Extruder Spheronizer: The Complete FAQ Guide in 2025

Imagine converting fine powders or sticky granules into uniform, spherical pellets that will not only make a product look and feel better but also make it work better. Be you in the pharmaceutical field of sustained-release medications or food production. With consistent granules for mixing, cosmetics in perfect beads, there's most probably a hand from the extruder spheronizer technology at work.

But what is actually going on inside these machines? How is the raw material taken through the process to end with the exact spheres, ready to be packaged or formulated?

Here in this guide, we dig the science behind an extruder spheronizer; therefore, the reasons it has become one of the cornerstones in many industrial practices. This guide takes on a transparent manner, the way that these two interact with one another: basic and critical steps when forming the pellet, fundamental parts to keep maintained, safety information, and more of the critical things making the modern palletization process on solid grounds.

1.What is an extruder spheronizer?

Extruder Spheronizer- Picture Courtesy: Umang Pharmatech

An extruder spheronizer is a specialized device employed for converting wetted powders into uniform, dense spheres or pellets of controlled shape and size. The extrusion spheronization process includes making the wet mass into cylinders through the extrusion and then breaking and rounding into spheres within the spheronizer and subsequently drying.

Although commonly applied in the pharmaceutical industry for the production of solid oral dosage forms, it also finds its application in agrochemicals, catalysts, and specialty chemicals to manufacture consistent, precisely shaped pellets with specific characteristics.

2.Which industries use extruder spheronizer?

Application industries- Picture Courtesy: Bora Pharmaceuticals

Extruder spheronizer are not specific to pharmaceutical industries but a game-changer in many industries for precision and consistency of pellet size and shape. Some of the industries that apply this innovative technology are as follows:

Pharmaceutical Industry

Pharmaceutical Industry

With a revolution in pharmaceutical manufacturing extruder spheronizer produces quality drug delivery pellets. Small pellets could capture up to 90% of active pharmaceutical ingredients and therefore can enhance the effect of therapy together with the compliance rate of patients by making dosing infrequent.The process starts by mixing the API, excipients, and solvents into a homogeneous mass which is then extruded in cylindrical shapes and then spheronized into uniform pellets. This gives a very smooth surface ideal for altering drug release profiles.

Food Industry

Fish feed pallets

The production of pellets of the same size is important to the food industry, as offered by extruder spheronizer. Imagine adding this technology to breakfast cereals, snack foods, pet foods, and even infant or supplementary foods. The extruder spheronizer improves bulk density, so ingredients such as flavors and sweeteners for instant soups and drink mixes can be handled more easily.

Agrochemical Industry

Biomass Fuel Pallets- Picture Courtesy: Biomass Energy Techniques Inc.

Suppose you are a farmer spraying fertilizers all over a large field. You want uniformity and less dust all over a large area for convenience and effectiveness. Extruder spheronizer come to your rescue. It provides perfectly uniform pellets, made for nutrient-rich fertilizers, pesticides, or soil conditioners, which could be spread and handled without any issues.

Catalyst Industry

Alumina based Catalyst Pellets- Picture Courtesy: Xiangrun

Extruder spheronizer are a vital role player in the catalyst industry. It produces catalyst pellets in an entirely uniform and spherical shape that maximizes reaction efficiency. Such pellets pack well inside reactors compared to any other irregularly shaped pellets.

Cosmetic Industry

Microbeads in exfoliating scrub- Picture Courtesy: Britannica

The extruder spheronizer plays an especially important role in cosmetic manufacture to ensure pellets and beads are uniform and perform the function intended within the product. Consider a cleansing exfoliating scrub – all those tiny microbeads so smooth, gentle yet really rubbing away at dead skin. Extruder spheronizer makes it possible.

Household and Industrial Cleaning Industry

Uniform granules for detergent powder

It is very important in the household and industrial cleaning industry to have the use of extruder spheronizer to generate spherical detergent granules that may help improve cleaning efficiency. Consider powdered laundry detergent that instantly dissolves in cold water, such as powdered laundry detergent; these uniform granules prevent clumping or even improve solubility for a better wash.

3.What are the benefits of extruder spheronizer?

Benefits of extruder spheronizer- Picture Courtesy: LCI

Extruder spheronizer offer many benefits for various industries, including the following:

| Uniformity

|

They produce pellets of uniform size and shape with active ingredients well distributed throughout the formulation. This uniformity contributes to better performance and stability in the product. |

| Flowability | Spheronized pellets exhibit better flow properties, and there is minimal chance of clumping or segregation during handling and processing, which is a crucial requirement in manufacturing. |

| Improved Dissolution | The pellet is in the form of a sphere; hence it can be more easily broken down in the liquid solution, thereby it increases its solubility and improves efficiency in operations such as detergents and medicines. |

| Increased Surface Area | The spherical form allows a maximum contact area of reactants or solvent with surface area, and this reaction is made very efficient with catalytic operation. |

| Controlled Release | Extrusion-spheronization is highly transformative for sustained-release formulations, offering exact control over pellet composition and release rate. Uniform, spherical pellets allow for higher drug loading with consistent delivery, reducing dosing frequency and enhancing therapeutic stability. With customizable excipients, this method meets diverse patient needs, improving both efficacy and compliance. Isn't it remarkable how this innovation can elevate treatment and adherence? |

| Less Dust Produced | Spheronization reduces the fine particles of the powder, so handling is done with less dust and there is a reduction in dusting and exposure to toxic dust in a working place. |

| Flexibility | Extruder spheronizer can be used to process wide ranges of products, including powders and granules and even liquid, hence they are applied in most industries. |

| Efficiency and Cost Savings | Extruder spheronizer can improve processing efficiency as well as product quality and therefore can reduce the production costs in the long run. |

4.How does an extruder spheronizer work and what are the basic principles of its working?

Principle of Extruder Spheronizer- Picture Courtesy: Glatt

The extruder spheronizer works on four basic steps that cumulatively create the perfect spheres in a uniform shape. Let's find out how this happens:

| Mixing | Imagine the combination of all the ingredients such as the active compound, binders, and water in a high-shear granulator. This will give a wet, cohesive mass that retains the shape but can flow by slipping into the next process. |

| Extrusion | This mixture then enters the extruder, where it is pushed through a screen, which forms spaghetti-like cylinders of the same diameter. |

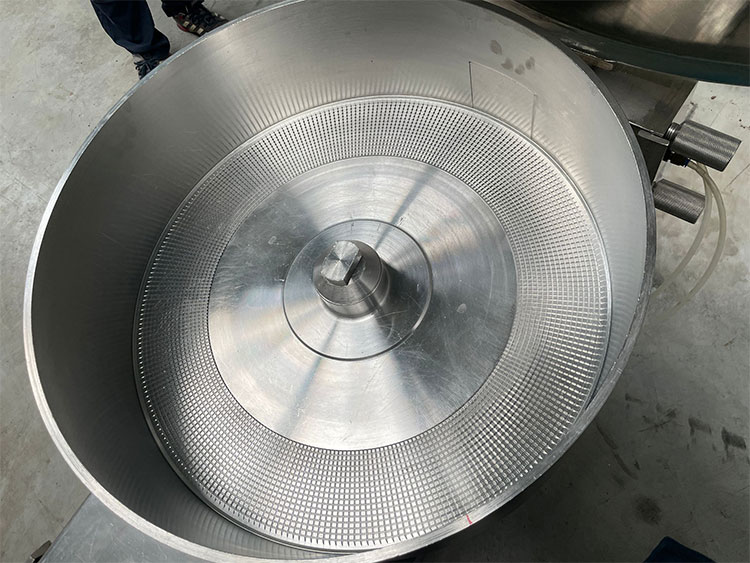

| Spheronization | Real magic happens in the spheronizer. The cylinders fall onto a fast-rotating friction plate; they bounce around in the bowl and hit each other, which gradually rounds them into perfect spheres. Pellets are formed here in minutes and the process is accurate. |

| Drying/ Coating | Finally, these uniform spheres are either dried for stability or coated, ready to be used in applications where the consistency of shape and size is most important, like pharmaceuticals or catalysts. |

5.Why extruder spheronizer are ideal for spherical granules and pellets?

Pellets- Picture Courtesy: Shutter stock

Extruder spheronizer aid in the manufacturing of completely spherical granules and pellets. Here's the reason, though: you can really pack in much more active ingredients without reaching the oversized pellets, and with high-potency products, it works great perfectly.

In addition to this, if you really want to mix two or more active agents, then this is something extruder spheronizer do without very much hassle, offering a ratio accuracy in each one that comes out.

This process also allows you to refine the properties of the particles so that you get high-density, low-moisture, and very smooth surfaces. The pellets come out dust-free with uniform shape and size making them highly reliable and easy to handle in any process.

6.What materials are suitable for being used in an extruder spheronizer?

Spheronization

Materials that can be processed in an extruder spheronizer include:

| Material | Example |

| Natural Extracts | Silymarin from milk thistle |

| Bacterial Cultures | Lactobacillus casei for probiotics |

| Pharmaceutical Drugs | Furosemide, Quinine sulfate, metformin hydrochloride |

| Poorly Soluble Drugs | Hydrochlorothiazide, Piroxicam |

| High Drug Load Formulations | 5-aminosalicylic acid (5-ASA) |

| Taste-Masked Compounds | Quinine sulfate, Metformin |

| Sustained-Release Compounds | Naringin |

| Dehydrated Agricultural Products | Canola meal |

| Pulsatile Release Drugs | Omeprazole with osmotic pressure-activated membranes |

| Bioadhesive Pellets | Hexylaminolevulinate for photodynamic therapy |

| Enteric-Coated Probiotics | live Lactobacillus casei for oral probiotic delivery. |

All these can be formulated into pellet types varying by changing the excipients and process parameters to specific release profiles and stability.

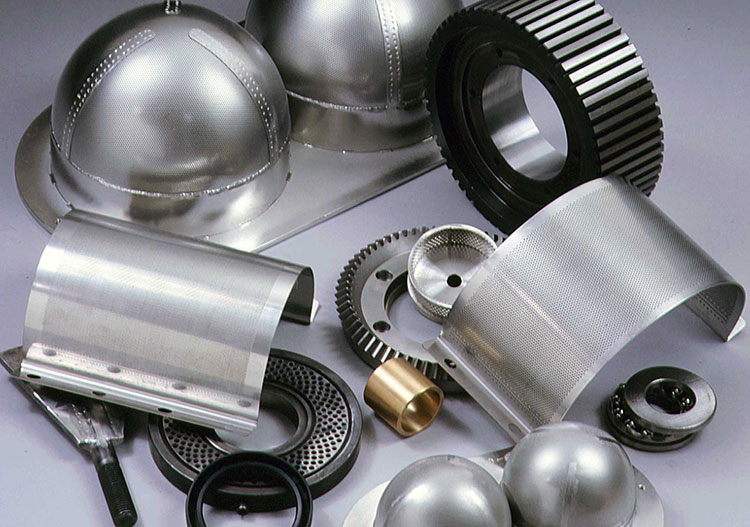

7.What are the main parts and elements of an extruder spheronizer?

Components of extruder spheronizer

Okay let's talk about the main parts of an extruder spheronizer and what they do with regards to quality pellets!

Feeder

Feeder

Just like the front door. The feeder makes sure to feed the powder blend; that is, the raw materials that include the actives and excipients; at a steady rate and in constant amounts into the system. The constant flow of the feeder is meant to make the entire procedure uniform.

Extruder

Extruder

The extruder is as if the heart of the machine. The screw, at its rotation, applies assorted mechanical forces; it blends, compresses, and transforms the mixture into the continuous extrudate when allowing it to pass through the system. That's where everything magical with texture and consistency begins.

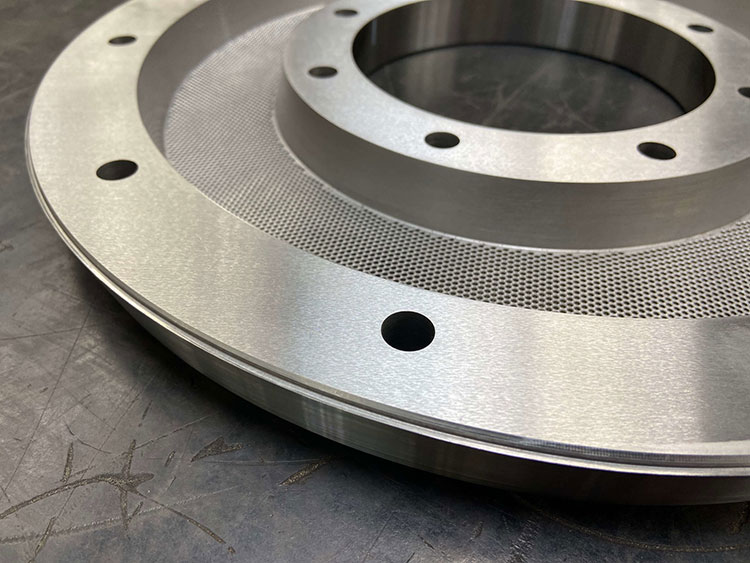

Die or Screen

Die/ Screen

The die at the end of the extruder gives shape to the extrudate in the form of cylindrical strands. It is almost like a sculptor shaping clay. The diameter of the die determines the size of the extrudate and is a precursor to the next step.

Spheronizer

Spheronizer- Picture Courtesy: Intimac

Imagine the spheronizer as a pellet-rounding artist. It takes the extrudate and, through friction and impact, turns it into perfectly spherical pellets. The rotating friction plate and stationary bowl create a dynamic environment where the magic of rounding happens!

Dryer

Drying of Pellets- Picture Courtesy: DG Pro-Tec

After spheronization, the pellets move to the dryer. It's like a spa for the pellets, removing the moisture, which increases their stability and durability. The better the drying of a pellet, the better quality and shelf life!

Coater (optional)

Spray Gun for Coating of Pellets- Picture Courtesy: Durr

Finally, when needed, the coater adds a protective coating to the pellets. It is just applying sunscreen; coatings may mask flavor, control release of the active ingredients, or protect pellets from moisture and light.

Each of these parts is critical in the process of extrusion-spheronization, working in harmony with each other in producing pellets that are uniform in appearance and quality for any kind of application. What feature do you find the most interesting?

8.How are extruder spheronizer categorized into different types?

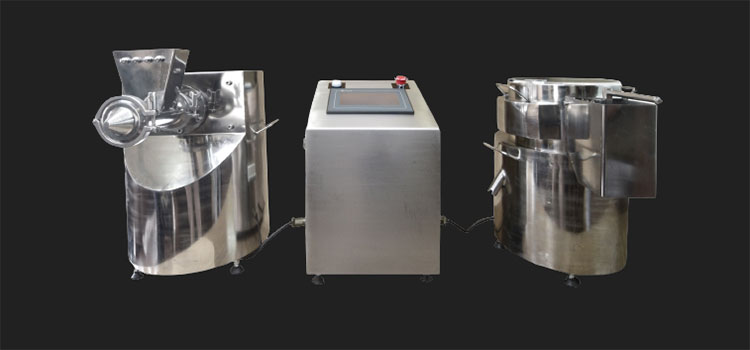

Extruder Spheronizer

Single-Stage Extrusion-Spheronization Systems

Single Stage Extruder Spheronizer- Picture Courtesy: Dorsa Tech

These are like the multitaskers of the group—extrusion and spheronization happen in a single chamber. Imagine a "one-pot" setup. This setup is rare, and it usually is made for materials that require least handling between the two of these steps. For the specific material, it's perfect since it minimizes movement, but it isn't ideal for everything.

Dual-Stage Integrated Systems

Dual Stage Extruder Spheronizer- Picture Courtesy: VJ Instruments

Now, imagine that two connected units operate perfectly together. The extruder feeds directly into the spheronizer. This is a seamless handover without material transfer and exposure to the outside world. Such an operation is conducive to mass production.

One saves handling time and even potential contamination. Imagine seamless efficiency where direct extrusion flows directly into direct spheronization, never stopping for one second.

Continuous Extrusion-Spheronization Systems

Continuous Extruder Spheronizer- Picture Courtesy: Caleva

Imagine a pellet conveyor belt. In these kinds of systems, there's always a feed of material going into the system and the system never stops! That's the powerhouse setup-ideal for high-volume production. The pellets are all in size and shape because of the process that never stops, therefore quality control is maintained. It's like the marathon runner of the group, steady and efficient.

9.What variables affect the quality and appearance of the granules obtained from Extruder Spheronizer?

Granules- Picture Courtesy: Avada Construction

Let's talk about each one of these variables that affects the quality and appearance of granules from an Extruder Spheronizer. Let's say we're fine-tuning this equipment together to make the perfect granules. Here's what we would focus on:

| Optimization of Formulation Parameters | Adjusting the Concentration of Binder.

Controlling Moisture Content. Selecting Appropriate Excipients and Particle Size |

| Fine-Tuning Process Settings | Setting Ideal Extrusion Speed and Screen Size.

Adjusting Spheronization Speed and Time. Choosing the Right Spheronizer Plate Design |

| Controlling Environmental Conditions | Regulating Temperature and Humidity. |

| Material Properties Assay | Improving Plasticity and Deformability.

Achieving Right Cohesiveness and Friability. |

10.How does the process of an extruder spheronizer compare to other methods of granulation?

Extrusion Spheronization- Picture Courtesy: Dorsa Tech

The Extruder Spheronizer process is unique compared to other approaches such as high-shear, fluidized bed, and roller compaction granulation. Here's how it compares:

| Extruder Spheronizer | Other Techniques |

| Shape and Uniformity | |

| Imagine you are choosing a granulation method for a project and weighing the pros and cons of an extruder spheronizer against other granulation techniques. The extruder spheronizer is unique in giving very spherical and uniform granules, ideal if you need precise shapes, as in controlled-release formulations. | Other techniques, like high shear or fluidized bed granulation, may yield granules, but not usually so regularly shaped; roller compaction gives dense sheets milled, so the granule shape varies. |

| Granule Density and Strength | |

| However, if strength is the major consideration, then an extruder spheronizer could be the best option as it yields strong, cohesive granules that could withstand the stress of processing. | High shear and roller compaction yield dense granules, but the lighter particles from fluidized bed granulation may not be as robust. |

| Moisture Content | |

| The process of extruder spheronization requires excellent care in controlling moisture content-too much or too little impacts the quality of the granule. | Fluid bed granulation allows in-process drying to control moisture, and the process may result in a more porous granule. |

| Scalability and Control | |

| Of course, with regard to scalability, the extruder spheronizer process can be controlled quite well over particle size and shape and therefore allows for production at larger scale. | High-shear and roller compaction granulators also scale up well, but fluid bed granulators require precise regulation of airflow and temperature control. |

When you are making a formulation that will require spherical particles of uniform size; for example, a modified-release drug or an encapsulated ingredient, you may be able to cut directly to the extruder spheronizer, but from a standpoint of versatility alone you may get more flexibility with either high-shear or fluid bed methods.

Every procedure has its own advantages, so knowing them helps to properly pick the right tool for your granulation needs.

11.What routine maintenance should be performed on extruder spheronizer to put it into optimal operation?

Maintenance of Extruder Spheronizer- Picture Courtesy: LCI

An extruder spheronizer should be kept constantly maintained for it to go at its best. Follow this short guide for what you must do as far as routine maintenance goes, which will be described step by step:

Cleaning, Daily

Begin the morning by cleaning the extruder spheronizer on a day-to-day basis. You must clear left-over materials to prevent re-contamination and easy, smooth running.

Lubrication

Check the proper lubrication of moving parts according to the manufacturer. Proper lubrication will provide less wear and tear or friction in the operation mechanism, ensuring it runs more economically.

Components Inspection

Critical parts like the die, screen, and blades are always checked for signs of wear or damage. Any worn parts are replaced to prevent operational problems.

Calibration Checks

All settings and controls must be calibrated to the right standards. This will ensure accuracy in the granulation process.

Cleaning Filters

If your device has filters, clean or replace them when necessary to avoid blockages that may cause problems with airflow and performance.

Monitor the operational parameters

One has to monitor KPI's such as temperature and pressure during operation. Regular monitoring can catch up any potential issue before it goes out of proportions.

Documentation

Maintain a maintenance log in order to monitor all activities performed on the machine. This helps in identifying patterns and helps in planning ahead for maintenance.

By including these routine maintenance activities in your operation, you can get the best out of your extruder spheronizer in terms of performance and longevity. Which area of maintenance would you like to explore further?

12.What are some common problems with extruder spheronizer, and how do these problems get solved?

Extruder Die-Picture Courtesy: IDAH

Common problems associated with extruder spheronizer severely affect the quality of the granules produced as well as overall efficiency. Have you experienced any of these issues? Let's look at some common problems and their solutions together:

| Problem | Solution |

| Granule Quality

Are you experiencing irregular shapes or sizes in your granules? |

Did you check the moisture content and binder concentration in your formulation? You might just need to fine-tune the extrusion speed and spheronization parameters. Don't forget to examine the uniformity of the raw materials! |

| Blockages in the Die or Screen

Is the extruder spheronizer giving you a hard time, either in slow throughput or operational upsets? |

Regular cleaning and screening of the die and screen can help prevent blockages. Material feed rate should be adjusted and the particle size of feed material should meet specifications in order to reduce blockages. |

| Excessive Heat Generation

Do you notice higher temperatures that can affect material quality? |

Monitor and control the temperature during operation. You should check your cooling mechanisms and ensure that the device has adequate ventilation to keep temperatures in check. |

| Varied Moisture Content

Are your granules moister in some parts of the batch than in other parts? |

Achieve precise measurement when blending and granulating. Inconsistency is the root problem - keep a leash on those moisture contents! |

| Dust Generation

Is dust creating too much of a nuisance and risk? |

Adopt dust control measures and ventilate your workplace. Even a proper material handling process to transfer can help you have less dust. |

| Low Throughput or Production Rate

Are your production rates not up to par? |

Check your operating conditions, feed rate, and spheronization time. Ensure your equipment is calibrated and your formulation is optimized for extrusion. |

| Preventive Wear and Tear

Are parts being worn out sooner than you thought they would? |

Check and maintain parts. Using better raw materials and following the manufacturer's maintenance schedule can help extend the life of your equipment. |

Do you have a particular problem you'd like to explore in more depth? By actively engaging with these issues and solutions, you can troubleshoot and improve the performance of your extruder spheronizer.

13.What precautionary measures should be taken while handling the extruder spheronizer?

Preventive Measures- Picture Courtesy: LLumin

Precautions that should be taken in handling an extruder spheronizer include safeguarding the quality of granulation and protecting the worker.

Personal Protective Equipment

Put on personal protective equipment: This would include the gloves, goggles, and lab coats as a safety measure against the chemicals and particles.

Proper Training

The operator is trained to use the extruder spheronizer because of its unique function and safety aspects. Therefore, the occurrence of accidents when the machine is known will be decreased.

Equipment Inspection

Every part of the equipment is inspected before starting it. Determine if there are loose connections or improper alignments and whether it has a safety feature that is functioning well.

Ventilation

Work in an area well-ventilated to keep the dust and fumes away, particularly when powders or volatile compounds are involved.

Never overload equipment

Overloading causes apparatus breakdowns, and there may be irregular granulation.

Emergency Procedure

The emergency shutdown procedures and the location for stop on the equipment are also known. The area also has to be labeled on signs as safe.

Monitoring Parameters

The parameters running in the process like critical temperature and moisture content also have to be continuously kept under check to prevent or lessen undesirable occurrences that can spoil the quality and safety of the product.

Material Transportation

The granules along with raw materials need transportation through the right methods or equipment that can reduce possibilities of spillage or any accidents.

Maintenance routine

Always maintain equipment regularly as scheduled by the equipment manufacturer. This means, the equipment is allowed to work efficiently and effectively during a period of time.

Conclusion

Extruder spheronizer are mainly the tools that help generate top-quality uniform pellets within industries dealing with pharmaceuticals, foods, and so forth. This is because the process of size and shape control of pellets is achieved in a precise manner for obtaining a better quality of performance and also to smoothen out the manufacturing process. Which part of your work can have possibilities with extruder spheronizer? Ask Allpack in exploring extruder spheronizer machines to start the production success together!

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide

Tell us your material or budget, we'll reply you ASAP within 24 hours

Tell us your material or budget, we'll reply you ASAP within 24 hours