Cheese Stick Counting Machine: The Complete Buying Guide in 2025

Cheese sticks are yummiest and boost the flavour of any cuisine. These flavorful cheese sticks are enjoyed with pizza, burger, and bread. But how taste of cheese stick is preserved? The answer is by packaging.

Packaging is best for maintaining the deliciousness of cheese sticks in every bite. It preserves the quality and nutrition of the cheese stick. Cheese sticks are packed in boxes and pouches. However, accurately placing the number of cheese sticks in a packing container is a challenging task but this challenge is made easier with the cheese stick counting machine.

This machine showcases state-of-the-art counting technology and increased automation, where human intervention is minimally required. Moreover, it is an extremely handy machine with absolute precision and high performance. Let’s get a detailed insight into the cheese stick counting machine.

1.What is Cheese Stick Counting Machine?

Allpack Cheese Stick Counting Machine

A cheese stick is a long piece of cheese that is coated with bread and batter. These sticks are packed in stylish and sturdy pouches and boxes to maintain the product integrity.

Have you wondered how cheese sticks are packed? Of course, the answer is simple. There is an efficient, and speedy machine that is specially constructed for counting and sorting cheese sticks called a cheese stick counting machine. It is manufactured to process and pack cheese sticks in pouches or sachets. It is very efficient because it precisely packs different types of cheese sticks.

2.Enlist the Advantages of the Cheese Stick Counting Machine.

The cheese stick counting machine is the greatest invention of modern times and it has a broad range of advantages that are great for money-making. These advantages offset the machine's initial investment costs. This machine effortlessly brings huge success for businesses. Some of the useful advantages of cheese stick counting machine are:

Enhanced Efficiency

Enhanced Efficiency- Picture Courtesy; ATM Marketplace

Efficiency and speed are two essential aspects of productivity. The cheese stick counting machine is the best example of a faultless fusion of consistency and increased efficiency. This machine has a continuous mode of operation without requiring the necessity of human labour, leading to streamlined production.

High Throughput

High Throughput- Picture Courtesy: Weekend at the Cottage

The cheese stick counting machine has increased throughput, as it quickly counts huge amounts of cheese sticks in a timely fashion. This rapid counting translates to increased production capacity. With this, businesses can easily achieve their targets and meet the deadlines.

Minimal Variations in Batches

Minimal Variations in Batches- Picture Courtesy: The Atlantic

With the cheese stick counting machine, there are minimal variations in batches because it counts and sorts the cheese stick with a high rate of accuracy. This machine has integrated state-of-the-art sensors and counting systems that are capable of providing precision in counting. This feature of the cheese stick counting machine dispenses a meticulous number of cheese sticks in the packaging.

Cost-Effectivity

Cost-Effectivity- Picture Courtesy: LinkedIn

The cheese stick counting machine is useful when it comes to saving money by replacing human labour. Resources are utilized elsewhere because less number of labourers are required to manage the machine. Furthermore, there is no overpacking with the cheese stick counting machine, consequently resulting in less waste. This saves overpackaging costs.

Reliability

Reliability- Picture Courtesy: LinkedIn

The cheese stick counting machine has unwavering steadfastness and reliability, playing a critical and intricate role in logistics and supply chain. Its reliability is linked with better quality control. The latter is responsible for upholding brand image and increasing customer confidence.

3.In What Industries Does Cheese Stick Counting Machine Used?

The cheese stick counting machine is important in a broad range of industries, especially the dairy, food, and bakery industries. This machine ascertains that stick-like items are packaged correctly and hygienically. Some of the industries that utilize cheese stick counting machines are:

Dairy Industry

Use of Cheese Stick Counting Machine in Dairy Industry- Picture Courtesy: Yummy.ph

The dairy industry is the primary sector where a cheese stick counting machine is applied. Its use is inevitable in the dairy industry, where counting and sorting of products like cheese sticks is daily seen. The dairy industry is the major utilizer of the cheese stick counting machine because of its accuracy.

Bakery Industry

Use of Cheese Stick Counting Machine in Bakery Industry- Picture Courtesy: Simply Gloria

Another important application of the cheese stick counting machine is the bakery industry. There is no exception that this machine precisely counts breadsticks and pretzel sticks and packs them in boxes or pouches. In the bakery industry, rolls and straws are also counted by cheese stick counting machine.

Confectionery Industry

Use of Cheese Stick Counting Machine in Confectionery- Picture Courtesy: Divine Specialties

It is yet another industry where the cheese stick counting machine is quite widespread. With this machine, precise and consistent premium packaging of confectionery items has been possible. This machine counts chocolates and candy sticks in the confectionery industry.

Frozen Food Industry

Use of Cheese Stick Counting Machine in Frozen Food Industry- Picture Courtesy: Allrecipes

Manufacturing of frozen sticks is increasingly popular in the food industry. This is no doubt that frozen food sticks are not processed by the cheese stick counting machine. This machine packs different kinds of frozen items like vegetable sticks, fish sticks, sausages, and chicken sticks in safe and tamper-proof packaging.

Nutraceutical Industry

Use of Cheese Stick Counting Machine in Nutraceutical Industry- Picture Courtesy: Proteinbolaget

Manufacturers are adopting new means of delivering nutrition to patients due to increased demand for nutritional products. Thus nowadays, we have nutritional bars, protein bars, meat bars, and energy bars elongated like a stick. Their number is assessed by the cheese stick counting machine in the nutraceutical industry.

Medical Industry

Use of Cheese Stick Counting Machine in Medical Industry- Picture Courtesy: Proteinbolaget

Although it seems strange, the cheese stick counting machine is also utilized in the medical industry. This machine readily and efficiently carries out the job of counting different kinds of medical devices like medical sticks, and tongue depressors. It ensures that each package receives the correct number of medical devices.

4.How Does the Cheese Stick Counting Machine Work?

The working steps of the cheese stick counting machine are distinct and sequential involving the use of different components of the machine. Here is an explanation of all these steps:

Loading

Loading of Cheese Sticks- Picture Courtesy: AIPAK

At the beginning of the operation, a large number of cheese sticks are fed into the hopper. Cheese sticks are loaded in the elevators by the operator from where these cheese sticks are deposited in the hopper.

Counting

Counting of Cheese Sticks- Picture Courtesy: AIPAK

This step depends upon the type of machine. usually, there are two different counting mechanisms.

Volumetric Counting

In this counting mechanism, cheese sticks are usually deposited into the vibratory tray. A tray or cup with a precalculated volume travels underneath the vibratory feeder and cheese sticks are dropped down from the vibratory tray into the container. A sensor signals, once preprogrammed volume is reached in the container and the feeding of stick packs from the vibratory feeder stops. These cheese sticks in the cup or tray are counted as one unit.

Combination Counting Scale

In this working stage, the cheese sticks are loaded from the hopper into the segmented elevator, where every segment has an integrated weighing scale. The scale estimates the weight of cheese sticks as they go along the elevator. Once a preset weight is achieved, the estimation of weight by weighing scale stops and cheese sticks is considered as one unit.

Discharging

Discharging- Picture Courtesy: AIPAK

After counting, the last step is the removal of cheese sticks from the machine. This step is performed by the conveyor belt that takes cheese sticks to the next packaging stage. Also, a dropping mechanism gently places the cheese sticks into a packaging pouch or box.

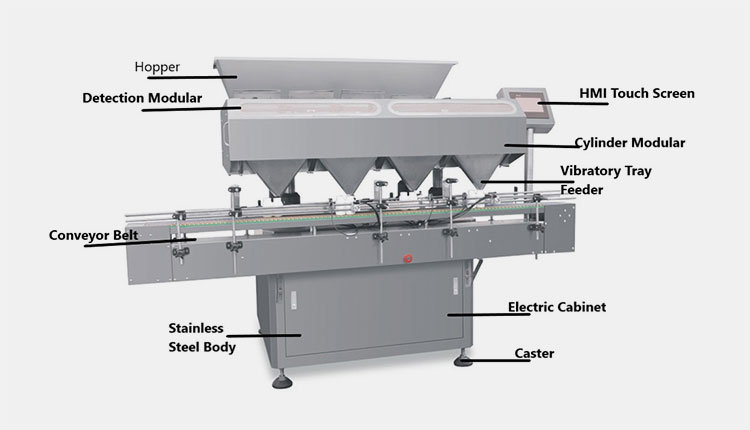

5.Enumerate the Parts of the Cheese Stick Counting Machine.

There are various parts present in the cheese stick counting machine that perform their specific role to execute flawless packaging. These parts are detailed one by one below:

Parts of Allpack Cheese Stick Counting Machine

Hopper

It is present at the topmost part of the cheese stick counting machine. it has a rectangular configuration and holds large quantities of cheese sticks for counting. It supplies a continuous amount of cheese stick to the detection modular.

Detection Module

This part has paramount importance in detecting and recognizing individual cheese sticks. It has different kinds of sensors like vision systems that are responsible for scanning visual aspects of cheese sticks like their size and shape. It also has weight sensors that determine the weight of individual cheese sticks.

Cylinder Module

It is a mechanical component, whose job is to process the movement of the cheese stick. It has a rotating cylinder with different pockets or cavities. Only valid cheese sticks enter the pockets of the cylinder module. This prevents defective cheese sticks from being loaded in the packaging container.

HMI Touch Screen

It acts like a bridge between machines and humans, connecting them through a user-friendly interface. Operators can supervise, control, monitor, program, and interact with the machine using the HMI interface. Moreover, this touchscreen interface also assists in data visualization.

Conveyor Belt

The trays for depositing the cheese sticks are loaded on the conveyor belt. As this belt moves, it transports trays underneath the vibratory feeder that feeds cheese sticks into the tray.

Stainless Steel Body

This part typically constitutes the frame and internal part of the cheese stick counting machine. The body of the machine is manufactured using stainless steel which is a sturdy and resistant material and is responsible for the long-lasting life of the cheese stick counting machine.

Vibratory Feeder

This part employs vibration to dispense the cheese stick from the filling nozzle to the loading tray. It is used for the consistent transport of the materials.

Electric Cabinet

It is a sturdy space in which different switches, replays, and circuit breakers are present. The electric cabinet is also termed the powerhouse of the machine because it stores different wires and cables that power up the cheese stick counting machine.

Caster

These are stabilizers that bear the entire weight of the cheese stick counting machine. They are used for supporting the machine and keeping it leveled.

6.What are Other Products Counted by Cheese Stick Counting Machine?

Industrial packaging encloses a broad range of products and cheese stick counting machine is a significant part of industrial packaging. Hence, the cheese stick counting machine counts a variety of products such as:

| Pills

Picture Courtesy: IFLScience |

The cheese stick counting machine counts different kinds of tablets like plain tablets, coated tablets, emulsion tablets, and chewable tablets. It also counts different types of capsules such as hard gel and softgel. These capsules are of different sizes and shapes. |

| Nutritional Supplements

Picture Courtesy: Life Vision Healthcare |

Nutritional supplements in the form of tablets and capsules. Their number is also estimated by this machine. Nutritional supplements are usually in the form of softgel capsules. |

| Confectionery

Picture Courtesy: Pinterest |

This machine also detects and counts different types of gummies, chewing gums, candies, beans, mints, coco balls, bounties, etc. The cheese stick counting machine offers precise counts for packaging different confectionery products. |

| Bakery Products

Picture Courtesy: Whiskful Cooking |

In bakeries, cheese stick counting machine is utilized for counting different kinds of biscuits, cookies, pretzels, and other bakery products. |

| Bath Beads

Picture Courtesy: Pinterest |

Tiny bath beads are also identified and counted by the sensors of the cheese stick counting machine. These beads dissolve quickly in water. |

| Cosmetic Capsules

Picture Courtesy: biocrown |

Cosmetic capsules are used for revitalizing the skin and contain different kinds of serum and oils. The cheese stick counting machine determines the number of these cosmetic capsules in the cosmetic industry. |

| Seeds

Picture Courtesy: 1mg |

Cheese stick counting machine has a role in the agriculture industry for estimating the number of seeds. |

| Hardware Components

|

It reduces the chance of missing components in the hardware industry by properly recognizing and counting different kinds of fasteners, nuts, bolts, and screws. |

7.Is the Cheese Stick Counting Machine Made of Food-Grade Materials?

Food-grade Materials in Cheese Stick Counting Machine

Are you concerned about the construction of a cheese stick counting machine and want to know about its material composition? Well, there is no need to worry as the cheese stick counting machine is typically made of food-grade materials. Safety and sterility of food materials are important in the food industry and the cheese stick counting machine counts food products, so it can easily ensure the sanitariness of the cheese sticks.

Food-grade materials prevent the contamination of cheese sticks by averting the risk of leaching harmful substances into the cheese sticks. Moreover, food-grade materials offer better cleanability as they are corrosion-resistant and can withstand treatment with harsh chemicals.

Stainless steel grades 304 and 316 are food-grade materials that are used for manufacturing hoppers, frames, vibratory feeders, and other parts. While, food-grade plastic makes cover, guard, and some components of conveyor belt.

8.How to Clean and Maintain Cheese Stick Counting Machine?

Maintenance of Cheese Stick Counting Machine- Picture Courtesy: ICT Group

To maintain the hygienic standards and to increase the operational life of the machine you should regularly clean and maintain the cheese stick counting machine. Proper maintenance and cleaning schedules must be followed to increase the uptime of the machine. Some cleaning and maintenance tips are detailed below:

| Cleaning | Disassemble parts like hopper, vibratory feeder, etc. after unplugging the machine for cleaning. Wipe down the surfaces of the cheese stick counting machine with a clean cloth to remove any loose debris or product buildup. Rinse and wash every part of the machine using food-grade detergent. Then use food-grade sanitizer to sanitize every part because they should not have bacterial growth. Use clean water for rinsing after washing and sanitizing and then air dry all the dismantled parts. After that reassemble them. |

| Inspection | It is a very important step in the maintenance, as any sign of wear and tear of parts is checked in this step. This step is performed routinely to look for loose nuts and bolts. Also, timely replace worn-out parts to avoid further damage to the machine. |

| Lubrication | In this step, every moving part of the machine is lubricated with food-grade lubricant. This ensures smooth working performance of the machine because lubrication decreases friction between moving parts. |

| Software Update | To access the latest security features and improvements in software, look for software updates and keep it up-to-date. This will improve counting and sorting operations. |

| Calibration | Calibrate the machine every week, especially the sensors and vibratory feeder. This step enhances the functionality of critical components that are involved in counting and sorting. |

9.What are the Quality Certifications of the Cheese Stick Counting Machine?

The performance, quality, and safety of the cheese stick counting machine are maintained through different certifications. There are a variety of quality certifications for the cheese stick counting machine. Some of these quality certifications are discussed below:

NSF International

NSF International- Picture Courtesy: PR Newswire

This quality certification is of paramount importance in the food industry for ensuring safety and antiseptic processing. The cheese stick counting machine has NSF International certification for notifying users that it does not contaminate any food item. This certification strongly focuses on the design construction and working of a cheese stick counting machine.

UL Certification

UL Certification- Picture Courtesy: Polycase

This certification is a measure of electric safety. By having this certification, the cheese stick counting machine meets standards of electric well-being. This certification ensures manufacturers that this machine has foolproof protection against electrical and fire accidents.

CE Marking

CE Marking

Having CE marking means that the cheese stick counting machine complies with European Union quality standards. The CE marking denotes that this machine fulfils the safety, health, and environmental guidelines imposed by European countries.

RoHS Certification

RoHS Certification- Picture Courtesy: ISO Singapore

This certification is significant for the machines sold in the European Union. This is because these countries impose strict regulations about the use of hazardous substances in the manufacturing of cheese counting machines. This certification ascertains food safety.

10.What are the Technical Issues and their Troubleshooting in the Cheese Stick Counting Machine?

Modern cheese stick counting machine is equipped with the latest technology and up-to-date features, yet they still encounter technical issues that significantly impact the performance efficiency of the machine. For seamless counting and packaging, these technical issues must be troubleshooted with the help of the following tips.

| Problem | Cause | Solution |

| Jamming of Conveyor Belt

|

The presence of dust or other debris on the conveyor belt

Worn-out conveyor belts Misalignment of conveyor belt Conveyor belt tension is not accurate Too much load on the conveyor |

Clean the conveyor belt

Replace the worn-out conveyor belt Properly align the conveyor belts Adjust the tension in conveyor belts Ease the load on the conveyor |

| Inaccurate Counting

|

Variation in the product sizes.

Poor calibration of the weighing scales The sensor is not levelled accurately. Error in the software |

Ensure consistent product sizes.

Properly calibrate the weighing scale and other parts. Align the sensor accurately Reset the software to prevent erroneous working |

| Failure in Detection of Cheese Sticks

Picture Courtesy: MAGNA |

Dust and debris found on the sensor

Sensors are not calibrated properly Error in the alignment of sensors Damaged sensors Electrical interference |

Properly wipe the sensors

Recalibrate sensors Fix the sensor alignment issues. Replace or repair faulty sensors. Check the sensor connection and ensure they are damage damage-free |

| Display Shows Incorrect Counts

Picture Courtesy: AIPAK |

Old software showing incorrect counting

Software error The software is not compatible with the system |

Restart the cheese stick counting machine to clear software problems

View the error log and detect the bugs in the software Re-update software |

| Cheese Stick Feeding Issues

|

Incorrect cheese stick placement | Properly feed the cheese sticks in the hopper |

11.What are the Main Points When Choosing a Cheese Stick Counting Machine?

It is the wish of every businessman to have an ideal machine but they get confused when it comes to the actual purchase process of a cheese stick counting machine. So, we are offering some useful tips to ponder. These tips are:

Production Volume

Production Volume

First, determine the scale of your business. Are you a small business owner or handling bulk quantities of cheese sticks? The size of your business will help you to calculate the production volume of your business and in this way, you can easily choose between small and large production-size cheese stick counting machines.

Machine Footprint

Machine Footprint- Picture Courtesy; SED Pharma

Measure your industrial space and buy the cheese stick counting machine that has a footprint similar to your space available. This will assist in the easy installation and setup of the machine. Furthermore, if to need to move the machine frequently then choose the machine with wheels for easier transportation.

Energy Efficiency

Energy Efficiency- Picture Courtesy: Prosegur

It is a pivotal factor when it comes to choosing a cheese stick counting machine. Energy-efficient machines mean lower utility bills. So, search for energy-efficient types of cheese stick counting machines to cut down your operational expenses.

Technological Innovation

Technological Innovation- Picture Courtesy: LinkedIn

Although initially technologically advanced machines may seem pricey, eventually they will help you save money by reducing the chances of error on the part of human operators and also by reducing training expenses. So, go for a cheese stick counting machine with state-of-the-art features like the Internet of Things, remote connectivity, and error detection.

Reputable Manufacturer

Reputable Manufacturer- Picture Courtesy: Yahoo Finance

It is the foremost significant factor when going into the market to purchase a cheese stick counting machine. First, search for the key reputable manufacturer by going through their websites and looking at the lists of positive reviews. Because reputable manufacturers are synonymous with the quality of the machine and after-sale support.

Conclusion

To put it in a nutshell, we will simply say that the cheese stick counting machine is a spectacular piece of technology that deals remarkably well with the counting of cheese sticks. It has extra accuracy and a high deal of efficiency. It shows steadfast reliability when it comes to bulk packaging of cheese sticks. It fulfills any packaging demand with its automation and convenience. It serves as a standalone machine or can be integrated with other packaging machines. Now if you need to purchase a cheese stick counting machine, then do consider a pioneer in machinery manufacturing like Allpack. For the best assistance contact our customer care.

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide