Your Most Excellent Bottle Unscrambler Manufacturer

- Easy to Clean and Disinfect

- Overload Protection Device

- Made Of High-quality Stainless Steel

Bottle Unscrambler

Allpack bottle unscrambler is made of high-quality to comply 304 stainless steel, which is easy to clean and sanitize. This machine is designed complying with GMP standards. It is suitable for arranging messy polyester bottles and arranging them in a row, then discharging them through a vacuum conveyor. A wind conveyor is connected with a bottle unscrambler and a filling machine to form an automatic production line. The bottle unscrambler can be used for different bottles by changing the bottle unscrambler mold. Bottle unscrambler is widely used in cosmetics, chemical industries, food, and other industries. This machine can be used in conjunction with an automatic packaging production line. There are two functions sending bottles and receiving bottles. This bottle unscrambler adopts a full English interface touch screen, and PLC microcomputer control system.

Bottle Unscrambler

APC-A100 Automatic High Speed Rotary Plastic Bottle Sorting Unscrambler

APC-A100 automatic high-speed rotary plastic bottle sorting unscrambler is equipped with a quantity control system and an overload protection device. With the advantages of easy operation, convenient maintenance, and stable performance, this bottle unscrambler can help you sort and arrange your bottles neatly and in order. The machine is made of high-quality 304 stainless steel complying with GMP standards which is easy to clean and disinfect. The high-speed bottle unscrambler is equipped with an electromechanical integration device, which is easy to arrange and position your bottles without labor work.

Easy To Clean And Disinfect

PLC Microcomputer Control System

Made Of High-quality 304 Stainless Steel Complying With GMP Standard

APC-A160 High Tech Automatic Pharmaceutical Plastic Bottle Sorting Unscrambler

APC-A160 high-tech automatic pharmaceutical plastic bottle sorting unscrambler is a high-tech bottle unscrambling machine that integrates mechatronics and bottle sorting and conveying. Just pour the bottles into the storage hopper, and it will automatically and orderly convey the bottles to the conveyor belt. This plastic bottle sorting unscrambler is in simple operation, convenient maintenance, and stable operation. It is equipped with a quantity control system and an overload protection device. The frame and the body are made of 304 high-quality stainless steel material, which is easy to clean and disinfect and meets GMP requirements.

Simple Operation

Overload Protection Device

Easy To Clean And Disinfect

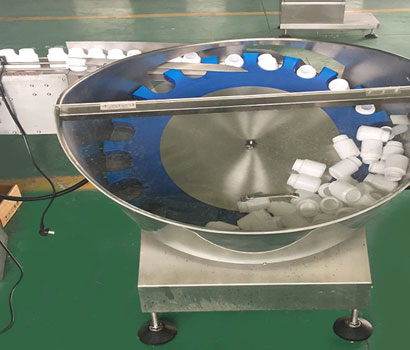

APCP-1 Semi-automatic Electronic Turntable Rotary Bottle Unscrambler

APCP-1 semi-automatic electronic turntable rotary bottle unscrambler is suitable for round bottles, square bottles, and flat square bottles of various materials, especially for large bottles unscrambling. This bottle unscrambler is easy to operate, and there is no need to replace parts for changing bottles, just simple adjustments. The APCP-1 bottle unscrambler is made of high-quality stainless steel for longer and more durable use. The bottle output speed is fast, and the performance is stable. The qualification rate is high, and the labor cost is greatly reduced. The bottle unscrambler has the function of automatic stop when the bottle is full and automatic start when there is no bottle.

Easy To Operate

Function Of Automatic Stop

Made Of High-quality Stainless Steel

The Buyer's Guide

Bottle Unscrambler: The Complete Buying Guide In 2025

The use of the bottle unscrambler machine has been increasingly growing in the past few years. As the world population is growing rapidly, there has been a rise in the demand for various consumer products. The manual labor would take a lot of time and would be unable to meet the demands of millions of people annually.

So why should you use a bottle unscrambler machine in the place of labor? What is so special about it that we replace people with a machine, creating unemployment? What is its significance and in which industrial sectors can this machine be used? In order to answer these questions, let us take a look at its various features and why it is the best option for organizing bottles in an industry.

1. What Is A Bottle Unscrambler?

A bottle unscrambler is a machine used to orient or position bottles in a certain way. In other words, it is a machine built from different components to organize the bottles which are dispersed randomly and are then sent to the production line in a conveyer belt system where they are filled with different types of liquid according to the requirements.

2. What Is the Working Principle of Bottle Unscrambler?

The working principle of bottle unscrambler is as follows

Firstly, the bottles which are oriented randomly are thrown into a hopper which has the ability to hold thousands of bottles at the same time.

Secondly, these bottles are handled from the hopper to other parts of the machine according to the direction in which they are facing until all of them are sorted in a standing position and sent to the bottle filler through the conveyer system.

Thirdly after filling the bottles with the desired liquid, they are sent to the capping machines where they are closed with the caps and finally to the labelling machine where they are labeled with the brands name.

3. What Is the Purpose Of Bottle Unscrambler?

Large- scale industries like pharmaceuticals, chemicals, food and oil refinery produce thousands of products daily. Manual labor is not used extensively because it is time consuming, expensive and is unable to do a lot of work which the machines are able to do. Thus these industries are provided with massive, high speed and extremely efficient machines so that they are able to manufacture thousands of products every day.

Bottle unscrambler machine is a perfect choice to get integrated with other machines in these industries. It is situated at the start of production line so they’re very critical for the initiation of the process. It is a high speed machine since its hopper has the ability to store thousands of bottles at the same time and quickly send them to the filling machines through the conveyer. Thus the use of it can provide the industries with fast, cost effective and efficient method to manufacture their products.

4. What Are the Components Of Bottle Unscrambler?

The basic components of a bottle unscrambler machine is as follows:

Hopper

The hopper acts like a storage and stores thousands of bottles before the process begins and then send them to the conveyer for packaging.

Taper plate

The taper plate ensures the smooth flow of the incoming bottles.

Turntable and tooling channel

They will help the bottles to maintain a specific position.

Aligner

The aligner makes sure that the bottles are not jammed or crowded together in the machine.

Mould

Mould helps to keep the bottle in place. Each mould is able to hold only one bottle.

Blower

The blower like an aligner prevents the bottles from getting jammed together. They also help to keep the bottles clean and invert them for vacuuming.

PLC controller

This automated system with the help of HMI control the bottle unscrambling process and monitors it.

Bottle storage

As the name suggests, it is used to store a specific number of bottles which are to be lifted. It is covered with glass to prevent dust contamination.

Bottle lifting device

This device moves the empty bottles from storage to different parts of machine.

Conveyer belt

This belt is used to transfer bottles. This is an automatic and simple process.

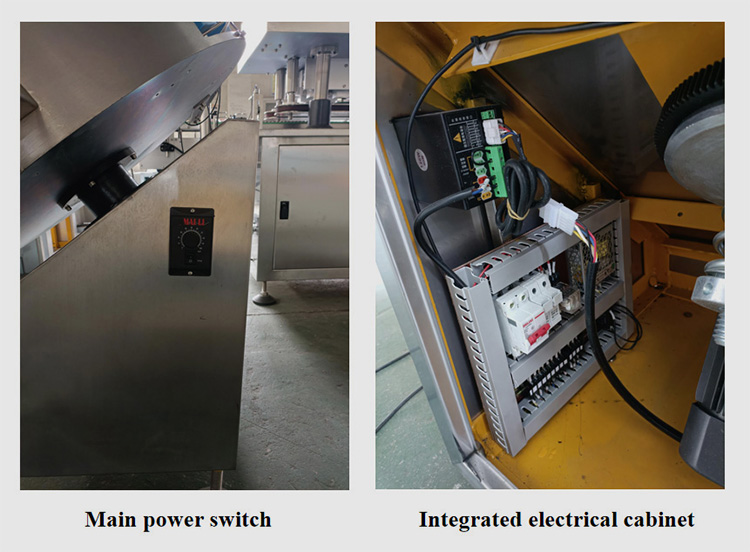

Main frame

This contains the electrical cabinet and pairs of supporting legs.

5. What Are the Types of Bottle Unscramblers?

There are various types of bottles unscrambler machines which have their own characteristics and features. There are a number of factors which need to be considered since this process involves the organization of bottles before their filling. These factors are unique to each industrial sector like pharmaceutical, chemical etc. let us look at the different types of this machine below.

Bottle unscrambler machine are differentiated into two modes.

Based On Automation

Automatic Bottle Unscrambler

This machine can be used for a variety of bottles such as round bottles, square bottles, bottles in which we can fill eye drops. This machine works on automated process to sort and organize bottles quickly in an efficient way. This machine can be integrated with a tablet counting machine, desiccant inserter, induction sealing machine, etc.

Semi-Automatic Bottle Unscrambler

This is a semi-automatic machine in which the bottles need to be placed on the turntable manually. The bottles will then be delivered to other parts of the machine automatically through the conveyer belt.

Based On Designing

High-Speed Round Bottle Unscrambler

As the name suggests, this machine works at a very high speed and is easy to use. It is used to organize irregular bottles and round plastic squares. It is mostly used in industries like the pharmaceutical and food industries.

Linear Unscrambler

This type of machine is made of stainless steel and have a strong hopper. This machine is quite beneficial to a lot of industries because it has the ability to convert small size bottles into medium size bottles without damaging them. But one of their biggest advantages is that they save a lot on energy bills since they do not use compressed air to restore the shape of the bottles.

Rotary Unscrambler

This type of machine is one of the most popular ones out there. It is extremely efficient and can be used for various kinds of bottles such as oval, rectangular or cylindrical boxes. They have a rotary positioner that organizes the bottles, thus restoring the shape and dimensions of the bottle. Since this machine also doesn’t use any compressed air, it also reduces the cost of energy bills.

Monobloc Unscrambler Or Rinser

This machine consists of a rotary unscrambler as well as a rinser. It is a multi-purpose machine that has the ability to unscramble the bottles and rinse them at the same time. Thus, this machine can provide industries with not just an unscrambling option but a cleaning option as well.

6. Industrial Applications of Bottle Unscrambler

The bottle unscrambler machine can be used in various industries such as pharmaceutical, chemical, cosmetic, agriculture, and food and refinery industry. We will discuss each of the industries below

Pharmaceutical Industry

The pharmaceutical industry deals with the manufacturing of medicines and drugs which are to be administered to patients in order to cure them or improve their lifestyles. Most of these medications are stored in thousands of bottles and shipped to different parts of the world. The use of a bottle unscrambler to organize these bottles would be the perfect option to handle these medicines with extreme care.

Refinery Industry

Refinery industry is an industry which takes crude oil, makes it go through distillation process and converts it into useful petroleum products such as gasoline, kerosene oil, diesel, jet fuel etc. these liquefied petroleum products are stored in containers or in bottles. The use of a bottle unscrambler would be the best way to assemble these bottles and containers and add fuel into them.

Food Industry

The food industry is involved in the production of various food items such as milk, soft drinks, ketchup, sauces and juices. All these food products need to be stored in jars, bottles and containers. The installation of the bottle unscrambler machine would be a wise decision in order to fill the bottles with these food items.

Industrial Agriculture

Industrial agriculture is a modern way of farming which uses advanced technological methods to give maximum crop yield and lower consumer costs. This industry relies heavily on products like fertilizers, pesticides to increase crop yield. Thus to contain these fertilizers and pesticides in containers, the use of bottle unscrambler machine is necessary to prevent use of expensive manual labor and ensure maximum profit margin.

Cosmetic Industry

Cosmetic industry deals with the manufacture of beauty products such as shampoos, moisturizers, serums, hair oils etc. these products have to be filled in bottles with extreme care. Thus the use of bottle unscrambler machine would be feasible to package these products.

Chemical Industry

Chemical industry is involved in the production of various chemicals and solvents which have extensive use in various other industrial sectors. The bottle unscrambler machine is widely used in chemical industry since these chemicals need protective packaging to keep them pure and prevent them from any contamination.

7. Advantages of Buying Bottle Unscrambler Machine. Is It Worth Buying?

The bottle unscrambler machine is a very popular machine to organize bottles. Its demand has been growing rapidly for the past few years because it has many advantages and should be the go to machine for any customer who wants an efficient production line in his industry. Let us discuss some of the advantages below.

Cost Effective

The machine is quite effective since it eliminates the need of expensive manual labor. It is automatic so it can work independently on its own.

High Output Capacity

Due to its high speed and automated process, it produces a high output capacity as compared to the manual loading and conveying of bottles.

Less Space Needed

The operation of bottle unscramble requires very little space.

Easy To Maintain

This machine requires low maintenance and almost never causes any hindrance to the process.

Flexible

This machine is quite versatile and can be used to organize various kinds of bottles of different shapes and sizes.

Precise

This machine is error free and does not make any mistakes since it is controlled by a computer.

8. Types Of Bottle Treated By Bottle Unscrambler?

Some bottle types are widely used in bottle unscrambling, such as PP, PET, HDPE, and PS. All of the bottles used in bottle unscrambler are briefly defined below.

PP Bottle

PET bottles is It has the potential to create exceedingly thin plastic components that are subjected to intense physical strain, such as the lids on conditioner and moisturizer bottles.

PET Bottle

Polyester’s chemical name, polyethylene terephthalate, is abbreviated as PET. PET, a transparent, robust, and lightweight plastic, is frequently used to package meals and drinks, particularly convenience-sized soft drinks, juices, and water.

HDPE Bottle

The chemical component ethylene is used to make high-density polyethylene (HDPE) resin. blow-molded HDPE bottles are used. Cleaning solvents, shampoos, motor oil, milk, as well as other liquid products, as well as medications and cosmetics, are all stored in bottles. A natural-colored HDPE polymer is used in the majority of milk and water bottles.

PS Bottle

Since polystyrene is recognized for its clarity and rigidity, these bottles are excellent for uses where material visibility is essential

9. How To Operate Bottle Unscrambler Accurately?

There are unique operating methods designed for the equipment to guarantee that it operates normally and safely:

- First, make sure the equipment is in good shape, has a valid identification, and has a record of how it was used during working hours.

- Clean the device in accordance with the cleaning method if the cleaning window has passed, then enter the device status identifier.

- Make sure there are no foreign objects in the container bin and tray and move the bottles plate and tray to assure they can function normally.

- Check the touchscreen interface and three photoelectric sensors after turning on the power switch. The touch screen will show a missing bottle alarm if both are powered on; if the bottle is missing but the electric eye is covered by a hand and the bottles is blocked, the screen will show a bottle blocking alarm, indicating that the dual photoelectric switches are functioning normally.

- When the compressor is ejected, the device can be operated normally by opening the compressed air and shaking the bottle bottom beneath the bottle scraper’s electric eye.

- Start the main engine and raise the start button on the touch screen, respectively, to check if the bottle unscrambler process makes any unusual noises.

- After turning on the device, ensure there are no odd circumstances.

- Starting the machine at a low pace allows it to be matched to the production speed by adjusting the elevating speed and de-bottling speed in accordance with the actual production.

- Stop the machine, turn off the power, and remove any leftover materials after production has finished.

10. Maintenance And How To Clean Bottle Unscrambler?

Bottle unscrambler machines are easy to clean and are of low maintenance. Let us take a look at some of the ways in which we can clean and maintain the machine

Lubrication

The constant use of the machine can cause a lot of friction between the different parts of the machine such as the motor and conveyer. To prevent this, a lubricator can used on them for smoothness, thus increasing their efficiency.

Air Rinser

The air rinser should be checked regularly to see if it is cleaning the bottles properly.

Electric Board

The electric board should be checked to see if all the connections are intact or not.

Prevention Of Dust Contamination

Sometimes, the machine gets filled with dust particles and as a result do not run smoothly if not cleaned regularly. So all the parts of the machine should be cleaned on a regular basis to prevent dust contamination.

11. Problems And Trouble Shooting Of Bottle Unscrambler Machine

Problems

Just like every machine has its pros and cons, the bottle unscrambler machine also has cons of its own. This machine like the other ones has a life after which its components start to break or do not run as efficiently as they did. These problems can pose a threat to industries as it hinders the production line and disrupts the whole manufacturing process resulting in decreased production and decreased profits.

Solutions

Prevent this from happening, fortunately, there is a way to solve these problems. Firstly, with constant cleaning and maintenance, the life of the components of the machine can be increased. Secondly, if after some time, some parts of the machine start to break down, they can be replaced with new ones. These parts are not very expensive and are readily available in the market or online. Thus the customer has various options and varieties to choose from and make his decision.

12. How To Choose A Bottle Unscrambler?

It can be challenging to purchase the bottle unscrambled. Knowing which choice is best for your company can be challenging given the abundance of possibilities.

The manufacturing supplier’s reputation

You should refrain from purchasing from unreliable and unbranded vendors. When you buy a machine from a reputable manufacturer, you can be confident that it will be of the highest quality because of their reputation for quality and expertise.

Output capacity

Always put your daily output capacity first to aid in selecting the best bottle unscrambler. Because doing so will preserve your process and production time, assessment is crucial.

Innovative technology

Selecting a bottle unscrambler with more innovative and advanced features would boost your manufacturing efficiency and make the process more controllable.

Production scale

The magnitude of your production would be dissimilar from that of a pharmaceutical company. A small-scale bottle unscrambler is necessary if you’re performing a lab-scale procedure, though. Choose the appropriate equipment by determining the type of scale of production you need.

Budget

Always look for reputable manufacturing companies that can comprehend your wants and provide you with a solution in a way that is both efficient and affordable.

13. Future Market Growth Of Bottle Unscrambler?

To keep a bottle unscrambler into your production line is always significant for your business. Its fast working output in a cost-economical procedure saves your time; hence your employee can do other tasks.

Moreover, the machine is confined to a lower maintenance ratio. If you have a small space in the working facility. then the most fascinating thing about bottle unscrambler is that it holds less space so that you can set this machine up to your requirement.

During the forecast period, which runs from 2022 to 2028, it is predicted that the global bottle and plastic water bottle unscrambler market will expand at a significant rate. The market is likely to increase over the anticipated period of time in 2020 since major companies are adopting strategies at an increasing rate.

The bottle and plastic bottle unscrambler market is the main subject of this study, which also covers segmentation information for additional regions at the regional and country levels.

Conclusion

The quick and simple operation of the bottle unscrambler helps in growing your business leap and bound. Many new advancements facilitate you to monitor the whole process whenever and wherever you are. When purchasing a bottle unscrambler, it is essential to ensure that the machine is strictly complied with cGMP standards and exhibits high output. Allpack has a reputable profile of packaging and manufacturing equipment. Bottle unscrambler has high feeding and discharging system with greater energy-saving properties. For Product Inquiries or Purchases Please Contact Our Team- We Will Be Pleased To Serve You Shortly.

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp:+86 18171018586

Tell us your material or budget, we'll reply you ASAP within 24 hours