Cheese Packaging Machine: The Complete FAQ Guide In 2025

Cheese Packaging Machine: The Complete FAQ Guide In 2025

Cheeses are one of the most popular food products on the market, they are soft and delicious, as a result, there are many people prefer eating them than other foodstuffs. Since there is a lot of demand, naturally there is a high production of cheese. Do you want to find an effective and efficient way to pack these cheeses?

Obviously, if you want to pack and sell cheeses, you need to possess a cheese packaging machine. How many types of machines can you use to pack cheeses? How can this machine work? Which components consist of a cheese packaging machine? How can you choose a good cheese packaging machine? You can find all the answers of these questions in the this blog.

1.What is cheese packaging machine?

Cheese packaging machine is a useful equipment which can pack cheese products such as cheese balls, cheese slices, cheese sticks and cheese blocks into different containers such as pouches and trays. According to different packaging requirements, there are many different types of cheese packaging machines, which have high production efficiency.

2.How can cheese packaging machine benefit you?

Cheese packaging machines can benefit you from different aspects, if you want to know the details, read the following content:

Digital Control

Cheese packaging machine adopts digital control, is equipped with smart and flexible control panel, as a result, the machine has a high degree of automation. And in the other hand, digital control is simple and convenient, therefore, you can easily operate a cheese packaging machine.

High Production Efficiency

As is mentioned that cheese packaging machine has a high degree of automation so that it can work very fast, moreover, this machine has high production capacity, can pack a large amount of cheeses per turn, which largely increases the whole production efficiency.

Versatile

Cheese packaging machine can meet different kinds of packaging demands, no matter you need to pack cheeses into bags, trays or other containers, you can easily find a cheese packaging machine to help you achieve this goal. Also, different cheese packaging machines can pack cheeses into different designed bags, such as 3-side sealed bags, stand up bags, guest bags and so on.

Stable Performance

Cheese packaging machines have stable performance, they can complete a series of operations such as bag forming, filling, sealing and cutting smoothly, the whole working process is orderly, without any mistakes. Therefore, cheese packaging machine is so popular in food industry.

3.What fields are cheese packaging machines used in?

Even though this machine is called cheese packaging machine, it is not only used to pack cheeses, it can also be applied in many industries such as food, pharmaceutical, cosmetic, daily necessaries, etc.

Food Industry

Certainly, cheese packaging machine is mainly used to pack cheeses, however, it can also be used to pack other food products such as bakery products, candies, nuts, chips, PET food, vegetables, fruits, cookies and so on. Cheese packaging machine can fill these food products into bags or other containers and then seal them.

Pharmaceutical Industry

As you can see that there are many packaging methods of pills, they can be filled into bottles, and they can be packed into bags. In addition, some small medical tools, such as masks, cotton sticks and so on, can be packed in bags or trays. Therefore, some types of cheese packaging machines can function in pharmaceutical industry.

Cosmetic Industry

Cosmetics in powder, granule and paste forms, can be packed in bags by cheese packaging machine, the machine produces small bags and fills the cosmetic products in them and then seals them, or fills cosmetic products into pre-made pouches and then seals them.

Daily Necessaries Industry

Cheese packaging machine can also be applied in daily necessaries industry, it can pack all kinds of small products such as small clips, toothpicks, small hooks, etc. Whether you want to pack daily necessaries into bags, trays or blisters, you can use a cheese packaging machine.

4.What are the different types of cheese packaging machines?How about their working principles and structures?

According to different cheese packaging demands, there are many different types of cheese packaging machines, which can mainly be divided into two major categories: vacuum cheese packaging machines and cheese bagging machines.

(1). Vacuum Cheese Packaging Machines

- Thermoforming Cheese Packaging Machine

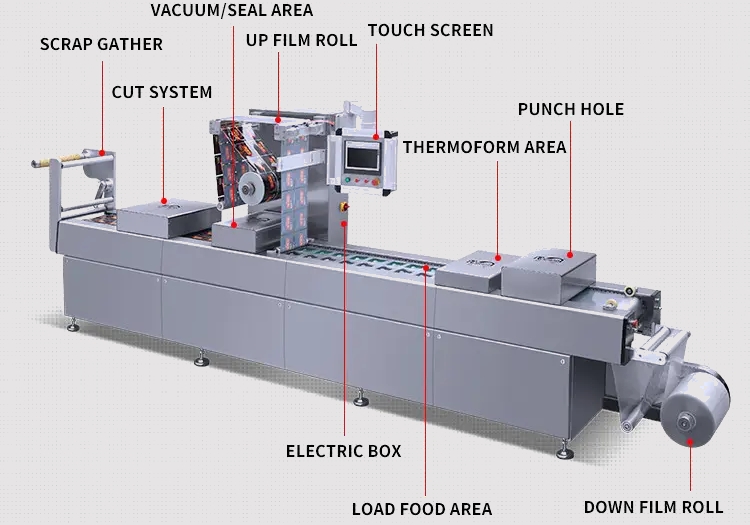

Thermoforming cheese packaging machine is a common type, it belongs to vacuum cheese packaging machines. This machine can heat all kinds of thermoforming materials, transfer them into required shapes with the help of vacuum suction, and pack cheeses into the produced containers, then sea them with thin film and cut them.

This cheese packaging machine is very flexible that it can provide different shaped containers which are suitable for various cheese products, also, it gives a tight and sanitary package for cheeses.

Working Principle:

Working Principle of Thermoforming Cheese Packaging Machine-Photo Credit: Dairy Foods Magazine

Thermoforming cheese packaging machine works by thermoforming and vacuum. At the beginning, the lower thin film is pulled and formed a container, and then the cheese is filled in it. Next step, the container enters the vacuum/seal area, the inside air is extracted, then, the upper thin film is put on it, they are heat sealed at this moment.

After being sealed, the packed product is cut and delivered to the discharge port, and the waste film material is recovered by the waste film retracting system.

Structure:

As the pictures shows, the structure of thermoforming cheese packaging machine is simple, it consists of down film roll, punch hole, thermoform area, load food area, up film roll, vacuum/ seal area, cut system, scrap gather, electric box and touch screen.

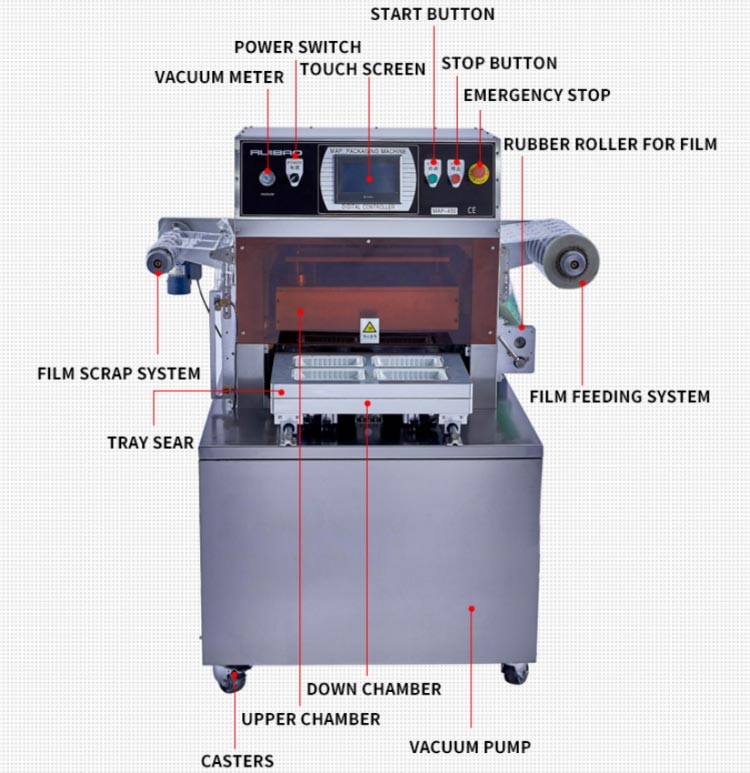

- Tray Vacuum Gas Flushing Cheese Packaging Machine

Tray vacuum gas flushing cheese packaging machine, as the name implied, it is to pack cheeses in trays and then seal them. This machine does not simply pump out the air in the tray to make it in a vacuum condition, after the air is exhausted, it will fill the tray with other gases. By using this type of cheese packaging machine, you can extend the shelf life of the products.

Working Principle:

When you using a tray vacuum gas flushing cheese packaging machine, firstly, you should put the cheese into the tray and close the machine, then the product is in the vacuum process, when this process is finished, the machine will fill insert gases such as nitrogen into the tray. And then, the tray is sealed with a layer of thin film and discharged, the whole packaging process is completed.

Structure:

To be honest, the main components of tray vacuum gas flushing vacuum packaging machine are touch screen and control panel, which can monitor the whole working process of the machine; rubber roller for film, film feeding system and film scrap system, which are very important for the tray sealing step; down chamber, upper chamber and vacuum pump, these are vital parts to achieve vacuum process.

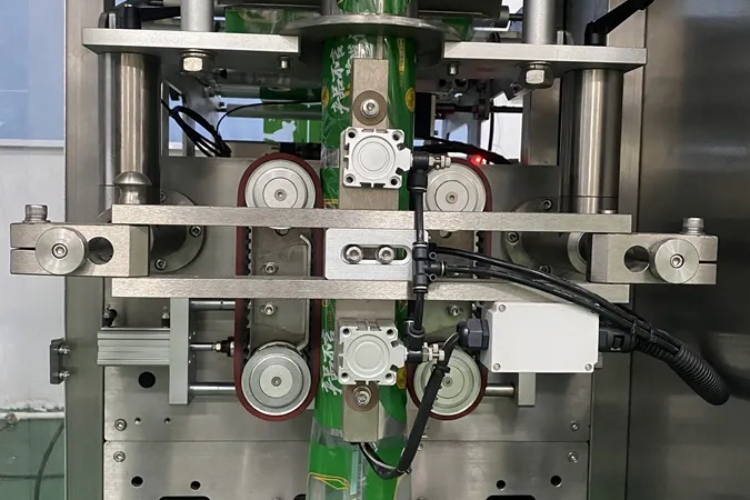

- Chamber Vacuum Cheese Packaging Machine

This type of cheese packaging machine is a little similar to the tray vacuum gas flushing cheese packaging machine, it is to extract the air in the container so that the product can be stored under a vacuum condition, to lengthen the storage time. Generally, the chamber vacuum cheese packaging machines have vacuum chambers, some of them have two chambers and the others only have one chamber.

Working Principle:

Chamber vacuum cheese packaging machine is based on the vacuum principle, it has one or two chambers, when the machine starts working, you should put the product into the chamber and close the chamber lid.

After you set the vacuum time and other parameters, the machine begin to extract the air in the bag or other container until it reaches vacuum, and then, the bag is sealed, the whole packaging process is finished.

Structure:

Look at here, chamber vacuum cheese packaging machine has vacuum chamber and vacuum pump which are used to extract the air in the container, a silicon bar which plays a role in sealing, the plexiglass cover and vacuum meter which let you monitor the vacuum process, and the control panel can make it easy to operate the machine.

(2). Cheese Bagging Machines

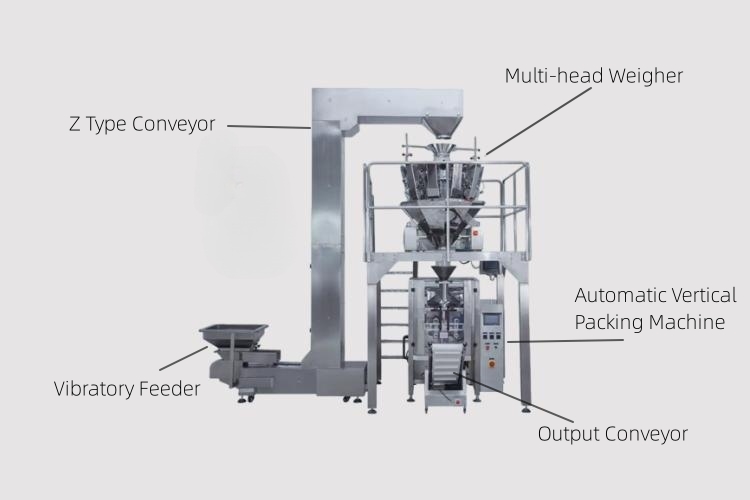

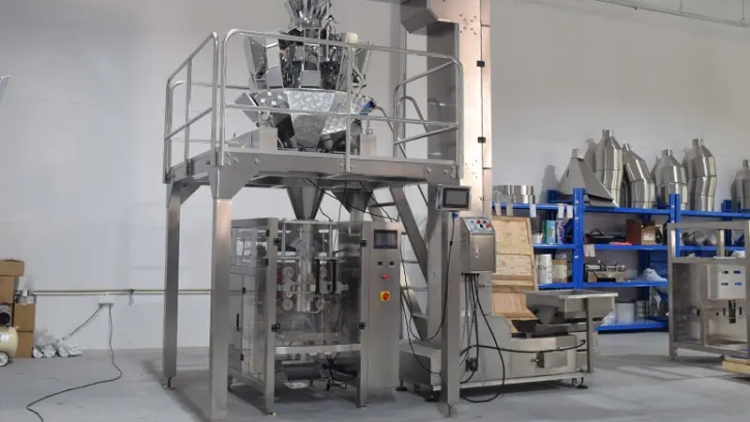

- Weighing Cheese Packaging Machine

The weighing cheese packaging machine is a type of large sized packaging equipment, it has a multi-head weigher which can precisely weigh the cheeses, and then it fills cheese into bags and seals, discharges them. This machine has high production output, can largely increase the production efficiency so that it is suitable for industrial applications.

Working Principle:

In weighing cheese packaging machine, the cheese products are fed into the vibratory feeder and then be delivered to the multi-head weigher by the Z conveyor. Then, these products are weighed and flow down to the automatic packing machine, where they are filled into bags, these bags are made by bag former, and after being filled, they are sealed and cut, and finally be discharged.

Structure:

Weighing cheese packaging machine is constituted of multi-head weigher, Z-type conveyor, vibratory feeder, automatic vertical packing machine and output conveyor. The vibratory feeder is used to store products to be packed, the Z-type conveyor, you can also call it lifter, is used to convey products.

The multi-head weigher is to weigh the products and the automatic vertical packing machine can play a role in bag forming, cutting, sealing and product filling. The output conveyor is to discharge the finished products.

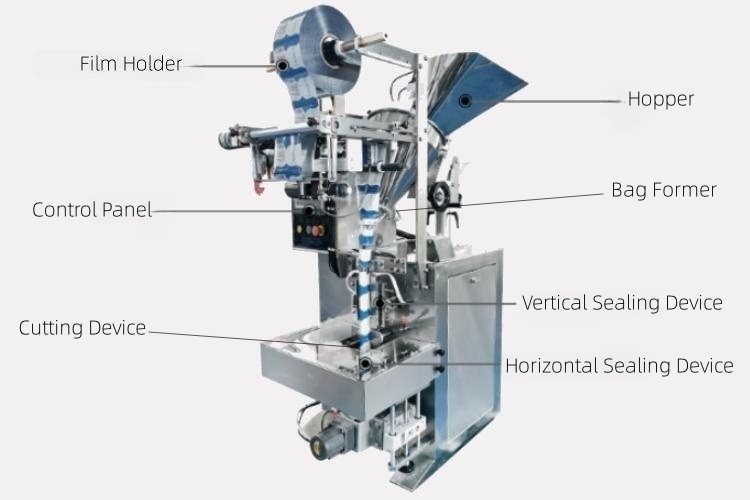

- Vertical Cheese Packaging Machine

The working direction of this type of cheese packaging machine is vertical, the cheeses are fed into the machine from the hopper which is on the top of the machine. The machine can complete the packaging steps such as bag making, cheese filling, bag sealing, cutting and discharging. Actually, this machine is similar to the weighing cheese packaging machine, but it is smaller than that one.

Working Principle:

Vertical packaging machine has high degree of automation, it can complete bag forming, filling, sealing, cutting operations efficiently. At first, the cheese is fed into the machine by hopper and then it falls into the next station, the bag former pulls the film from film holder and makes bags, the fallen cheese is filled into the bag, and then the bag is sealed and cut, and falls into the discharge conveyor.

Structure:

Generally speaking, vertical cheese packaging machine is made of hopper, film holder, bag former, vertical sealing device, horizontal sealing device, cutting device and control panel. These components all have their own functions.

Hopper is the entrance of cheese products, film holder is to store the thin film which is to make bags, bag former is to let the bag come into shape, vertical sealing device and horizontal sealing device play the role in sealing the 4 sides of the bag, and then cutting device cut off the connection of each two bag, and control panel is to turn on/off the machine and set up parameters.

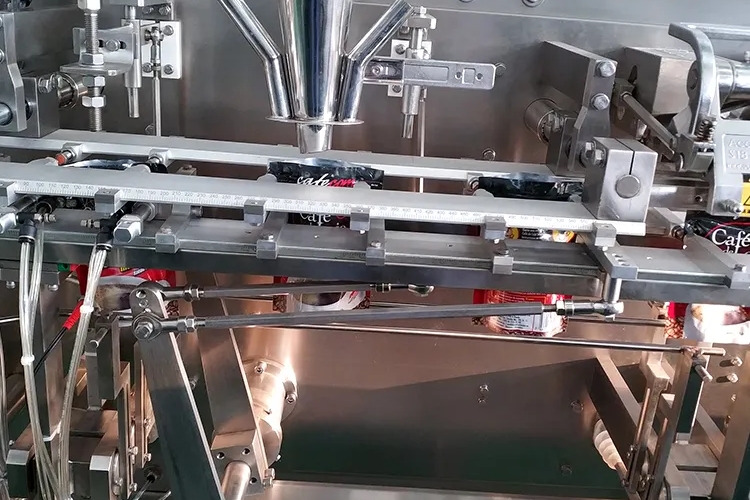

- Horizontal Cheese Packaging Machine

Different from vertical cheese packaging machine, this machine works horizontally, it has a feeding conveyor which can deliver cheese products to the next working station. But, the working process is the same as vertical cheese packaging machine, the film are produced to bags, and then the products are filled in, and then they are sealed and cut.

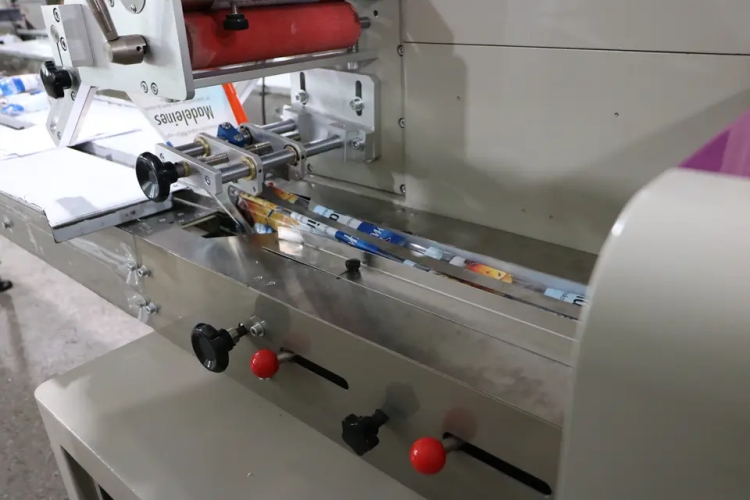

Working Principle:

The working principle of this machine is that the roll film enters the bag former through the packaging film driving roller and is then formed. And then the cheeses are sent into the bag former by the feeding conveyor, they are longitudinally sealed and transversely sealed and cut, and then be discharged.

Structure:

Horizontal cheese packaging machine is made of conveyor belt, film roller, bag former, sealing system, cutting system and control panel. Conveyor belt is to deliver the cheese, film roller is to store the film which is to make bags, bag former is to make packaging bags, sealing system can seal the thin film and cutting system is to cut down it so that the cheese is perfectly packed in the bag.

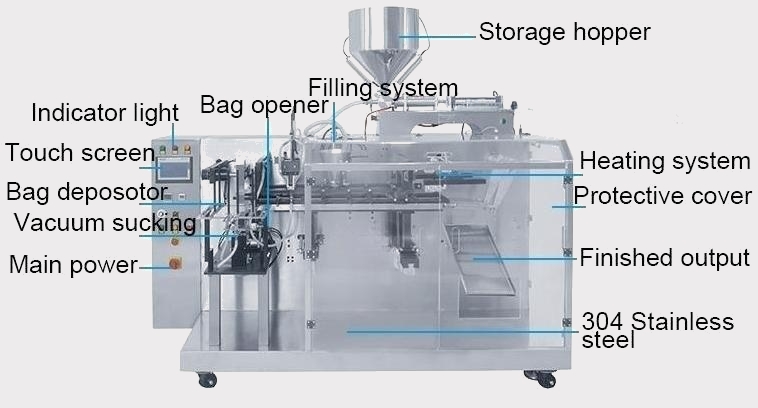

- Premade Pouch Cheese Packaging Machine

Premade pouch cheese packaging machine is also a type of cheese bagging machine, but, different from horizontal cheese packaging machine and the vertical one, this machine fill cheeses into premade pouches, it doesn’t need think film to make bags. With a premade pouch cheese packaging machine, you can pack your cheese products in various pouches such as 3-side sealed, 4-side sealed, stand up pouches and so on.

Working Principle:

The working principle of the premade pouch cheese packaging machine is to use the manipulator to take, open and seal your premade bags, and at the same time complete the functions of filling and coding under the coordinated control of the microcomputer, so as to realize the automation of cheese packaging.

Structure:

As the picture shows, premade pouch cheese packaging machine has many functional parts, but you only need pay attention to some major parts such as storage hopper, filling system, bag depositor, bag opener, heating system and touch screen.

The storage hopper is to store the cheese products, bag depositor is to store empty premade pouches, and the bag opener is to open these pouches so that filling system can fill cheeses into them, and the heating system is to heat seal the filled pouches. Besides, the function of touch screen is to set up all kinds of parameters.

5.How does vacuum cheese packaging machines differ from cheese bagging machines?

As is mentioned in the last question that there are two major categories of cheese packaging machine, one type is vacuum cheese packaging machine and the other one is cheese bagging machine. However, why are they two different types? What are the differences between them? Let’s discuss together.

- Difference in packaging methods

Vacuum cheese packaging machine and cheese bagging machine have different working principle, therefore, their packaging methods are different from each other. If you use a vacuum cheese packaging machine, the cheese product is already filled in a bag, the machine is to suck the air inside the bag and seal it.

But if you choose a cheese bagging machine, the cheese products are fed into the machine and packed in premade pouches or ready-made pouches, finally the pouches are sealed.

- Difference in packaging materials

In fact, the packaging materials of vacuum cheese packaging machine and cheese bagging machine are also different. For vacuum cheese packaging machine, the cheese products are packed in special vacuum seal bags; on the opposite, for cheese bagging machine, the products are packed in normal plastic bags.

- Difference in storage time

Can you guess which of these two machines can let cheeses have longer storage time? Obviously, it is vacuum cheese packaging machine. Why? It is because that it extract all the air in the bags so that there is no possibility of breeding bacteria and microorganisms.

But when it turns to cheese bagging machine, it just pack cheeses in normal plastic bags, can not prevent cheese from spoiling for a long term.

6.Which forms of packages can cheese packaging machine provide?

Since there are various types of cheese packaging machines on the market, they can meet different packaging demands of cheeses, so, which forms of packages can cheese packaging machine provide?

Tray Package

By using a tray vacuum gas flushing cheese packaging machine or thermoforming cheese packaging machines, you can seal cheeses in trays which can be designed to different shaped and made of different materials. Cheeses which are packed in trays look neat and beautiful, there are many cheese manufacturers prefer to use tray package to pack their products.

Vacuum Package

There is another form of package that is called vacuum package, this is offered by chamber vacuum cheese packaging machine. The cheese products are filled in vacuum seal bags and be vacuum packed, vacuum package can extend the shelf life of cheese.

Bag Package

Cheese packaging machines can also provide bag packages, all kinds of cheese bagging machines, such as the weighing cheese packaging machine, vertical one, horizontal one and the premade pouch one, all use bag packages to pack cheeses. And these cheese packaging machines provide different bag packages which are as follows:

(1). 3-side Seal Bag

3-side Seal Bag-Photo Credit: ePac Flexible Packaging

As the picture shows, the two sides and bottom of 3-side seal bag are tightly sealed, and the top is openable, this kind of package is very convenient for you. The weighing cheese packaging machine, horizontal cheese packaging machine and vertical cheese packaging machine can provide this package.

(2)4-side Seal Bag

4-side Seal Bag-Photo Credit: Burgen Packaging Machinery

Different from 3-side seal bag, the top, bottom and two sides of 4-side seal bag are all sealed, this package can provide a independent environment for cheese and reduce its exposure to air. If you want to use 4-side seal bag to pack cheeses, you can choose weighing cheese packaging machine, horizontal cheese packaging machine and vertical cheese packaging machine.

(3) Back Seal Bag

Back Seal Bag-Photo Credit: Emerald Packaging

Bag seal bag, also known as the middle seal bag, it is a kind of packaging bag that is sealed on the back of the bag body, and is also very suitable for cheese packaging. With such a package, the cheese product is very easy to open. Similarly, there are three types of cheese packaging machines provide back seal bag package, the weighing cheese packaging machine, the horizontal one and vertical one.

(4). Premade Pouch

Premade pouch is produced in advance, leaving the mouth open, and then be used to pack cheeses. There are a variety kinds of premade pouches such as stand up pouches, gusseted pouches, pillow pouches and so on.

This package can increase the production efficiency and provide beautiful appearance for cheese products, if you want to choose this form of package, the premade pouch cheese packaging machine can help you.

7.Are there any optional functions of cheese packaging machine?

The answer of this question is “Yes”, besides the existing functions, there are also some optional functions of cheese packaging machine, even though they are not necessary, they can improve the packaging effect.

Coding

You can add this function to the cheese bagging machines such as weighing cheese packaging machine, vertical cheese packaging machine, horizontal cheese packaging machine and premade pouch cheese packaging machine.

Generally, this machines are used to pack cheeses into bags, but with the coding function, they can add production dates of the products to the packaging bags, which can tell more information to customers.

Photoelectric Eye Color Tracing

The horizontal cheese packaging machine can add a photoelectric eye color tracing function, which can help the machine seal and cut bags more accurately, as a result, the cheese products will have neat appearances.

Vacuum Pump

Vacuum pump is a optional function of vacuum cheese packaging machines, as is known that these machines have their own vacuum pumps which are used to suck air. However, you can choose high grade imported vacuum pump which have strong suction so that the efficiency of your vacuum cheese packaging machine will be increased.

Automatic Rectifying Device

Weighing cheese packaging machine has a optional function which is called automatic rectifying device, it is used to correct the moving direction and side errors of the packaging film so that the machine can run normally, the probability of errors in the bag making step will be smaller.

8.How to lengthen the service life of cheese packaging machine?

Do you know how can you use a cheese packaging machine longer? How to keep a good performance of your cheese packaging machine? You must know that regular maintenance is the decisive factor to lengthen the service life of cheese packaging machine.

- Every time you finishing operating the cheese packaging machine, remember to clean it totally, make sure that there are no food crumbs in the corners of your machine.

- There are a variety of metal components inside the cheese packaging machine, if you want to let them keep high flexibility after long-time usage, you need to add lubricating oil on them regularly.

- When your cheese packaging machine has been used for a long time, you need to check whether there are any parts are damaged or loosen, if so, in order not to affect the normal use of the machine, you need to replace the damaged parts or tighten them in time.

9.How to choose the most suitable cheese packaging machine?

Do you know how to choose a proper cheese packaging machine? Have you figured out what factors need to be considered in advance? For most of you who are still puzzled, here are some reliable suggestions to help you.

Production Requirements

It is suggested that you need to figure out your production requirements at first, which kind of cheese product do you need to pack? What container do you want to use to pack cheeses? And also, the size of cheese product and sealing methods need to be put into consideration. These points can help you determine the correct type of cheese packaging machine.

Production Volume

And you also need to consider the production volume of the machine, when you want to buy a cheese packaging machine, you need to make it clear that whether its production volume can meet your production needs.

Packaging Diversity

It is better to choose a cheese packaging machine which has high packaging diversity, in other words, it can be able to pack cheese products which are in different shapes and sizes. Why you need to do that? It is because that a flexible cheese packaging machine can make your production process more convenient, and save your cost.

Reliable Machine Manufacturer

When you want to buy a cheese packaging machine, it is absolute that you need to choose a durable one. What should you do? The most convenient method is to find a reliable machine manufacturer, you can search for the top cheese packaging machine manufacturers on the website, or look the reviews of some manufacturers, to choose a good on.

High Quality After-sales Service

Certainly, the after-sales service is also important, if you buy a cheese packaging machine from a formal manufacturer or supplier, it will provide complete after-sales services which include installation, training, maintenance and warranty. These are necessary for you if you are a novice in cheese packaging field.

Conclusion

After reading this blog, do you think you have a further understanding of cheese packaging machine? As you know that there are different types of cheese packaging machines, which type of them do you think is the most suitable for you? Do you think you know it deeply? If you still have something curious about it, you can contact and consult us.

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide

Cheese Packaging Machine: The Complete FAQ Guide In 2025 Read More »