Chewing Gum Packaging: The Complete FAQ Guide In 2025

Don't you love playing blow and burst with your chewing gum? Of course you will! After all, it is one of the compelling reasons for people to chew gum unstoppably. But is it enough for picking your favorite chewing gum? Definitely not! There is another major factor which is actually responsible for inducing consumers to move ahead and pick the bubble pack which has touched their eyes and hearts.

This magnetic quality will be surely dedicated to the chewing gum packaging, which in true sense holds the benefits which must be praised. From securing chewing gum against quality degradation to maintaining its integrity, beautification, and texture, chewing gum packaging will provide you multitude of options to rejuvenate your production and get profited swiftly. So, let's uncover the diverse advantages of chewing gum packaging, its variations, and machines required for it!

1.What Is Chewing Gum?

Colorful chewing gum-Picture Courtesy: blushandpearls.com

Chewing gum also known as bubble gum is soft, adhesive food product used for chewing. It is often well flavored with sweet or sour taste to give refreshing feel. Bubble gum has been chewed by most of the people for multiple benefits such as protection of oral health, reducing tension, and sharpening memory etc.

Apart from that, chewing gum may be found in various shapes, sizes, colors, and flavors which greatly appeals to the eyes of kids, adults and even aged people. Hence, chewing gum is considered delicious confectionary along with other sweets like candy, gummy, and chocolate etc.

2.What Is Meant By Chewing Gum Packaging?

Different chewing gum packages-Picture Courtesy: linousha

Chewing gum packaging refers to the wrapping or covering of chewing gum into different types of packaging bags, containers, and boxes etc. These chewing gum packaging options are opted for the purpose of safe and convenient transportation of chewing gum on one side while advertising the brand and products of manufacturing industries on the other.

Moreover, it greatly assist in preserving the hygiene, aroma, and texture of chewing gum against moisture and pollution which ultimately extend its shelf life. Therefore, diverse means of packaging have been employed by designers to mold the fate of industries through effective chewing gum packaging. These all will be explained in the upcoming questions in detail.

3.What Are The Advantages Of Chewing Gum Packaging?

Chewing gum packaging holds with it extensive benefits both for your product as well as business. Some of the crucial advantages of chewing gum packaging are as follows:

Product Safety

Strawberry chewing gum packaging idea-Picture Courtesy: Behance

No doubt, the foremost benefit of chewing gum packaging is the product safety which is given to it in the form of durable layer around it. For instance, the packaging bags, boxes, and bottles etc., are highly compact to keep the chewing gum intact till opened by consumers.

Brand Promotion

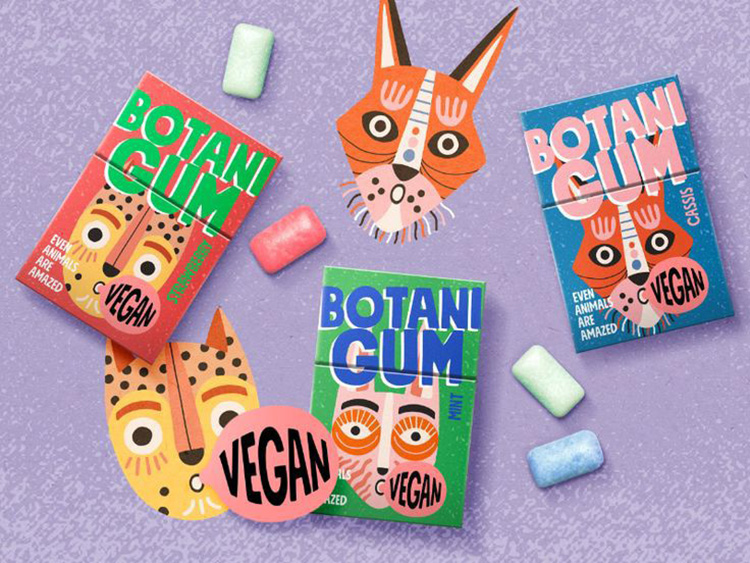

Plant based chewing gum packaging design-Picture Courtesy: packagingoftheworld.com

By using unique design packaging for your chewing gum will help you in uplifting your brand. In addition, the eye-catching labeling on your packages will automatically grab the attention of gum lovers to pick your gum packs and search for the same brand products in future.

Increase Shelf Life

Various powder gum jerrycans-Picture Courtesy: orientaltrading.com

Another advantage of packaging chewing gum is the extension of shelf life which you get. It is simply done because packaging is the assurity for your chewing gum to stay valid for a longer period of time.

Customer Satisfaction

Consumer holding chewing gum container-Picture Courtesy: checksgum.com

Although, people do like chewing gum, but when it comes to health care, they become much concerned about each product they consume. Here, comes the need for effective packaging to satisfy customer that your chewing gum is fully safe, hygienic, and free from hazardous substances which will be definitely done by displaying the ingredients through packaging.

Convenient Usage

Easy to use tape chewing gum-Picture Courtesy: insider.com

It has been found in human nature that convenience is the most attractive factor for people to go for. Same is the case with food products and so chewing gum. It implies, that chewing gum packaging, resealable bags, bottles, cans, and boxes, enable consumers to easily handle chewing gum wherever they are.

4.Describe The Popular Forms Of Chewing Gum Delivered In Chewing Gum Packaging?

Chewing gum can be divided into several different forms on various basis. Among them the popular ones are as follows:

On the Basis of Nature

| No | Names | Description | Picture |

| 1 | Solid | Solid chewing gum is the common type of chewing gum we chew in our daily routine. However, it is stretchable and have the same elasticity as other types of chewing gum which makes it favorable to form new shape. Solid gums are mostly coated with oil, starch, or glucose to give them shiny look and avoid sticking after packaging. |

Colorful hard chewing gum-Picture Courtesy: Party ideas |

| 2 | Powder | Chewing gum is also available in the form of powder. It is an enjoyable way to turn your powdered chewing gum into a liquid stretchable gum with the help of saliva. |

Powder chewing gum jerrycan-Picture Courtesy: oldtimecandy.com |

On the Basis of Shape

| No | Name | Description | Picture |

| 1 | Tape Chewing Gum | Tape chewing gum has tape like appearance due to its roll shape. It is delivered in a plastic object with having a thin opening through which gum is gradually released by pulling. |

Tape chewing gum packaging-Picture Courtesy: popsugar.com |

| 2 | Flat Chewing Gum | Flat chewing gum is the all time favorite gum of all age people because of its easy accessibility and wide range flavors availability. These chewing gum are made by separate machines to give them precise shape. |

Multi colored flat chewing gum-Picture Courtesy: Pinterest |

| 3 | Round Chewing Gum | Chewing gum may also be found in round shape with colors having similarity with watermelon, balls, football, and fruits etc. |

Colorful chewing gum balls-Picture Courtesy: createdby-diane.com |

| 4 | Square Chewing Gum | Square chewing gum come in a square shape, however, their colors and flavors may vary from single to multiple. Square chewing gum are frequently packed in larger package, but it may be delivered alone as a single serving. |

Square chewing gum-Picture Courtesy: Pinterest |

| 5 | Stick Chewing Gum | Stick chewing gum is another popular form of chewing gum which comes with sour flavor inside. |

Sticks chewing gum pack-Picture Courtesy: germandelistore.com |

| 6 | Pellets Chewing Gum | Chewing gum is also shaped in pellets form which are usually packed in blister packs or cans etc. |

Colorful chewing gum pellets-Picture Courtesy: Pinteres |

On the Basis of Texture

| No | Name | Description | Picture |

| 1 | Liquid Center Filled Chewing Gum | Liquid center filled chewing gum is the name of fun as it contains in it the juicy and flavored liquid inside which suddenly get released when the teeth touches center of the gum. Such type of chewing gum can be perfectly made by the center filling gum manufacturing equipment. |

Liquid center filled chewing gum presentation idea-Picture Courtesy: tangyshop.com |

| 2 | Powder Center Filled Chewing Gum | There are chewing gum which are filled with sour powders to give the person mouth watering taste after the powder get burst from inside. |

Center filled sour powder chewing gum-Picture Courtesy: madeinchina.com |

| 3 | Granules Mixed Chewing Gum | Chewing gum with mixed granules are also famous for their taste which is gradually released after cracking each granule while chewing bubble gum. |

Chewing Gum with granules particles-Picture Courtesy: candyfunhouse.ca |

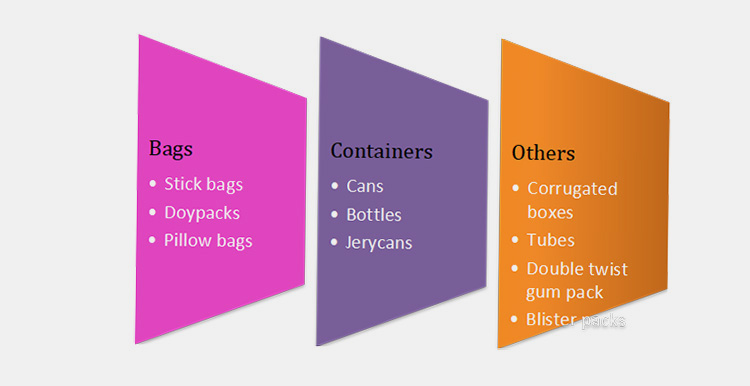

5.List Down The Popular Packaging Options Available For Chewing Gum Packaging?

Chewing gum can be packed in range of packages available in the market today. Below you will know about these packaging options in detail:

Bags

Bags are flexible product holding containers which can be used for packaging chewing gums. These vary in shape, size as well as material used such as:

Stick Packs

Chewing gum stick pack-Picture Courtesy: target.com

Stick packs are long narrow packaging bags made from either plastic or paper. They can be used for flat and powder chewing gum.

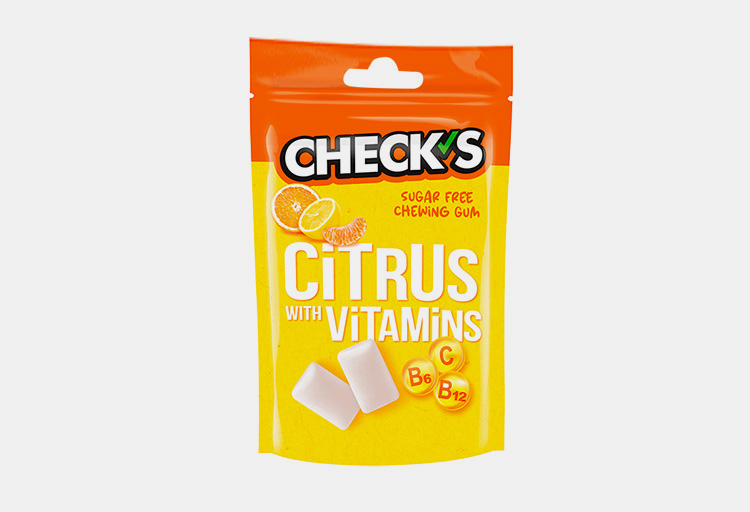

Doypacks

Citrus chewing gum in doypack-Picture Courtesy: checksgum.com

Doypacks are durable bags which stand upright. They are highly resistant to temperature, light, and moisture due to which the chewing gum packed in it remains the same. Moreover, doypacks have additional space for chewing gum to be adjusted in higher amount.

Pillow Bags

Center filled chewing gum in pillow bag-Picture Courtesy: consultaremedios.com.br

Pillow bags are pillow shaped packaging bags used for chewing gum packaging. They can be available in both large and small size. The large size pillow bags can hold multiple chewing gum, while as, small size bag can be used for single serving chewing gum..

Containers

Containers are durable and compact product holding objects also used for chewing gum. The common containers we often see with chewing gum are as follows:

Cans

Chewing gum can-Picture Courtesy: Pinterest

Can is a metallic containers made from thin layer of steel or tin. It is often available in various forms for storing and safely delivering of chewing gum.

Bottles

Chewing gum bottle packaging idea-Picture Courtesy: target.com

Bottles are ordinarily large containers made from plastic or glass with a body, neck, and a lid for closing. It is widely used for packaging chewing gum.

Jerrycans

Powdered chewing gum small jerrycans-Picture Courtesy: oldtimecandy.com

Small and beautifully colored jerrycans are also among the top packages which is prominently employed for storing and delivering of chewing gum especially in powder form.

Others

Other types of packaging options available for chewing gum packaging include:

Corrugated Boxes

Chewing gum in corrugated boxes-Picture Courtesy: forthemommas.com

Corrugated boxes is the name given to packaging material with double or triple layer of paper which is derived from wood. It is highly safe for chewing gum and environment as well.

Tubes

Mango chewing gum tube-Picture Courtesy: interdulces.com

Tubes are also used for liquid chewing gum packaging. Although, it is not so popular compared to other packages, however, it is quite easy to use due to squeezable option.

Double Twist Gum Pack

Double twist chewing gum packaging-Picture Courtesy: candywarehouse.com

Double twist chewing gum packaging refers to the wrapping of gum into a paper or plastic pack in center and twisting the edges on both side in opposite directions. This method of packaging chewing gum is cost-effective and convenient to apply.

Blister Packs

Blister colorful chewing gum-Picture Courtesy: goodmockups.com

Blister packs are rigid flexible packs made from thin transparent plastic. It is processed through heat to form the desired shape of chewing gum for easy packaging. Blister packs are good in terms of transparency and are light weighted.

6.What Is The General Process Of Chewing Gum Packaging?

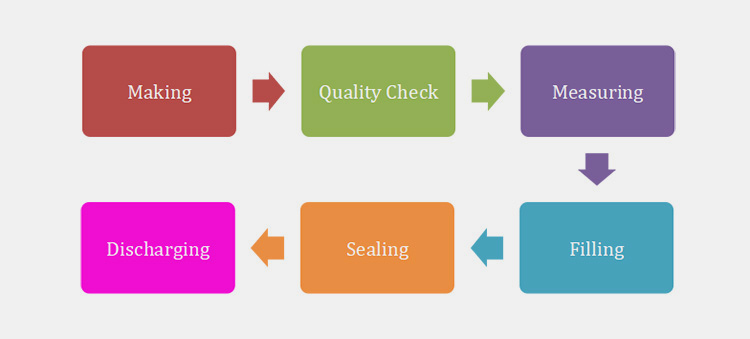

The general process of chewing gum packaging encompasses several crucial steps which must be studied accordingly. The major steps involved in chewing gum packaging are enlisted in the following paragraphs

Making

Chewing gum making process-Picture Courtesy: alpengummi.at

Before packaging any type of product including chewing gum, there is always an initial step which is indeed the product manufacturing. Therefore, firstly the chewing gum is well cooked by mixing the required ingredients for specific time in gum cooking machine.

Quality Check

Quality checking of chewing gum-Picture Courtesy: Refresh Gum

When the chewing gum undergone cooking phase, the prepared formulation is then tested in laboratories to check the quality of chewing gum. It will include the level of moisture present in chewing gum, flexibility, coating material, and texture. After this critical assessment gets completed, particular time would be noted under which the chewing gum is acceptable to consume.

Measuring

Chewing gum counting process-Picture Courtesy: exploredprk.com

Once, the making and quality checking process gets completed, the chewing gum are now ready for packaging. Therefore, different types of chewing gum packaging machines are used for this purpose, whose common aim is to accurately measure the required amount of chewing gum before filling. Hence, with the help of sensors, vibratory trays, and counting stations, chewing gum are measured.

Filling

Chewing gum stick filling-Picture Courtesy: symetal.gr

The measuring phase is directly followed by the filling of counted chewing gum into number of packages such as bottles, cans, and bags etc.

Sealing

Now, when the desired volume of chewing gum has been filled into the packages, the crucial step of sealing bags and boxes to ensure temper proof and air-tight sealing is done.

Discharging

Chewing gum discharging-Picture Courtesy: targoncavilla.com

At last, the packed chewing gum packages are discharged out of the machine through conveying system as final outlet.

7.Enumerate The Various Machines Required For Chewing Gum Packaging?

As there are multiple packaging options available for chewing gum packaging, you will find a long list of machines which are required for each type of chewing gum packaging. So, let's discover these machines separately:

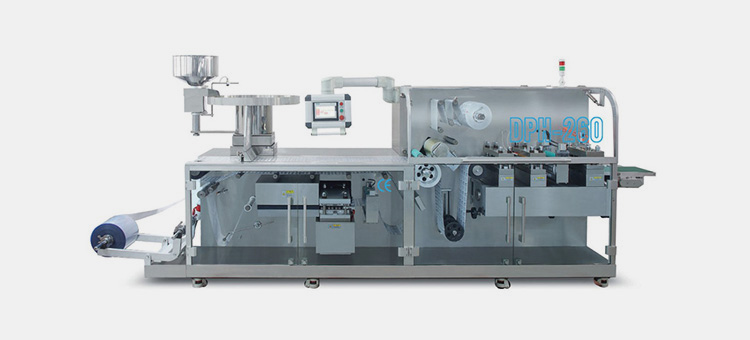

Chewing Gum Blister Packaging Machine

Chewing Gum Blister Packaging Machine-Aipak

Chewing gum blister packaging machine is employed to deal with the packing of chewing gum into flexible and transparent blisters. It simply takes the precise amount of chewing gum into blister molds and process it through heat which resulted in the formation of beautiful and clear chewing gum blister packs. This machine can be also used for confectionaries and products other than chewing gum such as candies, gummies, chocolates, and drugs etc

Chewing Gum Bag Packaging Machine

Chewing Gum Bag Packaging Machine-Aipak

Chewing gum bag packaging machine is particularly designed to carry out the task of packaging various forms of chewing gum into different shapes and sizes bags. This machine may also be further categorized into horizontal, vertical, stick pack, and pre-made bag packaging machine. The major assembly line of the machine consists of a PLC control system, stainless steel body, control cabinet, weighing and counting detection eye, conveyor belt, and bag sealing system etc. This type of machines are suitable for packaging chewing gum into different types of bags and pouches.

Chewing Gum Flow Wrap Packaging Machine

Chewing Gum Flow Wrap Packaging Machine-Aipak

Chewing gum flow wrap packaging machine is high speed packaging equipment used for wrapping chewing gum into aluminum foil or plastic film. The machine has been integrated with automatic features of alarm system, conveying system, control system, chewing gum wrapping and sealing etc. It performs the main function by pulling the film from roller on dual side and infusing the chewing gum inside two layer film. After that, the film is sealed on three side including top, bottom, and back side. At the end, the packed flow wrap gum pack is separated from rest of film with the help of cutter.

Chewing Gum Counting & Filling Machine

Chewing Gum Counting & Filling Machine-Aipak

As the name indicates, this machine is brought into the field to undertake the important objective of accurately counting large number of chewing gum and then fill these gum into various bottles and containers. The structure of machine is made up of several components including a hopper, vibratory trays, counting compartment, filling nozzles, conveying system, control panel, and detection system etc. By using these components, the machine effectively perform its function. This machine can be used for square chewing gum, balls chewing gum, and tablets/ capsules type chewing gum.

Chewing Gum Weighing & Filling Machine

Chewing Gum Weighing & Filling Machine-Aipak

Chewing gum weighing and filling machine is another machine used for the accurate packaging of chewing gum. This machine is especially designed to pack the granulated products into various shapes pouches, bottles, and boxes etc. It weighs the bulk chewing gum through multiple weighers and load it into packages. This type of machine may come in linear form or rotary form depending upon the need of the manufacturers.

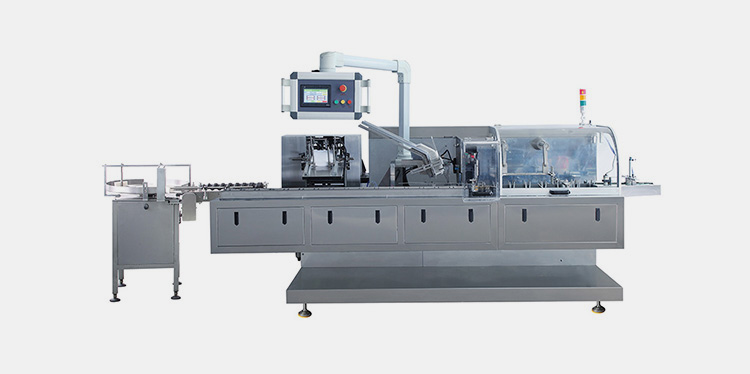

Chewing Gum Carton Packaging Machine

Chewing Gum Carton Packaging Machine-Aipak

Chewing gum carton packaging machine refers to the equipment which is used for packaging chewing gum and its packs into paper boxes. It is composed of a hopper, conveyor belt, product indeed station, robotic arms, sealing, coding, and embossing system. The machine efficiently forms the box and infiltrate the chewing gum into it automatically. These boxes are then sealed, coded, and embossed by the machine and ultimately discharged for further processing.

Chewing Gum Stick Wrapping Machine

Chewing gum stick wrapping machine-Picture Courtesy: san-ke.com

Chewing gum stick wrapping machine is another type of packaging machine used for wrapping flat chewing gum in a paper, foil, or plastic layer. The machine is composed of a gum hopper, conveyor belt, splitting system, film roller, control system, and motor etc. It starts working by taking chewing gum from hopper and pulling it on a flate surface after which the film is released by the roller over gum and machine wrap the gum. Similarly, the wrapped stick chewing gum are discharged by the conveyor belt.

8.What Are TheQuality Standards For Chewing Gum Packaging?

Quality certified icon-website.crosq.org

There are certain quality standards established by the international community for regulation of safe products. Hence, a company or product who comply these standards are safe to consume. These are as follows:

FDA

FDA stands for Food and Drug Administration whose primary objective is to make sure that all the drugs, food products, their manufacturing and packaging machinery are made by using quality material. In this way, it assures the safety of your health as well as your business by promoting the regulation of certified machinery.

ISO

International Organization for Standardization is another platform about whom you might have head as it is the key agency in shaping the fate of your business. Any industry which is certified by ISO is considered among the top best manufacturers who are always eager to provide hygienic and protected equipment as well as goods.

GMP

Good Manufacturing Practices is yet another significant organization which is well known for its famous five principles, Products, Processes, Procedures, Premises and lastly, People. Hence, either it is chewing gum packaging itself or its machinery, if it is approved by GMP, you are on safe track.

9.How To Enhance The Charm Of Chewing Gum Packaging?

There are lot of ways which can be adopted to give your chewing gum packaging more strength to catch the attention of viewers. So, let's explore what actually they are!

Mesmerizing Labeling

Chewing gum paper boxes-Picture Courtesy: packagingoftheworld.com

By mesmerizing labeling, all our mean is to design your chewing gum package labeling in such a way that it alone will be attractive. For this, you have to align numerous things together like gum flavor with the color of package labeling and much more.

Innovative Designing

Mere using old fashioned packaging options are not going to make any change in your business, rather you have to look for new and creative design. For instance, shaping your chewing gum packages according to the customer proclivities will indeed help you to gain more benefit.

Gift Pack Gum Packaging

Chewing gum with free puzzle inside-Picture Courtesy: lampa.it

Another trick which you can apply to distinguish your chewing gum from other brands and make it more grabbing for people is to provide little free gifts inside like shown in the picture above.

Biodegradable Packaging

Various flavored chewing gum-Picture Courtesy: designhappy.co.uk

By using biodegradable packaging options like that of paper, cans, and cardboards, there will be more chance for your product uplifting as environmental sustainability is becoming the key concern for many people.

Conclusion

To put in a nutshell, this FAQ guide has shedded the light on all essential factors which are related to chewing gum packaging. From studying product nature to the packaging solutions available, and machines used in chewing gum packaging, we have covered all the topics in this guide. We hope all of your complexities have been resolved to some extent after reading this comprehensive review. However, if you are still curious to know more about chewing gum packaging or machines used for it, then let us know with a single click. Thank you!

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide