Case Erector: The Complete Buying Guide In 2025

Are you planning to reduce the cost of your packaging while maintaining the integrity of your goods till deliverance to customers? If so! What is your opinion about using corrugated cartons for packaging? No doubt, corrugated cartons are environmental friendly, cheap in cost and durable enough to protect the texture of your goods. For achieving this purpose, case erector has been brought into the field to form and seal these cartons.

Case erector is the most reliable machine developed to end the manual efforts for packaging products. It uses automatic technology along with other features to accomplish the task. Moreover, the machine has intuitive operation, compact structure and easy maintenance with multiple dimensions. These along with several other aspects of case erector will be disclosed in this buying guide. So, let's discover it!

1.What Is A Case Erector?

Case erector-Picture Courtesy: indiamart

Case erector, also known as case former is a modular machine equipped with well engineered technology for erecting unformed cardboard boxes. The machine is made up of stainless steel body, protector and erecting facilitating tools and stations. By using these components, the machine picks up the cardboard, build it and seal it from bottom side in order to make it usable for packaging.

2.Explain The Benefits Of A Case Erector?

The underlying impeccable benefits of a case erector can help you gain the higher level of production in your packaging while maintaining the quality of cases:

Flexible

Picture Courtesy: Behance

The most prominent feature of a case erector is undoubtedly its resilience. For instance, the machine has been made in such a way that it supports the erection of different sizes cardboard boxes.

Enhance Productivity

Carton packaging workplace-Picture Courtesy: bostoni-nternational-shipping.com

By reducing staff hours, cutting down the time spent on erecting each box, and using automatic technology, case erector leads towards extending your current production. In addition, the basic speed of a case erector is forming 10 boxes per minute.

Reduces Inventory

Small inventory of cardboard boxes-Picture Courtesy: mmh.com

It is obvious that when you use a case erector, even small workplace area would be enough for it. It is because, there is no need to erect hundreds of cases for packaging, rather, you can simply use the case erector for forming required number of cases any time you want.

High Quality Erecting

Apple juice carton-Picture Courtesy: Behance

Using case erector can result in the formation of cases with the strength of 90 degree for all corners. It eventually, avoid leaving room for product friction caused by the unparalleled sides of cases.

Diminishes Shipping Damage

Shipping of packed cases-Picture Courtesy: dutconsulting.com

Most of the hand erected cartons are unsquared because of inadequate force which is required for it. In contrast, case erector is proficient in making uniform cases which ultimately diminishes the shipping damage during stacking.

3.Which Types Of Cases Does A Case Erector Process?

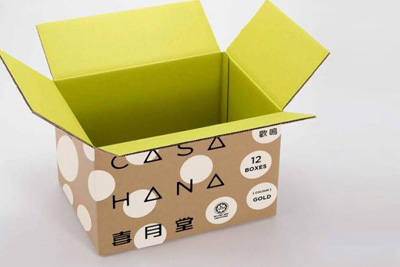

There is great variety in forms of corrugated cases which a case erector is capable of processing. These are shown in the table below:

| No | Type | Description | Picture |

| 1 | Regular slotted containers | Regular slotted containers are the most commonly used cases made up of cardboard. Such cartons have same length of their flaps, therefore, they meet at the point where sealing occurred. |

Opened corrugated carton-Picture Courtesy: Behance |

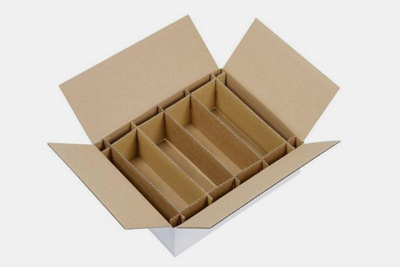

| 2 | Cardboard with inner compartments | This type of corrugated cartons have separate compartments inside them to ensure contactless packaging of items. For instance, chemical products, syrups bottles and glassware items can be collectively packed in this type of cases without any need for worrying about the damage to products. |

Opened cardboard with inner compartments-Picture Courtesy: de-pack.de |

| 3 | Half slotted containers | As the name indicates, half slotted containers have only one set of flaps which are located at the bottom. The top side of cartons has no flaps. Such cases are good for merchandising. |

Orange carton display-Picture Courtesy: halegroves.com |

| 4 | Semi Overlap slotted cartons | As the picture shows, the flaps of semi overlap slotted cartons over one another causing more durable sealing. These cartons are favorable to endure heavyweight, thus, are suitable for electronics, textiles and industrial tools etc. |

Side sealed cartons-Picture Courtesy: thedsgnblog.com |

| 5 | Center special slotted containers | Center special slotted cartons are the most compact cartons made in such a way, that their inner and outer flaps meet at the same point. In this way, the sealing of top and bottom is strong, and the carton can hold things safely without losing strength. |

Packed square case-Picture Courtesy: dribble.com |

4.What Are The Working Principles Of A Case Erector?

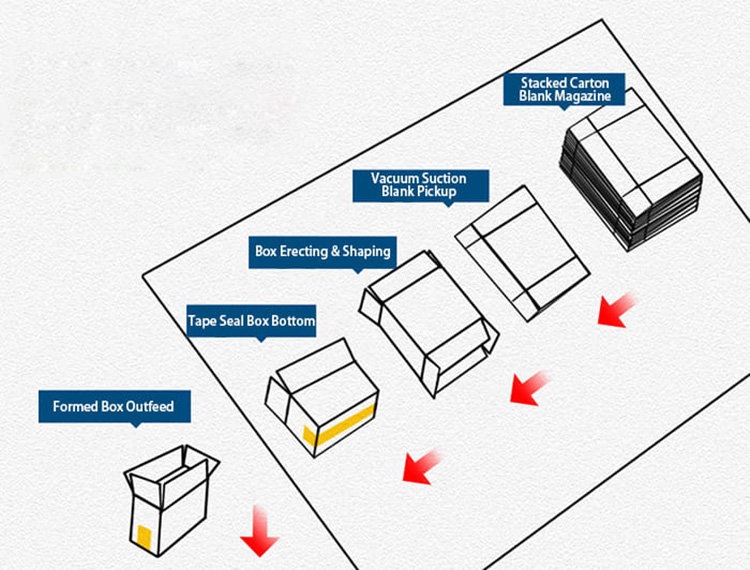

Working principles of case erector-Picture Courtesy: sirosilo.com

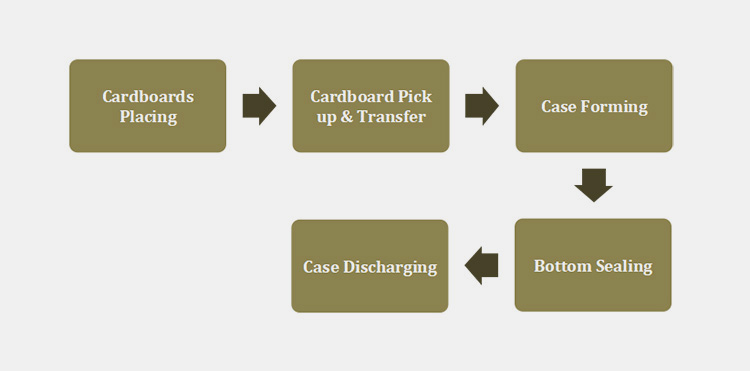

The case erector's mechanism of action is based on uncomplicated and simple working principles which are highlighted below:

Cardboards Placing

The first condition for operating case erector is to place enough number of unformed flat card boards on a blank magazine.

Cardboard Pick up and Transfer

In second step, after the machine is powered on, the vacuum suckers get energized and move ahead towards blank magazine for picking up cardboard through air sucking. After picking, the cardboard is transferred onto the case erecting station.

Case Forming

Now, the vacuum suction cups adopt adverse pulling effects which results in the formation of square case.

Bottom Sealing

At this stage, the plastic plows close the bottom flaps of case and push the case ahead where the taped moving wheels apply the tape to the opening of case flaps. Similarly, the bottom sealing of case take places here.

Case Discharging

At the end, the tucker will discharge the erected case by pushing it out of the machine towards case collection area.

5.Describe The Structure Of A Case Erector?

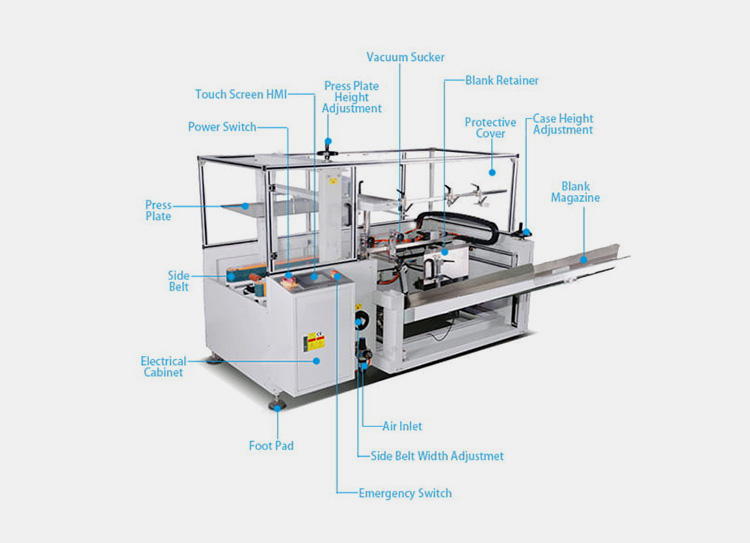

Structure of case erector-Picture Courtesy:

The ergonomic texture of a case erector is the combination of various components which are enumerated below:

Touch Screen HMI

Human machine interface is the touch screen panel located on the front side of machine. It is the key component for the reason of being provided basic parameters for operator adjustment and consequently communicating it to machine for operation.

Power Switch

Power switch is a big button situated alongside control panel. It is used for switching the machine on or turning it off.

Press Plate

Press Plate is a stainless steel flat plate positioned right above the side belts. It performs the function of pressing cases to avoid shaking and form swiftly.

Side Belt

There are two side belts integrated in case erector; one on the right side, while other on the left side. These belts are driven by a motor, when case is erected by the machine, it is pushed towards belts which moves the case out of machine.

Electrical Cabinet

Electrical cabinet is the case erector's brain by holding all the essential components including control system, electric eye, wires, air cylinder and knobs etc.

Foot Pad

There are four-foot pads attached to the case erector. These foot pads help in the stable performance of machine by showing great adherence to the surface and avoid causing vibration.

Emergency Switch

Emergency switch is red colored big round knob which can be clearly seen on the front of machine. It is helpful, when an abrupt break for machine is needed in case of malfunctioning.

Side Belt Width Adjustment

As case erector can form various sizes cases, side belt width adjustment is a great source of assistance to make it possible.

Air Inlet

Air inlet is a small device through which air cylinder supply the machine with air required for vacuum sucking.

Blank Magazine

Among other components, blank magazine is one of the fundamental unit which holds over it the bulk of unformed flat card boards. Its slide type stainless steel body effectively slips the card boards towards machine during process.

Case Height Adjustment

Case height adjustment is a tool used for maintaining the height of cases to be erected.

Protective Cover

The machine has transparent glass or plastic cover surrounded by it, which works as a protector against dust and pollution etc.

Blank Retainer

Blank retainer is situated at the end of blank magazine. Its task is to restrict the slipping of unformed flat cardboard by creating a barrier at the corner or on top until cardboards are sucked by the vacuum suckers.

Vacuum Sucker

Vacuum suckers are small concave type tools made up of flexible plastic. These tools have a hole inward through which air cylinder sucks the air inward and resultantly, the cardboards are attached to vacuum suckers.

Press Plate Height Adjustment

Press plate height adjustment is used for modifying the height of press plate as per case size requirement.

6.What Are The Applications Of A Case Erector?

The uses of a case erector are vast enough that they cannot be enumerated, however, some of the major applications of a case erector have been mentioned as under:

Food Industry - For retaining quality & texture

Orange corrugated cartons-Picture Courtesy: fruit tvizlet.me

Food industry is the foremost area which can never avoid the use of a case erector. Instead, all the food items including perishable, vegetables and fruits, and non-perishable, dry fruits, snacks, and condiments, require case erector's packaging for unharmed transportation on both domestic and international level.

Medical Industry - For preserving hygiene

Various medicines outlook-Picture Courtesy: Freepik

Now, the second most prominent sector with having enough demand for a case erector is no doubt medical industry, where all the items from pharmaceutical medicines to surgical tools are packed in corrugated cartons by taking help of this machine.

Chemical Industry - For ensuring safety

Chemical test tubes-Picture Courtesy:American Artists Representative

Similar to other fields, chemical industry also needs a case erector especially for the packaging of liquid chemicals for the purpose of ensuring their safety and avoiding any sort of haphazard which may create dangerous outcomes.

Hardware Industry - For maintaining sterility

Lamp packaging idea-Picture Courtesy: Bioscabotey.es

The jurisdiction area of hardware industry is unlimited. Let's talk about your routine, where you must be using a glass for drinking water, watching television while sitting in your drawing room and enjoying the cold sensation produced by the air conditioner. So, all these objects are hardware in nature which are packed in cardboard cartons erected by a case erector.

Textile Industry - For convenient portability

Textile market-Picture Courtesy: flickr.com

Textile industry is among other sectors to avail the services of a case erector for being significant tool to provide convenience in the packaging and portability of various types clothes.

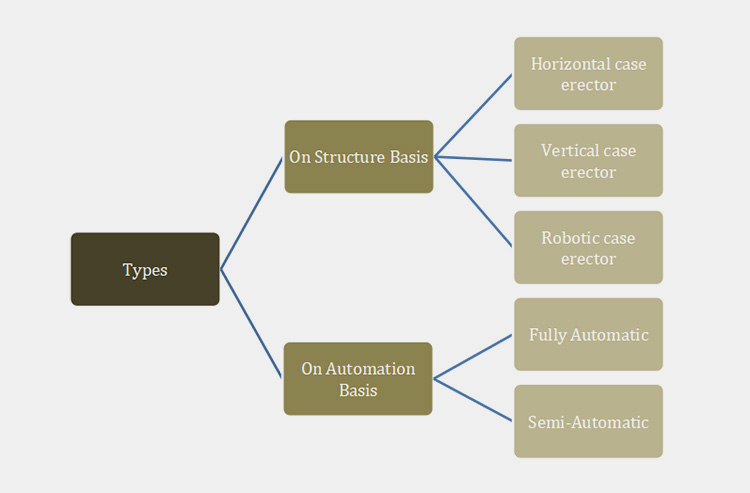

7.Enlist The Various Types Of A Case Erector?

Case erector may be found in various forms depending upon their functions and degree of automation they have. Therefore, following categorization of a case erector has been made for your ease:

Fully Automatic Case Erector

Automatic case erector-Picture Courtesy: gurkipack.com

The automatic case erector is an innovative machine assembled with intuitive PLC operating panel, vacuum suction system, air cylinder and robust stainless steel body. It is independent in cardboard picking, transfer, molding, folding and finally bottom sealing. This machine is perfect for large scale industries where the there is large volume of cases to be erected including food, medical and hardware industries etc.

Semi-Automatic Case Erector

Semi-automatic case erector-Picture Courtesy: wexxar.com

Semi-automatic case erector is versatile, but precise machine configured with automatic features. It is adopted for meeting good number of production by using affordable and reliable machine which can effectively achieve the concerned task with little manual intervention. The machine has small footprint consists of casters, stainless steel body, moving handle, case erecting and bottom sealing station. Semi-automatic case erector is suitable for medium scale industries.

Horizontal Case Erector

Horizontal case erector-Picture Courtesy: tbs-pack.de

Horizontal case erector is using latest and excellent technology to pack the different sizes cases while maintaining their safety against damage. It is often reliable for erecting small cases due to its compact structure which consists of a main frame, vacuum suction cups, blank magazine, flaps folders, bottom sealer and case discharger. It can be easily integrated into any production line for achieving the ultimate end of packaging your objects.

Vertical Case Erector

Vertical case erector-Picture Courtesy: gurkipack.com

Vertical case erector is high speed servo machine made with exceptional features to aid the perfect forming and bottom closing of large size cases. It has high stability ratio even for wrinkled cases. The machine is made up of servo system, electric detection system, control system and other hardware gadgets to make 90 degrees in all the corners of a case. Vertical case erector has proficiency in erecting large number of cases in short time, therefore, it is often found suitable for industries including tobacco, pharmaceutical, food, and hardware etc.

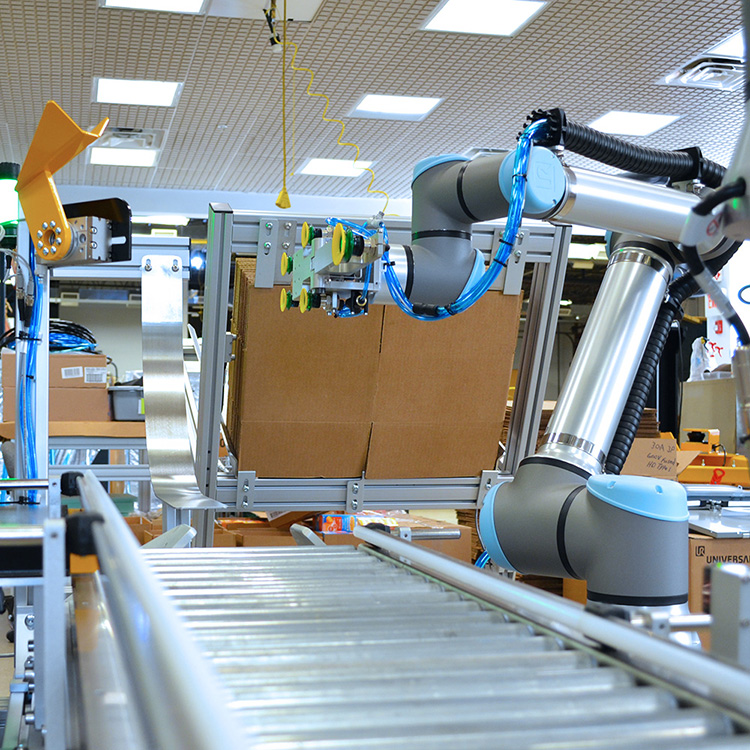

Robotic Random Case Erector

Robotic random case erector-Picture Courtesy: Onexia Robotics

Robotic random case erector is a modular machine with power of erecting up to four cases at a single time. It is composed of a robotic arm, multiple magazines for various sizes cases and a case erecting station. The robot pick up unformed cardboard and pass through the erecting station where case is first formed and then sealed simultaneously. Similarly, the robot places the erected cases onto guide rail or conveyor. This machine is perfect for large scale areas where goods are packed for wholesale markets or exportation.

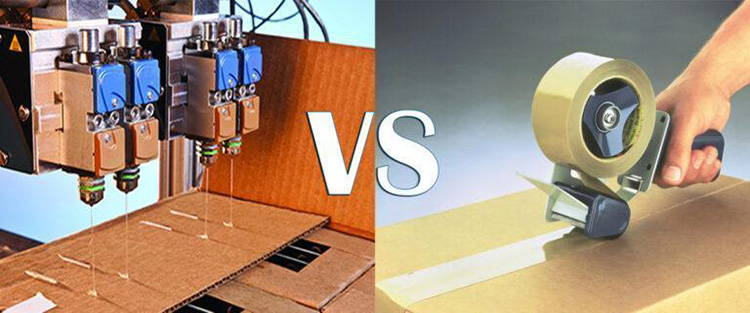

8.Differentiate Between HotMelt Glue Case Erector And Tape Case Erector?

Hot melt glue case erector and adhesive tape case erector are two different machines designed for accomplishing the same task. Following table is helpful to understand both the machines through distinctions prevailing between them:

| No | Features | Hot Melt Glue Case Erector | Tape Case Erector |

| 1 | Definition | Hot melt glue case erector is a machine employed to form and bottom seal the cases with glue | Tape case erector is a standard machine designed to erect and bottom seal the flat corrugated cartons |

| 2 | Structure | It consists of mainframe, blank magazine, control system, glue holding hopper and glue applicators | The machine is made up of stainless steel body, case feeding magazine, tape holder and applicator etc. |

| 3 | Sealing Material | Hot melt glue | Adhesive tape |

| 4 | Process | It picks up the blank case, form it, fold the flaps and seals the bottom via hot melt glue | It takes the flat cardboard, erect it, turns the flaps and close them through adhesive tape |

| 5 | Benefits | Long shelf life, high enduring power and low environmental degradation | Moisture resistant and cost-effective |

| 6 | Picture |

Hot melt glue case erector-Picture Courtesy: getpacked.com |

Tape case erector-Picture Courtesy: sting-pack.com |

9.Which Other Machines Can Be Integrated With A Case Erector To Make A Production Line?

Production line for a case erector-Picture Courtesy: kivo.nl

A case erector may be integrated with large number of machines for the easy packaging of your goods. These include:

Cardboard Box Making Machine

Cardboard box making machine is an inevitable equipment which is used alongside case erecting machine. It has been resulted by the upgradation in cardboard box making machine. The machine proficiently performs multi functions of slotting, scoring, creasing, slitting and ultimately cutting of the card boards to turn them into fresh unformed boxes.

Bag Inserter

Bag inserter is a machine designed to carry out the task of inserting different types of plastic and poly bags into erected cases. The machine starts working by taking plastic film from roller, turn it into a bag and insert the bag into a case.

Weigh Filler

Weigh Filler is an extremely important machine used along with a case erector. This machine has been engineered with ergonomic characteristics to facilitate the safe and automatic packing of goods into erected corrugated cases. Apart from weigh filler which is used to fill objects like tea leaves, coffee beans and grains etc., into cases, there is another machine used for filling of countable objects including bottles, bags and containers etc., which is called case packing machine.

Bag Closer

Bag closer is the part of production line for case erector which has been assigned with the task of closing bags laying inside the cases. It uses heat to seal the mouth of plastic bags.

Case Closer

Case closer is an important device employed to undertake the final closing of cases, after they get packed with commodities. The machine is also known as carton sealer due to affiliated task of sealing cartons via adhesive tape or hot melt glue.

Palletizer

Palletizer is a machine equipped with heavy-duty structure and advance technology for achieving highly responsible task of palletizing packed cases. It works by sorting, transferring and stacking cases onto a pallet.

Stretch Wrapping Machine

Stretch wrapping machine is optional but play important role in providing the strength to integrity of cases. The machine has a turntable over which a palletizer is kept. The machine holds a flexible plastic and wrap it around the cases laying over palletizer. Finally, the packaging process end here leading the manufacturers to mobilize their products to ships, cargos and trucks for transportation.

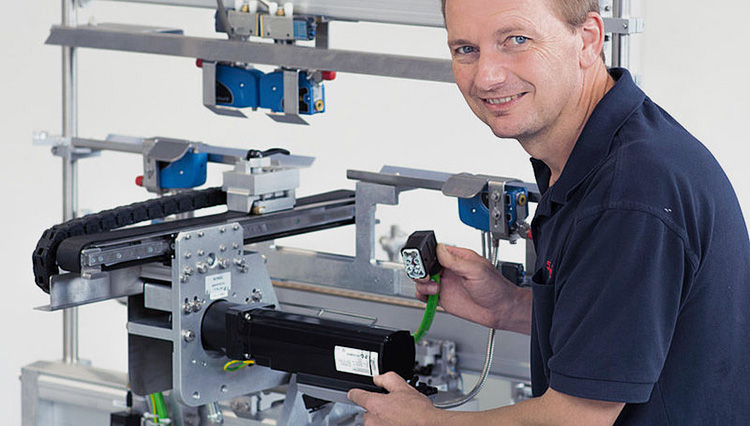

10.What Is The Preventive Maintenance Of A Case Erector?

Operator maintaining machine-Picture Courtesy: somic-packaging.com

Maintaining your case erector and operating it in a suitable environment are two crucial aspects for successful business operation. Therefore, to make you aware of the preventive maintenance of a case erector, we have highlighted some of the important steps for you to follow:

Safety precautions:Make sure to only allow the well-trained and experienced personnel for operating a case erector, otherwise, the mistakes of unqualified staff can hamper the way for successful completion of your case erecting.

Machine examination: During process, keep checking the incoming power to machine for adequate voltage and frequency. Also examine the pneumatic tools, spare parts and vacuum system.

Lubrication:Lubrication of conveyor system, linear breaking, shaft bearings and oil tank is necessary, however, excessive lubrication must be avoided as it can cause product contamination.

11.Give Remedies To Solve The Malfunctions Caused By A Case Erector During Operation?

It is obvious, that every machine has a chance of malfunctioning during operation, which if not solved timely, can cause great loss in form of product or machine damage. Hence, to equip you with troubleshooting in advance, below table is containing the relevant details:

| No | Malfunction | Causes | Remedies | Picture |

| 1 | The vacuum sucker do not produce strong pulling effects | There might be issue in air cylinder to maintain the regulation of air | Check the air inlet, if blocked then clean it |

Vacuum suckers-Picture Courtesy: gurkipack.com |

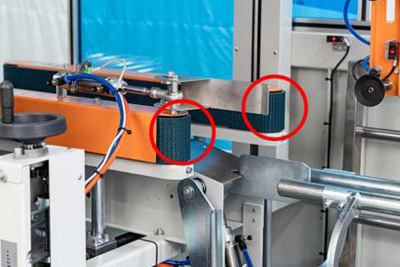

| 2 | There is problem in cutting adhesive tap | It may be due to unsharp reamer patch or jammed cutter tine | Clean the tape cutter and lubricate the reamer patch |

Encircled adhesive tape cutter-Picture Courtesy: kitmondo.com |

| 3 | The tape has a rough tail | Either the cutter is blunt or the pulling spring is loose | Remove the adhesive debris from cutter and tight the tape pulling screws |

Bottom sealing section of a case erector-Picture Courtesy: sirosilo.com |

| 4 | The case is blocked in the midway | Too much tight press plate and side belts suffocate the movement of a case | Adjust the height of press plate and width of side belts |

Encircled side belts-Picture Courtesy: gurkipack.com |

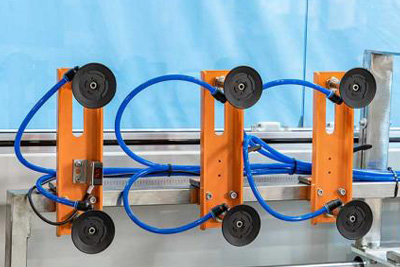

| 5 | The application of tape is off the track | It happens when the guiding wheel has unparalleled pressure | Make sure to accurately adjust the space of guiding roller each time using new cases |

Encircled labeling wheels-Picture Courtesy: kitmondo.com |

12.What Should Be Considered To Get The Best Case Erector?

In order to get the best case erector, it is important to consider several factors regarding the machine, its features as well as its assurance. These factors are enlisted below:

Reliability

Planning & project management idea for carton packaging-Picture Courtesy: hillman-consulting.co.uk

Cost-effectiveness, resilience, user-friendly operation and innovative features are the all colors which makes the term reliability meaningful. Hence, it is necessary to consider all these factors for purchasing the best case erector.

Method of Sealing Cases

Glue vs tape sealing-Picture Courtesy: appliedadhesives.con

Which method of sealing does the case erector use? Is it hot melt glue or adhesive tape sealing? If your products are heavyweight then hot melt glue case erector is the right option. On the other hand, adhesive tape sealing machine is suitable for light weight and sensitive products like medicines.

Degree of Automation

What is the ratio of your production? Is it higher reaching to hundreds of cartons on daily basis or is it limited to small number? Answering this question will ultimately lead you to either opt for a freestanding unit or packaging line.

Quality Assurance

Quality icon-Picture Courtesy: far-reaching.com

Never forget that you are going to change the fate of your business by introducing new case erector. It implies, that you must have confidence in the quality of supplier as well as their services. Therefore, to fulfill these requirements, you can check the quality certifications of the machine, the available warranty as well as after sale service for remote support and spare parts.

Conclusion

To summarize the discussion, case erector is the most desirable machine every medium to large scale industries want for their effective packaging and efficient production. It allows you to form and seal the cartons of your favorable sizes with precise erecting. Apart from that, Allpack case erector comes with distinct features and one year of warranty along with 24 hours available service for customer support. If you are concerned about purchasing a case erector, feel free to contact us!

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide