Button Counting Machine: The Complete Buying Guide in 2025

To counting buttons in textile manufacturing companies or other firms are very confusing. Sometimes you can over count them or under-count, after all after few attempts, it would be impossible to count them correctly.

Buttons are small disk that are sewn on your cloths either for fastening or for decoration.

In this article, I will talk about blessing of innovation and sciences that have solved this problem by bringing ‘Button Counting Machine’ to the competitive market world.

If you looking to purchase the machine, then this blog is for you; please read to get maximum advantages in order to procure the right machine for your production.

1.What is Button Counting Machine?

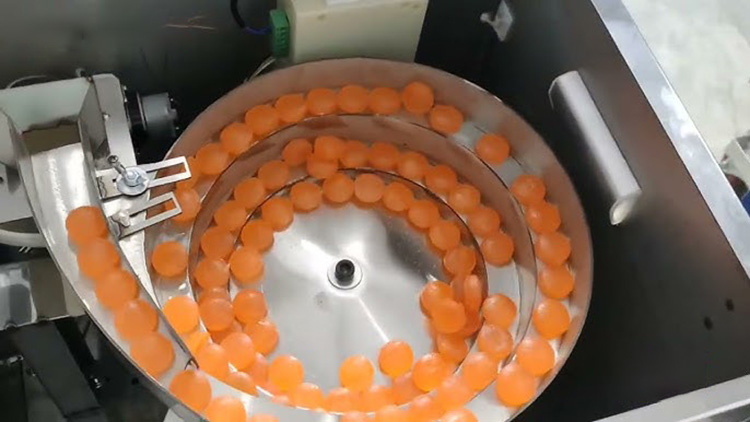

Button Counting Machine

Button counting machine is an effective tool which is used to count buttons, safety pins, beads and many more products and package them into pouches or bags

It has the amazing ability to transfer the product from the hopper into the vibratory plated and counting them, with only the desired number of products feeding into the pouches accounting for high yielding output, ensuring that your product is packaged in its original form without any spillage.

This machine is fast which can carry long hectic task in textile processing efficiently.

It comes in automatic, semi-automatic and manual. Depending on your production capacity you can choose the type accordingly.

2.Why You Need Button Counting Machine?

Button counting machine has several advantages which can prove beneficial for your company. This multi-featured equipment has lots to offer so let us discuss these benefits below.

100% Accuracy

Accuracy with Button Counting Machine- Picture Courtesy: ZHONGBAI PACKING MACHINERY

Button counting machine shows maximum efficiency since it gives 100% accurate results yielding maximum profits for your textile industry. This is possible because of the cutting edge, advanced technology it offers. It does not make any mistakes in counting and offers error free packaging.

Insensitive To Dust

Dust Resistant process in button counting machine- Picture Courtesy: fastenerpackagingmachine

The machine is dust resistant and completely blocks it off, keeping the machine clean. This is because the counting unit is separated from the tracks. As a result, the efficiency of the machine remains optimum.

Minimal Downtime for Cleaning

Say Bye to Downtime in Button Counting Machine

Since the parts of this machine are small and do not weigh heavy, it is easier to maintain them. Moreover, the collection of dust in counting unit also helps to minimize its cleaning process time. As a result, your textile production unit will run effortlessly without any downtime.

Easy Handling of Difficult Objects

Button Counting Machine- An easy-to-Handle Unit- Picture Courtesy: One Inch Round

This equipment is equipped with a wide track on which products can easily travel and packaged into pouches. Moreover, the easy filling process also makes it easy for handling and counting small, flat or differently shaped objects.

Fast Changeover

Efficient Changeover Options of Button Counting Machine- Picture Courtesy: Asking For Trouble

The parts of the machine are light in weight which makes the changeover of parts quick, helping in tool free release. Also, the detection of textile-based product data by sensors which includes its size and shape accounts for the fast changeover.

Embedded Broken Detection Capabilities

Fast Alarming Notifications in button counting machine- Picture Courtesy: FabCouture

Button counting machine has preinstalled sensors which can detect defected pieces like that of the buttons, beads and safety pins. These parts are not counted and poured into the pouches and instead sent to the rejection unit. Thus, saving your clothing business from profit loss and your precious time.

Low Maintenance

Easy Maintenance of Button Counting Machine- Picture Courtesy: UpKeep

The presence of feeders and motor in the machine prevent the calling of maintenance workers to fix and adjust the machine regularly. Thus, it helps you by avoiding unnecessary expenses and increasing your profit margin.

Automatic New Product Setup

Excellent Setup Keys of button counting machine- Picture Courtesy: UID

If you use this machine, you won’t have to worry about calibration since it offers an automatic calibration process. When the desired product is placed on the tool, the camera picks up its shape and size and the parameters are set accordingly. This prevents any man-made error and provides you with perfect, error free products.

3.What Industries Need Button Counting Machine?

Button counting machine is a versatile equipment which can be used in several industries. You can adjust it according to the field you belong to and it will work perfectly all right yielding optimum results. Below are the industries in which it can be used.

Textile Industry

Application of button counting machine in textile industry- Picture Courtesy: Michaels

This multi-billion dollar industry is responsible for manufacturing many goods such as threads, buttons, needles and cotton yarn. You can use button counting machine for counting them as you desire and packaging them. You can choose either an automatic or semi-automatic button counting machine, depending upon your production capacity.

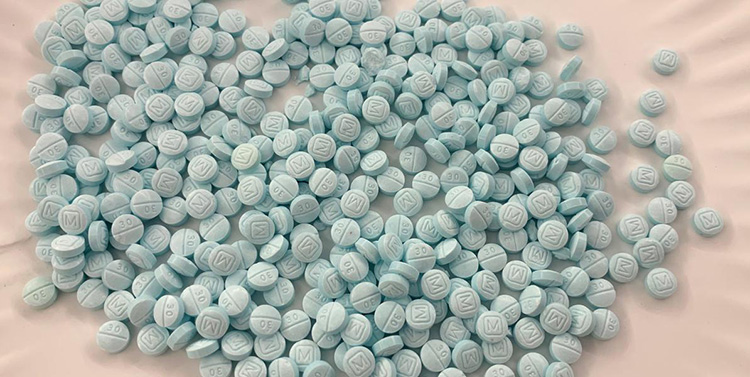

Pharmaceutical Industry

Application of button counting machine in pharmaceutical industry- Picture Courtesy: GER Pharma

This large scale industry is in great need of an equipment like button counting machine. It deals with products like soft pills, hard capsules, tablets and other medicinal drugs accurately and fill them in the desired pouches. You can opt for either automatic or semi-automatic button counting machine.

Food Industry

Application of button counting machine in food industry- Picture Courtesy: Fiar

Food industry deals with the manufacture of confectionary items like sweets, chocolates, gummy bears, toffees and other food items like cereals and grains. All these products can be packaged into containers with high precision by using a button counting machine for their counting.

Nutraceutical Industry

Application of button counting machine in nutraceutical industry- Picture Courtesy: Pretium Packaging

The Nutraceutical industry is critical in improving the standard of living of various people and helping them have a productive lifestyle by producing items like vitamin supplements and food pills. These capsule-like products can be counted by a button counting machine and then packaged into their desired containers.

Agriculture Industry

Application of button counting machine in agriculture industry- Picture Courtesy: DEA.gov

This industry is responsible for manufacturing items which provide food for humans and animals. Items like pesticides, insecticides and food goods like wheat grains, rice grains, animal fodder, pellets and much more can first be counted using button counting machine and then packaged into bags and containers.

Chemical Industry

Application of button counting machine in the chemical industry- Picture Courtesy: The Spruce

This versatile industry is responsible for making a variety of products like chemical fertilizers, caustic soda, rubber, limestone all requires an effective counting machine which can be used to feed them into bags and pouches with high precision and accuracy. Button counting machine can be used for this purpose.

Cosmetic Industry

Application of button counting machine in cosmetic industry

The cosmetic industry is speeding up its manufacturing of beauty products like wax beads, vitamin capsules, soaps and much more to meet the increasing demand. Thus, you can use a button counting machine for counting them and packaging it into aesthetically pleasing containers.

4.What is Working of Button Counting Machine?

The working principle of button counting machine is discussed below:

Step 1: Buttons Loading

Button Loading- Picture Courtesy: ZHONGBAI PACKING MACHINERY

The working on button counting machine starts upon loading the counting material into the feeding hopper. Now the buttons fall or enter slowly and gradually from the hopper to vibratory channels which are continuously shaking to orient the buttons and scan them.

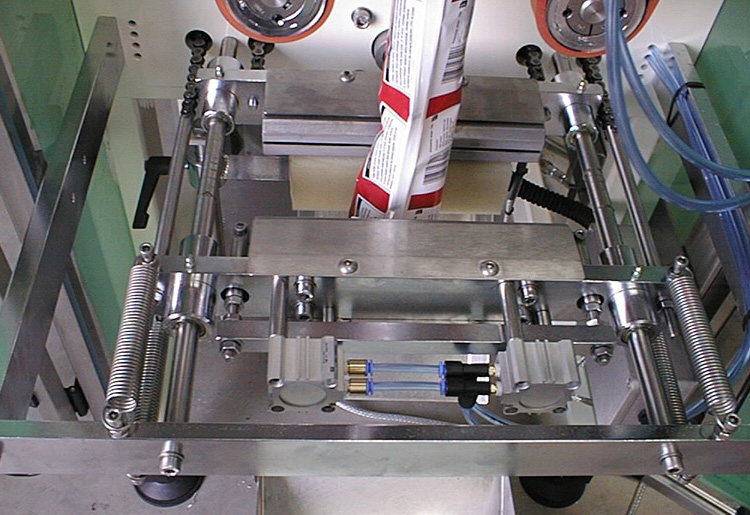

Step 2: Loading of Packaging Film

The packaging film for the formation of button pouches is placed on the film roller and is gradually passed to bag making station where sealing jaws form a partial pouch-like structure with sealing bottom edges.

Step 3: Counting & Filling

Buttons are now steadily entering the counting section which is a narrow filling nozzle with a sensor (visual mostly), the detection of correct button is allowed to fill the formed pouch while incorrect or faulty button is rejected. Each button passes through the flashlight or photo electric sensor with high camera vision will mark as counted and dispensed. These counted buttons are then loaded in the partially formed bag.

Step 4: Discharging

Cutting and Discharging- Picture Courtesy: AMP Rose

After filling the preprogrammed number of buttons in the bag then ends of two bags are cut from each other by the cutting blade. Now the filled bag is discharge out the machine by the chute.

5.What are Parts of Button Counting Machine?

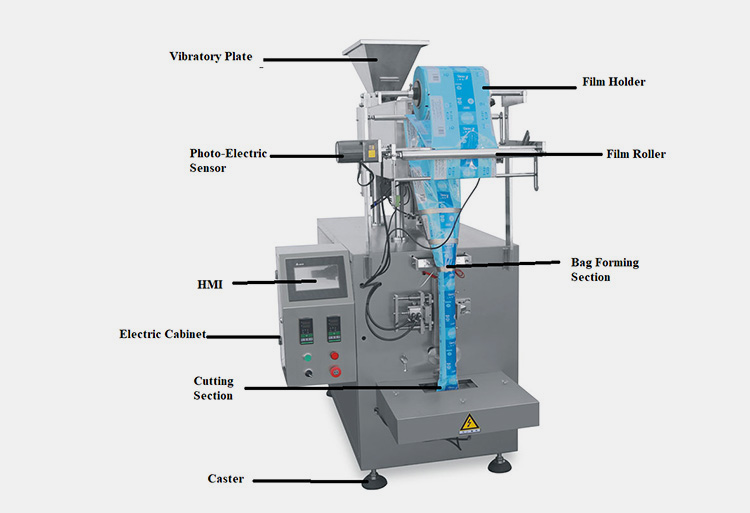

The parts of the button counting machine

| HMI Touchscreen

|

This is a smart interface that is responsible for receiving orders from users or technicians by inputting data using touchscreen keys presented on the display unit.

It is composed of various features such as keys (counting speed, time, timers, memory, etc); side by side you can run and stop the process and importantly various troubleshooting can be done by this unit. |

| Vibratory Plate

|

The vibratory channels are designed just after the hopper, once the buttons are falls directly on the parallel straight lines; its vibration ensure orientation and movement of buttons gradually toward the fillers.

These channels are mostly accompanied with scanner that strictly monitor the process and material. |

| Packaging Film Holder | It is a roller-like device on which a large role of packaging film is placed. It aids in a continuous supply of film for bag formation. |

| Film Roller | There are two-three roller parts present in the button counting machine that assist in the smooth movement of packaging film to the bag-forming unit. They keep the film under appropriate tension. |

| Bag Forming Station |

This is the part of a button counting machine that is offered with sealing bars that join two layers of packaging film for creating a pocket type structure. |

| Photo Electric Sensor

|

The photo electric sensor is equipped with camera vision systems or light detection systems that strike a light on the buttons and then measure the reflected light for their counting. |

| Electrical Cabinet

|

The electric cabinet is composed of an enclosed system that facilitates various electrical components such as electrical wires, plugs, motors, relays etc., to the button counting machine. |

| Cutting Section

|

The pouch filled with buttons is separated from the unfilled bags using a cutting knife or blade. In this section, the separation of two consecutive pouches occurs and then they get discharged from the machine. |

| Caster

|

This unit is composed of a stainless-steel framework of the button counting machine and a caster which is responsible for supporting the machine and allowing easy movement and installation from one facility to another. |

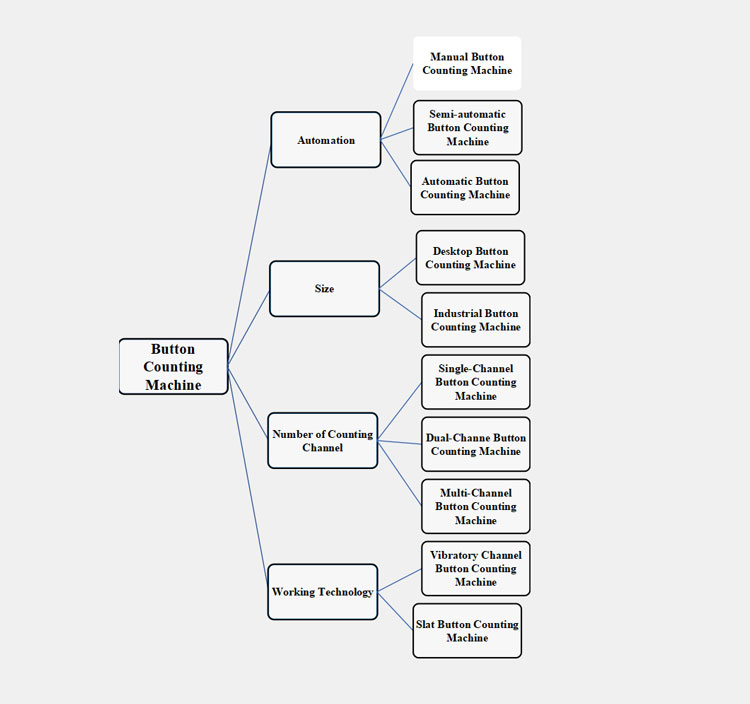

6.What are the Types of Button Counting Machine?

Button counting machines are classified into various kinds depending upon the automation level, technology, and size. The types of button counting machine is categorized into the following:

Depending Upon Automation

Today, button counting machine is available on various automation. The selection is based on whether you are comfortable with which type. The discuss below are the mentioned types:

A Manual Button Counting Machine

A Manual Button Counting Machine

This is a very simple version and easy to buy. As its name shows, the button counting process takes place which is based on manual handling as well as machine assistance. The user has to pour a specific quantity of buttons on the manual button counting machine and count each object by holding the counter tray.

Once you are done with counting, you can press the button present on the machine to release the number of buttons.

A manual button counting machine is suitable for small working facilities.

Semi-automatic Button Counting Machine

Semi-automatic Button Counting Machine- Picture Courtesy: Makwell

Unlike manual button counting machines, this is easy to use and gives you efficient results in bulk. Here, some of the work is based on human intervention, such as pouring of buttons, and placing and removal of filling objects such as sachet, pouches, or containers. However, the rest of the task is rapidly and operated by the machine.

A semi-automatic button counting machine is a good choice for small to moderate production setups.

Automatic Button Counting Machine

Automatic Button Counting Machine

Today, everyone prefers to add an automatic button counting machine as it is very helpful in giving you easy working, accurate results, and minimum to no human intervention. The buttons are fed into the vibratory channel of the machine where A to Z operation is performed by the machine itself without need of any supervision, or manual monitoring. This saves huge amounts of expenses in terms of labour pay as it does not need many operators to supervise machines.

This is a good selection for you if you’re running a large industry.

Depending Upon Machine’s Size

If you have a smaller installation space or working line; and running a large production process. Then, don’t worry about adding a button counting machine due to compact space issues. Check the various sizes availability:

Desktop Button Counting Machine

Desktop Button Counting Machine

This machine is mostly preferred in small textile industries, garments, or boutiques where you have astringent space, a closed system and a congested working environment.

Considering your tough schedule and swift results; a desktop button counting machine is designed.

The machine is referred to as semi-automatic where you can pour the number of buttons or decorative objects you need to count, and results will be displayed and dispensed.

Industrial Button Counting Machine

Industrial Button Counting Machine

Large textile industries mostly require button counting machines to run the counting process in bulk. The machine is capable of running huge procedures day and night without exhausting you and itself with maximum throughput. Advanced and computerized sensors and digital display aids in the quick and precise counting of buttons in these industries.

Number of Counting Channel

The button counting machine is featured with additional counting heads; if you’re interested to know a suitable type for you then check ahead.

Single-Channel Button Counting Machine

Single Channel Button Counting Machine

This is a conventional and commonly available type of button counting machine where a single vibratory channel is responsible for dropping and counting buttons. The machine is good for running small to moderate even large production batches. However, it has a slow counting capacity as compared to double and multi-plate button counting machines.

Dual-Channel Button Counting Machine

Double Channel Button Counting Machine

A button counting machine with two counting vibratory channel that gives you an increased capacity button counting throughput with a high accuracy rate. It is used in the medium and large-sized textile industries because of its higher counting speeds.

Multi-Channel Button Counting Machine

Super Fine Multi Channel Button Counting Machine

In this type, the button counting machine is designed with more than two vibratory channels which simultaneously count the numbers of buttons per hour. For example, thousands to thousands of buttons hourly. It is preferred by large-sized productions as they need to count large batches of buttons in a short time.

The machine offers you tremendous high-speed operation and results therefore considered a successful tool for large production industries.

Depending Upon Working Technology

A button counting machine is featured with distinct operation; check below to find which one is preferred and can be the best fit for your product type.

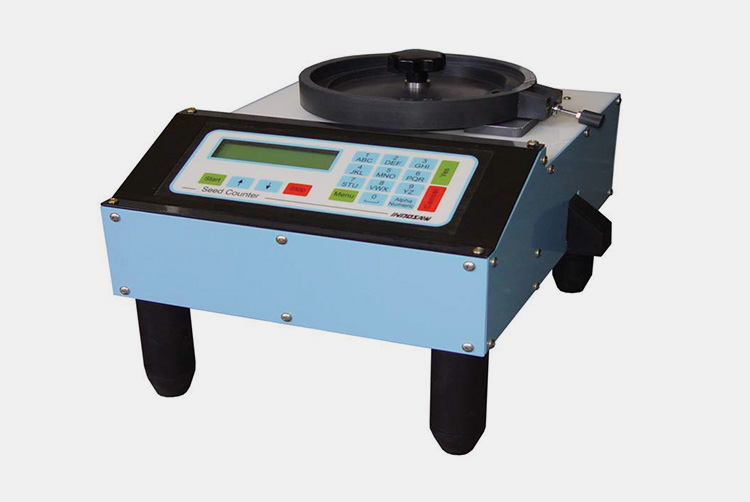

Vibratory Channel Button Counting Machine

Vibratory Channel Button Counting Machine

This is a conventional way of working where the number of vibratory or shaky channels addresses the various buttons toward counting heads.

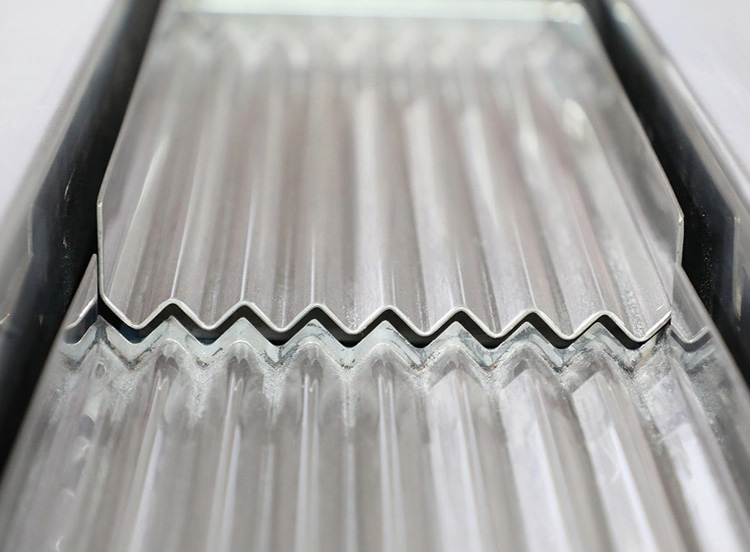

Slat Button Counting Machine

The Slat Button Counting Machine- Picture Courtesy: IPS

This is absolutely more innovative but comparatively an expensive option as compared to vibratory where a slat or belt leads to hold the button and count them when it fits into each slat, belt or pocket. There are thousands of slats available in the slat button counting machine hence it proves an accurate result and the fastest throughput.

7.What are the Problem and Solution of Button Counting Machine?

The button counting machine is an efficient tool but sometimes every user might find technical issues which needs to be solved immediately prior to falling into bigger problems. The number of technical issues are mentioned below with respective solutions.

| Malfunction State | Malfunction State | Malfunction Solution |

| Machine counts buttons twice instead one.

|

This is important problem which is caused by incorrect orbit outlet, or incorrect setting of filling nozzle. | You need to re-adjust the setting, installation, and re-calibrate the machine to correct the movement of the buttons. |

| The buttons marking is displayed constantly without Changing its number.

|

This is common problem where buttons are stuck around detector and blocks the movement of other material.

The presence of dust or any minute particle also cause the counting display problem.

|

It is recommended to clean the detector regularly. |

| Observe and clean the counting channels. | ||

| Slow the speed of counting process so button jamming problem can be reduced. | ||

| Buttons are on the Counter, but Machine does not Display them.

Buttons Not Showing- Picture Courtesy: LG Information Display

|

Machine setting or Disturbed or Hanged.

This problem could be due to circuit breakage or electric eye short circuit. |

Reset the machine’s setting. |

| Correct the wiring, replace damaged wires with new one. | ||

| Re-install the setting and run the test method. | ||

| Incorrect Number of Button Counting

|

This problem can arise due to the accumulation of dirt and debris.

The counting speed of buttons is too high. The detector is covered by unwanted particles. |

Regulate the speed of button counting. |

| Clean the surface of the detector and the machine. | ||

| Reset the machine and assess the problem by running the test. |

Conclusion

Counting buttons was a lethargic job in traditional days which has been replaced by the advent of contemporary advanced machines like button counting machines. Today, your business is profitable and time-saving if you have this robust machine in your setup. Choosing the right machine is always a wise decision that can either boost or fall your production. However, Allpack is there to offer promising services and machinery that won't compromise you by any means. Trust us to purchase excellent machines in such an affordable way! Contact us now.

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide