Capsule Essence Counting Machine: The Complete Buying Guide In 2025

The use of capsules is now almost everywhere whether pharmaceutical, food, or cosmetic industry. Most of them are being made for encasing liquid essence extracted from different sources especially for beauty purpose. Similarly, the production of capsules essence has noticed a significant growth. To deal with such large amount of capsule essence a machine naming Capsule Essence Counting Machine has been designed.

It facilitates the quick, precise, and hygienic counting of capsule essence along with many other products. The machine has automatic technology to efficiently carry out its vary tasks. Moreover, it follows simple operational procedure with compact structure and easy maintenance requirement. You can opt for the best machine in numerous types depending upon your needs. So, let's uncover all these attributes of a Capsule Essence Counting Machine in this buying guide!

1.What Is Meant By Capsule Essence?

Beauty capsule essence- Picture Courtesy: temu.com

Capsule essence refers to the concentrated liquid solution enclosed in a shell which is used for hair beauty and skincare routine. The types of capsule essence vary according to the kind of essence being filled in the capsule such as vitamin E essence, fish oil essence, hair serum essence, and others. These essences can be directly used or mixed with other beauty products like facial cream. Using softgel capsule is one of the most convenient, safe, and cost-effective way for storing essence.

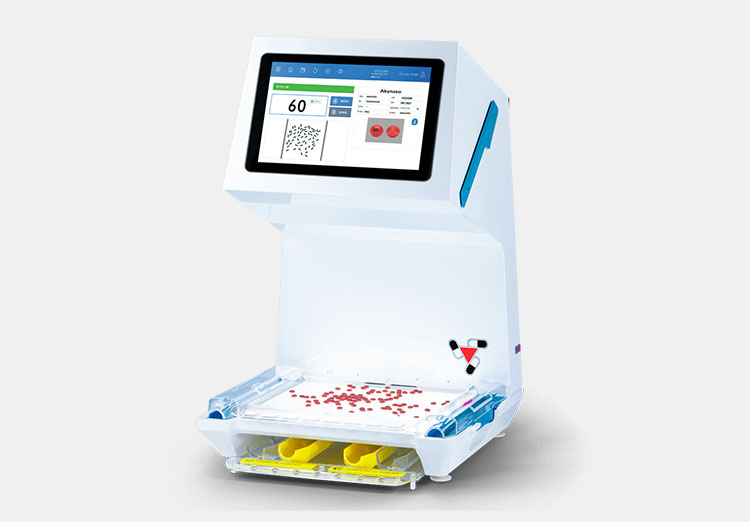

2.Define A Capsule Essence Counting Machine?

Allpack- APC-16 High speed tablet capsule counting machine

Capsule essence counting machine is an advanced equipment designed to intelligently count large number of capsules in a consistent manner. The machine is a product of sophisticated technology being tailored with multiple components including sensors, counting channels, and waste removal to effectively perform counting of capsule essence.

It simply undertakes the function by gradually taking bulk of capsules from the hopper and spreading them onto vibratory channels. Similarly, these capsules gets segregated and easily counted by the machine through sensors. Throughout operation, it shows up-to-the-mark precision level while reducing counting errors. It can be integrated with other machines to make a production line and help you in vary industries for the counting of capsules, tablets, confectioneries, and much more.

3.Enumerate The Features Of A Capsule Essence Counting Machine?

A capsule essence counting machine holds numerous features which can transform your production growth and perfection level in terms of counting. So, let's take an overview of these attributes!

Hygienic Body

Hygienic body of capsule essence counting machine- Picture Courtesy: njmpackaging.com

The body of machine matters a lot when it is supposed to deal with such sensitive objects like capsule essence and tablets etc. That's why, the structure of a capsule essence counting machine is the product of high-class material with all contact parts being made from antibacterial and corrosion resistant stainless steel. Hence, your capsules are processed in a safe and enclosed environment.

Automatic Operation

Automatic operation of capsule counting machine- Picture Courtesy: funtionpacking.com

Capsule essence counting machine is equipped with automatic technology to administer the entire operation of capsules counting independently. It uses vibratory trays, sensors, and counting compartments to carry out perfect counting of capsules and other objects.

Counting Efficiency

Efficient softgel capsule counting- Picture Courtesy: highpuritynaturalproducts.com

Manually counting your capsules will definitely require more time and effort. In contrast, with automatic functioning and up to 32 counting channels, a capsule essence counting machine works efficiently and is capable of finishing over 150 bottles in a minute.

Multi Tasking

No doubt, another crucial feature of a capsule essence counting machine is its multi tasking ability to perform capsules counting, waste rejecting, and capsules filling into containers.

Product Versatility

Different sizes of softgel capsules- Picture Courtesy: saintytec.com

The machine is highly qualified and adaptable to count any type of small objects regardless of their different shapes and sizes. For instance, it can be easily utilized for counting tablets, chocolate lentils, candies, and other hardware objects. Hence, its application is vast and extended to the fields beyond medical industry.

4.What Products Can Be Processed By A Capsule Essence Counting Machine?

The most prestigious characteristics of a capsule essence counting machine is its ability to deal with different materials. That's why, you can employ it for your multiple businesses. In this question, we will be showing you some products which a capsule essence counting machine can process. These include:

Capsules

Softgel capsules- Picture Courtesy: yellowimages.com

Each type of capsule including hard gel, softgel and capsule essence can be easily counted by a capsule essence counting machine and filled in different containers.

Tablets

Tablets presentation idea

Tablet is one of the most used form of oral dosage, therefore, it is produced in large quantity. In order to deal with the different sizes and shapes of tablets, a capsule essence counting machine can be used for precise counting.

Candies

Multiple color hard candies

Candies are sweet confectioneries with abundant of sugar. That's why, they are properly packed in enclosed containers to restrict insects and environmental effects. During packing the most crucial step is accurate counting of these candies for which a capsule essence counting machine is suitable.

Gummies

Fruit gummies

Gummies are gelatin-based chewable sweets which are both taken as confectioneries and now nutraceucals are also delivered in gummy form. Hence, a capsule essence counting machine is able to count these gummies properly.

Bubble Gum

Bubble gum jars

Bubble gum is a chewable snack which is not meant for swallowing. It is made up of a gum base along with flavorings and color etc. It is a popular form of confectionery, therefore, preferred by many people. Here it is crucial to mention that a capsule essence counting machine is able to count every shape and size of bubble gum.

Gel Blasters

Water gel blasters- Picture Courtesy: gelshadow.com

Gel blasters are small ball type objects filled with water. They are used for playing and require proper counting during packaging. That's why, this machine can be easily used for their counting.

Nuts & Screws

Bolts & nuts- Picture Courtesy: Freepik

Small hardware objects like nuts, screws, and other items are sold separately in bottles and boxes. Therefore, they need thorough counting to ensure accuracy and reduce the existence of useless materials. That's why, the help of a capsule essence counting machine can be taken to perform these tasks.

Insulin Needles

Insulin needles and safety lancets- Picture Courtesy: cremer.com

Small insulin needles and safety lancets can also be counted via a capsule essence counting machine and packed into desired containers safely.

Seeds

Seeds- Picture Courtesy: treehugger.com

Seeds and grains are so small that they cannot be counted correctly using a manual way. Since, the agricultural industry is largely dependent upon seeds, it is significant for manufacturers to adopt a safer and cost-effective way for the counting of seeds to multiply gains. Hence, this machine is ideally perfect for seeds counting.

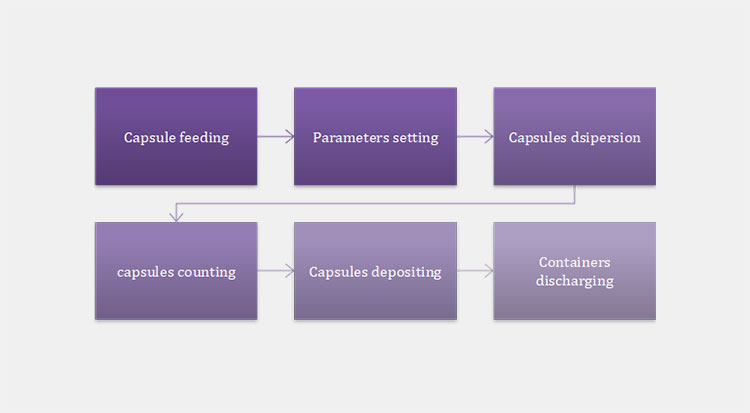

5.How To Operate A Capsule Essence Counting Machine?

In order to operate a capsule essence counting machine on right way, you need to understand its working principles which are sequentially explained below. So, let's start reading these principles and learn how to operate it!

Capsule Feeding

Capsule essence loading- Picture Courtesy: funtionpacking.com

Before starting a capsule essence counting machine it is necessary to check whether it is in working condition and then feed it with capsule essence. For this, you need to load the 2/3 of hopper with capsule essence. The hopper is located on top for convenient capsules supply.

At the same time, containers or packages which you will be using for filling of counted capsules should be supplied to the machine either directly placing them on conveyor or attaching the relevant feeding machine for consistent operation.

Parameters Setting

Now, when machine has been loaded with the capsules and packages, another step will be to adjust its functioning parameters such as the number of capsules you want to fill in each container. Along with that, the frequency of vibratory trays, the setting of sensors as well as conveyor speed should be adjusted.

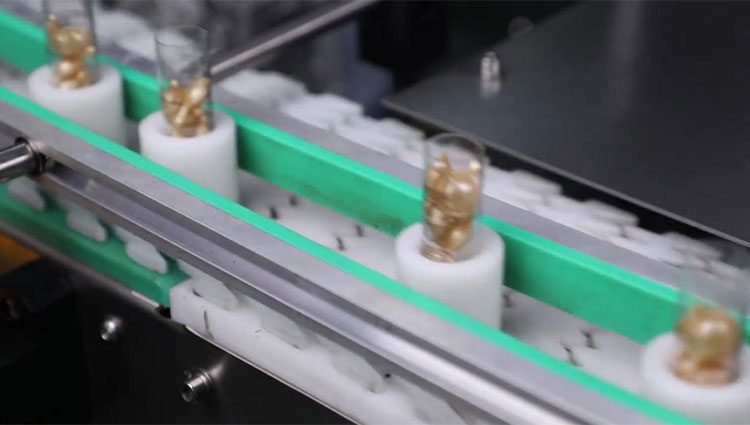

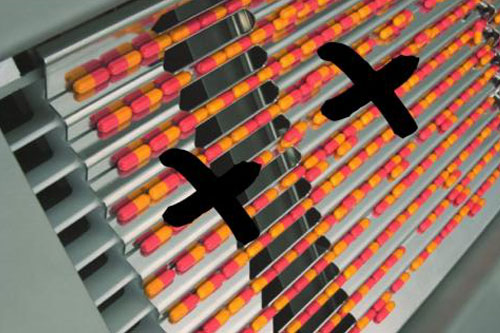

Capsules Dispersion

Capsule essence dispersion- Picture Courtesy: funtionpacking.com

Once parameters are fixed properly, you can turn the power button on to begin the operation. It will result in energizing the different parts of machine and the capsules laying inside hopper will begin dropping onto the vibratory trays. The constant vibration of trays lead the capsules to disperse and take hold in multiple linear channels.

Capsules Counting

Capsule essence counting- Picture Courtesy: funtionpacking.com

Upon dispersing, it becomes easy for sensors to detect capsules and they begin counting step. One after another, all the nearer capsules are counted by electric eyes and dropped into a counting compartment. During this phase, foreign objects, dust, and other useless particulates are extracted by fume extraction device and first collected in separate containers.

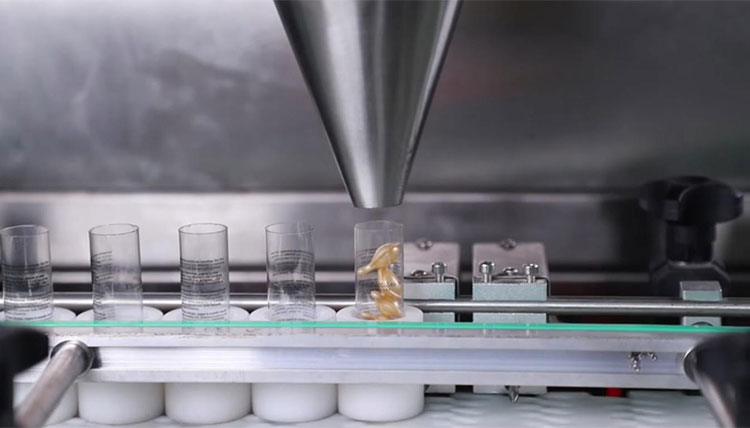

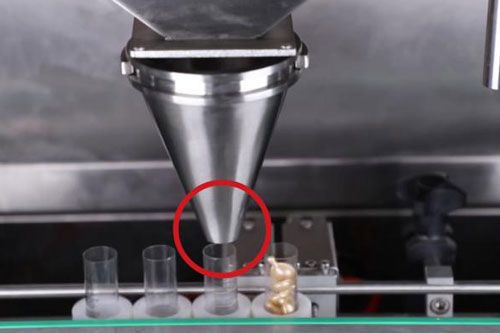

Capsules Depositing

Capsule essence depositing into bottle- Picture Courtesy: funtionpacking.com

Moving forward, the counted capsules will be deposited into the containers but before that, the presence of containers under filling heads must be done to ensure precise filling. After filling, these containers are mobilized from machine and their place is taken over by the empty ones.

Containers Discharging

Containers discharging- Picture Courtesy: funtionpacking.com

At the end, finished capsule essence containers are discharged from the machine by a conveyor belt towards collection container or further packaging in case of counting line.

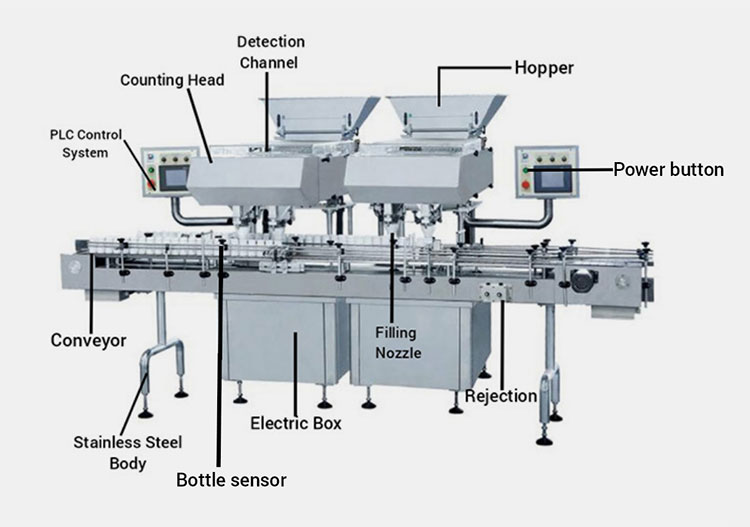

6.Describe The Structure Of A Capsule Essence Counting Machine?

Capsule essence counting machine is made up of durable stainless steel body with whom all other components are attached. Each of these components perform a specific task which are described below:

Structure of a capsule essence counting machine

Hopper

Hopper is a large size hollow container attached to the main machine and is located on its top. Here, the bulk of capsule essence is loaded to supply the machine with capsules for counting.

Detection Channel

Detection or vibratory channel is the core component of a capsule essence counting machine which disperse the capsules for counting. The number of trays depends upon the machine type; however, two to three trays are attached to every machine which are placed in such a way that the start of each tray is laid under the end edge of previous tray.

PLC Control System

It is a type of small computer manifested by a touch screen device which display over it multiple data information about the number of capsules to be counted, performance of sensors, and machine controlling features etc. By using this touch screen penal, user fix commands in the machine according to which it is operated.

Counting Head

Counting head is a place characterized by the number of compartments where counted capsules are stored till they leave machine and filled into containers. It has a transparent window for clear observation.

Stainless Steel Body

The machine has stainless steel body which is fully protected against bacteria and corrosion. Moreover, it has certain parts like protection window and adjustment tools for modifying the height of capsules filling head in accordance with the size of different containers.

Filling Nozzle

It refers to a nozzle having broad ending that is connected to the counted compartment and a narrow mouth through which capsules are deposited into containers.

Conveyor

Conveyor is the transport unit of machine which is greatly useful for mobilizing containers from one end of the machine to another in order to fill them with counted capsules. It adds to the consistency and efficiency of a capsule essence counting machine.

Rejection

A capsule essence counting machine has rejection system which reject the deformed capsules and foreign objects by collecting them in a separate chamber. In this way, the counting process is carried out without any error.

Power Button

Power button is a main switched situated on the front of machine. It is connected to other components of machine, therefore, turning it on result in the starting of machine's operation.

Bottle Sensor

It is a small electric eye located on the side of conveyor rods. When bottles or containers pass through conveyor, it detects their presence and send message to machine for releasing counted capsules. Therefore, it helps in reducing material waste.

Electric Box

Electric box is an electric enclosure which encases in it the various electrical components such as wires, switches, and fuses to keep them in one place.

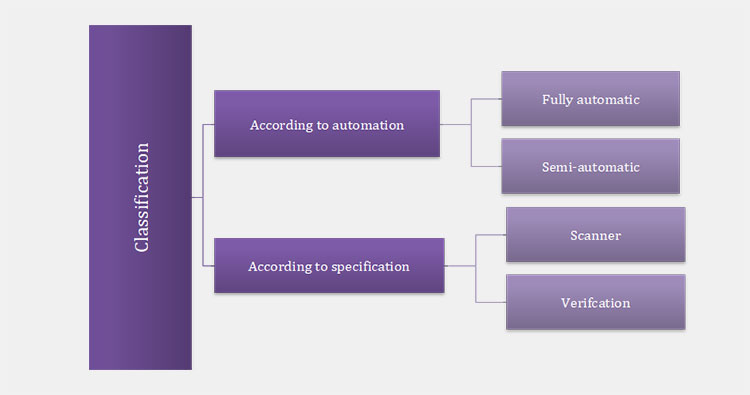

7.What Is The Classification Of A Capsule Essence Counting Machine?

Capsule essence counting machine can be classified into different types. All these types are explained below in detail:

According to Automation

Fully Automatic Capsule Essence Counting Machine

Allpack- APC-32 auto counter 32 channel tablets counting machine

Fully automatic capsule essence counting machine is a sophisticated machine with ultrafast performance capability. It is available in one to 4 filling heads with up to 32 channels for counting capsule essence. The machine can also be integrated with other machines to form a line and process tablets, capsules, and candies of different shapes and sizes. The counting efficiency of fully automatic machine is filling up to 150 bottles in a minute.

Structure

It has a complex structure with multiple vibratory channels, filling heads, separate hoppers, electric cabinet, conveyor, touch screen penal, sensors, fume extraction device, and transported window for product protection.

Working Process

It carries out the function of capsule essence counting by following automatic steps once loaded with material and settled. Similarly, it takes capsules from hopper, process them through counting phase, and discharge the counted capsules into passing bottles. These bottles are then automatically transferred from the machine through conveyor.

Semi-Automatic Capsule Essence Counting Machine

Allpack- Pill Counter Machine YL-2

Semi-automatic capsule essence counting machine is a medium size cost-effective machine with small footprint. It is often termed as tabletop or desktop capsule essence counting machine for the reason that it covers less space and can be easily operated in pharmacies, hospitals, and dispensaries etc. Its counting speed is good and dependent upon operator intervention.

Structure

The machine has precise body with major components including a hopper with transparent lid, control unit, capsule counting workstation, main frame, filling heads, and u-shaped stand.

Working Process

The machine require operator to load it with capsule essence and containers. After starting machine, it processes the capsules for counting and fill the containers with counted capsules. At the end, operator manually pick up the filled bottles.

According to Specifications

Digital Scanner Capsule Essence Counting Machine

Vivid pharmacy pill counter- Picture Courtesy: pillcounters.com

Another type of machine is digital scanner capsule essence counting machine which uses scanning technology to perform counting function. It has simple operation with photoelectric detection which reduce counting errors.

Structure

The machine is an assembly of several components comprising a detection tray, digital display, side capsule holders, and control system.

Working Process

The machine can be operated by pouring your capsule essence over the detection tray and spreading them. After that, the photoelectric sensor takes picture of capsules and display it over the scree. Similarly, capsules are counted and now they can be discharged from machine and filled into container.

Digital Verification Capsule Essence Counting Machine

Kirby Lester KL1Plus Pill Counter- Picture Courtesy: kirbylester.com

This type of digital capsule essence counting machine is extremely useful for pharmacies and research laboratories. The machine has built-in verification system for the counting of capsule essence. Its large display aids the user to keep knowing the number of capsules which are counted.

Structure

It has small body with major parts including a bowl on top, glass vessel for capsule passing, large size touch screen interface, capsule counting sensor, and a plastic bucket for counted capsules storage.

Working Process

It can be brought into operation by pouring capsule essence manually into the bowl. Similarly, these capsules will be detected by the sensor and dropped into a plastic bucket. At the same time, digital control panel will keep showing the number of capsules counted and dropped into container. After the desired number of capsule essences are counted, the container will be removed from machine and emptied for next round.

8.Highlight The Applications Of A Capsule Essence Counting Machine?

The use of a capsule essence counting machine can be found in myraid of industries and manufacturing facilities. Some of the prominent ones are highlighted below:

Medical Industry

Medical industry icon- Picture Courtesy: Freepik

Medical industry is one of the top beneficiaries of a capsule essence counting machine which has been used for decades to carry out the precise counting of pills, capsules, insulin pens, and syringe needles etc.

Veterinary Industry

Doctor treating dog- Picture Courtesy: apple.news

Veterinary industry is growing rapidly due to the increasing concern for animals and pets’ medical treatment. Thus, different types of medications in form of tablets, capsules, and pills are produced for them. To count all of these essentials, a capsule essence counting machine is perfectly applicable.

Beauty Care Industry

Beauty capsule essence- Picture Courtesy: stylecaster.com

Capsule essence is now commonly employed for delivering beauty care liquids such as vitamin capsules, Omega-3 capsules, and other whitening agents. They are used for glowing skin, anti-aging treatment, and removing dark circles. Hence, like other capsules they are also meant to be counted for which a capsule essence counting machine is utilized.

Hardware Industry

Various buttons- Picture Courtesy: shein.com

Hardware industry encompasses all the sectors where objects like nuts, screws, pearls, beats, buttons, and stationary items such as eraser and sharpener etc., are produced. Similarly, all these goods are properly packed in different packages for which thorough counting step should be followed. Here is where is need of a capsule essence counting machine is realized.

Confectionery Industry

Mix candies and gummies

The use of a capsule essence counting machine is inevitable in confectionery industry where manufacturing and processing of products including candies, gummies, jellies, chocolates, and bubble gum is a daily task. Therefore, to count them during packaging, the help of machine is taken.

Agricultural Industry

Seeds- Picture Courtesy: wideopeneats.com

Last but not least, agricultural industry is another field where the use of a capsule essence counting machine has been admired for counting seeds and grains etc.

9.What Is The Production Line For A Capsule Essence Counting Machine?

Large production facilities where thousands of capsules, pills, and similar other products are made on daily basis require entire production lines for meeting the desired ends and targets. In this way, there is a full-fledged line for capsule essence counting machine which is composed of different machines. Together they enable the line to perform multiple tasks automatically in one way. One such example is given below:

Allpack High Speed Automatic Multifunction Capsule Tablet Pill Counting Line

Bottle Unscrambler

Bottle unscrambler constitute the very first unit of a capsule essence counting line. It is made up of a stainless steel body with several other components including a bottle unscrambling disc, transparent window, electric enclosure, control panel, and a conveyor. Its major function is to align the randomly positioned bottles through rotary disc and supply these bottles to the line for filling.

Capsule Counting Machine

It is the core section of the production line for the reason that it carries out actual task of capsule essence counting. It is an assembly of multiple parts comprising a large size hopper, vibratory trays, counting compartments, filling heads, sensors, fume extraction device, bottle detector, and control system.

The machine performs its function by taking bulk of capsules from hopper and expanding them onto vibratory trays. Afterwards, these capsules are counted and deposited into bottles.

Desiccant Inserting Machine

Desiccant inserting machine is the third unit of production line which has been assigned with the task of inserting desiccant bag into each passing bottle. It has a small body with few parts including a silica film roll, bag cutter, sensor, and control system etc. It carries out the function of inserting desiccant bag by first unwinding the silica film roll, and then cutting it on given mark. Similarly, it drops the silica gel bag into a container.

Bottle Capping Machine

This machine is incorporated into the capsule essence counting line for the purpose of tightly capping capsule filled bottles. It has a complex body with dual sections: one providing caps over the bottles, while as, the other screw the caps for tight closure. Its major components include cap feeder, chucks, gripper disck, and conveyor etc.

Induction Sealing Machine

Induction sealing machine is another crucial machine utilized for adding additional strength to the bottles by applying induction sealing technology. It is a product of several tools including an induction coil, electrical connection, induction sealing head, main frame, conveying system, and control unit. It works by using an electromagnetic field to let the foil of cap stick to bottle mouth and create a tamper proof seal.

Labeling Machine

Labeling machine is the last unit of the production line which is responsible for applying labels to finished capsule bottles. It has a compact body which consists of a stainless support structure, PLC control panel, and a worktable over which label wheel, applicator, label pulleys, and a fur brush is located. Together these parts enable the machine to unwind label from roll, split it on right place, accurately apply it around passing bottles, and pass them through a fur brush to ensure bubble free labeling.

10.What Quality Standards Should A Capsule Essence Counting Machine Should Meet With?

Standard icon- Picture Courtesy: businessprocessincubator.com

In today's fast paced world, where you will find the growing manufacturers and suppliers in every field, capsule essence counting machine manufacturers are also large in number. However, it does not indicate that all of their equipment are of high quality standard rather it makes the competition for quality machine more tough.

Therefore, certain quality standards have been established by the international community to make sure the machine is complying all the necessary requirements for safe and healthy life. In this way, underlying quality standards are crucial for determining the quality of a capsule essence counting machine. These include:

- International Organization for Standardization (ISO)

- Food and Drug Administration (FDA)

- Good Manufacturing Practices (GMP)

- Conformate European (CE)

11.How To Conduct Routine Maintenance And Cleaning Schedule For A Capsule Essence Counting Machine?

It is important to conduct routine maintenance and cleaning for your capsule essence counting machine, so as not to affect the service life and performance of the machine. Therefore, you need to follow certain guidelines which we have provided below:

User maintaining machine- Picture Courtesy: har-tech.com

Cleaning

Disassemble the detachable parts of machine including the hopper, vibration plates, counting compartments, transparent cover, and filling heads.

Wash the parts with distilled water and non-acidic detergent or recommended cleaning agent.

Dry clean these parts and locate on the exact place by taking help from manual.

Gently wipe the surface of sensors and touch screen interface by using dry cloth.

Maintenance

Regularly check the structural adjustment of machine such as height adjustment, the placement of vibratory trays, and glass cover.

Keep tightening the screws and nuts of loose parts.

Repair the affected parts and changeover damaged parts for effective performance.

Keep greasing the moving parts of machine to reduce friction and wear and tear of parts.

12.Explain The Troubleshooting Of A Capsule Essence Counting Machine?

In case of sudden breakdowns or malfunctioning of a capsule essence counting machine during operation, you need to simply understand the nature of problem and take action accordingly. In this way, below table will be helpful:

| i. Capsule detection problem | ||

Capsule counting error- Picture Courtesy: njmpackaging.com |

Cause:

The sensor is polluted with dust. Fume extraction device is not working causing sensor to blur. |

Solution:

Clean the sensor for accurate functioning. Check and correct the fume extraction device to work properly. |

| ii. Capsule counting error | ||

Highlighting capsule counting error |

Cause:

The vibratory trays are wrongly placed. Speed of vibratory motor is incorrect. Counting compartment glass is polluted due to which capsules drop directly into container. |

Solution:

Accurately place the vibratory trays. Adjust the speed of vibratory motor. Regularly clean the sensors and glass window over vibratory channels and compartments for precise counting. |

| iii. Capsule dispersion during filling into containers | ||

Marking gap between filling head & container- Picture Courtesy: funtionpacking.com |

Cause:

There is gap between the filling head and container mouth. |

Solution:

Reduce the gap by adjusting the height of filling head in accordance with container size. |

| iv. Capsule essence jamming | ||

Highlighting the placement of vibratory trays |

Cause:

It occurs when the speed of vibratory motor is too much. The wrong placement of counting channels may stick capsules in the space between them. |

Solution:

Reduce the speed of vibratory motor. Remove the counting channels and place them in right way, so, that no place for capsule jamming will be left. |

13.Tips For Choosing The Best Capsule Essence Counting Machine?

Multiple question wander in a mind which is busy in deciding to choose the best machine. Similar is the case you choosing a capsule essence counting machine. So, we have come up with valuable tips whose consideration will help you get the best compatible machine!

Production Needs

Allpack- Capsule essence counting

The very first thing to look for is understanding your production needs. This question carries great importance as it answers whether you are running a small business, medium size manufacturing, or having large scale industries. Hence, it will help you choose among fully automatic, semi-automatic, and laboratory type small digital machine.

Machine Specifications

Specifications icon

Although capsule essence counting machine comes in automatic technology, yet each type possess different attributes which are different from other machines. So, you need to understand the different types of capsule essence counting machine as explained in the question no 7. After that, opt for the machine whose operational efficiency, product versatility, and output ratio suits your requirements.

Installation

Successful installation of a capsule essence counting machine is a blessing and you have a big role in it. You will be thinking how? But the answer is simple! You need to be attentive while selecting the area, floor space, and machine integration with the production line. These factors will help you in the effective installation of the machine.

Warranty Policy

Warranty and quality icon-Picture Courtesy: nzl.sika.com

The quality of machine is as important as its role in your business. Hence, make sure to satisfy yourself by confirming the machine adherence to all necessary standards and it should have a proof in form of warranty.

Conclusion

Let's wrap up this detailed buying guide about a Capsule Essence Counting Machine with a reminder that this equipment is becoming a key part of the pharmaceutical, nutraceucal, veterinary, food, cosmetic, and many other industries. Its use has addressed the problem of packaging inaccuracies, customer doubts, and increased the chances for profit returns. Moreover, it is extremely easy-to-use and applicable to multiple objects. So, no need to make further delays. Just contact us through our website and we will present you with the outstanding line of a capsule essence counting machine by Allpack!

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide