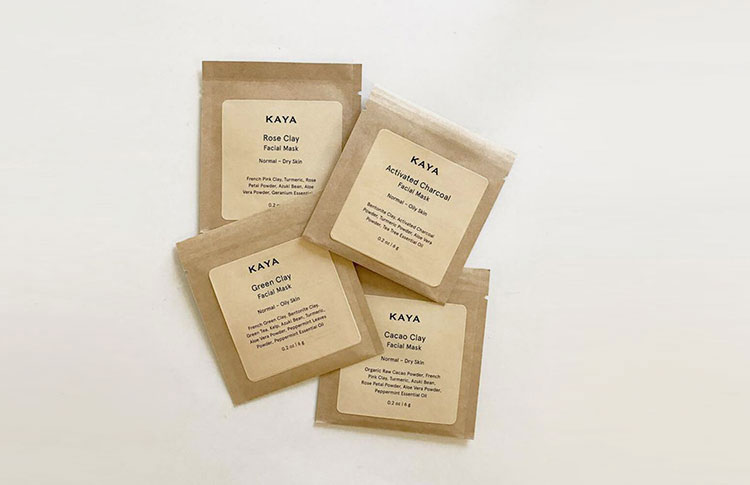

Cosmetic industry

Cosmetic industry

This packaging machine is versatile, and not only used in tobacco industry. Its benefits are extended to the cosmetic industry. Dry hair color, shampoo, lotion and other cosmetic products are accessed by using snus packaging machine. It is convenient for cosmetic brands that offers travel- sized pouches.

5.What are the components of a snus packaging machine?

ALLPACK ultrasonic snus packaging machine

1.Touch screen

2.Temperature control system

3.Electricity box

4.Storage hopper

5.Feeding tube

6.Former

7.Vertical sealer

8.Horizontal sealer

9.Cutting system

| 1 | Touch screen |

Touch screen controls every function of the machine, from loading to packaging. You can change speed, time, stop and start the machine by using this, with on a single touch of screen. This plays important role in efficient working of machine. |

| 2 | Temperature control system |

This system controls temperature during sealing pouches. It ensures reliable sealing and quality |

| 3 | Electricity box | It consists of all the electrical wires and automation system of the machine. There is ventilation in electrical box to protect the wires from overheating. |

| 4 | Storage hopper | Hopper is made from stainless steel. Materials (snus, dry detergent, herbal product etc.) are loaded in hopper. In some of the advance model, there is sensor that detects if material level is decreasing. It also has a mixing mechanism that mix the moist material to protect them from being in clumps. |

| 5 | Feeding tube | This tube feeds the material of any type to the dosing system where the material is accurately and precisely measured. |

| 6 | Former | Here, a packaging pouches or sachets are formed. A packaging material; paper, biodegradable laminate or plastic. Perfectly pouch style formats such as stick pack; portion pouch and pillow pouch are formed. |

| 7 | Vertical sealer | Vertical sealer seals the pouches in vertical position. This sealer presses the edge by using heat, ultrasonic energy or pressure |

| 8 | Horizontal sealer | After the above sealing, horizontal sealing is done at top and bottom of the pouches. It is the final step to give pouches a clean look. After filling pouches from the desired materials, top and bottom of the pouches is done tightly |

| 9 | Cutting system | The filled and sealed pouches are transferred to cutting system. Here, a sheet of pouches is cut into the pieces with great precision in order to avoid damage to the sealing and materials in pouches. |

6.What are the working steps of the snus packaging machine?

Have you ever wondered how snus and other dry materials are packed in pouches with outstanding sealing? Behind each perfect thing of pouches, various steps work in a flow. Here below you will get to know. Let’s start.

Loading → pouch formation → filling → packaging

Loading

The working process starts with loading material in the hopper. In it, material is stored before it is passed to another process. However, the hopper is made from stainless steel that protects those materials from germs and any other contamination. Some of the hoppers have mixers that help to properly mix the material to keep them from clumps.

In advanced snus packaging machine, there is a sensor in hopper that gives an alarm to the operator to aware that there is less volume of material in hopper.

Pouch formation

Pouch formation

The material needs a medium to be filled in. But how and from what materials they are made of? Well, packaging materials are used as per your demand. For pouch formation, a packaging film is laid in former where it is changed in pouch shapes.

If a machine is fill and seal type, then it uses a pre-formed pouches and ready them for filling.

Filling

Filling

The next important step is filling the pouches. This step must be carefully and accurately done. Whether you are filling materials like snus, dry powder or any granules, the SOP’s must be kept in consideration.

The pouches are precisely filled by using dosing system, no overfilling or underfilling are caused by this. The dosing system must be of auger fillers and vibratory trays depending on the type of product. The vibratory tray loose cut snus or granules and auger fillers for powders.

Packaging

Packaging- Picture courtesy: jochamp.com

After the above sealing, horizontal sealing is done at the top and bottom of the pouches. It is the final step to give pouches a clean look. After filling pouches with the desired materials, the top and bottom of the pouches is done tightly.

Here comes the last step, the packaging. The goal is not only to seal it and give protection to the material in pouches, but also product of your overall performance, a presentation, and the catchy vibes it holds.

Snus packaging machine uses vertical and horizontal sealers to seal the pouches by using ultrasonic energy and heat. This ensures temper- proof and hygienic closing of pouches.

Packaging has a long way to go- after sealing, the sealed pouches are moved forward to the cutting station where they are trimmed and make them ready for cartooning. Does it open easily? Yes, of course. Tear notches are added by some of the systems for easy tearing.

7.What is the different machine that can be integrated with snus packaging machine to form various kinds of production line?

The automation level you are targeting depends on how the machines are integrated into the production line and depend on production needs. You will learn about the integrated machines in the following below discussion.

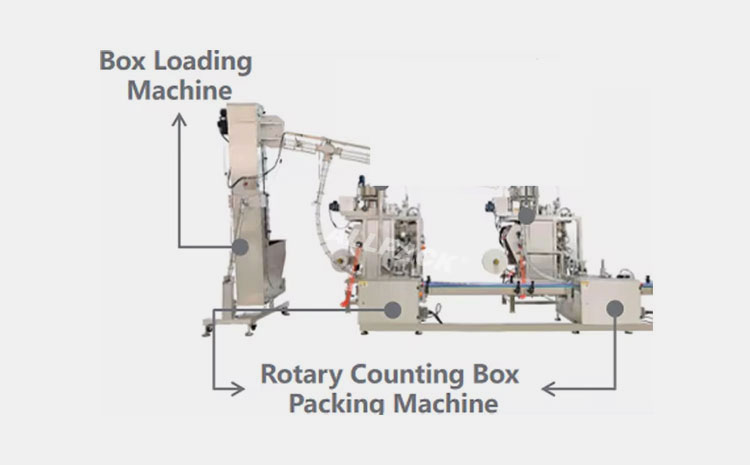

Box loading and counting machine

Box loading and counting machine

These machines are used in an integrated manner. Here, counting and loading of pre-made boxes take place. Rotary counting box packing machine is designed to count that each unit is accurately and precisely dispensed in each container. This is done by optical sensor. What happens next? Then, the counted units are dropped in the open box.

The box loading machine positioned and loaded the boxes. There is a box erection system that rejects the misaligned boxes. It has a wire chute with photoelectric no box detection. To detect bag orientation, there are curtain counting system that ensures ag packing rather than bag quantity. These integrated machines are used by medium and large-scale industries.

Shared conveyor belt

Shared conveyor belt system facilitates the various step-by-step processes, ensures efficient movement of material from one station to another. This system supports the production line or integrate units. The conveyor belt is used in the production line such as it receives the cans from labeling/ sealing station.

Moreover, while counting cans, it is passed through the conveyor which has a sensor to detect if cans don’t match the batch size. It has a photoelectric detection and pneumatic box-stopping mechanism to prevent any kind of interruptions due to box jams. The PLC controlled the speed and position, aligned with the box loading robot.

Automatic lidding machine

ALLPACK automatic lidding machine

As the name indicates, automatic lidding machine is designed to place lids on jars, can and containers. This is done to ensure a leak-proof sealing that maintains the product freshness. What happened in this machine is that the filled containers are moved to the lidding station where lids are taken from the wire chute and placed a lid on them. Scratches on lids are prevented by using a rubber coated pressure rollers and balanced rubber wheels.

Now you might think that a machine will know that the containers have and haven’t a lid? Well, there are sensors that detect the lid presence on cans or jars. After this, machine press the lid and by using heat or snap lock mechanism, seals them and discharge them.

If you talk about the pressing speed, then it is 45 boxes per minute. It has a PLC and touch screen to control the operations of machine.

Automated labeling machine

ALLPACK automated labeling machine

It is used to label jars, cans and cartons. As labeling is important, therefore it is attentively done. For this, the products are moved to the labeling station. By using rollers or brushes, labels are peeled off from the rolls and labeled on the product using heat and pressure.

Labels are wrapped on the top, bottom or sides of jars, cans and containers. It includes an expiry date, batch number, and barcodes.

Fully automatic sleeve style heat -shrinks wrapping machine

ALLPACK fully automatic sleeve style heat -shrinks wrapping machine

It uses plastic film to wrap around the cans and containers. By using heat, the film is tightly shrunk on the item to ensure protection from moisture and is taper-proof. You can see the product from this film.

How plastic film is wrapped around the items? By passing through the roll of plastic film (can be PVC or PE), these are wrapped in sleeve of film. Then, they are sealed using heated sealing bar and moved to the shrink tunnel where hot air is used to shrink plastic film around the product tightly. The wrapped items are discharged from the shrink tunnel for cooling down and solidifying.

8.What are the various production lines of snus packaging machine?

There are 4-lanes, 10 lanes, and 20 lanes snus packaging machine production line. Are you excited to know about them? Here is the explanation of each of them.

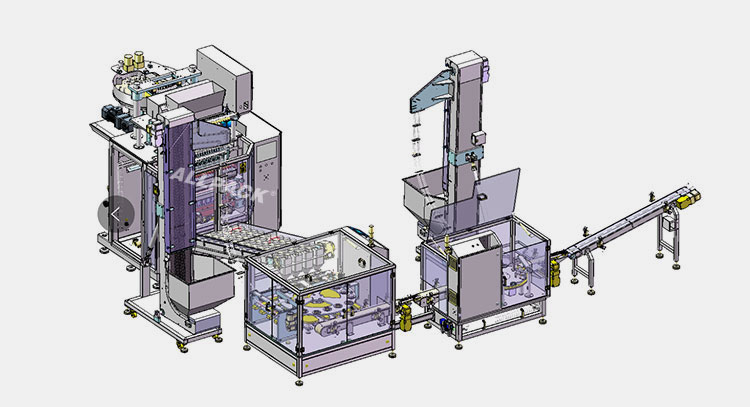

4-lanes snus packaging machine production line

ALLPACK 4-lanes snus packaging machine production line

This type of production line operates 4 lanes, each of them doing its own operation such as dosing, filling, cutting, and packaging. It is suitable for medium-scale businesses and provides an automated system. A question may arise when you buy this production line what is the production speed of this?

Well, typically it produces 300 to 500 range of pouches per minute. The production speed also depends on the packaging material and product. For accurate and precise dosing of the dry snus and herbal materials, auger filler is used.

Advantages

You don’t need bundle of money to buy this. It is cost effective and provides you with automated system.

4-lanes snus packaging machine production line is versatile in nature; handle different size and material pouches.

Vast and expanded floor is not needed for its operation. It can be adjusted in limited floor area.

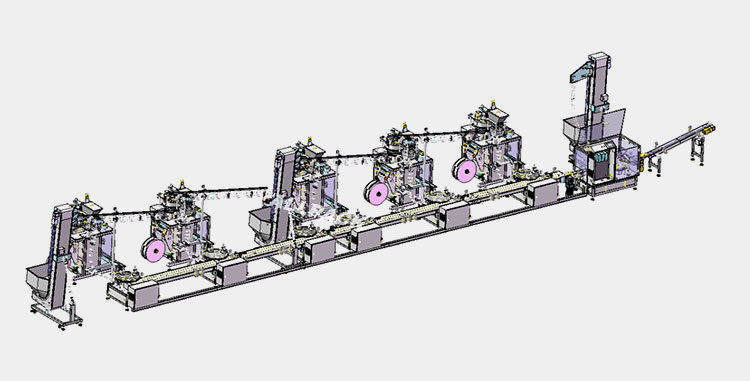

10- lanes snus packaging machine production line

ALLPACK 10-lanes snus packaging machine production line

This lane operates 10-lanes which work in coordinated manner to ensure uniformity and accuracy, but each has its functions. It gives large volume of products and has fully automated setup.

The applicable material for the 10-lanes production line is non-woven packaging material, which produces pouches of width 15mm and length of 15 to 20mm. it is suitable for medium to large operations with its handling product production with growing demands.

Sealing is a very important factor in the quality of the product. So, to enhance chewing sensation, there is inner and outer sealing structure for vertical sealing without curling.

Advantages

Its production size is large as compared to investment in it.

For its operation, it does not require large space.

It is cost-effective for the company to try to expand their operation.

20-lanes snus packaging machine production line

ALLPACK 20-lanes snus packaging machine production line

20-lane line is ideal for large-scale factories, designed to achieve the highest level of production. This line operates in parallel with robotic features that enhance productivity.

It handles various products such as dry and moist snus, herbal products, and caffeine-based blends. Machine supports different packaging materials such as biodegradable material, paper and laminated film. With high-speed system of 30-45 cuts per minute, it handles pouch sizes of 13mm in width and 20-50mm in length.

This production line is used by large enterprises and leading global brands to meet the high demand of supplying major retail chains.

Advantages

Ensures high quality sealing system for secure packaging.

This is ideal for manufacturer producing high volume at industrial level.

Supports multiple product packaging/types with customizable layouts.

9.What other products can be packed using the snus packaging machine?

A snus packaging machine were originally used to pack snus, but its importance is expanded to other industries to pack various products. you will know about what other products that are packed using snus packaging machine.

Candies and sweet

Candies and sweet-picture courtesy: verywellhealth.com

Candies and sweet powder are packed in snus pouches style. Kids and teens are excited to grab these catchy and small pouches.

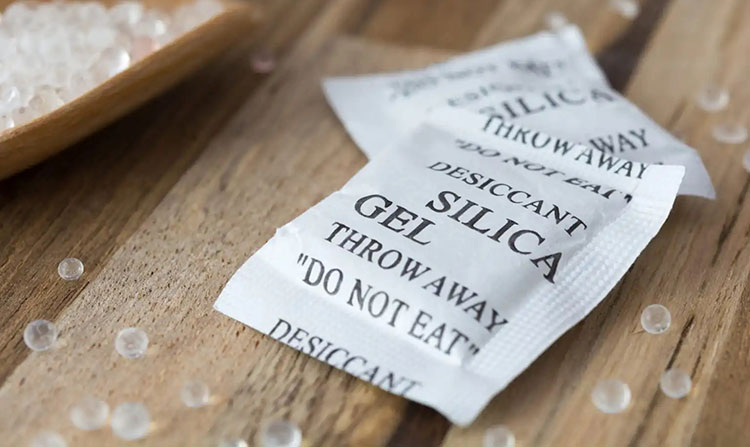

Dry detergents

Dry detergent

Snus packaging machine is also used to pack dry detergents. It can be dishwasher, dry soap etc. These are fill and packed with concise measurement and ensures its protection even at humidity.

Pet freshener

Pet freshener

Pet based industries use this machine to handle pet-based products such as pet fresheners, dental powder etc. These are cleanly packed in small and easy to administer pouches.

Vitamin powders

Vitamin powders

Vitamin powders are packed in snus design sachets. Whether vitamin powder is meant to be chewed, dissolved in mouth, or dissolved in water, all these are accurately fill and packaged by snus packaging machine.

10.What are the packaging options for snus packaging machine?

A snus packaging machine provides you with different packaging options. You can customize packaging of any type. Let’s have a look at the packaging options it provides.

| Packaging options | |

| Aluminum or metal made cans

Aluminum or metal made cans |

Snus products can be packed using cans. These are made from plastic or aluminum with lid and cap. You can store large o small quantity of any products in these cans. |

| Plastic made cans

Plastic made cans |

Snus products are also packed in plastic cans. These are made from PET or PVC, and a cost effective. They provide a good barrier against moisture. |

| Tins

Tins-Picture courtesy: herma.com |

Tins are used for snus packaging. These are made from tin-plate. There is no much difference between tins and cans. They are more decorative. |

11.What are the factors to consider when choosing a snus packaging machine?

If you’re a new to buy the snus packaging machine then following factors are to e consider when choosing this machine.

Capacity

A first thing you need to check is the production capacity. As this can help your company production at high rate. If machine has high working capacity per minute, it will not only reduce time consuming but will increase the production.

Flexibility

Flexibility-Picture courtesy: loyalmachine.com

Most of the products are packed in various packages. All you have to do is ask your supplier whether the machine is flexible in handling different product types or not. If all the functions are in one machine, then you will not need to buy more machines for this. It will save your budget.

Cost

Cost-Picture courtesy: qdb.com

The important factor to consider is cost of the machine that the machine you are buying is compatible with price and give you the output according to the price. It is obvious that expensive machine will be quite efficient as compare to the cheap one. But, look for the machine that is affordable and best qualities.

Compatibility

Compatibility-Picture courtesy: CASAA

In today’s world, more focus is on use of biodegradable materials, and its demand is also growing. Therefore, check the machine compatible to your material you are intending to use. Not all the machines handle all the materials. So, advance checking is necessary.

Humidity

While selecting the snus packaging machine, you should select it according to your product humidity. Snus and other materials can be in dry and moist forms. Therefore, there are various snus packaging machines designed for this purpose; a wet-type snus packaging machine and dry type snus packaging machine.

If your product has moderate humidity of 10% to 45%, then select ultrasonic 4-row wet snus packaging machine that handles semi-moist. If humidity is less than 10%, select an ultrasonic dry snus packaging machine or 10-row for dry granules.

Conclusion

To conclude this detailed guide on a snus packaging machine, it must be concluded that demand for smokeless tobacco is growing. So, this needs a high-quality packaging machine. It not only packages snus products but also deals with dry and blended materials. Snus packaging machine is integrated with other machines to form various production lines. If you are interested in buying any of these machines, ALLPACK has different varieties of it.

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp:+86 18171018586