Capsule Counting and Filling Machine: The Complete Buying Guide in 2025

Do you want a capsule counting error was just a problem of past? Are you looking for revolutionize your production business with new levels of success?

Today, where everyone looks for perfection a capsule counting and filling machine importance cannot never be neglected. This is a significant equipment give an outstanding result in the term of saving your time, offer accuracy and catering bulk production.

Before investing on capsule counting and filling machine. We would suggest you read through this blog to find updated guidance about what you look for.

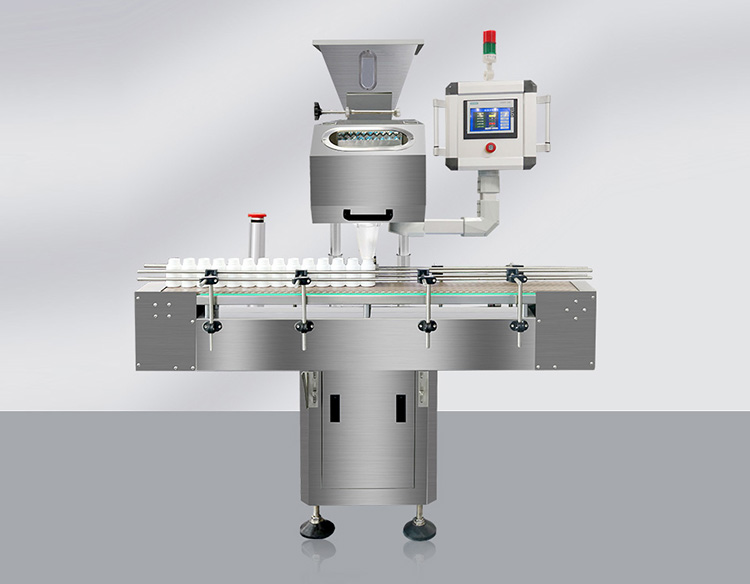

1.What is Capsule Counting and Filling Machine?

A capsule counting and filling machine is a specialized equipment that assist in counting and filling of capsule in huge quantities without any involvement of manual handling. This machine offers the user trouble-free operation in various industries for various applications.

The counting and filling product include hard gelatin capsule, soft gelatin capsule, and various types of products we discussed below. Moreover, the machine performs this function precisely with use for advance features like filling nozzles, sensor, touchscreen system etc. that helps in running process with reduced chances of product’s spillage or errors.

2.What are industrial uses for Capsule Counting and Filling Machine?

Capsule counting and filling machine has a wide range of applications and can be used in several manufacturing industries such as pharmaceutical, chemical, food, agriculture, and cosmetic industry. Let’s discuss each of these industries below.

Pharmaceutical Industry

This industry deals with the production of medicines and drugs which are needed to cure illness and disease. capsule counting and filling machine will be very important to this industry since it needs an accurate counting and filling equipment to ensure proper dosage for safe consumption for e.g pills, tablets, and gummies.

Chemical Industry

Many chemicals such as aluminum beads, buffer pellets, and others need an effective way counting and fill them safely. This can be done with the help of capsule counting and filling machine which can offer a secure way to package them into pouches or bags to keep them safe from harmful external factors.

Food Industry

Picture Courtesy-Sam’s club

Food items such as food tablets, and candy can be filled into decorative boxes by using capsule counting and filling machine. This will ensure that they are packaged safely to preserve their freshness and prevent them from getting stale.

Nutraceutical Industry

This industry is involved in the manufacturing of food tablets and vitamin supplements which are used to improve people’s lifestyles. Using capsule counting and filling machines would be a great option to fill this nutrition filled products into jars or bottles.

Agriculture Industry

Many agriculture products which are derived from crops such as wheat, maize as well as pellets and fertilizers need capsule counting and filling machine to package them safely so that they can be protected from harmful environmental factors and ensure their proper transportation to their destination.

Cosmetic Industry

Picture Courtesy-GoSupp

Cosmetic industry utilizes capsule counting and filling machine for packaging material like capsule facial serum, waxing beads, manicure, pedicure material such as bees wax beads, paraffin beads etc.,

Stationery Industry

Picture Courtesy-Amazon

This production sector uses a capsule counting and filling machine for packaging materials such as erasers sharpeners, fancy tools like keychain toppers and other into assign packaging containers.

3.What Is the Working of Capsule Counting And Filling Machine?

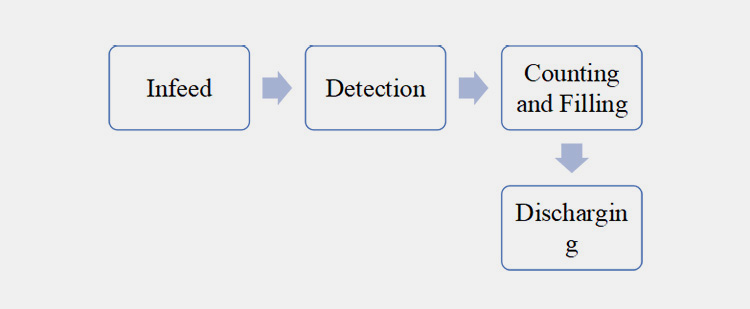

A capsule counting and filling machine is a robust counting solution that follows pretty simple working principle. The various different models which may offer slight difference in working but the major steps are the same. Our cleared demonstration about each step is given below:

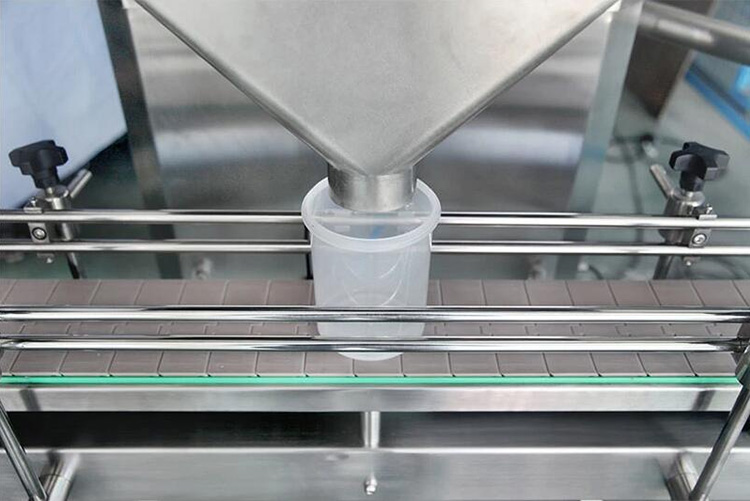

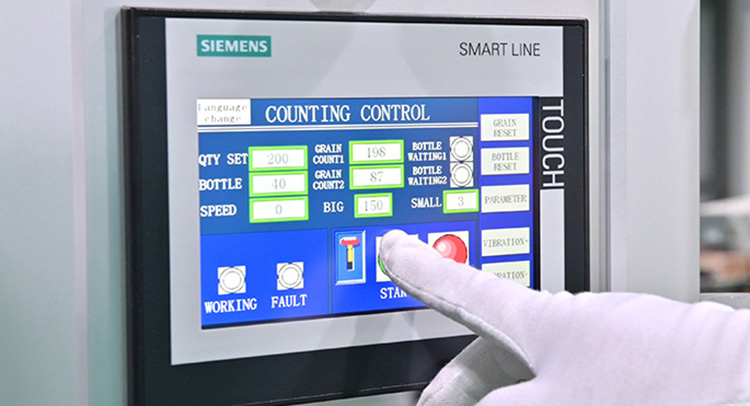

Infeed

This is the first step where packaging containers are loaded onto the system that mostly fed via machine of an integrated system such as unscrambler machine. The operator feed in the parameters using PLC and Starts the machine where hopper that is loaded with capsules bulk starts to transfer them toward the next phase.

Detection Phase

Soon after feeding, capsule are moves toward filling procedure via detection phase that helps in assessing the physical appearance of the capsule. For e.g., color, texture, stickiness or smoothness, etc., The objective of this phase to allows stable and correct capsule and rejects the faulted one.

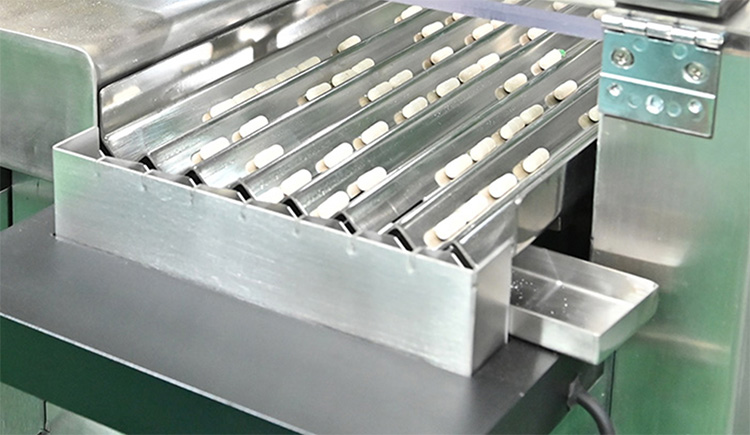

Counting and Filling Phase

There are various vibratory channels that transport the aligned sequence of the capsules toward filling nozzles where sensors help in showing presence of each capsule and notify it as counted one and drops them into filling containers. This is the fastest process where hundreds of capsules pass through the filling nozzles in each minute.

Discharging

Upon filling the container, it moves and allow next container. The filled container discharge the machine by the help of conveyor and integrate with the other unit of the production line.

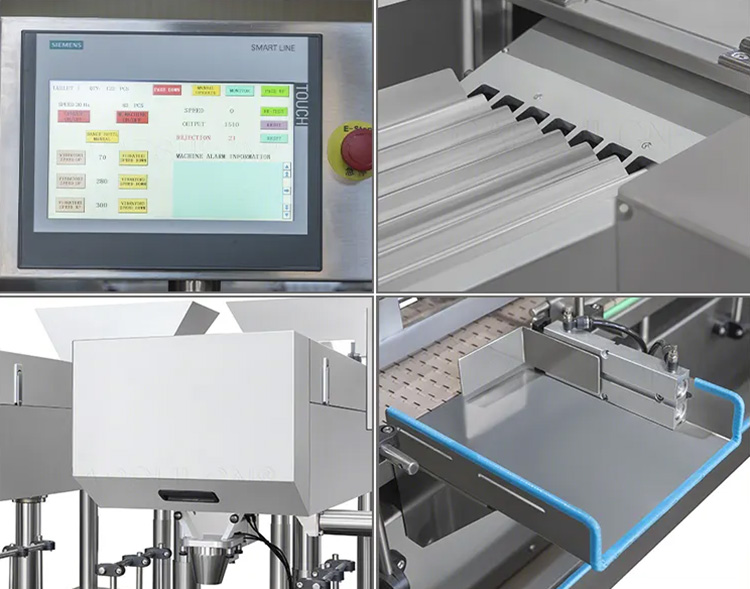

4.What Are the Major Parts of Capsule Counting and Filling Machine?

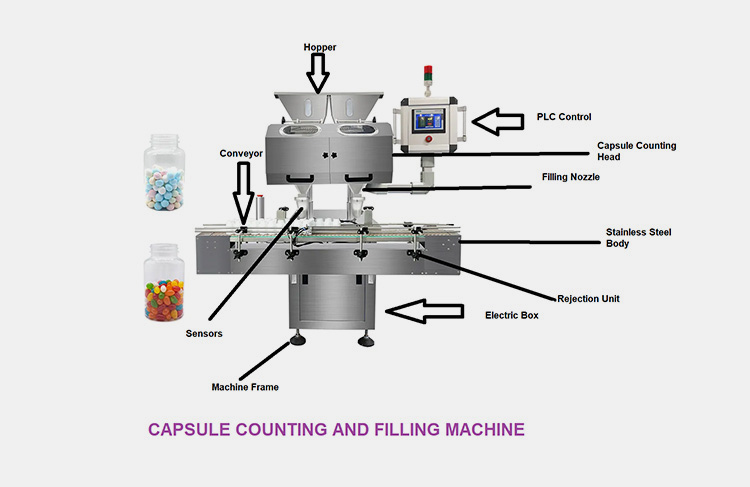

A capsule counting and filling machine is a multi-dimensional equipment which is designed with assembling various important parts to give you accurate capsule counting and filling task. The list of following components of capsule counting and filling machine are discussed below:

Hopper

This is the major core of the machine that performs a substantial role in storing optimum quantities of capsules that waits for counting and filling procedure. This is also positioned as the most above of the machine to carry seamless flow of the material into each packaging container via gentle vibration to begin the counting process.

