Your Best Capsule Polishing Machine

- Adopt Frequency Converter

- Sensitive, Reliable, and Stable

- Excellent Design for Quick Cleaning

Capsule Polishing Machine

Allpack capsule polishing machine is designed basically to inspect capsules after powder filling operation prior to final packing. Filled capsules travel from the hopper to the vibrating tray and passes through the inspection belt, which is provided with light arrangement for visual inspection of damaged or rejected capsules prior to polishing. All Allpack capsule polishing machine uses the rotating brush principle to clean the capsules on continuous basis. Capsules are fed into the polishing chamber where a rotating spiral brush removes the powder particles sticking from the outer surface of capsules. The polishing chamber is to be connected to a vacuum cleaner to suck the de-dusted powder from the polishing chamber. This helps improving the polishing quality of capsules.It not only has a polishing function, but also has a sorting function to eliminate static electricity.

Capsule Polishing Machine

HPT-II Capsule Polisher with Sorter

Allpack HPT-II capsule polisher is a special capsule polishing machine with the sorting function. It can not only remove the dust on the surface of the capsule to improve smoothness and eliminate static electricity, but also it can take advantage of neoteric waste rejecting device with negative pressure to automatically reject the capsule which has small filling volume, empty shell, fragment, and separation of capsule body and capsule cap. The machine is suitable for all types of capsules. All parts of this machine adopt fast connection devices, and they can be dismantled for cleaning and connected quickly, which is very convenient and quick.

Adopts frequency converter

Sensitive, reliable, and stable

304 stainless steel

NFJ-150 Automatic Capsule Polishing Machine

Allpack NFJ-150 automatic capsule polishing machine is an advanced capsule polishing machine with sorting function, the whole machine is made from stainless steel, fast connection of roller brush leads to disassemble easily and clean thoroughly. Frequency inverter controls the speed of the motor, so it can bear big start-up force and run very stably and reliable. It is not only applied to polishing capsule,and eliminating the static electricity, but also applied to ejecting empty capsule, little dosage capsule, separated capsule and fragment, this machine is suitable for all sizes of capsules without the need to change parts.

Automatically reject ultra light weight capsules

Excellent design for quick cleaning

Adopts frequency converter

The Buyer's Guide

Capsule Polishing Machine:The Complete Buying Guide In 2025

As an auxiliary machine of the capsule filling machine, capsule polishing machine is able to provide the final process for the capsules – polishing. Capsule polishing machine contributes the final important force to the final product of the capsule, and is a very important machine. Let’s take a look at the role of the capsule polishing machine!

1.What Is A Capsule PolishingMachine?

Capsule Polishing Machine

Capsule polishing machine also called as capsule polisher, is a special polishing equipment for capsules and tablets. The capsule polishing machine can remove the dust on the surface of capsules and tablets, improving the surface finish, and is suitable for the production of various capsules and tablets.

Capsules and Tablets

2.Why You Need A Capsule Polishing Machine?

Capsule polishing machine is an essential equipment for manufacturing capsules and tablets. This equipment can complete the polishing, sorting and vacuuming of the capsules, so that the capsules can be well ingested and digested by the human body.

Capsule Polishing Machine

Clean and Nice

Capsules

Capsule polishing machine can be specially used for capsule polishing and sorting to remove dust on the capsule surface and improve the smoothness of the capsule surface. It can make polished capsules brighter, cleaner and more beautiful.

Widely Applied

Capsules and Tablets

Capsule polishing machine is widely used in pharmaceutical, food, chemical and other industries. And the capsule polishing machine complies with relevant standards such as GMP, CFR and FDA, and may provide you with customized services.

Auxiliary for Capsule Filling Machine

Capsule Filling Machine

The capsule polishing machine can not only be used alone, but also can be connected to the capsule filling machine for supporting use. This can facilitate the timely removal of dust from the filled capsules and facilitate bottling.

Cost Saving

The models of capsule polishing machines are generally designed to be very compact and used in conjunction with capsule filling machines. Therefore, the price of capsule polishing machines is generally more affordable. And the cost of manual selection can be saved, making the work more efficient.

There are so many ways that we can benefit from capsule polishing machine. If you need a capsule filling machine, then you must need a capsule polishing too. With so many benefits, then you now need to have a deep consideration to buy a right and good one for yourself.

3.How Many Types Of Capsule PolishingMachines Are There?

According to the spindle layout characteristics of the polishing machine, capsule polishing machines are divided into a vertical capsule polishing machine and a horizontal capsule polishing machine.

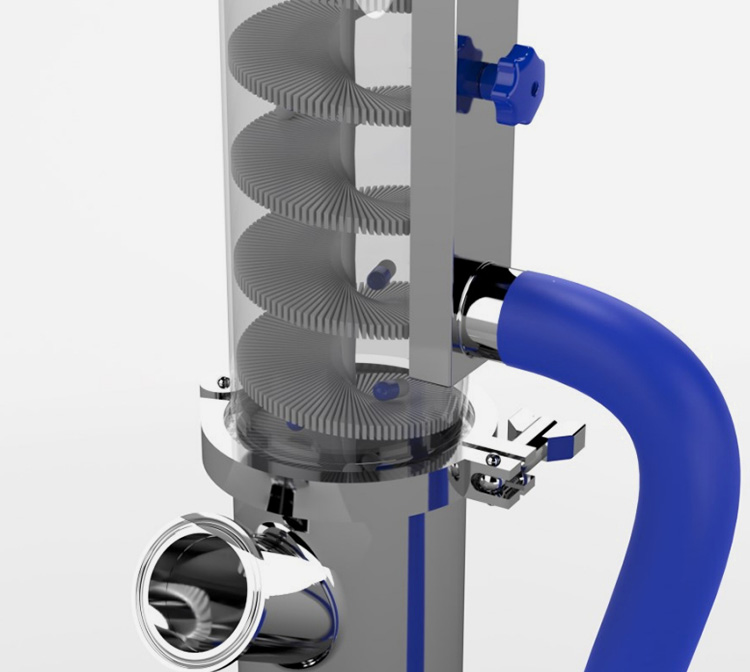

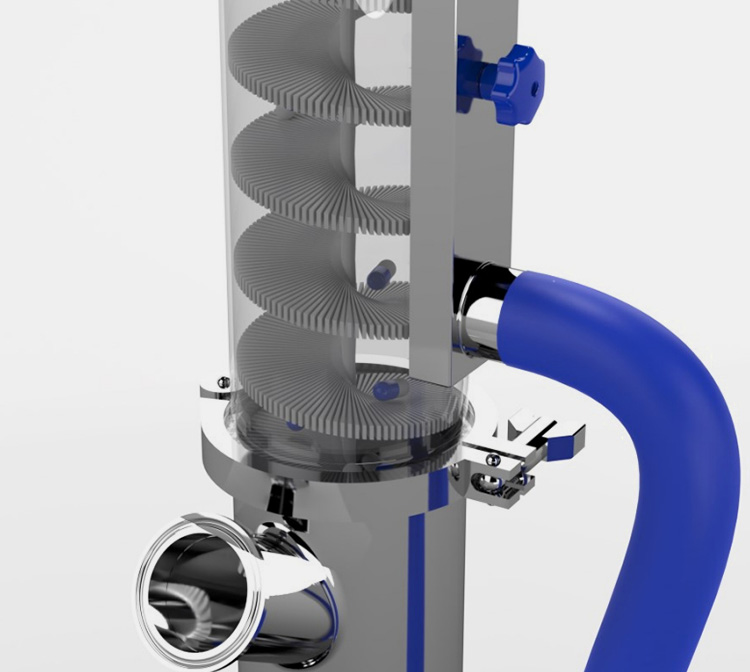

Vertical Capsule Polishing Machine

Vertical Type

Vertical capsule polishing machine has dual functions of capsule polishing and lifting. The entrance of the machine can be connected with any type of capsule filling machine.

Export

The export can be connected with capsule sorting device and metal testing machine.

Polishing, Lifting, and Sorting

To achieve polishing, lifting, sorting, testing of the production model. The machine adopts a number of new technologies and human design concepts.

Horizontal Capsule Polishing Machine

Horizontal Type

Horizontal capsule polishing machine can effectively remove the dust on the surface of the capsule to get high surface finish and eliminate the static electricity. It is suitable for all capsules of different sizes.

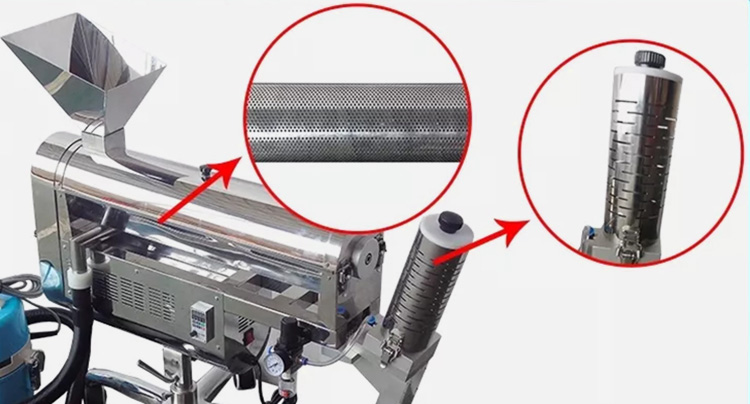

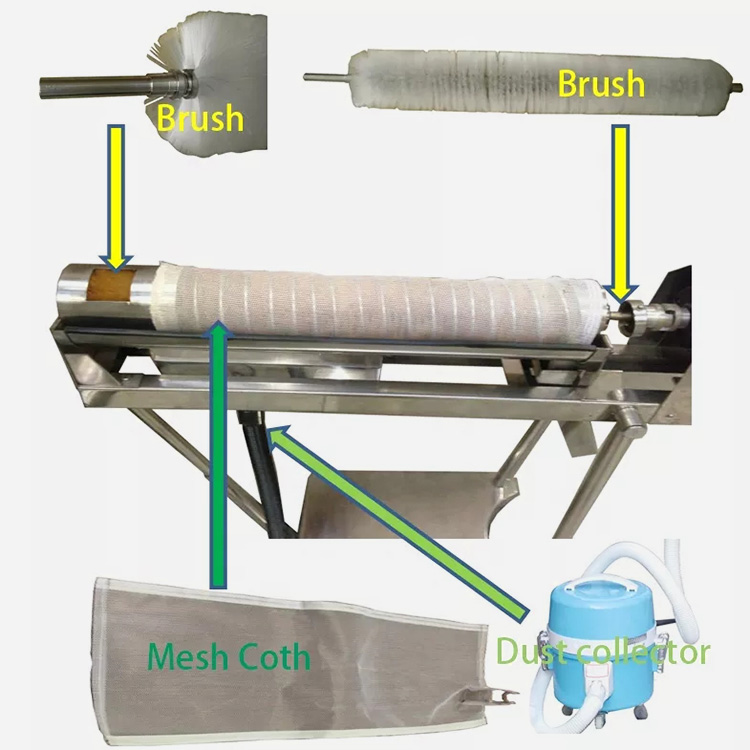

Mesh Cartridge and Brush

The mesh cartridge and the brush are connected by compression fitting, easy to assemble or disassemble, and can be cleaned thoroughly.

Motor

The motor speed is controlled by the frequency changer and can withstand large starting torque, therefore making the machine run smoothly and steadily.

Except for the vertical and horizontal design, all the functions of these two type capsule polishing machine are the same. You can choose the one which most suits your polishing needs.

4.What Are The Main Parts Of The Capsule Polishing Machines?

The main parts are important for the capsule polishing machine which are the base of all these type machines. The main parts of the capsule polishing machine from the vertical type and the horizontal type are different and you will learn from these two types separately.

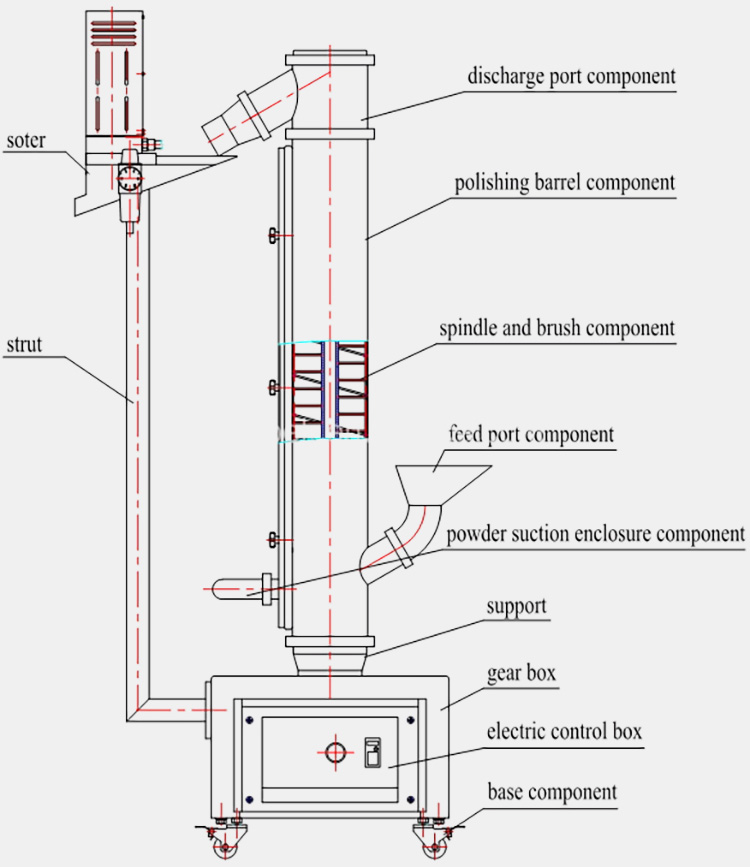

Main Parts of Vertical Capsule Polishing Machine

There are main 11 parts of the vertical capsule polishing machines including base component, electric control box, gear box, support, powder suction enclosure component, feed port component, spindle and brush component, polishing barrel component, discharge port component, strut, sorter.

Control Panel

Control panel can help you controlling the in, off and speed of the polishing machine.

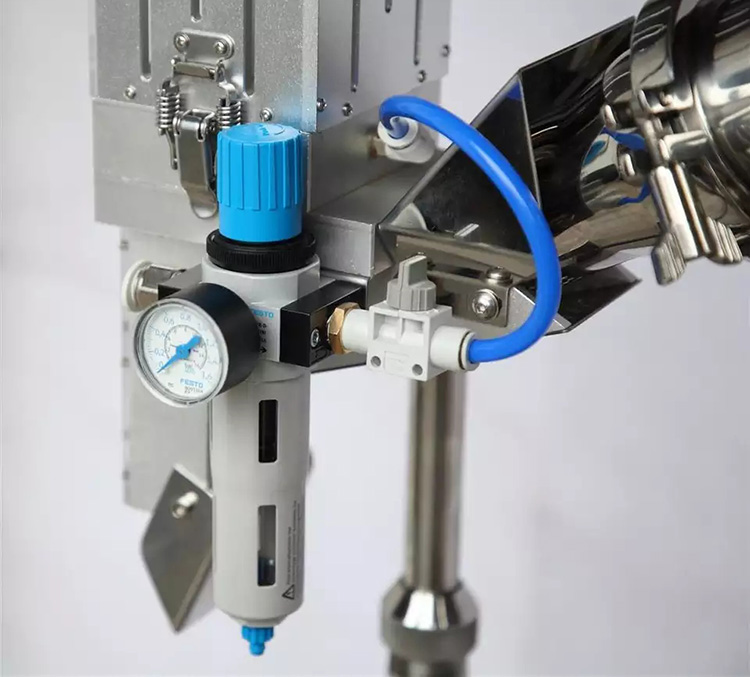

Pressure Gauge

Pressure Gauge can help you with the adjusting of the working pressure of the machine.

Discharge Port

Discharge port can help you with uploading the polished capsules and tablets into the sorter for the sorting process.

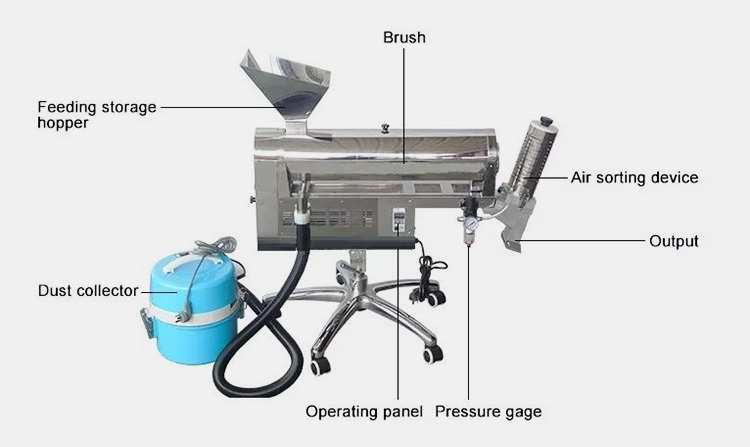

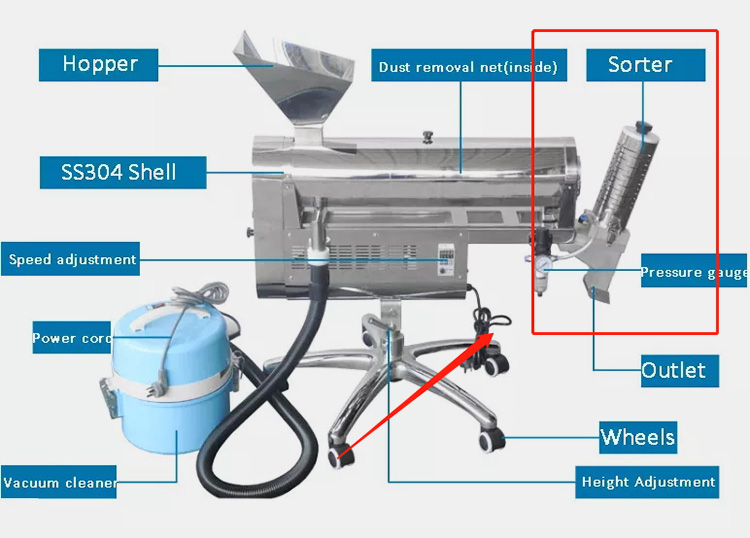

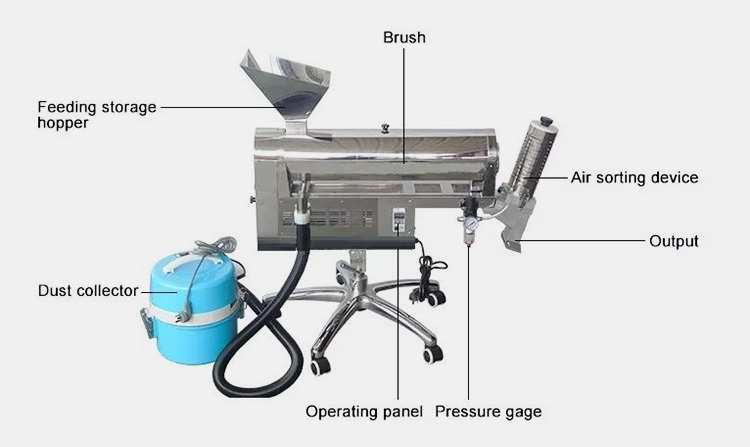

Main Parts of Horizontal Capsule Polishing Machine

There are 7 main parts of the horizontal capsule polishing machine including feeding storage hopper, dust collector, operating panel, pressure gauge, output, brush, and air sorting device.

Feeding Storage Hopper

Feeding storage hopper can help you uploading the capsules and tablets with continuous feeding.

Operating Panel and Pressure Gauge

The operating panel can help you with the polishing speed adjusting, and the machine on and off. The pressure gauge can help you with the pressure adjusting.

Brush and Air Sorting Device

The brush can help you with the cleaning and polishing of capsules and tablets. The air sorting device can help you with sorting out the empty capsules.

Output

The output can help you with continuously unloading the finished capsules and tablets.

Most parts above are the vital one for the capsule polishing machine and it needs monthly check and maintenance to ensure its fluent working and life.

5.What Are The Main Features Of The Capsule Polishing Machines?

Different type capsule polishing machine has different feature and there main features lies in below:

Features of Vertical Capsule Polishing Machine

Polishing and Lifting

It has the dual function of polishing and lifting the capsule, leaving a high space for connecting subsequent equipment.

Adjustable

The entrance and exit of the machine can be adjusted by 360 degrees, which is convenient for production and saves space.

Sorting

Capsule sorting device can automatically sort the capsule with light loading, empty shell, fragments and body cap capsule

Quick-mounting Connection

The whole machine adopts the quick-mounting type connection structure, which makes the disassembly and installation of the machine more convenient and fast.

316L Materials

All parts contacting with drugs shall be made of 316L materials or materials meeting the requirements of modern drug production requirements.

Brushes

The brushes on the main shaft can be detached and cleaned thoroughly. The whole machine can be cleaned without dead angle.

GMP Requirements

It meets the requirements of GMP.

Features of Horizontal Capsule Polishing Machine

Height and Angle Adjustable

The height and angle can be adjusted to fit into any chute of the capsule filling machines and tablet presses so the products can be polished immediately after production.

Sorting

It can eliminate static, and automatically reject ultra light weight capsules, fragment and empty capsules.

Metal Net

The capsules are not directly contact with the metal net to protect the printed capsule effectively.

Brush

New type of brush is durable and can be change easily.

Easy Maintenance

Excellent design for quick cleaning and straightforward maintenance.

Frequency Converter

Adopts frequency converter, which is great for continuous long hours of operations

Belts

Drive by synchronous belt to reduce noise and vibration of the machine.

All Capsules Sizes

It is suitable for all sizes of capsules without any change parts.

GMP Requirements

All the main parts are made of premium stainless steel are in compliance with pharmaceutical GMP requirements.

The features of these two type capsule polishing machine are some different and some way the same. After learning these same ways and different ways, you now may understand the capsule polishing machine well.

6.What Are The Working Principles Of The Capsule Polishing Machines?

These are the working principles both for the vertical capsule polishing machine and horizontal capsule polishing machine.

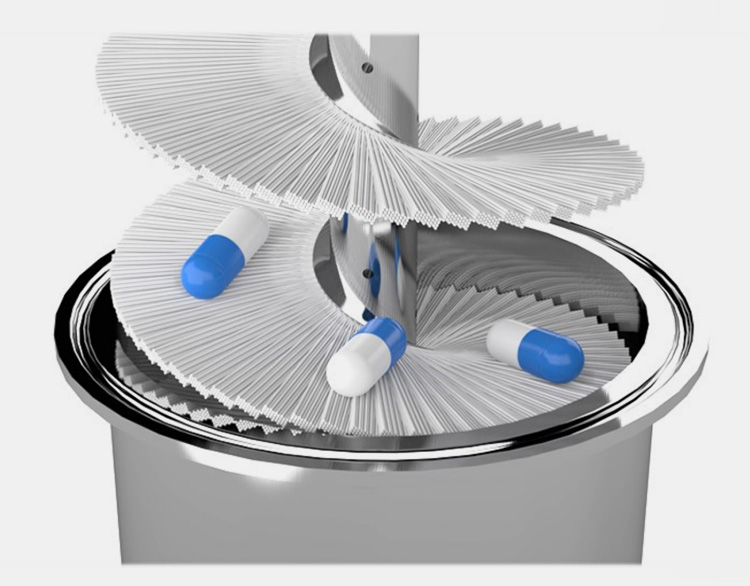

Brush Rotation

During the working process of the capsule polishing machine, the rotating movement of the brush drives the capsule to make a circular spiral movement along the wall of the polishing tube, so that the capsule advances along the helical spring.

Capsule Polishing

Under the continuous friction with the brush and the wall of the polishing cylinder, the outer surface of the capsule shell is rubbed to a smooth state—that is, it is polished. The polished capsules enter the waste hopper from the discharge port.

Eliminating

In the waste hopper, due to the effect of negative pressure, the capsules are lifted by the airflow under the action of the airflow, and the unqualified capsules with light weight are lifted, so that they enter the vacuum cleaner through the suction pipe.

Removing

Qualified capsules with heavy weight continue to fall, and are discharged through the movable discharge hopper, effectively achieving the purpose of polishing and removing waste.

Vacuuming

The powder and fine fragments that are brushed off during the polishing process enter the sealed cylinder through the small holes on the wall of the polishing cylinder, and are sucked into the vacuum cleaner for recovery.

The working principles for both types are the same, and all of them including brushing, polishing, eliminating, removing, and vacuuming.

7.What Are The Operations Of Capsule Polishing Machines?

Capsule polishing machine is equipment used for capsule dedusting, polishing, feeding and sorting, which complies with pharmaceutical regulations. The capsule polishing machine is modularized and does not require tools for disassembly and assembly.

The operation, cleaning and maintenance of the capsule polishing machine are simple and safe. When you need a trial run before officially running the capsule polishing machine.

Notice

It is necessary to determine the forward speed of the capsule and the amount of compressed air for reject sorting.

Operation Steps of Capsule Polishing Machine:

Test Run

Turn on the power switch to make the machine start running.

Adjust and Observe

Adjust the speed control knob and observe the vibration, noise and stability of the machine.

Select Speed

Put a small amount of empty shell capsules and finished capsules from the feed port. Adjust the speed control button and observe the travel speed of the capsule, select a suitable speed.

Connect to Capsule Filling Machine

Connect the machine with clean compressed air, and check whether the compressed air pipeline is normal.

Sorting Process

Observe the sorting of empty shell capsules by compressed air at the outlet. The empty shell capsules can be collected smoothly and the finished capsules can be discharged smoothly by adjusting the filter pressure reducing valve knob.

Connect to Vacuum Cleaner

Connect the vacuum cleaner, check whether the pipeline of the vacuum cleaner is unobstructed, and whether the vacuum cleaner is normal.

Speed Control

If there is no abnormality, turn the speed control knob to the 4th scale position and run it for 30 minutes without load.

Turn Off

When encountering an abnormal situation, the running switch should be turned off immediately to stop the capsule polishing machine from running.

Officially Run

When it is confirmed that there is no abnormality in the trial operation, the capsule polishing machine can be put into formal operation.

Move Capsule Polishing Machine to the Discharging Port

Move the capsule polishing machine to the side of the discharge port of the capsule filling machine, lock the casters so that the feed port of the machine is docked with the discharge port of the capsule polishing machine.

Place Product Barrel

Place the finished product barrel under the discharge port, turn on the power switch and turn on the switch to make the machine start to run.

Adjust the Speed

Adjust the speed control knob to the position of the 5 to 6 scale, and connect the vacuum cleaner and the compressed air source.

Start the capsule polisher

According to the speed of the capsule filling machine, the operating speed of the capsule polishing machine is finally determined.

Turn Off the Capsule Filling Machine

When the production is over, the capsule filling machine should be turned off first.

Turn Off the Capsule Polishing Machine

After all the tablets in the polishing cylinder are discharged, turn the speed control knob to the minimum, then turn off the capsule polishing machine, and finally disconnect the power supply.

The operating steps for both types of capsule polishing machine are the same and you should follow it closely when you are applying this kind of machine.

8.What Types And Sizes Of Capsules And Tablets Can Be Polished By The Capsule Polishing Machine?

Most of the capsule polishing machine are suitable for all types and sizes of capsules.

Types of Capsules

There are two one type of capsules: hard shelled

Hard-shelled Capsules

Hard-shelled capsules, which contain dry, powdered ingredients or miniature pellets made by e.g. processes of extrusion or spheronization. These are made in two halves: a smaller-diameter “body” that is filled and then sealed using a larger-diameter “cap”.

The soft capsule and tablets can not be applied for the capsule polishing machines. The soft capsules are mainly filled with liquids or oils which do not contains powders. So there is no powder for the machine to dedust and polish.

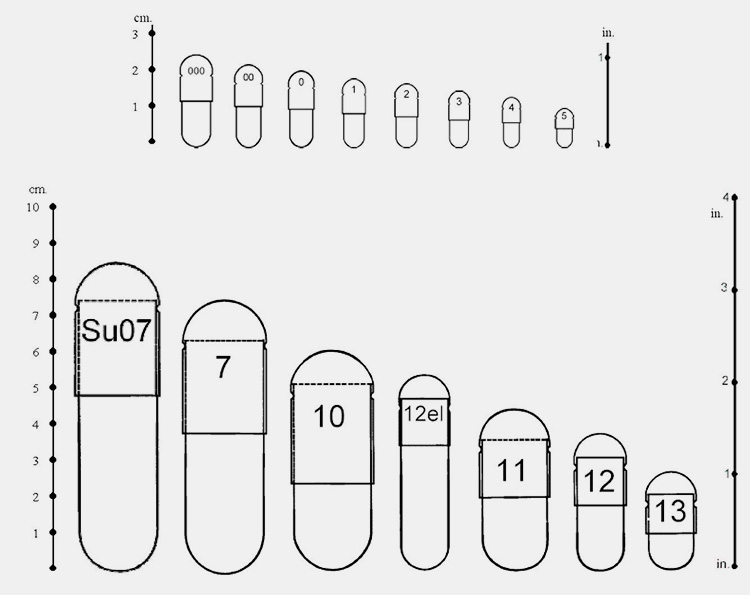

Sizes of Capsules

There are 16 main sizes of capsules including 000, 00, 0, 1, 2, 3, 4, 5, Su07, 7, 10, 12el, 11, 12, 13. All those sizes of capsules can be applied and polished by the capsule polish machine.

The capsule polishing machine can be applied for polishing and dedusting all types of hard capsules and all sizes of capsules.

9.Can You Integrate Capsule Polishing Machine And Capsule Sorting Machine Into One Single Machine?

Before to know this answer, you should know what is a capsule sorting machine first. There are two types things which are capsule sorting machine and capsule sorting device.

Capsule Sorting Machine

Capsule sorting machine also called as capsule sorter, is a machine that can be used to select out the empty capsules which are loose pieces as well as scraps after capsule filling and polishing. Capsule sorting machine can also automatically select out those capsules with lighter dosage. The machine can be connected to the main production line, and can be used separately.

Capsule Sorting Device

Capsule sorting device also called as sorter is a device that connected to the end of the capsule polishing machine that can help you with sorting out the polished capsules and tablets which are empty or unqualified. Capsule sorting device cannot be applied alone or with the production line. It has to be connected with the capsule polishing machines.

The capsule sorting machine cannot be connected to the capsule polishing machine, and it should be used alone. However, you can integrate the capsule sorting device with the capsule polishing machine, and it will greatly help the capsule polishing machine.

10.What Are The Differences Between Capsule Polishing Machines With Capsule Dedusters?

After learning about the capsule polishing machine and the capsule sorting machine, you may wonder what is a capsule deduster.

Capsule Deduster

Capsule deduster also called tablet deduster is a machine applied for dedusting the polished tablets and capsules in the pharmaceutical industry, but mainly applied for the tablets.

There are three main differences between the capsule polishing machine and capsule deduster including machine application, main function, and machine parts.

Machine Application

Capsule polishing machines are mainly applied for the capsules, though it can be applied for capsule.

Capsule Polishing Machine Application

Capsule dedusters are mainly applied for all types of tablets.

Capsule Deduster Application

Main Function

Capsule polishing machines are manly applied for polishing, sorting the capsules and tablets. Capsule polishing machines can remove the dust on the surface of capsules and tablets, sorting out the empty or unqualified capsules and tablets. It can the function of dedusting.

Capsule dedusters are mainly applied for removing the burr dust from the tablets and capsules. The whole production is intuitive and visible. Capsule dedusters do not have the function of polishing and sorting.

Machine Parts

There are 7 main parts of the horizontal capsule polishing machine including feeding storage hopper, dust collector, operating panel, pressure gauge, output, brush, and air sorting device.

Structures of Capsule Polishing Machine

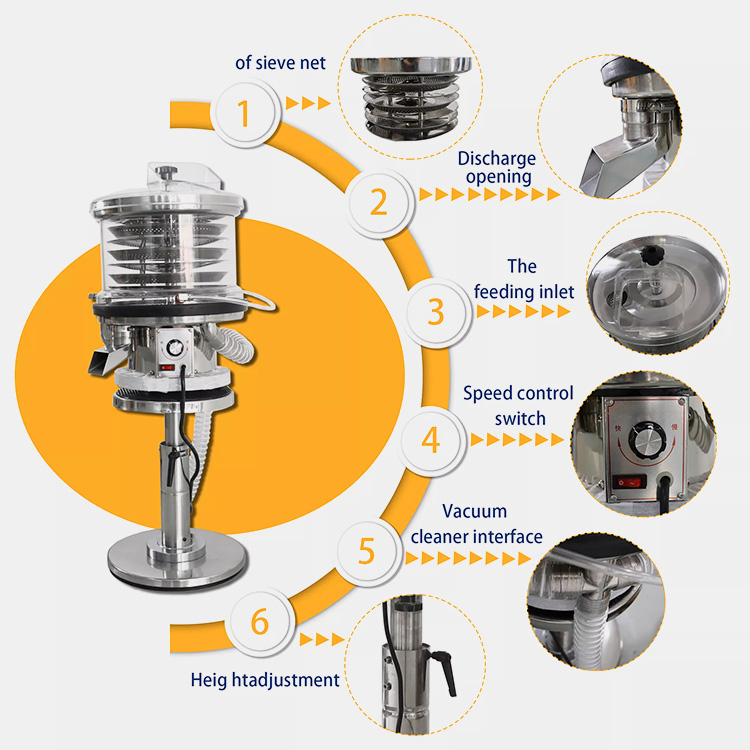

There are 6 main parts of the capsule deduster including sieve net, discharge opening, feeding inlet, speed control switch, vacuum cleaner, and height adjustment.

Structures of Capsule Deduster

The may differences are lie in the application, main function, main parts.

Conclusion

Capsule polishing machine or capsule polisher is an indispensable auxiliary machine for capsule filling machine. When you are considering a capsule filling machine, you must not forget to choose a suitable capsule polishing machine at the same time. If you have other questions or needs about capsule polishing machine, welcome your discussion and consultation.

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp:+86 18171018586