Powder Packing Machine: The Complete Buying Guide In 2025

Packing powder is a challenging task due to its vulnerability to flow, moisture and contamination. On the other hand, the rapidly growing demand for powders has made it impossible for manufacturers to manually pack the various powders into bags and containers. Therefore, Allpack's powder packing machine is particularly designed for the accomplishment of filling and packing powders in range of flexible packaging containers.

The machine's eclectic specifications give you an opportunity to adopt cost-effective packaging methods such as bags and pouches etc., while at the same time allowing you to gain customer satisfaction by maintaining the integrity and convenience for consumers. Moreover, its elegant construction, packing versatility and user-friendly operational procedure can give you more than enough benefits. So, let's get all these advantages associated with a powder packing machine!

1.What Is A Powder Packing Machine?

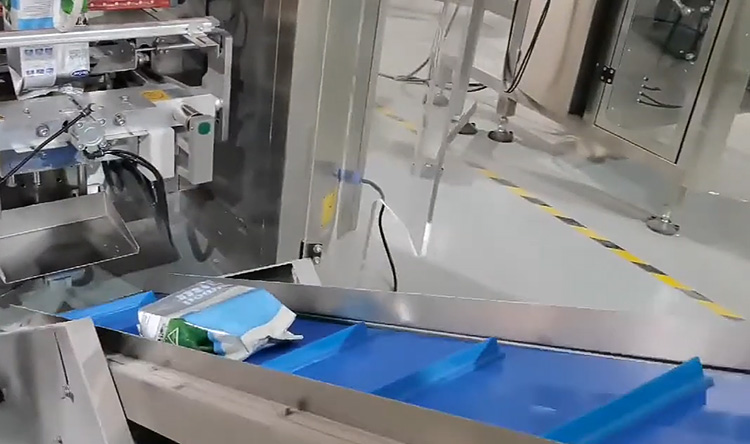

Powder Packing Machine-Allpack

Powders are dry fine particles made from the crushing of solid material such as flour, protein powders and coffee powder etc. As powders are dusty by nature, they easily get flow and affected by the external elements such as moisture and air etc., during packaging. To tackle this issue, a powder packing machine has been employed into the field to precisely pack the various powders into bags and containers.

This powder packing machine is a composite assembly of different parts all made up of stainless steel to avoid product contamination or bacterial presence. It is proficient in maintaining the uniformity of powder packing during process. For achieving this aim, the machine intelligently measure powder quantity and fill it into sachets, bags or containers.

2.What Is Meant By Free Flowing And Non-Free Flowing Powder Processed By A Powder Packing Machine?

Powders are fundamentally divided on the basis of free flowing or non-free flowing characteristics. It is crucial to determine which type of powder you are going to pack, as it can affect the quality of your packaging if neglected. To assist you in this regard, the table below will demonstrate some of the essential information about both types of powders:

| No | Factors | Free Flowing Powders | Non-Free Flowing Powders |

| 1 | Definition | Powders which have high gravitational force and tend to fall easily are known as free flowing powders | Powders with high cohesiveness and low gravitational force are termed as non-free flowing powders as they get stuck together |

| 2 | Nature | Non-cohesive | Highly cohesive and sticky |

| 3 | How to determine | Put the finger in powder, if it does not leave indentation to your finger then it is free flowing powder | If the powder gets adhere to your finger and leaves indentation, then it is non-free flowing powder |

| 4 | Examples | Sugar, semolina and glucose powder etc. | Custard powder, milk powder and starch etc. |

| 5 | Packing machine type | Volumetric and straight free flowing auger filler | Non-free flowing curved auger filler |

| 6 | Picture |

Sugar in bowl-Picture Courtesy: sweetestmenu.com |

Starch presentation idea-Picture Courtesy: homehacks.co |

3.Explain The Essential Attributes Of A Powder Packing Machine?

Powder packing machine is created with lots of qualities and attributes which are explained below:

Packaging Accuracy

Powder packing machine is known for its packaging precision due to high degree of automation. This feature makes the machine capable of performing all the tasks from powder measuring to powder filling into containers automatically. This eventually reduces manual intervention and enhances packaging accuracy.

Increase Production

Multi stick packs-Picture Courtesy: neora.com

Manual packing of powders result in many shortcomings among which low productivity is the major issue. However, this problem has been resolved by the powder packing machine which can pack around 30 bags in a minute.

Extend Shelf Life

Spices in jars-Picture Courtesy: skinnyms.com

Powder packing machine is a great source of protecting the quality and freshness of powders. By doing so, the shelf life of range of powders is extended, and the consumers get same taste and aroma of powders when opening the pack which is packed months and even years ago.

Resilient

Various packaging bags & containers-Picture Courtesy: thedieline.com

Resilience is the key attribute of a powder packing machine for the reason that it has the ability to fill and seal diverse types of powders and containers. Moreover, the quick parts' changeover of machine makes it more adaptable for filling powders into different size bottles and bags.

Easy Maintenance

Easy maintenance icon-Picture Courtesy: biorotor.com

With simple structure, convenient operation, and intuitive control system, the machine is easy to install and maintain during the entire working lifetime.

4.How To Operate A Powder Packing Machine?

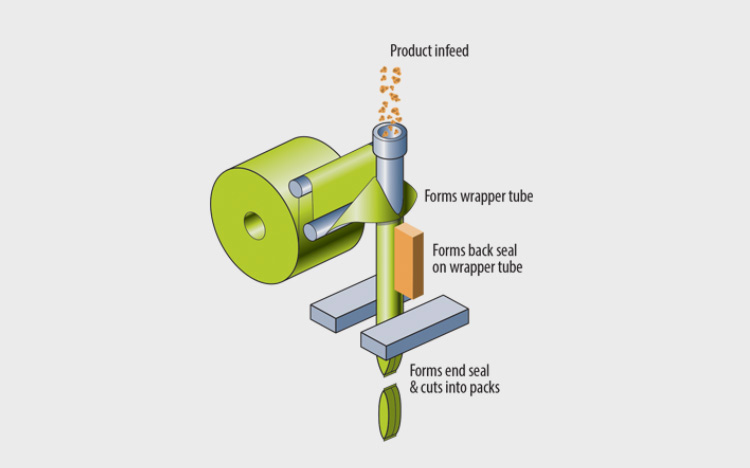

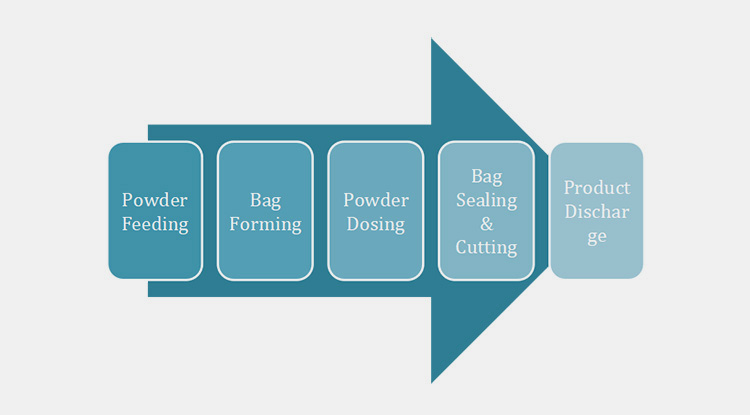

Working process of a powder packing machine-Picture Courtesy: labelsandlabeling.com

The operational procedure of a powder packing machine involves several steps which must be well understood in order to better operate the machine. These working principles are elaborated below:

Powder Feeding

Various powders-Picture Courtesy: syntegon.com

The process of powder packing begins with operator feeding the hopper with bulk of powder. Once the hopper is loaded, user can turn the machine on to start the powder packing.

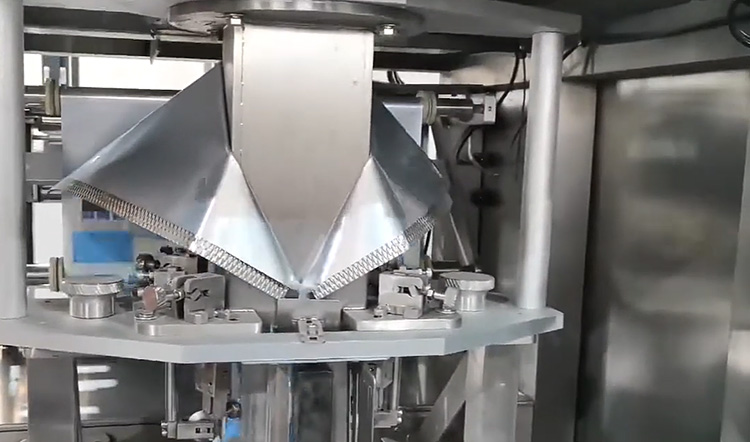

Bag Forming

Vertical bag formation-Picture Courtesy: bojupacking.com

In the second step, formation of bag takes place where film is pulled by the machine towards forming tube. When the film is twisted around the forming tube, vertical sealer seals the bag from backside and lower sealer seals the bag from lower end. Eventually, bag is formed and ready to be loaded with powder.

Powder Dosing

Powder dosing into bag-Picture Courtesy: bojupacking.com

Now, after the bag is formed, the machine will measure powder via auger filler or free flowing filler and will dose it into the formed bag through a nozzle.

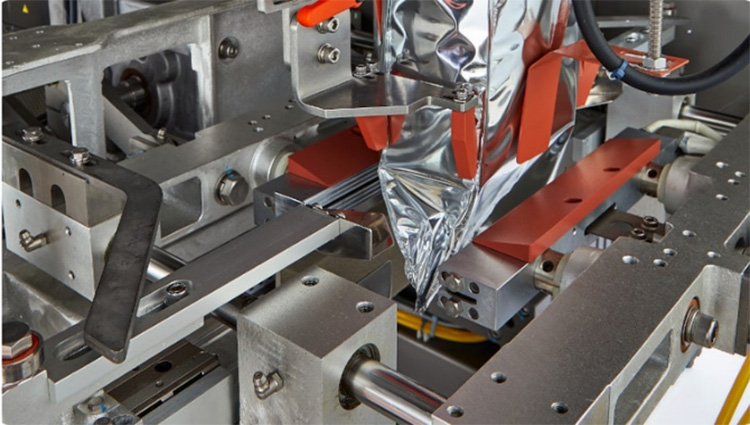

Bag Sealing & Cutting

Bag sealing-Picture Courtesy: jochamp.com

Proceeding further, the filled powder bag will be sealed through heated sealer. At the same time, the packed bag will be cut down by the cutter and bag will fall over the discharge chute.

Product Discharge

Bags discharging-Picture Courtesy: bojupacking.com

Finally, all the powder packed bags will be discharged by the conveyor having separate apartments for each bag.

5.Describe The physical Structure Of A Powder Packing Machine?

Structure of powder packing machine-Picture Courtesy: indiamart.com

The structure of a powder packing machine is composed of the following major components:

Packaging Roll Film

Packaging film roll is a roll of eco-friendly plastic which is either labeled or transparent. The roll is fitted into machine for the purpose of forming plastic bags for packaging various powders.

Material Hopper

Material hopper is a stainless steel container with large material in-feed area and narrow ending attached to the filling nozzle. It is located on the top side of machine for holding bulk volume of powder. Inside hopper, is a set of agitator blades and auger through which powders are measured and transported to the filling heads.

Quantitative Control Panel

This part of machine is responsible for allowing user to interact with the machine by displaying several options for operation including weight of powder to be filled in each bag and the speed of agitator blades etc.

Discharge Hole

Discharge hole is also known as filling head or filling nozzle which is linked to the end of hopper. It simply doses the bags and containers with accurately measured powder.

Packing Molding Device

It plays a key roll in giving the shape to the bags during operation. The device molds the flat shape of film into a bag by wrapping the film around its cylindrical body.

Microcomputer

This microcomputer in a powder packing machine works as the brain of machine. It stores in it the data fixed by operator. Moreover, operator can use it to control the operation of machine including the area of bag cutting and sealing etc.

Heat Sealing

Heat sealing station is an important part of the powder packing machine which seals the top, bottom and vertical back of bag by using heat.

Power Switch

Power switch is situated on the front of machine and facilitate user to instantly switch on or power off the machine.

Bag Moving Wheels

These are small rubber wheels which move the bag downward after it is filled with powder.

Separator

Separator is also called cutter which cuts the bag from rest of film.

Universal Wheel

Universal wheels are casters attached to the lower side of powder packing machine. They are able to rotate around 360 degrees, therefore, making it convenient to mobilize the machine from one place to another.

6.Enumerate The Various Types Of Packaging Bags Processed By A Powder Packing Machine?

There are multiple types of packaging bags which can be formed and processed by a powder packing machine. These include:

Sachets

Powder sachet display-Picture Courtesy: bumpnbub.com

Sachets are small plastic or aluminum foil bags with three or four sides sealing. They are perfect to hold small amount of powder usually used for each dosage. Therefore, these bags are often used in medical industry and food industry for serving of medicine dosage, spices and milk powder etc.

Gusseted Bags

Gusseted detergent powder bag-Picture Courtesy: Behance

Gusset is an additional layer of film added to the packaging bag during processing. In implies that gusseted bags are larger and have extra room for holding bulk powders. For instance, each gusseted bag has the capacity to store up to 2 kg of powder. Hence, such types of bags are able to be processed by a powder packing machine.

Stick Packs

Various powder stick packs-Picture Courtesy: neora.com

Stick packs are long narrow bags or sachets used for single serving. They require less packaging material, more handy to carry and easy to use. They also have beautiful shape which appeals to consumers, therefore, most of the manufacturers prefer using stick packs for single serving of coffee, sugar and calcium powder instead of sachets.

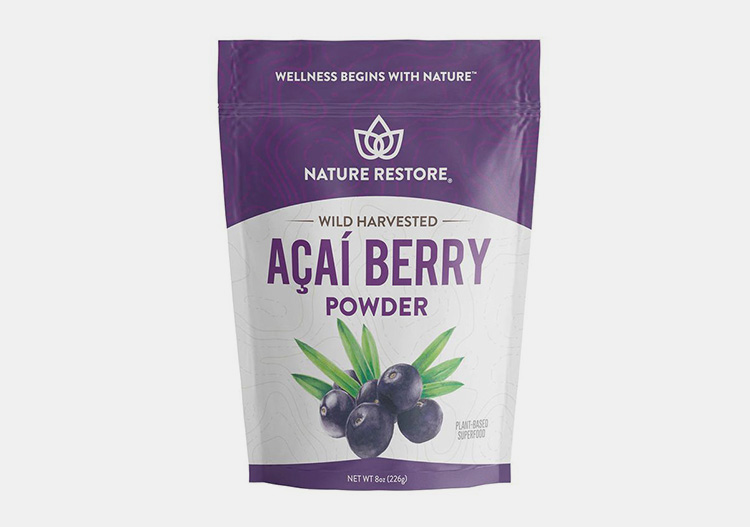

Doypack Pouches

Cherry powder doypack pouch-Picture Courtesy: naturestore.com

Doypack or standup pouches are straight bags with the ability to stand and reseal. They are more durable due to multi layer rigid structure made up of aluminum and plastic film. Doypacks are more safe to resist temperature, moisture and light as a result powders requiring strict safety can be easily packed in these pouches.

Pillow Bags

Chilli pillow bag-Picture Courtesy: Pacteck Ecopack

As the name depicts, pillow bags are pillow shaped packaging packs which are commonly used for powders. Unlike doypacks, they are used for single serving and cannot be resealed.

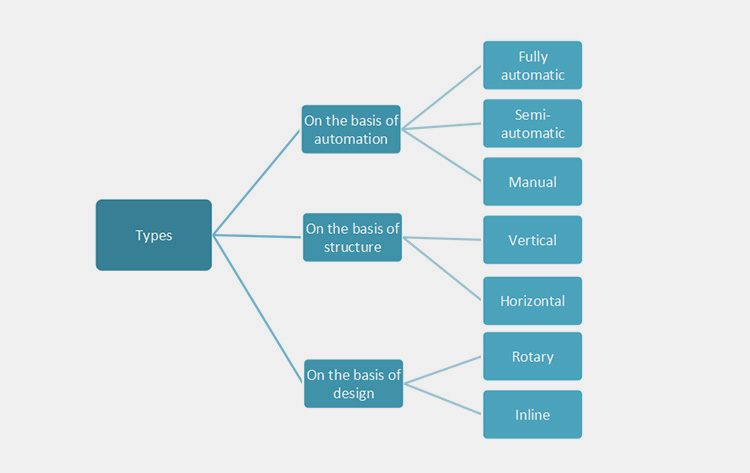

7.What Is The Classification Of A Powder Packing Machine?

Powder packing machine can be classified into different types on several basis. A detailed description of each type has been provided in below paragraphs:

On the Basis of Automation

Fully Automatic Powder Packing Machine

Fully automatic powder packing machine-Picture Courtesy: samfull.net

Fully automatic powder packing machine is composed of a feeding station, product hopper, control system, bag forming mechanism, and a product discharge conveyor. By working together, these components enable the machine to undertake the process of powder packing independently without any need for manual interference. Although, the structure of fully automatic machine is complex, and it is expensive, but, its production efficiency is outstanding and suitable for all the large scale manufacturing firms.

Semi-Automatic Powder Packing Machine

Semi-automatic powder packing machine-Allpack

Semi-automatic powder packing machine requires the operator intervention to accomplish the powder packing task. It consists of a hopper, dosing system, weighing unit, filling nozzle and a stand. The operator places a bag or container under the filling head and switch on the machine after which machine automatically measure the volume of powder and pour it into the container. The rest processing of bag sealing and container capping is done by other machines. Production facilities of relatively medium scale can better take advantage of this machine.

Manual Powder Packing Machine

Picture Courtesy: dahepowderfiller.com

Manual powder filling machine is more precise and cost-effective in terms of structure and price. It can be operated through a foot pedal. The user fill bags and containers by placing them under the filling nozzle and press the foot pedal or a handle to get the containers filled. This machine is beneficial for small level business.

On the Basis of Structure

Vertical Powder Packing Machine

Vertical Powder Packing Machine-Allpack

Vertical powder packing machine is vertical shape machine designed with distinctive features to form, fill, and seal various styles and sizes powder bags. It is ideal for the filling of granulated powders. It consists of a material hopper, bag forming mechanism, stainless main frame, automated powder weighing and filling system. It is the best suitable for milk powder, detergent powder, coconut powder, and spice powder etc.

Horizontal Powder Packing Machine

Horizontal powder packing machine-Allpack

This type of machine has horizontal structure as well as powder packing system. The machine is independent in performing the entire task of bag forming, filling, and sealing. Its horizontal design makes the machine a better choice for powders which requires additional safety such as chemicals and pharmaceutical powders. Moreover, this machine is capable of filling pre-made pouches and doypacks. Thus, manufacturers from medical, food, and chemical industries can use it for achieving their powder packing ends.

On the Basis of Design

Rotary Powder Packing Machine

Rotary powder packing machine-Picture Courtesy:lenismachines.com

Rotary powder packing machine is high performance powder packing machine utilized for filling powders into pre-made pouches and bags. Its structure is totally different from standard powder packing machine with multiple stations each performing different task encompassing bag pulling, opening, filling, sealing and discharging sequentially. Industries with excessive workload and requiring efficient powder packing machine for pre-made bags filling are always eager to use this machine.

Inline Powder Packing Machine

Inline powder packing machine-Allpack

Inline powder packing machine is entirely different from rotary powder packing machine in terms of structure, processing as well as function. This machine has single or multiple filling nozzles through which it fills the bags, bottles, or containers with precise amount of powder. It can be adjusted for small to large sizes containers, therefore, there is not such rigid limitation for product volume to be filled in bags. Unlike rotary powder packing machine, this machine follows a straight and serialized manner for powder packing.

