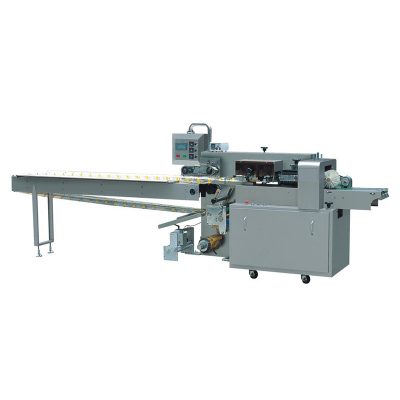

Your Best Flow Wrap Machine Manufacturer

- Reciprocating Tool-proof Structure

- Double-frequency Conversion Control

- High-sensitivity Photoelectric Eye Color Tracking System

Allpack Flow Wrap Machine

Allpack flow wrap machines are all horizontally designed for packaging various kinds of regular products in different industries into pillow pouches. This packaging machine can complete the whole process of bag forming, material filling and sealing, and product discharging. The whole packaging process is protective and consistent and heat will be applied to the bottom and ends of the film to form a sealed, flexible package. Allpack flow wrap machine uses heat and pressure to make an uptight seal which prevents unnecessary movement of the product. This packaging machine can also be equipped with gas flushers that further stabilize the products against environmental degradation. Equipped with the high-sensitivity electro-optic eye color code tracking system, this flow wrap machine can offer you a more accurate sealing and cutting position. This packaging machine can be controlled by independent PID, which is suitable for coating of various materials. With double inverter control, the bag length is set and cut immediately. There is no need for the empty run adjustment which can save your time and your films.