What are the Advantages of Carton Packaging?

What are the Advantages of Carton Packaging?

Do you know why businesses more frequently use carton packaging? Why are carton packaging options becoming increasingly popular among enterprises? What makes it different from other packaging choices, and why is it becoming more and more favored in the current market?

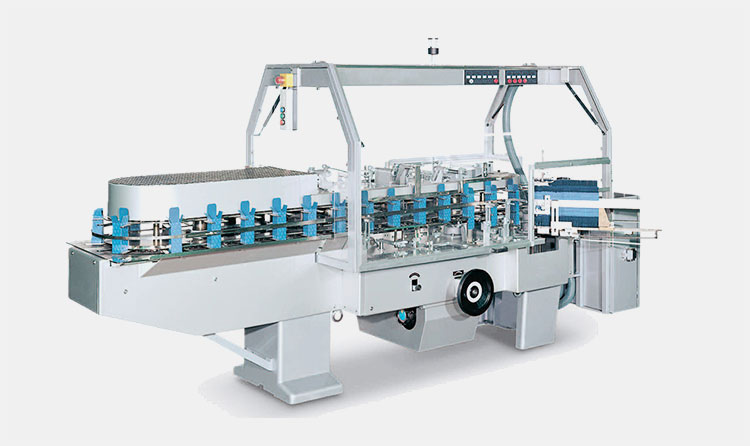

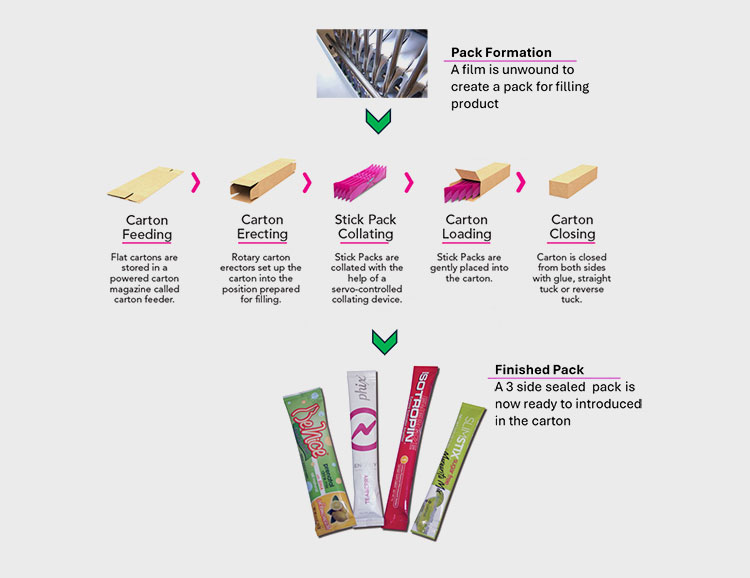

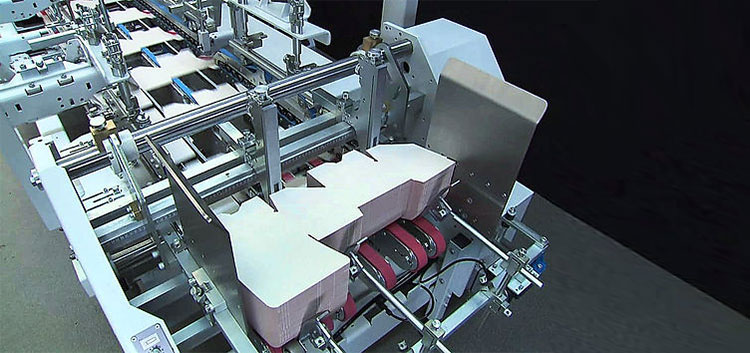

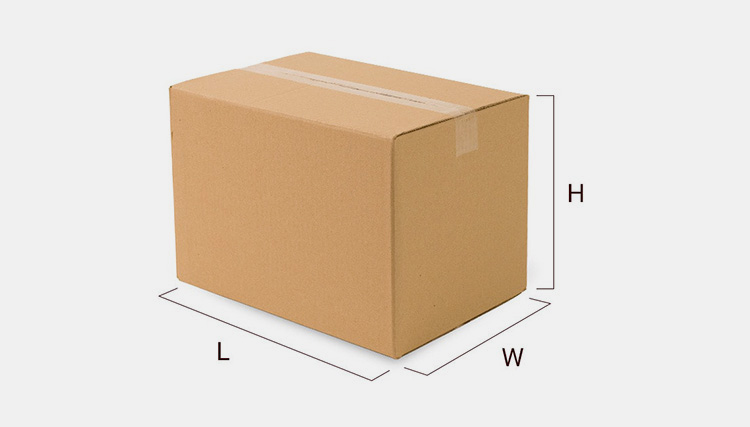

Picture Courtesy: PackMoo

Due to increasing environmental concerns, organizations are looking for more eco-friendly solutions for packaging without sacrificing utility or quality. So, how does carton packaging contribute to waste reduction and resource preservation?