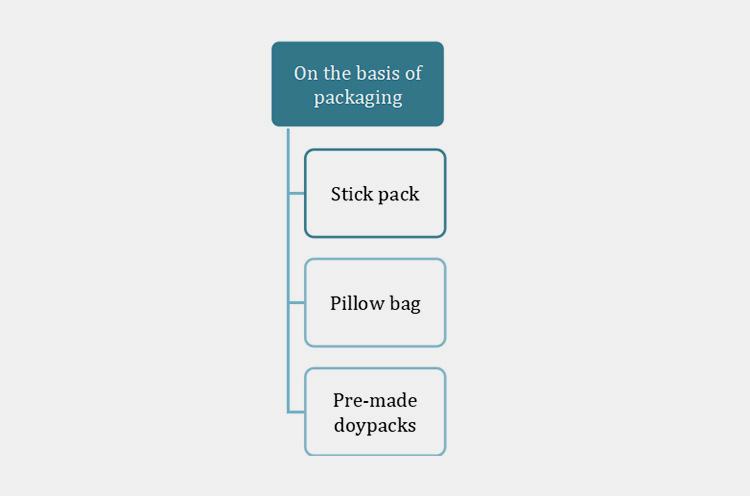

On the Basis of Packaging

Stick Pack Powder Packing Machine

Picture Courtesy: samfull.net

Stick pack powder packing machine is another type of powder packing machine with proficiency in packaging multi type stick packs. It can be further categorized into single line or multi-line machine with the former packing single stick pack while later can pack multiple stick packs simultaneously. The structure of the machine is completely different due to the formation and packaging of stick packs. It can be used in food industries pharmaceutical industries, and nutraceutical industries for packing single serving powders.

Pillow Bag Powder Packing Machine

Pillow bag powder packing machine-Picture Courtesy: samfull.net

Pillow bag powder packing machine is the most flexible type of powder packing machine which can perfectly form and process several types of bags including pillow bag, gusseted bag, and flat bags etc. It is fully automated by nature, therefore, adopt instant changeover of parts to changing demand of the operator. Apart from that, the machine can be integrated with other machines to complete the production line including a powder feeding station, conveyor belt, and a cartoning machine.

Pre-made Doypack/Pouch Powder Packing Machine

Doypack powder packing machine-Picture Courtesy: samfull.net

This unique design machine is specialized in filling and sealing pre-made doypack and pouches with powders. The machine is designed with fully automated technology and fast changeover of parts for various sizes bags. The entire body is made up of stainless steel which ensures stable operation. In addition, with multi function capabilities, bag detection, pouch opening, powder filling, bag sucking, sealing, and data printing, the machine has exceptional features to fulfill all the needs of manufacturers in terms of packaging pre-made bags.

8.Highlight The Prominent Manufacturing Sectors Where A Powder Packing Machine Is Popularly Used?

The below description about vast applications of a powder packing machine will better enable you to know the areas with need for a powder packing machine:

Food Industry

Spices bottles-Picture Courtesy: ourhappyhive.com

Food industry is the area where you would find the need of a powder packing machine inevitable. It is due to excessive powders which are produced and packed in food industries such as flour, custard powder, chocolate powder, spices, and starches etc.

Pharmaceutical Industry

Medicated powder bag-Picture Courtesy: swisspac.com

Powder packing machine's efficient packaging has resulted in the convenient and fast packaging of various pharmaceutical powders from oral dosage of medicated powder to the powders used for external injury. For instance, most of the single serving powders are often medicated which are processed by pharmaceutical industry with the help of this machine.

Dairy Industry

Milk powder bags-Picture Courtesy: Behance

The reliance on preserved dry powders for kids, elders, and other uses, dairy industry is expanding day by day. It has resultantly grown a good demand for the powder packing machine to pack the dry powders into stick packs, gusseted bags and bottles etc.

