Your Reliable Cup Sealer Machine

- Thermophone Electric Eye Recognition

- Sophisticated Sharp Cutting Head

- Leakproof Function

Cup Sealer Machine

Allpack cup sealer machines are mainly used to seal cups and small plastic containers, such as drinks and food. In addition, our machines’ molds can be customized according to the shape and size of our customer container sample. The cup sealing machine, not only can seal plastic cup, but also seal paper cup, each machine take four moldsshops, like 95mm sealing cup mold & 90mm sealing cup mold, 75mm sealing cup mold & 88mm sealing cup mold. One minute can seal 6 cups of drinks. It is very popular in restaurants, dessert shops, beverage shops, milk tea shops, coffee shop, etc. Allpack provides manual, semi automatic, and automatic types of cup sealers, to meet various cup sealing demands on the market. A cup semi-automatic sealer machine is a very efficient means to seal your cups in a very short duration of time.

Cup Sealer Machine

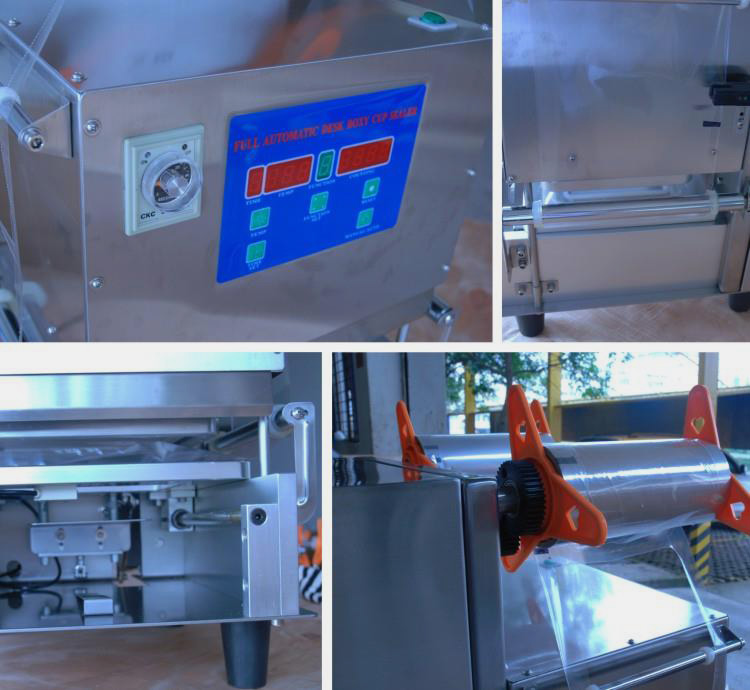

HL-95A Automatic Type Cup Sealer

The HL-95A automatic type cup sealer of Allpack can seal 720 cups per hour, it can be customized so that it can seal all kinds of cups which are in different shapes and sizes. The cup sealer can increase the production speed for people, in addition, it is designed compact, so it can save much space, which makes it convenient to use. This cup sealer machine is widely used in beverage industry, bubble tea shops and restaurants.

Long Service Life

Intelligent Control System

Smooth&Accurate Sealing

HL-95B Semi Automatic Type Cup Sealer

Allpack HL-95B semi automatic type cup sealer is simple to operate, it is equipped with a handle, you need to press the handle to seal cups. It can seal different shapes of cups such as bowl-shaped, rectangular, square, hexagonal, oval and round. This cup sealer machine is suitable for milk tea shops and family usage since it can be easily put on each desktop.

Stainless Steel Construction

Automatic Film Roll

Advanced Operation Panel

HL-95C Manual Operated Cup Sealer

Allpack HL-95C manual operated cup sealer need to be operated by yourself totally, thus it is suitable for small scale production. This machine is generally used in food and beverage industries, pharmaceutical industry, commodity industry and so on. The same as the semi automatic model, this cup sealer also has a handle, so it is quite easy to operate, it can seal 700-900 cups per hour. The hermetic seal thus formed is almost flawless and does not allow any spilling or leakage.

User Friendly Structure

Low Power Consumption

Hand Press Operation

The Buyer's Guide

Cup Sealer Machine: The Complete Buying Guide in 2025

Packaging and sealing of multiple plastic cups that contain different elements in them is a hard task to perform manually because the inner content get wasted sometime.

To overcome the sealing problems for plastic cups a unique machine which is called cup sealer is introduced to the workers to perform the sealing operation in a perfect way.

You might be wondering what is this machine, how it works? From where I can purchase it and many more so, this guide will answer your all questions so keep your eyes wide open and let’s start reading.

1.What is a cup sealer machine?

Cup Sealer Machine

A cup sealer machine is an effective, efficient, and economical machine that helps seal cups of different materials. This machine puts a seal of a suitable film according to your cup material on the top of the cup by heating the sides of the ring and then simply seals the film forming a hermetic seal.

A cup sealer machine forms a hermetic seal by either melting the film or the sides of the cup to be sealed or sometimes both. The hermetic seal thus formed is almost flawless and does not allow any spilling or leakage.

2.Explain the different advantages of the cup sealer machine?

A cup sealer machine has many advantages that can be very beneficial for your business and can help you save time and money. Some of these advantages are discussed below.

Increases Productivity

A cup sealer machine is a very efficient mean to seal your cups in a very short duration of time. Especially the automatic cup sealer machine works fast and can seal up to 400 cups per hour. In this way, it increases the productivity of your business.

Reduces Expenses

A cup sealer machine reduces your expenses by cutting down the need of hiring more employees. Just imagine if you have to seal 300 cups in one hour manually without using a cup sealer machine, you will have to hire a lot of employees to do this job. On the other hand, if you use an automatic cup sealer machine instead, you can do this task with only one operator who operates the machine, and the rest of the job is done by the cup sealer machine. Also, the cup sealer machine uses a very less amount of sealing films as compared to humans as the wastage of the film is minimal.

Safe Sealing

A cup sealer machine ensures that the seals formed by it are safe so that there is no spillage or leakage of the liquid from the cup. In this way, it saves you from financial losses that might have occurred in case of leakage or spilling.

Easy to Use

A cup sealer machine is really easy to use and does not require much expertise to operate it. So, you do not have to hire a highly professional operator and pay him a heavy salary. This saves you money as well.

Inexpensive

Unlike most machines, a cup sealer machine is not expensive. You can buy it at very cheaper prices and so it can prove to be a great and beneficial investment in your business.

Versatile

A cup sealer machine is a piece of versatile and multi-purpose equipment that can be used to seal cups of a variety of sizes, and materials containing different liquids.

3.Which type of cups you can seal with a cup sealer machine?

A cup sealer machine can be used to seal a variety of cups made of different materials. Some of these are discussed below.

PP Cup

PP stands for Polypropylene. Polypropylene is a polymer of polyene monomers. PP cups have good resistance against outside heat.

PET Cups

PET stands for Polyethylene Terephthalate. PET cups have higher resistance against the outside cold as compared to PP cups.

PE Cups

PE stands for Polyethylene. It is suitable for both hot and cold liquids and can maintain their temperature for a longer duration

4.What are the different kinds of cup sealer machines?

There are three different kinds of cup sealer machines- manual, semi-automatic, and fully automatic cup sealer machines. These are explained in detail below.

Manual cup sealer Machine

A manual cup sealer machine is a manually controlled variant of the cup sealer machine. It requires an employee to fill the cup with the liquid, put it in the machine, place the sealing film on the top of the cup, and then pull down the machine lever to form a hermetic seal on the cup.

The productivity of the manual cup sealer machine is lesser than the semi-automated and fully automated cup sealer machines. It can seal around five thousand cups in a single shift.

Working Scenario

Coming onto the working, a manual cup sealer is a simple machine that can be operated by one person, with no need to have special skills or knowledge. The operation requires the user to insert a cup into the machine, press down a lever, and then wait for the sealing process to be completed.

Advantages

- Manual cup sealers are a good choice for businesses that need to quickly and effectively create sealed cups for their products, as they can be operated quickly and without any special skills or knowledge.

- They are usually much more cost-effective than their automatic counterparts, making them a great choice for businesses on a budget.

- Highly reliable and require little to no maintenance, ensuring that businesses can count on them to get the job done quickly and efficiently.

Disadvantages

- Manual cup sealers are limited in the size of the cup they can work with, as the cups must fit into a specific slot in order for them to be sealed properly.

- They are also limited in the types of material that can be used for sealing, and may not work with certain materials or products.

- These sealers are generally slower than automatic sealers.

Components

Cup Holder

This component holds the cup in place during the sealing process.

Sealing Head

The sealing head houses a heating element and acts as the primary source of heat for sealing.

Stand

The stand keeps the sealer in a stable, upright position during operation and also helps to protect the machine from being damaged by accidental spills or drops.

Lever

The lever is used to initiate the sealing process, as well as to shut off the machine when it is not in use.

Safety Switch

The safety switch ensures that the sealer is only activated when the lever is in the correct position.

Semi-Automatic cup sealer Machine

A semi-automatic cup sealer machine requires lesser human intervention than the manual cup sealer machine. It requires the operator to put the empty cups into the machine and then just take the filled and sealed cups out of the machine. Filling and sealing of the cups are done by the semi-automatic cup sealer machine itself.

Because it does most of the work itself, the productivity is higher than the manual variant. It can seal around eight thousand cups in a single shift.

Working Scenario

The semi-automatic cup sealer machine is a versatile machine used in many industries. It works by placing the cups on the machine and then using a pneumatic system to close the foil covering. This helps to seal the cups securely and without any gaps. The machine is able to work with a variety of cup sizes and seals them in seconds.

Advantages

The semi-automatic cup sealer machine is a great way to speed up production and reduce labor costs.

- The machine requires minimal training and can be operated by a single person.

- The machine is also easy to use and maintain, making it an ideal choice for any business.

- Additionally, the machine can be used to seal a variety of different materials, including plastic, paper, and aluminum.

Disadvantages

While the semi-automatic cup sealer machine is a great option for businesses, it does have some drawbacks.

- The machine can be expensive to purchase and may require additional maintenance.

- Additionally, the machine can be noisy and may require a dedicated space for operation.

Components

A semi-automatic cup sealer machine consists of several components. These include:

Pneumatic system

Different Parts of cup sealer machine

The pneumatic system is responsible for powering the machine and providing air pressure to the hopper and air cylinder

A hopper and an air cylinder

Hopper is responsible for feeding cups into the machine while the air cylinder is used to force the sealing head down onto the cups

A sealing head

It is one of the major and main components in the cup sealer machine which is used to create a tight seal around the cup and its contents.

The cup sealer

Finally, the cup sealer is responsible for cutting off the excess material of the seal.

Fully Automatic sup sealer Machine

A fully automatic cup sealer machine requires absolutely no human intervention. It does all the work by itself. A fully automatic cup sealer machine fills and seals the cup and then gives out the final product on its own without any manual help.

The fully automatic cup sealer machine is the most efficient and productive cup sealer machine but it is more expensive than the other two types. If you own a large business and your productivity requirements are greater than the capacity of the manual and the semi-automatic cup sealer machines, then you should go for the fully automatic cup sealer machine as it will save you time and money in the longer run.

Working Scenario

The fully automatic cup sealer machine is designed to help reduce the amount of time and effort that goes into sealing packaging. It works by using a vacuum system to suck the air out of a special plastic film. This vacuum feature helps to create an airtight seal around the packaging, ensuring that it remains secure for transit and storage.

The machine also features a built-in heating element that quickly seals the film around the packaging, making it tamper-proof. The machine also has a safety feature that prevents it from being opened while the film is still hot. This helps to ensure that the contents inside the packaging remain secure.

Additionally, the machine has an adjustable timer that allows users to adjust the sealing speed depending on their needs.

Advantages

The fully automatic cup sealer machine is a great option for any business that needs to package its products in a secure and efficient manner.

- The machine helps to save time and effort in the packing process, while also ensuring that the packaging is completely secure.

- Additionally, it has a built-in safety feature that helps to prevent tampering with the contents inside.

- Finally, the adjustable timer allows users to customize the sealing speed depending on their specific needs.

This helps to ensure that the sealing process is done quickly and efficiently.

Disadvantages

The main disadvantage of the fully automatic cup sealer machine is its cost.

- These machines are generally more expensive than manual sealing systems, so they may not be suitable for businesses on a tighter budget.

- Additionally, some users may find that the adjustable timer can be difficult to use or adjust.

- Finally, due to its vacuum system, the machine is not suitable for use with metal or glass containers.

Components

The fully automatic cup sealer machine is composed of several different components. These include:

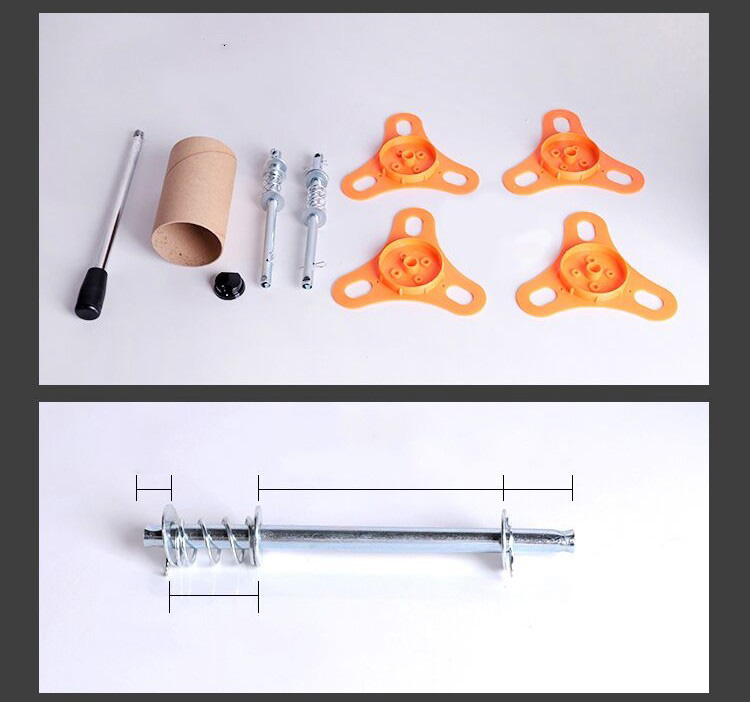

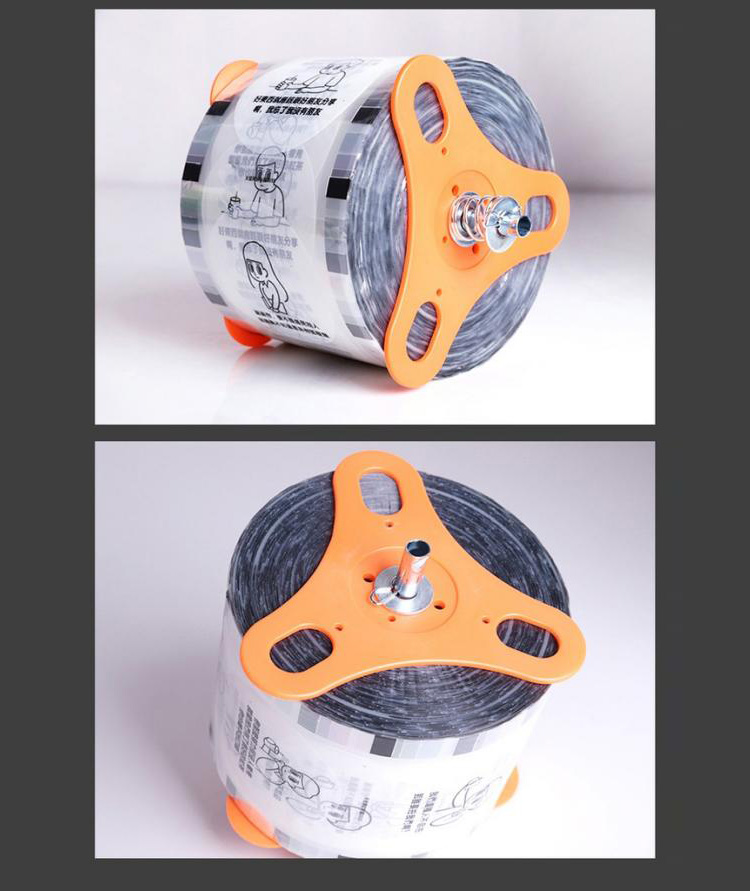

Plastic film feeder

The main principle of a plastic film feeder is to provide plastic film when the cup is placed in the sealing assembly.

Vacuum system

Vacuum system simple performs the air removal process and vacuum creation during the sealing of a cup.

Heating element

In this component when the plastic film is set on the cup mouth then heating will be given to make the seal leakage free.

Adjustable timer

An adjustable timer simply helps you to define a specific time period that you can use to heat the product and how much speed you want to make during the sealing process.

Each of these components plays an important role in helping to create a secure seal around the package.

Additionally, the machine is powered by electricity, meaning that it needs to be plugged into a power source in order to work properly

5.What type of sealing film/plastic does a cup sealer machine uses for sealing purpose?

A cup sealer machine uses different types of sealing films to seal different types of cups. Some of the sealing films used by the cup sealer machine are listed below.

PP Films

The polypropylene sealing films or PP films are the sealing films that are best compatible with the PP cups and thus are used to seal them. These films form a very strong seal over the PP cups.

PE Films

The polyethylene sealing films are used to hermetically seal not only the PE cups but also most of the PP cups. The seal formed by the PE films is not as strong as the PP films and so the advantage of the PE films is that they can be peeled off very easily unlike the PP films that you cannot peel off.

PET-ES Films

The PET-ES sealing films are the most widely compatible sealing films that can be used to seal a wide range of cups made of paper, plastic, Styrofoam, etc.

Paper Films

The paper sealing films have been gaining popularity because of their environment-friendly nature. It is believed to decrease plastic usage which is considered a hazard to the environment.

Paper sealing films are compatible with some of the PP and most of the PE cups.

Aluminum Films

The aluminum sealing films are the only kind of foil sealing films. They are mostly used to seal the cups containing dairy products.

6.Which business mostly uses the cup sealer machine for sealing?

A cup sealer machine is an essential and a very important part of many businesses around the world. Some of the businesses that use the cup sealer machine are listed below.

Beverage Industry

Many beverage industries use the cup sealer machine to hermetically seals their cups or containers containing liquid products to prevent any spillage or leakage.

Dairy Industry

Dairy goods manufacturers also use the cup sealer machine to seal the containers containing their products such as cheese, milk, yogurt, yeast, etc. The dairy industries mostly use aluminum sealing film to seal their products. These seals ensure the quality assurance of the products.

Tea and Coffee Shops

Tea and coffee shops extensively use the cup sealer machine to seal the cups containing tea or coffee. Mostly PP or PE films are used for sealing purposes.

Food Industry

The food industry uses the cup sealer machine to seal their containers air-tight to ensure that the food inside the containers remains fresh during their shelf life. The seal protects the food from the impurities and the humidity present in the air. Most commonly food industry uses the cup sealer machine to seal food products such as vegetables, meat, seafood, etc.

Wine Industry

The wine industry also uses the cup sealer machine to seal the bottles containing wines so that the wine remains preserved during its shelf life.

Manual, semi-automatic, and fully automatic cup sealer machines are used in different industries depending upon the size and the productivity requirement of the industry.

7. How to select the best cup sealer machine?

Selecting the right cup sealer machine for your business is a very crucial decision because it is very important to buy the cup sealer machine that best suits your business. When buying a cup sealer machine, you should keep the following points in your mind.

Find a Trusted Manufacturer

You should make sure that the manufacturer you are buying a machine from is trustworthy and that the products they make are reliable. Always check for customer reviews before buying the cup sealer machine so that you do not get scammed.

Repairability of the cup sealer Machine

You should always make sure that the cup sealer machine you are going to buy is repairable and that you can easily find the right mechanic to repair any fault in the machine.

Spare Parts Availability

Before buying a cup sealer machine, make sure that its spare parts are easily available in your area to avoid any inconvenience later.

Find the Best Price

Always try to find the best price for the cup sealer machine you are going to buy. Never compromise on the quality but look for the best possible price.

Compatibility

When buying the cup sealer machine, select the one that is best compatible with your business. Go for the one that meets your productivity requirements and saves your precious time and money too.

Beware of the Scammers

If you are planning to buy a cup sealer machine online, always beware of scammers. There are many scammers on the internet, so you should be very vigilant while choosing the cup sealer machine.

8.How to troubleshoot problems while working with cup sealer machine?

Some common issues with cup sealer and how you can troubleshoot them easily.

Jammed Sealing Mechanism:

The sealing mechanism may become jammed due to excess material or foreign objects stuck in the machine. In this case, it is important to immediately unplug the unit and take it apart to clear out any material or objects that may be blocking the sealer.

Poorly Sealed Cups

If your cups are not properly sealed, it could be due to a misalignment of the sealer lid and cup. To fix this issue, you will need to adjust the height of the lid and make sure it is properly aligned with the cup.

Sealer Not Working Properly

The sealer may not be working properly due to a power issue or an electrical malfunction. To fix this, you should check the power supply and ensure that it is connected properly. If the issue persists, you may need to replace the sealer.

Tips for longer lifespan of cup sealer:

- Avoid overfilling the cups with liquid or other materials as this can cause excessive strain on the sealer.

- Ensure that the power supply is connected properly and not overloaded.

- Make sure to store the cup sealer in a cool, dry place away from direct sunlight.

9.What is the process to install a cup sealer machine?

A step-by-step guidance to install a cup sealer machine.

Choose a Suitable Cup Sealer Machine

Determine the size of your cups and the type of material you will be sealed to ensure you have the right size and type of sealer for your application.

Select a Safe Location

Choose a level surface, away from any heat sources and vibration.

Set Up the Machine

Follow the manufacturer’s instructions to properly assemble the cup sealer machine.

Connect the Machine to a Power Source

Ensure all necessary cords and power supplies are connected safely and securely.

Test the Machine

Run a few tests runs using empty cups with lids to ensure the sealer is working properly before beginning production.

Begin Sealing

Place filled cups into the designated area of the machine, press down on the sealer arm and watch as it seals your cups completely.

Maintain and Clean the Machine

Regularly clean and maintain your cup sealer machine to ensure it is working properly.

Conclusion

A cup sealer machine can prove to be a huge blessing for your industry. With its key qualities being efficient, effective and cost effective, it can be a great asset for your business. Being cheaper than most of the machines is an additional quality. You should consider buying this machine if you make products that needs to get sealed because Allpack's cup sealer Machine assures that the quality of your product remains preserved throughout the shelf life. Please feel free to contact us at any time.

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp:+86 18171018586