Carton packaging is made primarily from recyclable and sustainable materials. It offers numerous incredible benefits, including reducing environmental impacts and improved product preservation. Moreover, it is a versatile solution that can be utilized for multiple product types across industries.

This article explains the main advantages of carton packaging, such as its affordability, practicality, and eco-friendliness, and demonstrates why it is the go-to option for contemporary packaging requirements.

1.Carton Packaging and its Types

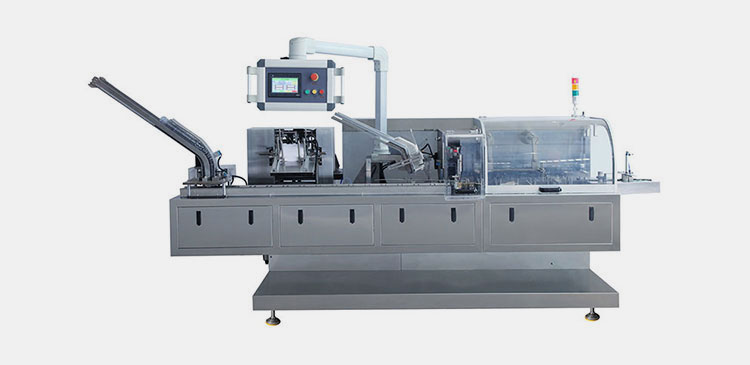

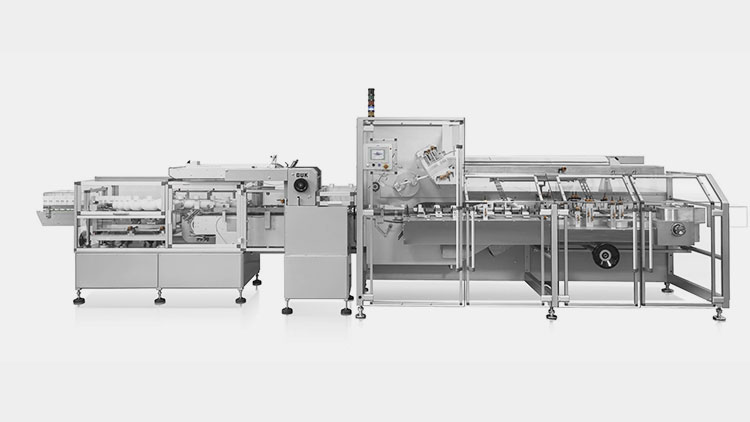

Carton Packaging – Picture Courtesy: PackMoJo

Carton packaging is a common and versatile type of packaging, typically composed of cardboard or paperboard. Being composed of sustainable resources and frequently recyclable, it's an environmentally beneficial choice.

Packaging is an inevitable segment of several businesses, whether you own a traditional business or running an e-commerce enterprise. Carton packaging is ideal for a variety of sectors, including food, drink, and household products, since it is portable, resilient, and secures items. Apart from the protection factor, it is also a crucial element in serving your marketing purposes.

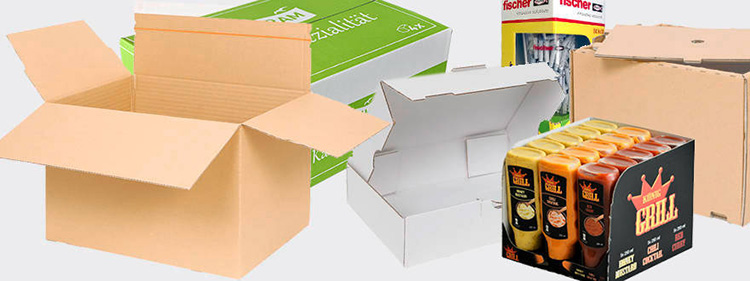

Types of Carton Packaging

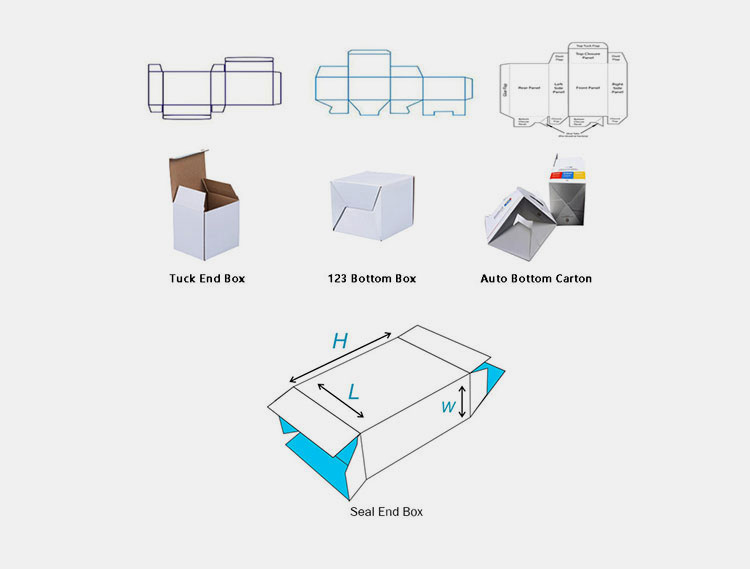

Carton packaging can be broadly classified into two major types. They both have crucial functions in packaging, but their uses, structures, and costs are very different. These types are further described below:

Folding Carton Packaging

Folding Carton Packaging

Folding cartons are also known as paperboard cartons. They are flexible and lightweight and typically shipped flat to save space during storage and transportation. When they are being packaged, they are folded into a shape. They are usually designed from a single paper sheet.

Furthermore, they are also customized with printings and coatings to meet branding needs. The typical use of such packaging includes cereal boxes, pharmaceuticals, and food boxes (fast food etc).

Rigid Carton Packaging

Rigid Carton Packaging

Rigid cartons are non-collapsible and offer a more substantial, robust construction. They are frequently utilized for upscale or premium goods where preservation and display are essential.

They are composed of thicker cardboard or paperboard, providing extra strength and durability. In some of its versions, the two parts of such cartons (top and bottom halves) are detached and are typically made from different materials. These boxes can be personalized with premium finishes, creating a sumptuous unpacking experience.

They are comparatively more expensive due to the quality of construction materials. Rigid cartons are often used for shoe and electronic goods packaging.

2.Various Forms of Carton Packaging in Use

The two types of carton packaging come in several forms, each with unique features and advantages. Some common forms of carton packaging are described below:

Paperboard Carton Packaging

Paperboard – Picture Courtesy: Box Agency

Paperboard Carton Packaging – Picture Courtesy: WestRock

Paperboard boxes are lightweight cartons that are made up of thick paper. The benefit of using such cartons is that they can be customized with colorful printing and are easily folded. They are popularly utilized for products to be kept on shelves of retail stores.

These cartons are laminated to add the desired strength and water resistance. The un-laminated paperboard cartons can be recycled easily. The common products that are packaged in paperboard cartons include cosmetics, pharmaceuticals, cereals, and other consumer products.

Corrugated Carton Packaging

Corrugated Board

Corrugated Carton Packaging – Picture Courtesy: Cactus Containers

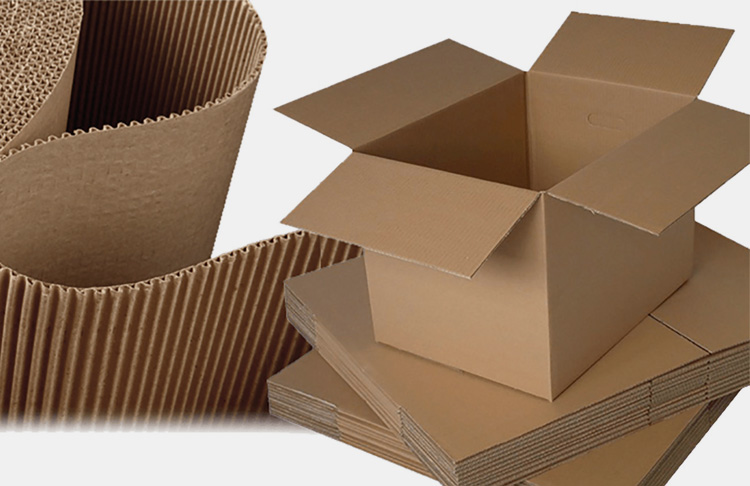

Corrugated cartons are the most commonly used boxes for packaging multiple products. They are composed of corrugated sheets, each comprising three layers of paper (the middle wavy layer, which is also known as a flute, is sandwiched between two flat layers). The wavy paper layer provides a tempering effect to the product.

These boxes are lightweight, yet strong and durable. They are available in varying sizes and thickness. They are frequently employed for product storage and shipping. They offer extra protection to fragile goods.

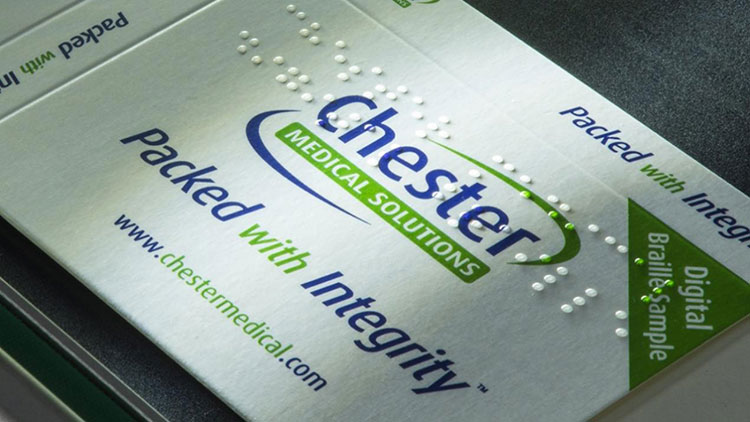

Braille Carton Packaging

Braille Carton Packaging

These cartons include embossed braille characters for the convenience of blind or visually impaired individuals. These boxes help them to identify products. They are typically used in the food and pharmaceutical industries.

Slotted Carton Packaging

Slotted Carton Packaging

These cartons are structured with foldable slots to provide safe and simple-to-assemble packaging. They are composed of corrugated paper sheets and are perfect for goods that need to be packaged in a flexible, protected manner. They are frequently utilized for packing for online sales and shipment.

Aseptic Carton Packaging

Aseptic Carton Packaging

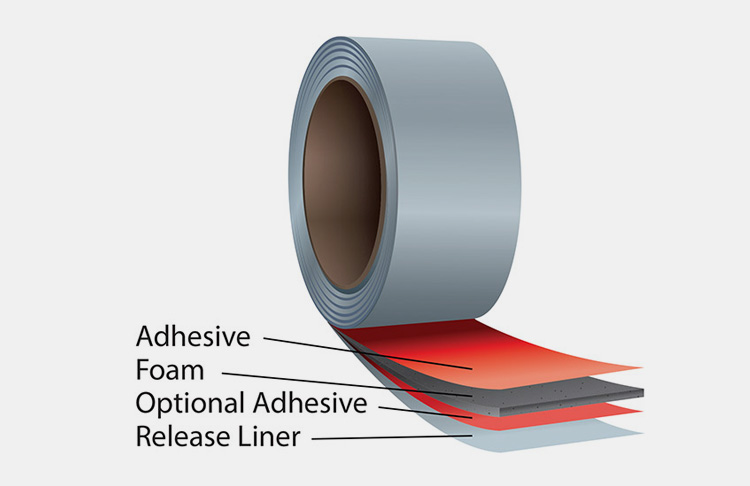

Aseptic carton packaging is designed with multiple layers of sustainable materials, like paperboard, plastic, and aluminum. These layers are attached using different methods, such as heat or adhesives. Due to the multi-layer arrangement, these cartons are difficult to recycle.

These boxes keep the products sterile, secure, and preserved, increasing their shelf-life. They have a special property of withstanding extreme environmental conditions. They are typically employed for liquid products, such as milk, juice, soups, and other perishable items

3.What are the Advantages of Carton Packaging?

Several incredible benefits carton packaging offers to your business are described below:

Effective Protection

Effective Protection

Carton boxes provide strong and long-lasting packaging, creating a protective shell that encloses your delicate item. Cartons, as opposed to flimsy plastic bags, are robust and sturdy enough to tolerate several knocks during product transportation.

Apart from the physical protection, carton packaging also protects your product against microbial contamination. During extreme temperatures and long transportation routes, your product may get muggy, resulting in microbial growth. Here comes the role and importance of carton boxes. These boxes will shield the product from getting muggy.

Food and medication goods need this form of protection more than anything else since they are more likely to become wet and degrade.

Cost-Effective Solution

Cost-Effective Solution

Another remarkable benefit of carton packaging is its cost-effectiveness. The construction materials of carton boxes are inexpensive, so the price of these boxes is low. Furthermore, these boxes have a flat surface and can be piled up on one another, reducing space requirements during storage and transportation. This results in the reduction of overall storage and transportation costs.

And most importantly, we know that these boxes are recyclable, so money can be saved using recycled carton boxes.

Customization

Customization

Carton packaging can be easily customized according to your needs and demands. They have excellent ink absorption features, allowing you to imprint texts or colors to make your packaging elegant and appealing. Moreover, the boxes can also be customized to your desired size.

More significantly, the personalization of cartons can help increase brand recall. Carton printing options include your logo, trademark color, and product details. This enables your business to establish a distinct, identifiable brand in the eyes of the public.

Environmental Friendly Option

Environmental Friendly Option

You might be aware of the increasing worldwide tendencies toward sustainability. And this also applies to the packaging sector. Carton packaging is the global demand for a sustainable packaging solution. The majority of carton boxes are composed of recyclable materials, reducing the environmental impacts of packaging.

This is beneficial not just for the environment but also for branding. Businesses that employ carton packing are typically thought of as being highly ecologically aware. Consequently, customers will see the organization as having a strong sense of social responsibility.

Flexibility

Flexibility

Carton packaging is a highly adaptable solution. They come in several-size boxes. You can adopt the perfect-sized carton for your products. Many businesses highly acknowledge such flexible adaptation.

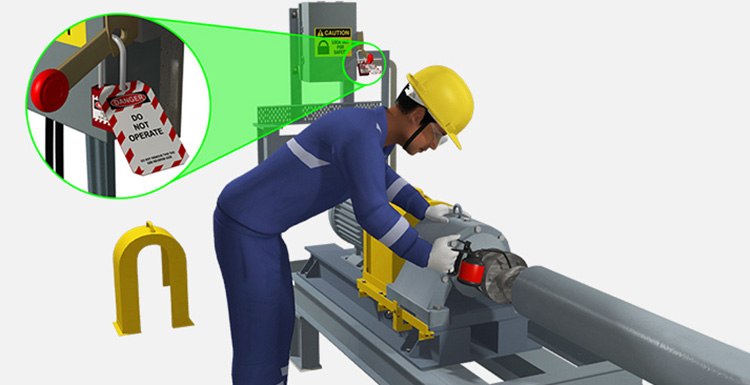

Temper-Evident Featuring

Temper-Evident Featuring

Carton packaging can be designed with temper-evident features, providing additional safety and evidence of product damage or opening before the end consumers take it. This feature satisfies the customer and helps increase confidence in the integrity of the pharmaceuticals. This feature is frequently used in the pharmaceutical industry due to the critical nature of medical goods.

4.Applications of Carton Packaging

Carton packaging is employed in several sectors because of its adaptability, environmental sustainability, and safety properties. Some of the major industries that mostly depend on carton packaging are listed below:

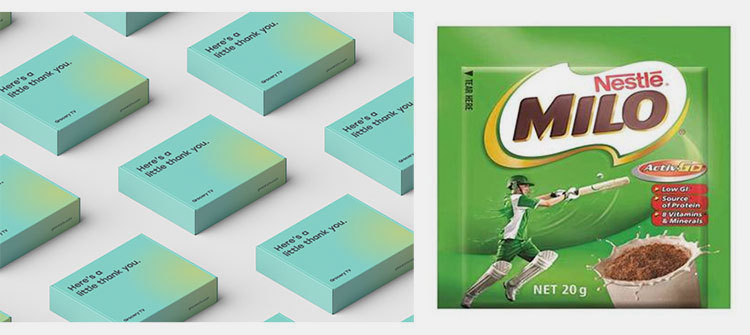

Food and Beverage Industry

Applications of Carton Packaging in the Food & Beverage Industry

Various forms of carton packaging are used to package dry goods, frozen items, dairy goods, snacks, and beverages. These boxes preserve the product’s freshness for a long period and keep them secure during shipping and stocking.

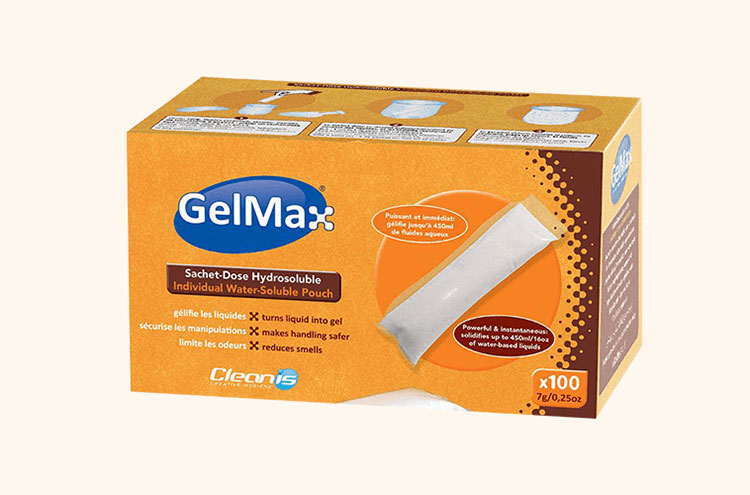

Healthcare Industry

Applications of Carton Packaging in the Healthcare Industry – Picture Courtesy: CCL Healthcare

Several healthcare items, such as drugs, medical devices, supplements, and other healthcare goods are securely packaged in carton packaging. These cartons are easily customizable according to the product’s size. Additionally, carton packaging can be personalized with accessibility features (such as Braille) and temper-evident properties to keep the product secure during shipping.

Personal Care Industry

Applications of Carton Packaging in the Personal Care Industry

Several cosmetic goods, like lotions, creams, shampoos, and makeup items are effectively packaged in carton packaging. The cartons provide a high-end appearance and feel, are readily customizable with choices for superior finishing, and strengthen the visual impact of the brand

Consumer Electronics Industry

Applications of Carton Packaging in the Consumer Electronics Industry – Picture Courtesy: Zenpack

Customized carton packaging is also utilized for multiple electronic gadgets, such as tablets, headphones, mobiles, and smartwatches. The cartons offer branding possibilities and safeguard delicate gadgets during transportation. Rigid carton boxes may add an elegant touch to the unpacking experience.

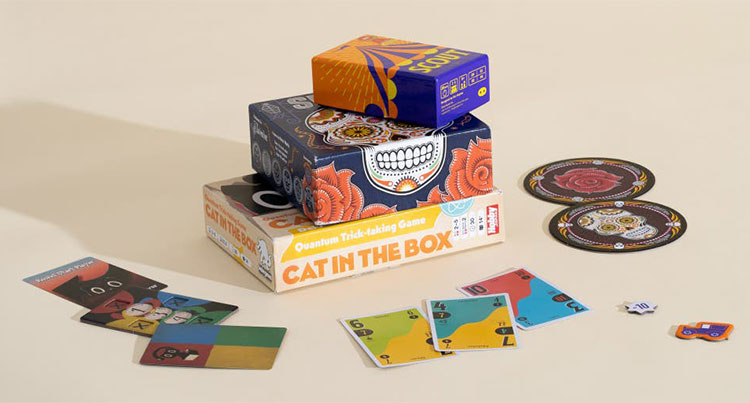

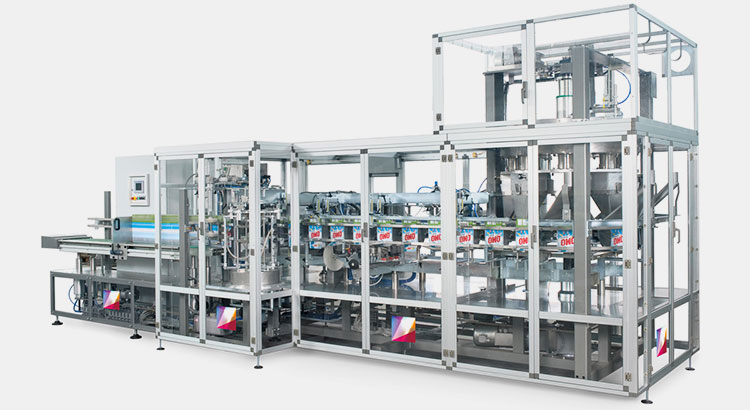

E-commerce and Retail Industry

Applications of Carton Packaging in the E-Commerce & Retail Industry

In the e-commerce and retail sector, corrugated and slotted carton packaging is frequently used for shipping multiple goods. These boxes protect goods during transportation. They can be stacked easily and customized to adjust during shipping and storage.

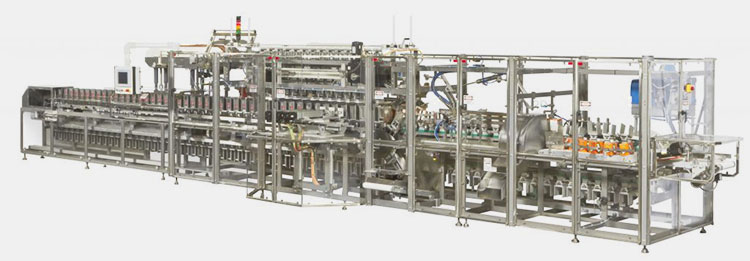

Home Appliances Industry

Applications of Carton Packaging in the Home Appliances Industry

Kitchenware, glassware, and other home appliances are effectively packaged in various carton packaging. Slotted and corrugated boxes are often used for heavy and fragile appliances, ensuring product stability and safety.

Textile and Footwear Industry

Applications of Carton Packaging in the Textile & Footwear Industry – Picture Courtesy: Bags

Carton packaging also provides secure shipping and storage of shoes, clothing, and other accessories. The cartons offer a decent and environmentally responsible alternative for premium or designer goods, improving the shopping experience for customers with eye-catching packaging.

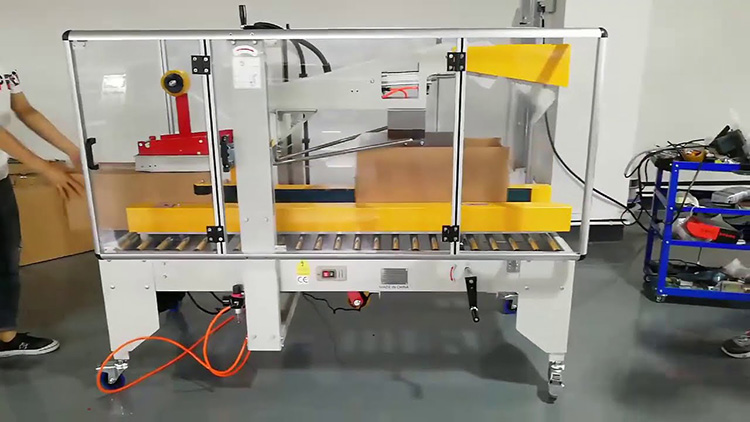

The Bottom Line

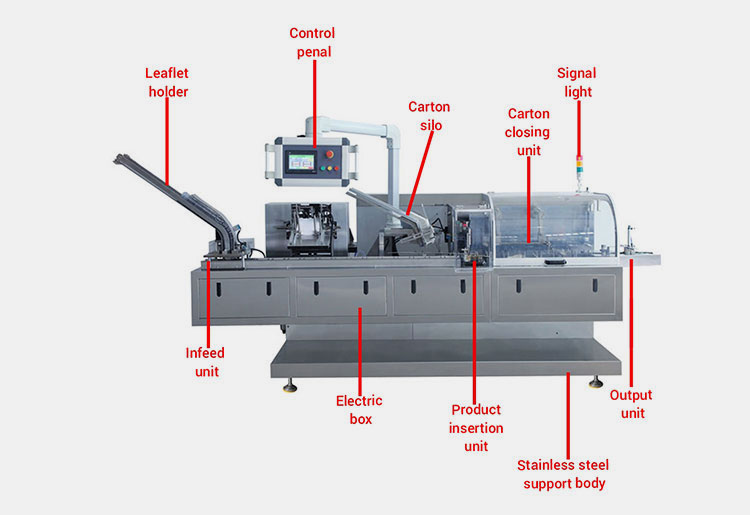

Carton packaging is not merely a packaging container. It has several advantages, from effective product protection to reducing environmental effects. It has several applications across industries due to its durability, strength, versatility, and adaptation. Whether you own a retail setup, e-commerce, apparel, logistics, or high-end items business, carton packaging is exactly your perfect solution. So, why not provide your brand with the appropriate packaging? When your product enters the carton packaging market, it will stand out as the most visually striking item on the racks. If you want to know more about the advantages of carton packaging, or our automatic cartoning machine,please feel free to contact the Allpack, you will be guided in a better way!

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide

What are the Advantages of Carton Packaging? Read More »

Tell us your material or budget, we'll reply you ASAP within 24 hours

Tell us your material or budget, we'll reply you ASAP within 24 hours