Daily Chemical Industry

Detergent powder bag-Picture Courtesy: ebay.com

Daily chemical industry involves the processing of powders such as detergent powders. These powders require proper measuring and packaging which is carried out by a powder packing machine.

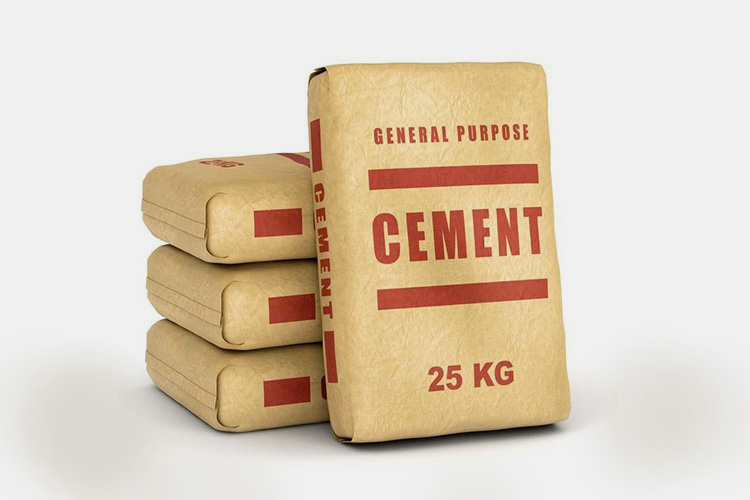

Cement Industry

Cement bags-Picture Courtesy: familyhandyman.com

Cement industry is the large scale industrial sector where powder packing machine is all time usable. With the help of this machine, the manufacturers are able to pack their cement powder into large bags.

Agricultural Industry

Garden soil bag-Picture Courtesy: lowes.com

Powders including pesticides, insecticides, herbicides, and agricultural fertilizers are often packed in small to large sacks for which a powder packing machine has been used for many years. It shows the adequate desire for a powder packing machine from agricultural sector.

9.Which Factors Are Essential For The Installation Of A Powder Packing Machine?

Technicians installing machine-Picture Courtesy: taitaja2022.fi

The proper installation of a powder packing machine is essential. Therefore, some of the crucial factors must be considered in this way including the following:

Mechanical Installation

Mechanical installation refers to the fixation of structural adjustment of powder packing machine. Under this, it is necessary to install the machine on even and flat area free of haphazard which may causes vibration. Moreover, the machine must be installed in a ventilated area with enough presence of air. These two factors will reduce the chances of machine vibration and pollution during process.

Electrical Installation

Electrical installation implies that a powder packing machine should be placed in an area where the machine can access sufficient power. In addition to that, all wiring of the machine must be accurately fixed as per user manual of the machine to avoid erroneous electrical connections which can lead to machine as well as product damage.

10.Explain The Cleaning And Maintenance Procedure Of A Powder Packing Machine?

In order to execute the powder packing machine for a longer time with smooth performance, it is necessary to keep the machine clean and have essential steps taken for its maintenance. In this way, the underlying facts will be helpful:

Machine installation Picture Courtesy: mangumsinc.com

Cleaning

Cleaning of the machine is obligatory on daily basis, as it assures the safety of your products. For this, few parts of machine including hopper, agitator blades, and other tools should be disassembled and washed away to remove out debris and dust remains from powders. These parts must be washed away, however, the HMI, sensors, and filling nozzles should be kept away from direct wash, instead they may be cleaned with a tidy moistened cloth.

Maintenance

Maintenance include the fixation of all external components as well as internal controlling features of the machine. It is important, to adjust the filling head's height, sealing station, powder volume, and sensors as per changing demand of the packaging.

11.Give Remedies To The Common Errors Caused By A Powder Packing Machine During Operation?