PLC Control

A programmable logic controller is known as the brain of the machine that integrate various factors into it and receive input from user and send messages to each component to achieve working.

Filling Nozzle

This is a vibratory unit that are equipped with detection channels offering continuous vibration to facilitate the dropping of capsule in proper way toward packaging container. Some machine are designed with more than one filling nozzle to run fast counting and filling of capsule in every minute.

Counting Head

The capsule counting heads allow accurate number of capsule toward filling nozzle. The series of processes take place following proper detecting channels.

Conveyor

This unit acts as a transporter that ensure smooth infeed of packaging container toward filling nozzles. Upon counting and filling process, the conveyor belt moves and discharge the container followed by allowing next.

Rejection Unit

If any capsule is deformed or damaged, there are directly rejected and discarded to rejection unit. This unit safeguarding the production system ensuring end-user that counted and filled containers are accurate and consistent.

Sensors

A high-degree sensors acts as gatekeeper of the machine that detects the presence of the capsule and mark as counted toward the PLC unit. Plus, if your product is damage, sensors notifies and send them toward rejection unit to proceed production as uninterrupted.

Stainless Steel Body

A capsule counting and filling body is made up of highly durable stainless-steel body that offers safety, reducing cross-contamination, and ease of cleanliness.

Electric Box

All electrical components such as wiring, switches, plugs of the machine are enclosed in a cabinet that helps in regulating electrical activity under safe manner.

5.How Capsule Counting and Filling Machine Benefits You?

A capsule counting and filling machine is absolutely essential requirement of today’s industrial production unit. This is because of several beneficial factors it offers you every time. Such as

Super-Fast

Switching On The machine with feeding the data such as running speed, counting and filling process will begins with process to give you exact number of capsule counting and filling need every time. This is super-fast solution than manual handling.

Super Accurate Counting and Filling

Making errors was a thing of the past. A capsule counting and filling machine is super accurate in the term of counting due to high advanced technology that senses once capsule strike on the counting channel.The presence of detectors and featured cameras ensuring exact number of capsules that fills in the container every time.

User Friendly- Easy to Use

Indeed, a capsule counting and filling machine is a compact and robust counting and filling machine that allows users with easy operating access by using touch screen parameters to control the system.

Easy to Mingle with Other Machines

This is well-structured and designed with professional skills which allows to integrate with other machines to run the production unit smoothly. For e.g. unscrambler, washing machine, labelling machine. Etc.,

A Time Saver

Picture Courtesy- Busch Machinery

Nevertheless, spending hours and energy on manual counting and filling procedure is now replaced with a time saver solution of incorporating a capsule counting and filling machine into your production business.

Boosting Production

Picture Courtesy-Sanle

A capsule counting and filling machine is a promising machine that helps in growing your business in saving multiple options like money, time, energy, manpower and other.

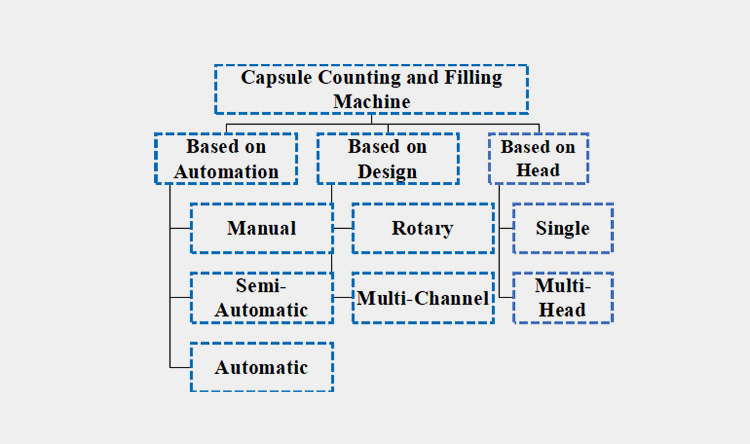

6.What are the Types of Capsule Counting and Filling Machine?

There are several types of capsule counting and filling machine that gives efficient functionality to the end-user depending on their requirements. Such as:

BASED ON AUTOMATION

Based on automation, a capsule counting and filling machine is categorized into the following:

Manual Capsule Counting and Filling Machine

This is most preferable type of capsule counting and filling machine for smaller businesses. This is because it is cost-economical and easy counting solutions where capsules are spread onto the counting try where it can fix into each cavity and helps you in error-free counting. The entire procedure can be performed by user himself. This is an easy to use machine which do not require any tips, trick, or training.

Semi-Automatic Capsule Counting and Filling Machine

This is the smart solution for medium to large production batches where loading and unloading of containers can be done manually, but remaining functions can be performed automatically. This machine can run medium to large batches in hours. Therefore, many industries and hospitals use semi-automatic machines as it gives you accurate and fast result.

Automatic Capsule Counting and Filling Machine

This is an advanced solution for top-notch production industries and excellent machine for running hassle-free large batches without requirement of any manual operation. You just need to feed in the parameters and switch on the machine. This machine is equipped with sensors, detectors and multiple channels, etc., that allows end-user with accurate output. This is the reason this is the most demanded and popular equipment that offer high profitability and business success.

BASED ON MACHINE DESIGN

Based on design, a capsule counting and filling machine is categorized into the following:

Rotary Bowl Capsule Counting and Filling Machine

This is a vibratory capsule counting and filling machine which is equipped with rotary bowl feeding unit that supply and counts capsules automatically and accurately. A rotary bowl is fixed with vertical base that moves and allows capsules to arrange and sort them selves by dropping into channel or pockets. This machine is also a fastest unit ensuring precise and error -free results.

Multi-Channel Capsule Counting and Filling Machine

This machine is featured with multiple channel that helps in counting and filling of capsule by offering them gentle shaky pathway to capsule at the same time. This machine is worth buying for large production sector as it can cater bulk production processes automatically.

BASED ON COUNTING HEAD

Considering counting heads, the capsule counting and filling machine is divided into the following:

Single Head Counting and Filling Machine

A capsule counting and filling machine featured with a single counting head offering precise and accurate throughput. This machine is suitable for moderate production capacity lines.

Multi Head Counting and Filling Machine

A multiple counting heads of capsule counting and filling machine is an exceptional advancement that has emerged and adopted by largest production companies for fastest and error -free counting and filling tasks.

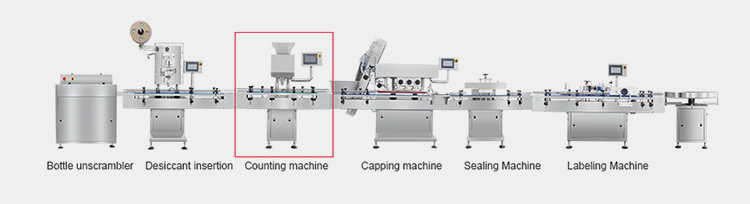

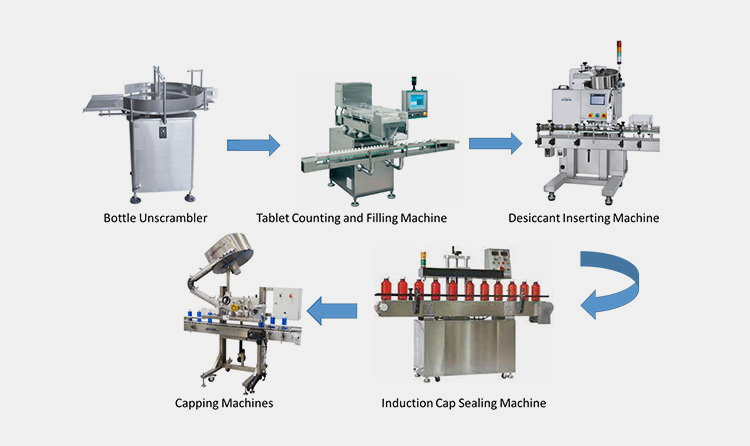

7.What is the Production line of Capsule Counting and Filling Machine?

Capsule counting and filling machine has completely streamlined of different machines comprised to form a production lien for mass production in several industries according to the product specificity.

| Machine | Description |

| Bottle Unscrambler | These machines ensures proper alignment of empty bottles throughout the production line to enable smooth and continuous processing without causing any interruptions.It is the primary to prevents the jaming of the bottles in bulks in the conveyor system. It helps in the maintenance of product quality by minimizing the risk of overfilling and underfilling. |

| Capsule Counting And Filling Machine | Capsule counting and filling machines are used to count and dispense capsules with high precision and accuracy.This machine helps increase product efficiency by saving time and human exposure, preventing contamination. |

| Desiccant Inserting Machine | For moisture sensitive capsules, these machines are used to insert desiccant pouches in each bottle accuratly to assure and physical or chemical changes induced by humidity. It profoundly contributes in consumer satisfaction and safety. |

| Capping Machine | Capping machines are used to seal the container by different snap caps, Roll on caps, crown caps, plastic caps as part of production line. It works with high production speed by reducing the production costs and most commonly used in food and beverages industries and phrmaceuticals. |

| Induction Cap Sealing Machine | For providing leak and spilling proof airtight seal as a preventive measure for moisture sensitive tablets by induction cap sealing machines. These machines assures quality of the product from any physical and chemical changes induced by humidity.Being the last step in the production line, it adds on an extension in the quality of the product. |

8.What Type of Products Can Capsule Counting And Filling Machine Fill?

Capsule counting and filling machine is one of a kind which can package any product. So, it can build your company to a profitability for catering various products such as:

| Hard gelatin capsules /Soft Gelatin/Tablets/Pill

The solid dosage form such as pills, tablets, various capsules require capsule counting and filling machine to package them into pouches or bottles and known as a great way to cater to mentioned products. |

|

| Candies/ Gummy Candies

Candies/ gummy candies are confectionary sweetened items which need accurate packaging to maintain weight and fill required number of items. These candies are packaged with the help of capsule counting and filling machine, thus, preventing any counting error and cross-contamination during handling. |

|

| Wax Beads

These are solid, circular shaped substances which when heated get liquefied and are then used to remove body hair. Packaging them into pouches using capsule counting and filling machine would be a sustainable move. |

|

| Laundry Pods

Laundry pods are small sized capsule like balls which are filled with liquid detergent in a predetermined quantity. They can be easily packaged by using capsule counting and filling machine. |

|

9.What Type of Packaging Material Capsule Counting And Filling Machine Can Fill?

Are you wondering whether this machine will be able to fill capsules in not just one, but several different kinds of packaging, giving you an edge over other companies in terms of attractive and versatile packaging? Then yes! It has the ability to fill your products in different kinds of packaging materials of various shapes and sizes. These are:

| Sachet

This easy to tear, flexible and convenient packaging can be used to store any kind of supplements or powdered medicine inside. Capsule counting and filling machine can fill the desired product into these sachets by the weighing filling method in a predetermined quantity. |

|

| Stand-Up Pouches

This packaging is one of the most flexible ones out there. It prevents the spillage of the product and keeps it fresh and secure. A capsule counting and filling machine helps you in the counting and filling of these capsules into these pouches efficiently. |

|

| Bottles

These bottles are made with highest quality materials to increase the shelf life of the capsules. They protect them from sunlight, air and moisture by preventing their contact with the capsules inside. Capsule counting and filling machine is the suitable machine to perform counting and filling of these bottles perfectly. |

|

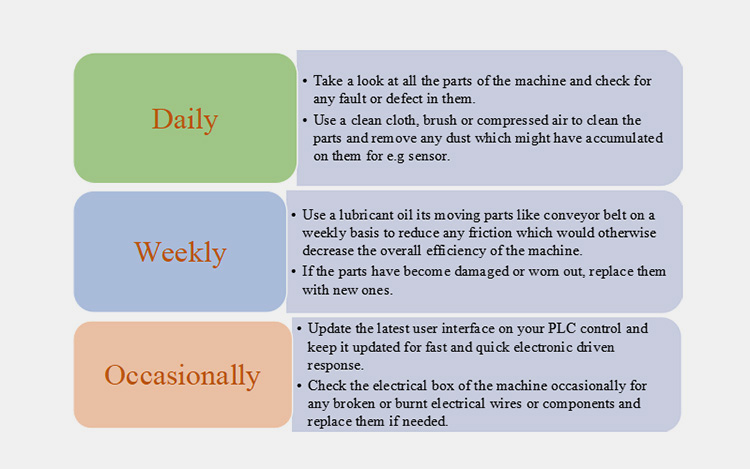

10.How To Clean and Maintain Capsule Counting and Filling Machine?

Just like every other machine which requires proper maintenance and regular cleaning for its optimization, capsule counting and filling machine also requires some steps to increase its lifespan. Below are the ways in which we can do this.

11.What Are Common Problems and Troubleshooting of Capsule Counting And Filling Machine?

| Problem | Solution | Picture |

| Capsules are Filled but not Displayed

This problem is accompanied by abnormal counting and overfilling of container without notifying the counting of each capsule. |

Locate the sensor and reset it.

Clean the sensor using alcohol dampened cloth on glass eye in a vertical and horizontal motion. Visually inspect and assure no debris or obstacle is presented there. |

|

| Capsules are Miscounted

This is the problem where capsules are miscounted due to overlapping of content or too excess height of the hopper or poor counting sensitivity. |

Slow down the counting speed.

Re-adjust the height of the hopper to the filling nozzle. Wipe the sensor surface using above cleaning method. |

|

| The Unit Counts Itself

This is the problem that is occurred due to poor sensitivity to detector. Plus, System setting were not calibrated. |

Clean the sensor.

Recalibrate the setting. Re-feed the data. Run a test to evaluate the process and proceed the production. |

|

12.What Factors Should Be Considered Before Buying Capsule Counting and Filling Machine?

Are you afraid of investing in the wrong capsule counting and filling machine? Don’t worry! You are not the only one. It is a nightmare for a lot of people who are too worried about the consequences they might face if they buy the machine which is incompatible with their production line. Let’s discuss some of the points which would ensure that you buy the best type for your factory and not incur any heavy losses.

Production Capacity

This factor is important since your factory’s production capacity will decide which type of capsule counting and filling machine you would need to buy. If you have a very high production capacity, then you would need an automatic capsule counting and filling machine to cater to your large-scale business.

Budget Friendly

Capsule counting and filling machine ranges from cheaper manual types to expensive automatic ones. If you do not have any financial restrictions, then go for automatic capsule counting and filling machine, but if you budget is low, then semi-automatic or manual ones would better for you.

Multi-Faceted

Capsule counting and filling machines have many types which have the ability to fill different type of containers. It can fill containers ranging from stand-up pouches, plastic bottles, bags, PVC PET containers and jars. These containers can be easily filled by automatic and semi-automatic capsule counting and filling machines.

Installation Area

It is highly critical for you to check how much area your production line can offer to install capsule filling and counting machine since some automatic machines would take large space. Whereas the semi-automatic or manual capsule counting and filling machine would have low space requirements.

Manufacturer Reliability

Don’t rush into buying capsule counting and filling machine from anyone who’s eager to sell their products. Check his company’s reviews on google and make sure he is reliable by checking if company has authorized documents to prove authenticity and product quality.

Conclusion

In conclusion, a capsule counting and filling machine is a multi-dimensional equipment that performs counting and filling of not only capsules, but many other products such as pill, tablets, candies, beans, etc., Moreover, this machine can perfectly and accurately do this job in a hassle-free manner. So, what are you looking for? If you’re willing to invest in this robust equipment; we would recommend contacting us. Allpack is the hub of providing excellent machineries related to capsule counting and filling purposes. Message us now.

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide