Your Premier Labeling Machine

- Pneumatic Labeling Work

- Photoelectric Detection Function

- Servo Control Conveying

Labeling Machines

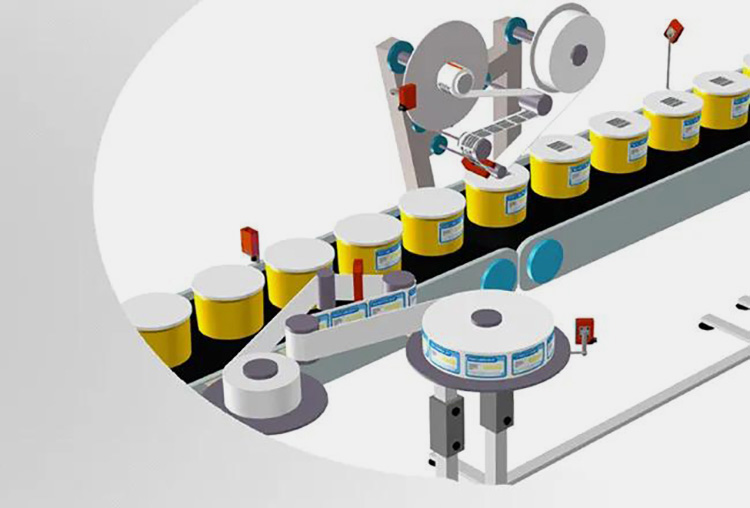

Allpack labeling machines are applicable to circumferential labeling of various cylindrical products. Such as cosmetic bottles, shampoo bottles, shower gel bottles, medicine bottles, jam bottles, essential oil bottles, sauce bottles, wine bottles, mineral water bottles, beverage bottles, glue bottles, etc. For different sizes of square, flat, tapered, cylindrical, and other bottle shapes, they can complete single-sided and double-sided labeling of products. All Allpack labeling machines have powerful function,you can get all kinds of manual,semi-auto,full automatic labeling machines to meet your actual production requirements.They can achieve circumferential position labeling and non-position labeling easily by switch control. This labeling machine is easy to use and adjust. The new workers can use or adjust it easily after simple training.

Labeling Machines

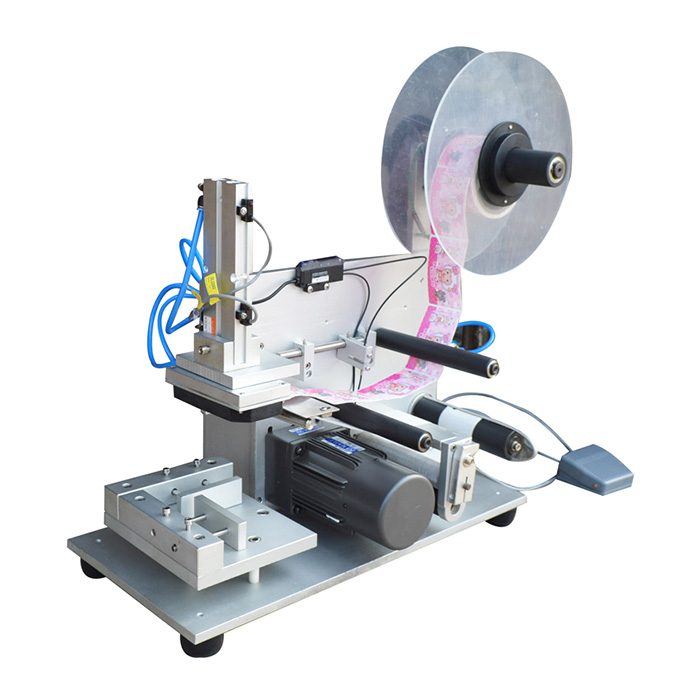

HD-103 Manual Hand Operated Labeling Machine For Adhesive Sticker Round Bottle

HD-103 manual hand-operated labeling machines for adhesive sticker round bottles are manually designed for your work. They are specially designed for round PET bottles, vials, water bottles, plastic bottles, glass bottles, and metal bottles. The adhesive sticker labeling machines are widely used for food, beverage, rice and oil, medicine, daily, and chemical industries. With pneumatic labeling work, it can improve the labeling speed and label effectivity. There is no need for electricity and it can work only by hand. With a working efficiency of 20 to 25 pcs per minute, this hand labeling machine can control the labeling accuracy within ±0.5mm.

Light Machine Weight

Pneumatic Labeling Work

Adhesive Sticker For Round Bottles

MT50 Self-Adhesive Round Bottle Labeling Machine With High Production Efficiency

MT50 self-adhesive round bottle labeling machines use self-adhesive roller labeling papers. The self-adhesive labeling machine has the characteristics of cleanness, no mold, beautiful appearance, firmness, no falling off after labeling, and high production efficiency. MT50 self-adhesive round bottle labeling machines are suitable for a wide range of applications.

Card Adjustment

Synchronous Belt Traction

Self-adhesive Roller Labeling Papers

MT-50 Semi-automatic Round Plastic PET Bottle Sticker Labeling Machine

MT-50 semi-automatic round plastic PET bottle sticker labeling machine is suitable for self-adhesive labels or self-adhesive films of different sizes on various round bottles, high-precision, high-speed, automatic dispensing, and labeling. The ingenious design allows you to mechanically adjust some structural combinations and label winding, and you can easily and freely adjust the label position. All of this makes it easy to change products and labels. The conveyor parts are fully enclosed to avoid abnormal conditions and make them safer to use.

Sensor Control Or Step Control

Automatic And Semi-automatic Control

Structural Combinations And Label Winding

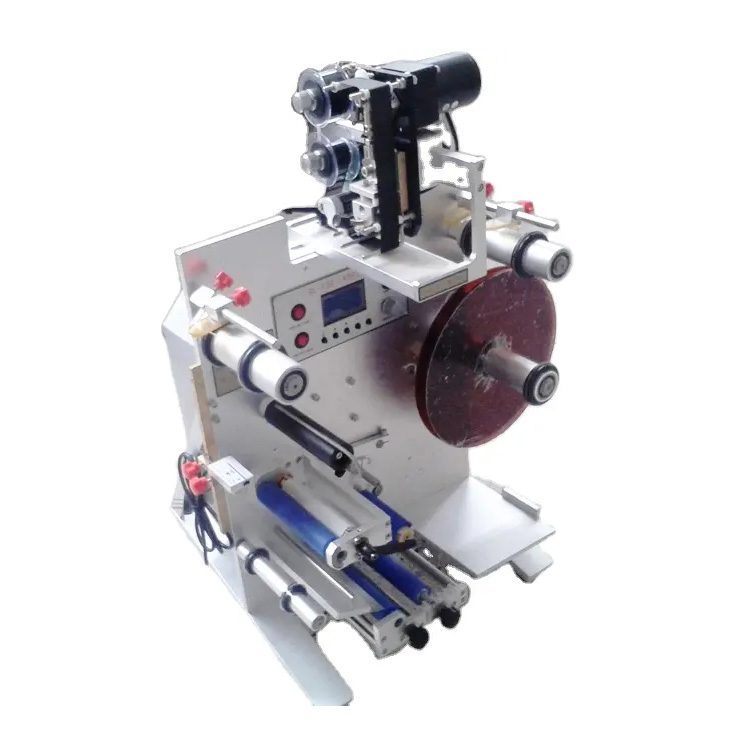

MT-50D Semi-automatic Plastic Round Bottle Labeling Machine With Coder

MT-50D semi-automatic plastic round bottle labeling machine with coder is an ideal equipment for semi-automatic labeling of round bottles on the packaging of daily chemicals, food and beverage, medicine, chemical, and other light industrial products. This machine is suitable for the production of round bottles of various specifications and small batches of multiple varieties. It can only be used for stand-alone labeling.

Hot Stamp Ribbon

Semi-automatic Labeling

Convenient Maintenance

MT-60 Semi-automatic Square Rectangle Flat Bottle Labeling Machine With Pedal Switch

MT-60 semi-automatic square rectangle flat bottle labeling machine with the pedal switch is suitable for self-adhesive labels, self-adhesive films or electronic barcodes, etc. labeling and is widely used in cosmetics, toys, electronics, medicine, and other fields. This semi-automatic labeling machine applies the suction method to stick the label on various square workpieces, such as cosmetic flat bottles, packaging boxes, plastic covers, etc. The labeling device can be replaced on uneven surfaces such as concave and curved surfaces.

Convenient Maintenance

Used On Any Regular Or Irregular Surface

High Precision And Good Working Performance

LT-80 New Type Semi-automatic Adhesive Film Round Bottle Labeling Machine

LT-80 new type semi-automatic adhesive film round bottle labeling machine is suitable for self-adhesive labels or self-adhesive films of different sizes on various round bottles, high-precision, high-speed, automatic dispensing, and labeling. It is mainly applied in round bottles, round cans, PET bottles, plastic bottles, glass bottles, metal bottles, etc. With good labeling accuracy and stability, this machine can offer you high-quality labels without wrinkles and bubbles. With powerful functions, circumferential positional and non-positional labeling can be easily achieved.

High-speed

High-precision

Labeling Accuracy And Stability

YT-30100 Semi-automatic Irregular Plane Round Bottle Sleeve Labeling Machine

YT-30100 semi-automatic irregular plane round bottle sleeve labeling machine is suitable for irregular bottle sleeve labeling. It can be used for labeling various workpiece planes, arc surfaces, and concave surfaces, and can be used for labeling irregular workpieces. This plane labeling machine applies a PLC control system and subdivision stepping motor to drive and send labels. The feeding mechanism is equipped with a brake function to ensure that the label tape is tensioned and the label detection is accurate.

Bottles Sleeve Labeling

Sturdy And Durable Structure

Used For Labeling Irregular Workpieces

YT-31200 Semi-automatic Round Bottle Square Bottle Sticker Labeling Machine

YT-31200 semi-automatic round bottle square bottle sticker labeling machine adopts high-precision labeling technology, that the labeling accuracy can reach within ±0.5mm and meets the requirements of high-precision labeling. This labeling machine supports taper labeling and circular labeling. The operation is simple and convenient. All the peeling, feeding, labeling, and labeling can be completed automatically. The labeling process can be completed by manual loading and unloading. The operation is safe. The transmission parts are wrapped, and the circuit and gas circuit is arranged separately to avoid abnormal occurrences that make it safer to use.

Manual Loading And Unloading

High-precision Labeling Technology

Supports Taper Labeling And Circular Labeling

YT-41300 Semi-automatic Desktop Plastic Bottle Labeling Machine For Self-adhesive Label

YT-41300 semi-automatic desktop plastic bottle labeling machine for the self-adhesive label has the function of single sticking and double sticking, which can be switched on the touch screen. It can be used for labeling cylindrical objects of various specifications, such as xylitol and cosmetic round bottles. The desktop labeling machine can print the production batch number and other information on the label. This machine can be widely applied in food, medicine, daily chemical, electronics, hardware, plastic, and other industries.

For Self-adhesive Label

Print Production Batch Number

Be Switched And Positioned Arbitrarily

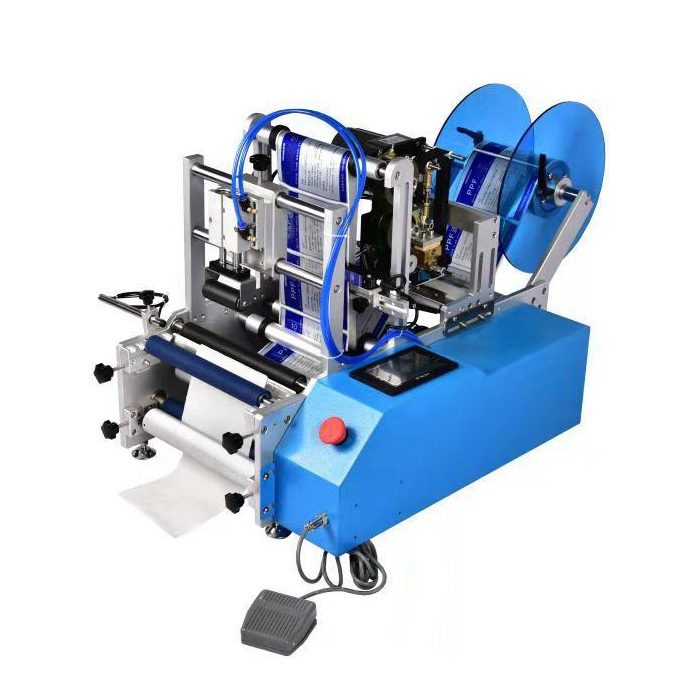

SL-130 Semi-Automatic High Efficiency Labelling Machine Double Labeller For 2 Labels With Printer

SL-130 semi-automatic labeling machine double labeler for 2 labels with the printer is suitable for labeling round bottles of various sizes, such as glass bottles, plastic bottles, metal bottles, shampoo bottles, small conical bottles, round cosmetic bottles, etc. It is especially suitable for labeling and coding products with small quantities and many varieties. It is an ideal equipment for semi-automatic labeling of round bottles on the packaging of daily chemical, food and beverage, pharmaceutical, chemical, and other light industrial products.

PLC Control System

Reliable Performance

Sensor Electronic Control System

Table Type Round Bottle Labeling Machine For Various Cylindrical Objects

The table-type round bottle labeling machine has many advantages, including a small footprint and a lightweight design, making it ideal for use in tight spaces. It is suitable for labeling various cylindrical objects and vertical round bottles and suitable for small batch labeling production. This table-type labeling machine adopts PLC control for automatic processing, which makes the labeling speed fast, saves you a lot of time, and improves your work efficiency.

Emergency Safety Off Button

Table-type Round Bottle Labeling

PLC Control For Automatic Processing

The Buyer's Guide

Labeling Machine: The Complete Buying Guide In 2025

Every product in the market is not free from labels for that purpose each company uses a labeling machine to display a lot of its information for consumers including, its name, price of the product, batch information, barcodes, stock information, and other important related information too.

Labeling machines in the market are available in different designs and shapes according to their purpose, among them, some are fully automatic and others are semi-automatic labeling machines. Before going into more details individually let us discuss some points these relate to:

1. What Is A Labeling Machine?

A labeling machine is equipment used to label a variety of products, boxes, items, bottles, packages, etc. This machine is also referred to as an industrial labeling machine and is used to apply a label, brand, and decoration on the products such as containers, packed materials, boxes, or others. Different industries use labeling machines to show details of the products on the box or the in the packed materials, these include batch details, price information, barcodes, stock details, etc.

2. Why Do Manufacturers Have Demands For Labeling Machines?

As mentioned that labeling machines are used in many kinds of industries, but why it has such a large range of applications? why do manufacturers need to use labeling machines? In other words, what are the purposes of labeling machines?

Brand Promotion

Manufacturers print their brand names on labels, and add these labels to their products, in the supermarket, products of different brands have different labels, when people choose these products, they can have an image of the brand of the products. Through labeling, manufacturers can get the effect of brand promotion, and enlarge their brand popularity.

Give Customers Useful Information

And stand at the customer level, the labels provided by producers can give them some useful information about the products such as usage instructions, date of manufacture, and other information. This information can help customers to choose the right products, which also helps the manufacturers to a certain degree.

Draw Attention

Some manufacturers will design labels that accord with people’s aesthetics, and add beautiful patterns or other designs to the labels, the products with unique beautiful labels will attract more attention than those without labels.

Help Distinguish

The manufacturers will produce thousands of products every day, these products belong to different batches and can easily be confused during the warehousing process. Sticking labels to these products means that give them specific identities, to help workers distinguish them.

3. What Are The Advantages Of Labeling Machines?

The reason why labeling machines are widely used in many filed, on the one hand, it can help manufacturers in their business, on the other hand, it is because labeling machine has many advantages which are as follows:

Versatility

Once a product need to be sold in supermarkets, shopping malls, and stores, it needs to be labeled, a store sells products that come from all kinds of industries, in other words, there are many industries that need to use labeling machines, so this machine is versatile.

High Efficiency

Automatic labeling machines and semi-automatic labeling machines can label bottles or other products automatically, the speed is much faster than manual labeling. If you use a labeling machine, the production efficiency will be largely improved.

Cost Effective

In general, the price of a labeling machine will not be high, but this machine will provide you with high production capacity. In terms of cost performance, the labeling machine is an ideal device for you to label products.

User Friendly

The operation of a labeling machine is quite easy, no matter if it is an automatic one or a semi-automatic one. The automatic labeling machine has a high degree of automation, it doesn’t need too much manual intervention, the semi-automatic labeling machine is easy to use, so, they are all user-friendly.

Durable

The labeling machine is made of high-quality law materials, and it has good performance, if you maintain your labeling machine regularly, it can have a very long service life. Therefore, actually, the labeling machines are quite durable.

4. What Are The Applications Of Labeling Machines?

The labeling machine has numerous applications in many industries, these include,

- The labeling machine can be used in different industries such as Pharma Syrup, Edible Oil, Dry Syrup, Honey, Hair Oil, Lubricant Oil, Shampoo, Fruit Juice, Cosmetics, Drink Juice, Phenol, Talcum Powder, Ayurveda Powder, and many other related industries.

- It uses to label printing on electrical components, Stationary, Adhesive, Dental Products, Adhesives, Petroleum Jelly, Hair Straightener, Cosmetic Lotions, and others.

- It can also be used for 3inting on the products, or items.

Based on the types of labeling machines, it has different applications, such as,

| Types of Labeling Machine | Application | |

| Semi-automatic labeling machine | It has application in industries that uses small-scale products, such as apply to label round bottles and vials, etc |  |

| Fully-automatic labeling machine | It has been applied for labeling plane, oval, or square-shaped goods backside labeling. |  |

| High-speed labeling machine | It is used to apply a label on vials, and containers of other vertical-type products at high speed. |  |

| Vial labeling machine | It uses to apply labels on the round-shaped small-size container and test tubes. |  |

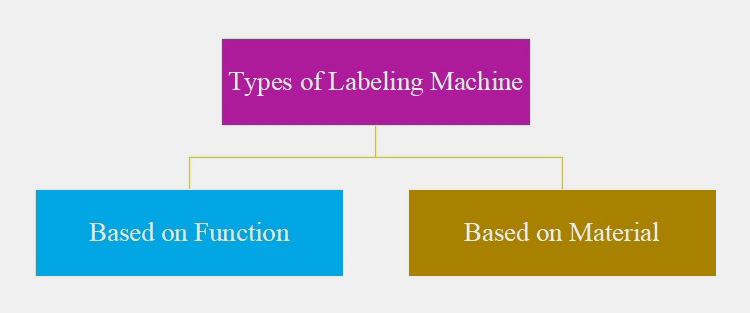

5. How Many Types Of Labeling Machines Are Available?

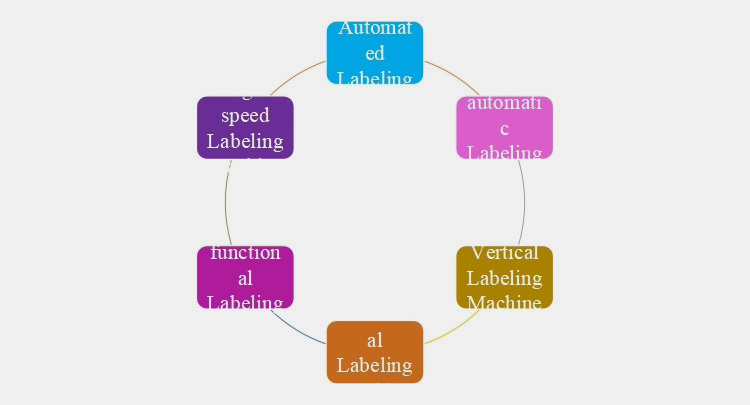

Labeling machines have different types, based on their function it is categorized as;

A) Based on function

Fully Automatic Labeling Machine

It is used for partial and complete labeling and mainly for high-capacity products. It has a conveyor for the adjustment of the labeling of the product. It can be useful for labeling bulk packaging materials and it is more accurate than others.

Semi-Automatic Labeling Machine

This is for labeling square and cylindrical type products, also useful for low mechanical resistance materials such as plastic bottles. It can also be incorporated with a hi-tech container system, fiber optic label, and stepper motor drive.

Vertical Labeling Machine

This type of labeling machine depends on the size of the materials used, it can label 150 containers within minutes and is also considered user-friendly. The surface materials can easily be labeled due to the vertical labeling machines.

Horizontal Labeling Machine

It is considered the ideal machine for labeling unstable items, it can be used for partial and full labeling. It can be applied to label more than 100 products within minutes and it is also user-friendly with a fully-automatic labeling system.

Multi-Functional Labeling Machine

It can be used for multiple shapes and sizes of products, so it is best for labeling the bottles and can be handled a variety of shapes with high accuracy. It is a more stable labeling machine than the others.

High-Speed Labeling Machine

It is a fully-automatic labeling machine and is also called a high-capacity labeling machine. It is considered highly flexible and good efficient. It can be applied to label more than 1000 products within a minute. It is considered more accurate than others, meanwhile, it is a faster labeling machine than others.

B)Based on the material

The other types of labeling machine are based on the materials used for labeling, these include:

Wet Glue Labeling Machine

It uses liquid glue at room temperature for labeling. These machines are applied to label rigid container and bottles which includes beers and spirit bottles.

Hot Melt Glue Labeling Machine

It uses adhesive materials (solid materials) for labeling. It is also a variant of a wet glue labeling machine.

Pre-Gummed Labeling Machine

This machine is very rare and it uses gum that passed through water sprayed to make adhesive material.

Pressure-Sensitive Self-Adhesive Labeling Machine

This type of machine does not require water to make adhesive materials whereas it uses pre-glued labels.

Heat Seal Labeling Machine

It uses heat seal materials with pressure-sensitive labels.

Print And Apply Label Printing Machine

It applied labels with print information such as the production date, batch number, shipment data, price, weight, etc.

6. Automatic Labeling Machine VS Semi Automatic Labeling Machine

In general,the most common labeling machines are fully automatic labeling machine and semi-automatic labeling machine,perhaps you are confused about the difference of these two types of labeling machine,next let’s explore together.

| Automatic Labeling Machine | Semi-auto Labeling Machine | |

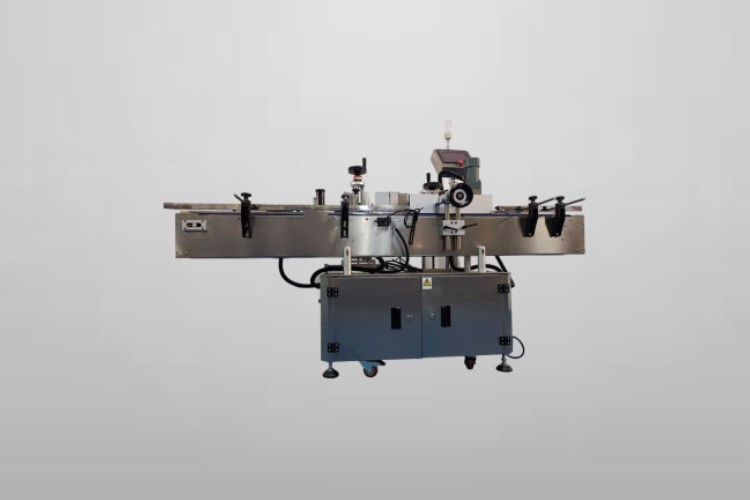

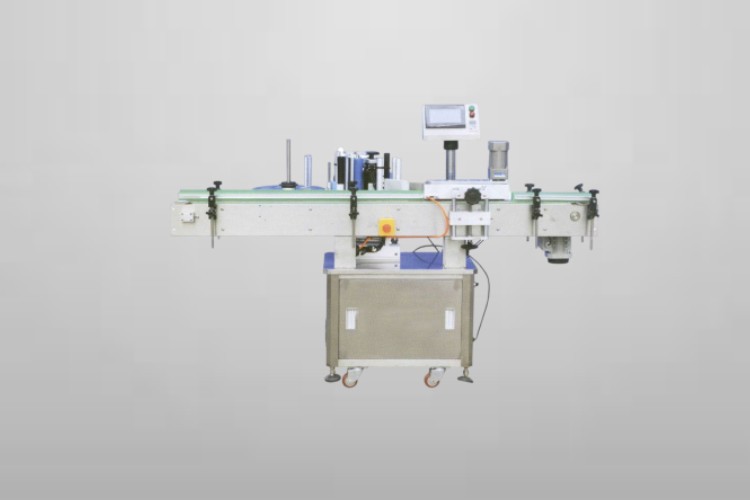

| Appearance |  |

|

| Production Capacity | The automatic labeling machine can work at a high speed, so it has high production capacity comparatively | Comparatively, the speed of a semi-automatic labeling machine is slower than that of an automatic labeling machine, so its production capacity is relevantly lower |

| Working Process | The working process of automatic labeling machine is fully automatic, the machine feeds bottles and labels by itself, doesn’t need manual intervention. | Semi-automatic labeling machine, as the name shows,in its working process, it need the operator to feed bottles and arrange the labels |

| Size | The structure of the automatic labeling machine is a little complex and this machine is larger than the semi-automatic one | The semi-automatic labeling machine is designed compact,it is small, can be put on the desktop |

| Packaging Application | The automatic labeling machine is suitable for labeling various products which have different shaped and surface, it is not just limit in round bottles generally | Generally speaking, the semi-automatic labeling machine is usually used to label round bottles or other small bottles. |

| Production Scale | The automatic labeling machine can label a large number of bottles in a short time and can perfectly meet manufacturers’ demands, it is more suitable for medium to large-scale production | Since the labeling process of a semi-automatic labeling machine is manually operated, this machine is more suitable for small-scale production requirements. |

7. What Kinds Of Labeling Could Be Possible From The Labeling Machine?

The labeling on the cartons, bottles, boxes, and containers, is of different types. The types of labeling that are possible due to the labeling machine include a primary label, barcode, hologram labels, price labels, address labels, security labels, and labels related to product information which would be helpful to identify the products easily.

| Primary Labeling: The primary label is printed on the front or top of the product, it contains important information related to the product. |

| Barcode Labeling: Barcode labeling is the main component of the product management and tracking system. It uses a thermal printer that generates labels with barcodes including graphics, text, and logos. |

| Hologram Labeling: It is the most common type of label for brand promotion, from which the product can be easily identified. It also shows the price of the product and the address for delivering and shipping the product easily. |

| Security Label: It uses to define safety-related information on the products at the top front and back of the container. It is useful for easily tracking security information related to the product which helps to prevent any risk. |

| Product Information Label: The information about the product includes its name, logos, unit measurement, and description of the items also. It can be a label on a container, jar or bottle, etc. |

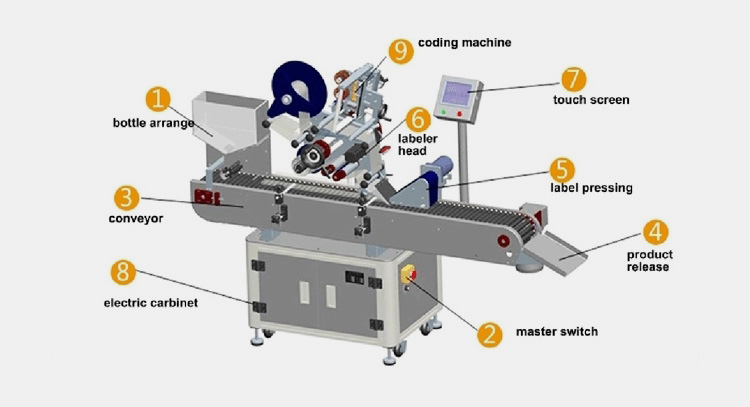

8. How Many Parts Of The Labeling Machine Are There?

The labeling machine has different parts for specific functions, these parts include;

| PARTS OF MACHINE | FUNCTION |

| Feeding Hopper | Feeding hopper plays a vital role during labeling and increases the accuracy of the labeling of the products. It feeds the ampoules for labeling to a machine. |

| Date printing setting | It is used for printing manufacturer’s dates, expiry dates, batch numbers, barcodes, and many others. |

| Labeling Station | It has two main components that are head and a labeling pad. If printing on a container is not possible due to some reason, so this part could be considered an ideal solution. |

| Touch screen control panel | The latest labeling equipment is more accurate than the others, among accuracy it also has the latest technique system, that the touch screen control panel. |

| Drive mechanism | It is further categorized into three elements, which include motor, conveyor, and roller system respectively. The motor act as the heart of the system, the conveyor used for the movement of the container for labeling, and the roller are the which connects the motor to the conveyor. |

| Plate for putting a label | It is also an important part of the labeling machine, in which the label is adjusted to print the label. Labeling machine uses different types of plates for printing it depends on the type of machine used to print the bottle. |

| Discharge mechanism | During printing, some other portion of the container becomes printed, which can be easily removed by the discharge mechanism. |

| Automated system | It uses a program stored in software, and it is fully automated, to perform it requires complete knowledge of each part of the labeling machine. It is mostly in the touch-screen panel. |

| Rejection unit | It is not possible to detect an error during labeling, in fact, more difficult to analyze the error in high-speed labeling machines. So, the rejection unit is best for all types of labeling machines to detect error and eliminate it. It is based on an automatic system. |

| Safety system | The safety button in the labeling machine is placed to ensure safety-related issues. It is the most important part of the labeling machine which prevents incidents. |

9. What Is The Working Principle Of A Labeling Machine?

All the parts in the labeling machine play an important role during the printing of the items, containers, bottles, etc.

The working principle of the labeling machine starts from the feeding hopper. Initially, the item is placed and moved due to the conveyor belt and the labeling becomes begins. Then the container starts to move due to scrolling materials to adjust its right position. After labeling the container, the container easily removes from the machine for that monitoring of the sensor is available on the labeling machine.

10. How To Operate A Labeling Machine?

After knowing the working principle of labeling machines and how the machine work, another thing you need to learn is how to operate the machine.

- Check whether the machine is clean, if there is dust, you need to swipe it with a cloth, and then turn on the power supply, and let the machine run to check whether the components can normally work.

- If the machine doesn’t have any problem, the next step is to set up parameters such as labeling speed, labeling position, distances, etc.

- If your machine is a fully automatic labeling machine, you need to put bottles on the conveyor line, then the machine will deliver them to be labeled. But if your machine is a semi-automatic labeling machine, you need to put bottles on the labeling position manually, then press the labeling handle, when the handle moves, the labels will move together, then the labeling of a bottle is completed.

- When the labeling process is finished, you need to turn off the power supply of the machine, take away the unqualified bottles and clean up the body and grooves of the machine to make it more convenient to use the next time.

11. How To Maintain A Labeling Machine?

Whether a machine can have a long service time, depends on good maintenance, in this part, you will learn how to maintain your labeling machine, which can help you reduce some troubles.

- The labeling machines are equipped with rollers, you need to clean them regularly to ensure the good performance of machines.

- Clean the sensors of labeling machines regularly, and when you do this operation, remember to be careful, do not use force.

- When you need to clean the labeling machine, just use a cloth to wipe the outside, don’t let the machine touch water.

- Replace the components of the machine regularly to maintain the life of the machine.

- There are some components of the labeling machine that are easy to be worn, you need to lubricate them regularly.

- Do not use the machine for a long time, you need to let the labeling machine rest after a period of time working.

12. How To Troubleshoot Labeling Machines?

Sometimes, even if you have maintained the machine regularly, it still occurs problems, when this situation occurs, how to resolve the problems, please read the next text.

Incorrect Label Position

Check the peeling plate and holder, to check whether they are paralleled, if not, the position is wrong, you need to adjust the position to let them be paralleled.

The Label Is Creased

The reason for this situation is that the speed of labeling is too quick that the product can not keep up with such a speed, you just need to adjust the parameter of the machine, to slow down its labeling speed.

The Roller Is Not Smooth

If the roller isn’t smooth, the most possible reason is that there is dust on it, you need to clean the roller.

Label the Attaches Drive Shaft

Maybe the glue of labels is too thin or too much so that it will flow on the drive shaft, you can adjust the distance between the rubber block and the rubberizing wheel.

13. What Factors Should You Keep In Mind While Buying A Labeling Machine?

When you have a need to buy a labeling machine, there are some factors you need to consider, if you make them clear, it will be helpful for you to choose a good machine.

Model Of Labeling Machine

There are many types of labeling machines on the market, perhaps it is dazzling for fledglings, but don’t worry, it is quite easy. You need to consider the products you want to label, the surface of these products, and the production scale. Considering these factors can help you choose the right type of labeling machine.

Reliable Manufacturer

When you determine to buy which type of labeling machine, the next thing you need to consider is which manufacturer is better. There are many manufacturers that produce labeling machines, but not each of them will provide you with high-quality machines. Try to choose these manufacturers which have good reputations and customer feedback.

Affordable Budget

Besides the type of machine and manufacturer of the machine, the most essential factor is your budget, and how much money can you invest in labeling machines. If you have an abundant budget and you need to label a large number of products, you can choose a fully automatic labeling machine or high-speed labeling machine.

On the contrary, if you don’t have enough money, and just use a labeling machine to label a small number of products, you can choose a semi-automatic labeling machine or a tabletop labeling machine.

Working Space

And you also need to consider the space of your workshop, and where will you use a labeling machine, if you have a large-sized workshop, you can choose a fully automatic labeling machine, multifunctional labeling machine, high-speed labeling machine, and so on; nut if your workshop is quite small or you plan to use the machine on a table, you can choose semi-automatic labeling machine or a manual one.

Conclusion

Whenever you see any product in the market, the labels on the products make it more attractive. Moreover, the label on the items shows important information related to price, date, batch number, stock information, barcode, safety, and other security-related information. Allpack is the best company that provides reliable equipment. For any queries Or product Information Please Contact Us Right now!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp:+86 18171018586

Tell us your material or budget, we'll reply to you ASAP within 24 hours

Tell us your material or budget, we'll reply to you ASAP within 24 hours