Similar to other machines, problems may arise when using a powder packing machine. To tackle these issues, the table below will provide enough remedies to cure them easily:

| No | Errors | Possible Causes | Remedies | Picture |

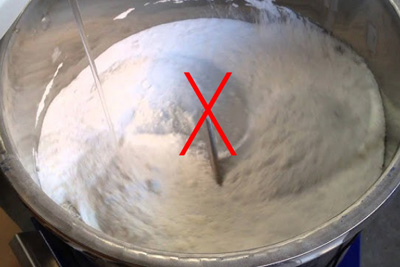

| 1 | Inadequate powder flow | Forcing too much fine or dense powders can cause poor flow of powders during operation | It can be fixed by using the powder of accurate consistency and removing out all barriers and blockages which may be inside the filling heads |

Inconsistent powder in hopper-Picture Courtesy: Youtube |

| 2 | Packs leakages | It often occurs when powder trap inside the sealing area due to dusty nature | Make sure the powder is less dusty and also adopt the use of a dust aspiration system for such powders to avoid packs leakage |

Leaked powder stick pack-Picture Courtesy: freepeople.com |

| 3 | Defective bag sealing | Excessive temperature, incorrect pressure, and polluted sealing bars may result in poor bag sealing | Solve the issue by adjusting the temperature and pressure of sealing bar, and also clean the dirty sealing bars |

Marked powder sachet-Picture Courtesy: nuzest-usa.com |

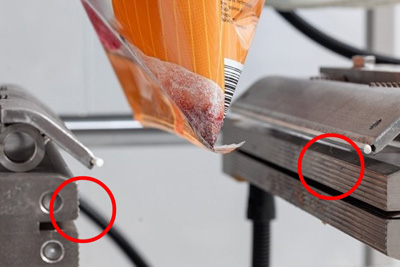

| 4 | Film is incorrectly tracking | Either the film carriage do not move freely or the roller is wrongly placed | Make sure the film carriage move freely by lubricating it, and also adjust the film roll position to parallel sides | Encircled film feeding roll-Picture Courtesy: sthengli.cn |

| 5 | Jamming of sealing jaws | Low air pressure and wrong time setting between bag filling and sealing can cause jaw jamming | It can be resolved by modifying the timing of filler and sealer as well as releasing adequate air pressure to sealing bars |

Encircled sealing jaws-Picture Courtesy: vikingmasek.com |

12.What Are The Helpful Tips For Choosing Right Powder Packing Machine?

Choosing the right powder packing machine fully depends upon your need of the machine, and to realize it you must have proper knowledge about your production as well as other aspects which are explained below:

Nature of the Powder

Starch & flour-Picture Courtesy: Pinterest

It is important to assess the nature of powder you are currently processing. For instance, whether is it free flowing or non-free flowing? If it is free flowing, then you will require a straight free flowing auger filler. However, in case the powder you process is non-free flowing, then you will have to purchase an auger filler for smooth and continuous powder packing.

Packaging Type

Various powder packaging designs-Picture Courtesy: worldbranddesign.com

Another significant tip for your convenience is to determine the type of packaging you want to proceed with. Whether you want to deliver your products in single serving packs or large bags with capacity up to 25 kg? Similarly, are your favor to either opt for forming your own packaging bags for powders or purchasing pre-made bags will contribute to select the machine which is best complying all your needs.

Safety Features

As you are going to pack your vary powder stuff, it becomes obligatory to check the integrated safety features of the machine. It includes the robust stainless steel construction, protective enclosure, and dust-proof enclosed jaw drive to ensure safe operation.

Quality Assurance

Quality assurance icon-Picture Courtesy: linkedin.com

It is important to satisfy yourself with adequate quality assurance given by the vendor, after all, you are spending your good amount of money on the machine. Hence, the quality certifications accredited to the company by international quality standards such as ISO, FDA and GMP, and the warranty policy of supplier can be checked for this purpose.

Conclusion

To put in a nutshell, powder packing machine is a vast terminology that encompasses in it range of machines for the effective and specialized packaging of powders. Its fast performance, adaptability to extensive packaging types, and broad classification helps you to pack any type of free flowing or non-free flowing powders into bags, bottles, and containers. Besides, Allpack's outstanding machinery for powder packing is a sound machine to purchase which is also having one year of warranty and installation support.. If you are concerned about purchasing it, feel free to approach us via given link!

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide