China Top Pharmaceutical Dryer Supplier

High Processing Efficiency

Good Drying and Mixing Effect

Superior Performance and Reliability

Pharmaceutical Dryer

Allpack pharmaceutical dryers are widely used in the pharmaceutical, chemical, food, cosmetics industries, and so on to deal with raw materials like powder, particles, granules, and pellets with good effects and high efficiency. Processing and handling the raw materials with mixing, drying, granulating, coating, and pelletizing, the pharmaceutical dryer can ensure the utmost product with good quality, purity, fluidity, and solubleness without contaminating the raw materials. These pharmaceutical dryers are suitable for dealing with raw materials that are unstable or thermal sensitive, containing strong irritative and toxic gases and the solvent needs to recover especially for thermosensitive material with original color, flavor, and chemical features.

The Buyer's Guide

Pharmaceutical Dryer: The Complete FAQ Guide In 2025

Drying of material is a significant step in pharmaceutical field to carry out manufacturing of tablets, pills, and capsules etc. In order to reduce the compromise on quality of ingredients while drying, the conventional ways of drying these substances are now fading away. Its role has been taken away by the advanced Pharmaceutical Dryer.

This sophisticated equipment is designed in such a way that the quality and essence of materials remain protected throughout drying phase. Not only this, but the machine offers user-friendly operation with robust structure and simple maintenance. You can choose between wide range of types while looking at your own needs. So, make sure to read each question explained below!

1.What Is A Pharmaceutical Dryer?

Allpack- LPG Series High-speed Centrifuge Atomizing Pharmaceutical Dryer

Pharmaceutical dryer is an advanced equipment used for the drying of powder, granules, and pellets in pharmaceutical field. The machine has an enclosed structure that provide aseptic environment for the removal of moisture content from particles.

Different methods are utilized for drying that vary according to type of machine being used such as air drying, spray drying, and vacuum drying etc. Similarly, the desired stability, strength, as well as size of particles is attained which helps in drug manufacturing especially solid dosage form including tablets and capsules.

2.Explain The Benefits Of A Pharmaceutical Dryer?

Pharmaceutical dryer offers potential benefits including improved product quality, easy handling, efficiency, and more. Let's know each in a bit detail!

Improved Product Quality

Scattered granules of capsule- Picture Courtesy: anishpharma.com

The gentle processing regulated inside pharmaceutical dryer helps in the formation of uniform particles. Consequently, the quality of end product is enhanced very easily.

Enhanced Safety

Another crucial advantage of the pharmaceutical dryer is its safety for retaining the properties of particles. For instance, the use of conductive dryer assist in eliminating dust explosion, while as, vacuum dryer is suitable for heat sensitive substances.

Increase Productivity

Various dry powders in scoops- Picture Courtesy: eminenceorganics.com

Manufacturers look for efficient solutions that can help them increase production. This is possible with pharmaceutical dryer which dry materials at relatively low energy consumption.

Small Footprint

Allpack- SZG Series Double Cone Rotary Vacuum Dryer

Manufacturing facilities often lack large space facility due to multiple machines. However, you will not face this problem with a pharmaceutical dryer which has precise body with simple construction covering less space and is easy to mobilize.

Highly Automated

The most prominent feature for which this machine is admired is its high level automation. This characteristic distinguishes it from manual equipment which requires lots of struggle but still end up with poor quality finished material. Thus, pharmaceutical dryer is adaptable to be further integrated with other machines.

3.What Is The Role Of A Pharmaceutical Dryer In Pharmaceutical Industry?

Pharmaceutical powder with tablets & capsules- Picture Courtesy: manufacturingchemist.com

Pharmaceutical dryer has a huge role in pharmaceutical industry which can be better understood by looking into the processing carried out here. As a matter of fact, the mixture of APIs with excipients and solvent often needs to be well dried, so, further granulation is possible which is easily done by this tool.

Similarly, the equipment is useful in helping pharmacists to conveniently grind material after thorough drying. These procedures are undertaken under strict quality control which is again highlighting another significance of a pharmaceutical dryer of being safe structurally.

Apart from this, consistency of particulates are paid heed in pharmaceutical industry for producing stable and effective drugs. In this way, the machine manage the weight and bulk density of compounds.

4.What Are The Working Principles Of A Pharmaceutical Dryer?

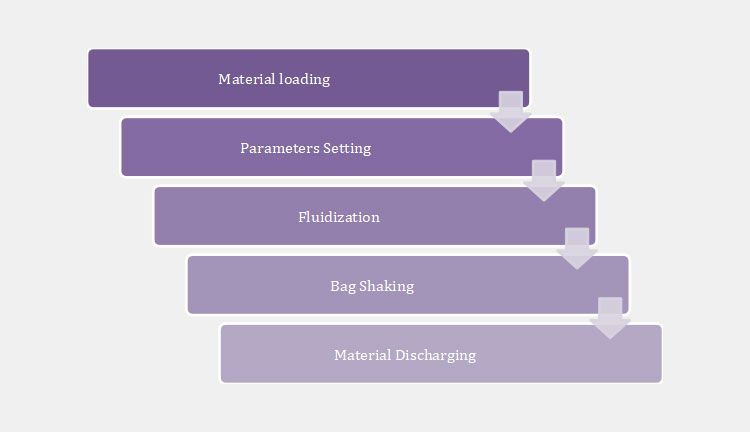

As far as the working principles of a pharmaceutical dryer is concerned, so, it follows easy operation which is based on few steps. Although, there are different types of pharmaceutical dryer, and each has little bit distinct way of operation which you will know in the upcoming question. Here, working principles of a fluid bed dryer will be discussed. These include:

Material Loading

Material loading- Picture Courtesy: SAMETO

Firstly, the bulk material is loaded into the bowl shaped hopper of fluid bed dryer which is located at the bottom. The clamps are tightly sealed to the main frame to avoid shaking of filled chamber.

Parameters Setting

Parameters setting on touch screen interface- Picture Courtesy: SAMETO

As soon as the material is loaded, operator is supposed to set the basic parameters of machine via control panel. This touch screen interface will provide multiple information about dryer such as the frequency of heat and flow of air etc. Similarly, after setting the parameters, machine will be ready to get started.

Fluidization

Fluidization- Picture Courtesy: SAMETO

Once the pharmaceutical dryer is powered on, the hot air is introduced inside the chamber through perforated bed. This phenomenon is known as fluidization. The continuous passing of hot air through material vessel led the particles to move in upward direction. Ultimately, each granule is effectively dried.

Bag Shaking

Bag shaking- Picture Courtesy: SAMETO

During fluidization phase, the excessive flow of air moves the particles towards upper side where they get trapped in the bags. So, when the process ends up, these bags are well shaked to get the trapped particles fall down in vessel.

Material Discharging

Material discharging- Picture Courtesy: SAMETO

Finally, the dried granules are collected in a vessel and discharged from the dryer.

5.Describe The Components Of A Pharmaceutical Dryer?

A pharmaceutical dryer consists of the following components:

Components of Allpack's GF Series High Efficiency Fluidized Bed Dryer

Air Outlet

It is situated on the top of pharmaceutical dryer from where processed air is exerted from the bed into open air.

Control Panel

Control panel consists of several knobs along with digital display. Together, these enable the user to set commands in machine and control it through fixing parameters.

Air Inlet

Air inlet is a rectangular station which is responsible for preparing air for material drying by taking air from outside and combining it with heat to create clean hot air.

Electric Cabinet

Electric cabinet is an enclosure that encases all the electrical connections including wires, fuses, and switches etc.

Bowl

It refers to the container seated in the bottom side of pharmaceutical dryer. It is used for loading the batch of material into drying chamber through which heated filtered air passes.

Universal Wheels

Pharmaceutical dryer also has various universal wheels attached to its body which helps in convenient mobilization.

Main Frame

It constitutes the parts which support the overall body of the machine.

Extension Chamber

It is also called expansion chamber which forms the central part of the dryer tower. It reduces the air velocity which exit the system which helps in lowering the material being lost with air.

Filter Housing Chamber

This unit is located above the extension chamber. Inside it, there are filter sacks or bags which prevent the particles from escaping with air by storing them.

6.What Are The Types Of A Pharmaceutical Dryer?

There is a long lasting list of pharmaceutical dryer available in market. Each machine offers special features in accordance with the demand for the nature of particles. Explanation of these types are given as under:

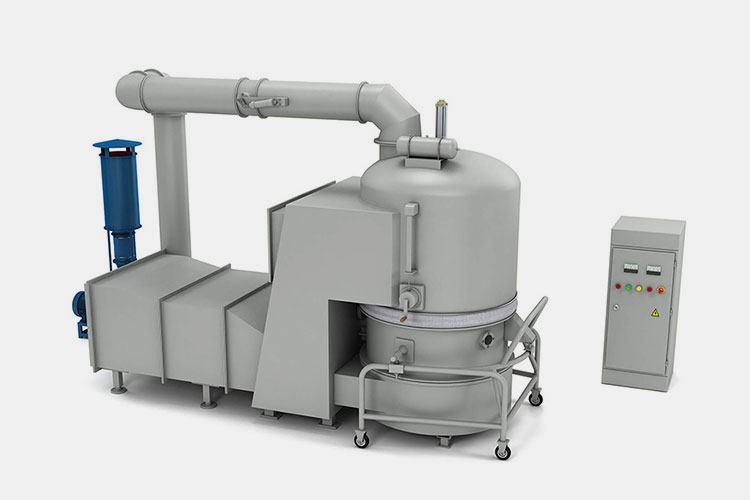

Fluid Bed Dryer

Allpack- FG Series Fluid Bed Dryer

Fluid bed dryer is the most popular type of pharmaceutical dryer with unique round design that lack dead corners for trapping particulates. It performs multiple functions of ingredients mixing, drying, and granulation. Similarly, it improves the structural integrity and solubility properties of molecules.

It has automatic system to carry out drying by using hot air for liquid evaporation. That's why, industries processing condiments, medicines, and fertilizers etc., use this machine.

Centrifuge Atomizing Pharmaceutical Dryer

Allpack- LPG Series High-speed Centrifuge Atomizing Pharmaceutical Dryer

This is another special category of a pharmaceutical dryer specifically designed to process emulsion, liquor, and suspending liquids. It has robust construction which is easily manageable.

It works by utilizing the core component of centrifugally tomizer which is located on top side. The liquid droplets are dried with the help of heated air. Consequently, final product is achieved in form uniform particles. It is best suitable for ceramics, glass, polymers, and dyes etc.

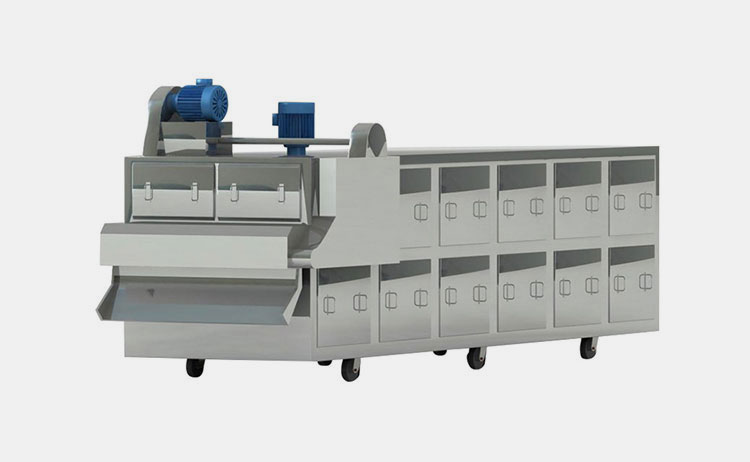

Mesh Belt Pharmaceutical Dryer

Allpack- DW Series Mesh-belt Pharmaceutical Dryer

Mesh belt pharmaceutical dryer is an innovative device designed in a distinctive manner with a wire net of mesh. It can be utilized by pouring the substances uniformly over mesh. As this equipment has multiple units for drying, hot air is circulated individually. Similarly, the hot air passing from either bottom or top side through the mesh tray which ultimately make the material get dry quickly.

This pharmaceutical dryer is highly adaptable and can be adjusted as per user demands. The major industries where it is applicable include food industry, electronic industry, and plastic industry etc.

Hot Air Circulating Pharmaceutical Dryer

Allpack- Model RXH Series Hot Air Circulating Pharmaceutical Dryer

As the name indicates, this type of pharmaceutical dryer is composed of a heavy-duty structure inside with proper ventilation system for drying various products. The internal oven is quite effective to get the substances dry instantly. You can select among wide variety of drying sources such as hot water, steam, or electricity etc.

It can be simply brought into operation by placing the material into trays section and letting the heat source on. The rest system is automatic for temperature control. It is useful for fresh food like fruits, vegetables, seafood and hardware drying.

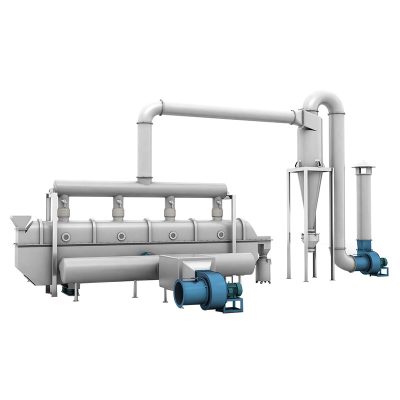

Boiling Pharmaceutical Dryer

Allpack- GFG Efficient Boiling Pharmaceutical Dryer

This pharmaceutical dryer is particularly designed for explosion protection. It has long standing structure with integrated systems for drying. It utilizes centrifugal blower along with cold air suction to carry out drying. By doing so, the undesired dusty molecules are eliminated.

Afterwards, the drying step is a final phase for drying substances like damp powder and granules.

7.What Are The Uses Of A Pharmaceutical Dryer?

Pharmaceutical dryer is widely applicable to several industries where processing of granules, pellets, and powder is routinely carried out. They are explained below:

Drug Manufacturing Industry

Tablets manufacturing- Picture Courtesy: stockcake.com

The importance of a pharmaceutical dryer is evident in drug manufacturing companies like pharmaceutical industry and nutraceucal industry where tablets, capsules, and other products are produced. As hygiene is given preference in this field, this machine is a good option to be utilized.

Botanical Industry

Various plants derived drugs- Picture Courtesy: naturalremedieshumanhealth.com

Plant-derived medicines like homeopathic and herbal medicines are also prevalent among people which also involves thorough drying. Thus, a pharmaceutical dryer can be used in this sector.

Beauty Care Industry

Various cosmetic products- Picture Courtesy: admitad.com

Glitters, eye shadow, compact powder and highlighters are among the common cosmetic products which we use for our beauty care. Similar to other products, they are also produced after thorough manufacturing which include a drying machine. Hence, a pharmaceutical dryer is applicable in beauty care industry.

Food Industry

Various spices- Picture Courtesy: kansaslivingmagazine.com

Drying is a crucial step in food production especially for small substances like pellets and granules. In this way, a pharmaceutical dryer may be used in pet food and prefabricated food industry.

Chemical Industry

Detergent powder- Picture Courtesy: okcredit.in

Pharmaceutical dryer is also used in chemical industry for enclosed drying of substances like chemical powder, dyes, and detergent powder etc., that may otherwise flow into air and cause pollution as well as product waste.

8.How To Maintain A Pharmaceutical Dryer?

Operator maintaining a pharmaceutical dryer- Picture Courtesy: zirbus.com

In order to make your pharmaceutical dryer function properly and smoothly for a long period of time, it is necessary to maintain it regularly. In this way, few can be helpful as such as:

Cleaning:Due to high sensitivity and hygiene purpose, pharmaceutical dryers must be cleaned on regular basis to avoid cross contamination and accumulation of dust.

Inspection:Keep inspecting the various parts and functions of the machine during operation and adjust the parts accordingly.

Parts Changeover:In case of parts damage or wear and tear, it is wise to timely replace it before their escalation into further issues.

Calibration:Make sure to calibrate the temperature and air-drying system periodically to validate the machine high performance.

9.What Quality Standards Should A Pharmaceutical Dryer Meet With?

Quality standards are key indicators to show the durability and quality of machine being produced. Therefore, certain platforms are established to create and regulate rules for assuring the quality of machines. These are as follows:

GMP icon- Picture Courtesy: eriks.com

International Organization for Standardization (ISO)

ISO represents broad standards for pharmaceutical dryer to enhance its quality, reduce errors, improve production efficiency and protect public health.

Good Manufacturing Practices (GMP)

GMP also aims at maintaining stringent check on the manufacturing of machines like pharmaceutical dryer. It particularly deals with the construction material of machines which must be stainless steel and corrosion resistant.

Food and Drugs Administration (FDA)

USA Food and Drugs Administration is an agency created to promote public health safety. Therefore, drugs and associated machine manufacturing are the main topics under their discussion.

Conformate European (CE)

CE is a collective mark for European Union countries. Thus, pharmaceutical dryer meant to either produced or sold their must be certified by it.

10.Factors To Consider When Buying A Pharmaceutical Dryer?

Never underestimate the importance of consideration in when buying a pharmaceutical dryer for your business. In this way, underlying factors are of key importance:

Dryer Specifications

Don't forget to look into the characteristics of a pharmaceutical dryer which you want to purchase. For this, you need to simply check its capacity, drying rate, as well as air distribution level. It is important because different machines have different specifications.

Regulatory Compliance

Regulatory compliance icon- Picture Courtesy: traceone.com

Quality is no exception in pharmaceutical industry and similar is the case when it comes to select a pharmaceutical dryer. So, make sure it is certified by globally recognized organizations such as GMP and ISO etc.

Production Output

Another thing you should pay heed to is to check whether you need a pharmaceutical dryer for lab scale or commercial scale production.

Budget

Budget presentation idea- Picture Courtesy: moneywise.com

Budget is a must have factor that must be necessarily considered. Keeping in view your financial condition, you may opt for a new or used machine.

Conclusion

To put in a nutshell, Pharmaceutical Dryer is of paramount importance which is growing day by day in fields like pharmacy, food, and chemical manufacturing. In such a scenario, it is crucial to have adequate knowledge regarding its working, structure, types and benefits etc. Apart from this, always try to make a vigilant choice by considering the above-mentioned factors. Besides that, if you are interested in purchasing a sophisticated pharmaceutical dryer, then Allpack has an extensive line with one year of warranty. So, don't miss the opportunity. For further information contact us!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp:+86 18171018586