Bottling And Labeling Machine: The Complete Buying Guide In 2025

Bottling and labeling machine are the key players behind the success of every pharma. Do you know how it carries the complete production conveniently? We are here to help! Bottling And Labeling Machine: The Complete Buying Guide In 2024 is all about the essential factors that you are looking for!

Picture Courtesy: UGA Today

If you’re planning to set up the unit for faster and accurate packaging throughput, then go through this blog, this is because you will be able to know from basics to advance knowledge related to bottling and labeling machine. let’s get started.

1.What Is a Bottling and Labeling Machine?

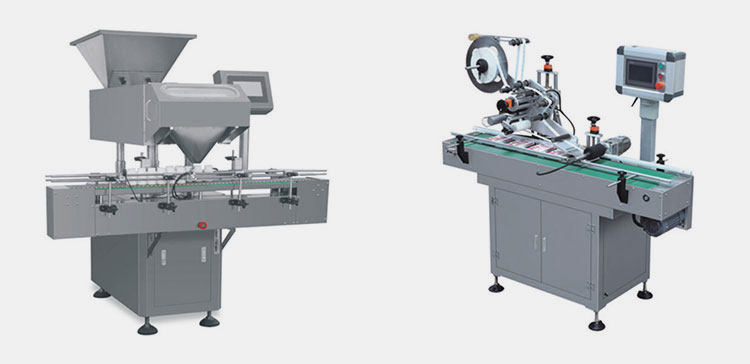

Bottling and Labeling Machine

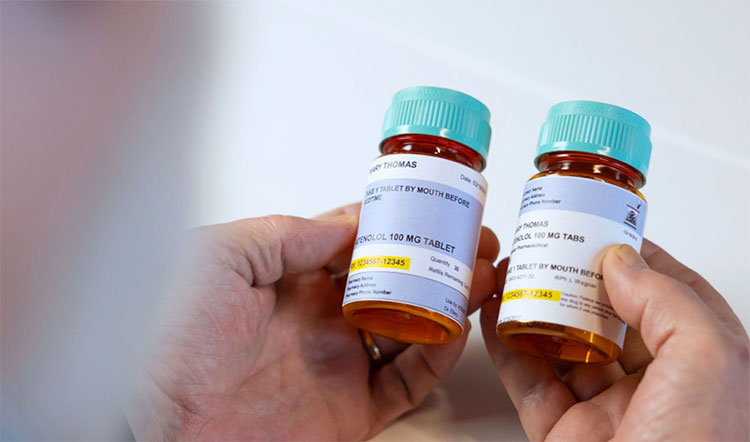

A bottling and labeling machine is a specialized equipment that everyone utilizes in certain areas where packaging of materials such as tablets, pills, capsules, and other relevant items take place.

This machine helps in the counting of accurate number of tablets or pills into bottles followed by precise sticking of the label for enhancing its branding and identity.

Here’s how the machine is responsible for not only counting pills and inserting them into each bottle as assigned by you but also capable of transferring those bottles toward the labeling section where they’re subjected to get labels via several other mechanisms.

This means, that it can be done by using hot glue, cold glue, compression, and others. This is very important equipment that assures that medications are accurately counted and labeled that’s why every manufacturer really looks for it.

2.How Bottling and Labeling Machine Benefits You?

A bottling and labeling machine is a linear and integrated concept of filling and labeling bottles using a sensor and automatic work unit. This advanced machine is of various benefits that offers to its customers. Some of the major benefits include:

100% Accurate Bottling

Error Free Bottles

This means that the bottling and labeling machine is capable of counting and filling products into bottles without carrying the risk of error.

Hence, each bottle is receiving an excellent quantity as mentioned in the label. So, your mentioned amount is exactly matches what present inside the bottle therefore patient gets what they deserve.

Reliable & Durable

Reliable Product- Picture Courtesy: Alumni.Oudi

A bottling and labeling machine is a one-stop solution that is able to run large production batches with no- breakdowns or interruptions.

This is all because of its design and implementation of advanced innovation that ensures reliable and durable performance and increasing overall productivity.

Sleek Construction & Meets Pharma Grade Standards

High Quality Standard Compliance- Picture Courtesy: Sound of Breaking Glass

The machine is made up of high-quality materials that meet pharma grade standards, which is not only adhering quality and regulatory requirements but easy to use and guarantees no contamination.

Fast Acting Unit

Fast Acting Machine

The machine is designed with features that allow fast and greater operation speed including bottling and labeling in an efficient manner. Its high-performing pace results in fast action thus meeting high production demand with quality.

Compliant with Various Solid Dosage

Ideal for Various Types of Solid Dosage Form- Picture Courtesy: Mirage News

Whether you’re hooked to tablets, capsules, pills, or caplets., the bottling and labeling machine is promising to cater to them without wasting your time in setting up the different procedures or changeover. It is flexible for you to enjoy a manufacturing job.

Ideal Standalone Unit

Excellent working- Picture Courtesy: National Custom Compounding

This means a bottling and labeling machine is ideal enough to bring the operation without needing any additional equipment integration. It is an easier solution that is self-sufficient with simple installation and simple operability.

3.How Bottling and Labeling Machine Serving Various Industries?

Suppose a manufacturing company is operating without a bottling and labeling machine. astonished? Because it is not possible to carry quality production services without this robust machine. This machine is hooked to wide industrial applications; although we will mention some of the very important industries as it is not possible to describe all.

Pharmaceutical Industry

Applications in the Pharma Industry- Picture Courtesy: Perfect Imprints

How would you feel about a brand that claims in the label but is untrue? Especially when it comes to bottling medicine and conveying messages about dosages, information which must be based on proven grounds. In pharmaceuticals, bottling, and labeling machines play a significant role in the fast and accurate counting of respective products such as tablets, capsules, pills, etc in a hygienic manner.

Food Industry

Foodie Flavours Gums in the Food and Beverage Industry

Think of foods that are always mouth-watering. Manufacturing of food enhancer cubes, candies, gummies, chocolates, coffee beans, bubble gums, sweeteners bounties, and so many food products is taking place in the food industry. For the packaging process, you will need to add a bottling and labeling machine to carry accurate counting of these items in each bottle with product labeling over its outer surface.

Nutraceutical Industry

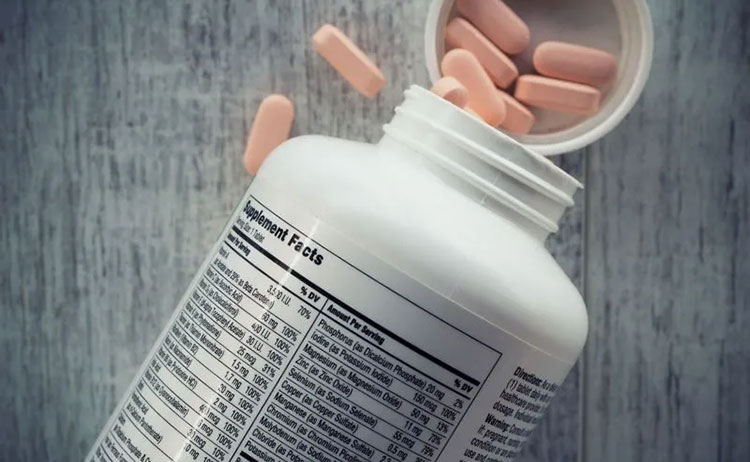

Applications in the Nutraceutical Industry

Everyone loves nutraceutical products as they boost your health without any prompt side effects. Today, the nutraceutical industry displays an equal demand for bottling and labeling machine like any other industry. Nutraceutical items such as vitamins, probiotics, health supplements in tablets, and capsule formulations need a bottling and labeling machine for packaging and boosting branding as the machine is efficient enough to carry these tasks in a promising way.

Cosmetics Industry

Beauty Pills in Cosmetics Industry- Picture Courtesy: Live Strong

It is not surprising that bottling and labeling machine are important for packaging cosmetics products. If you are wondering about the types of products then they include hair products, foaming bars, waxing beans, serum packed in capsules, beauty tablets used during skin cleansing, etc.,

However, cosmetic products need to be branded high via catchy labeling with colorful graphics. These all tasks are promisingly performed by bottling and labeling machine.

Chemical Industry

Applications in the chemical industry

A chemical product without a label is always harmful. A manufacturer must be extra careful for accurate bottle filling with justified and true information about that product. Of course, performing these tasks manually is much more hazardous to your workers. Therefore, a bottling and labeling machine is used for quick and safe dispensing and labeling of products like pH tablets, chemical granules, alkaline and acidic tablets, as well as organic and inorganic hard formulations.

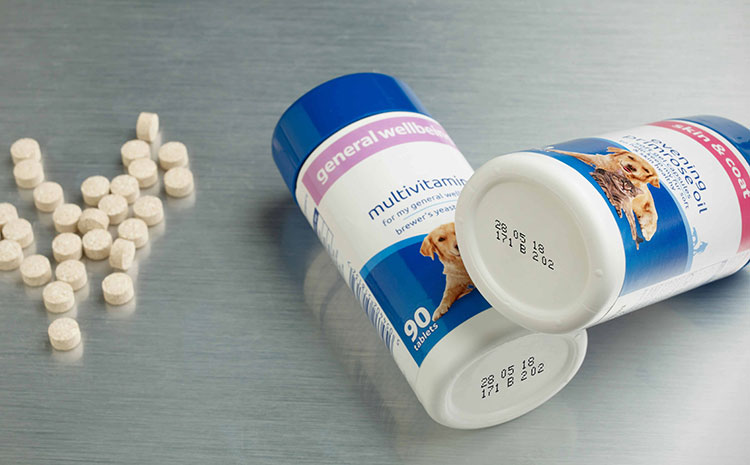

Veterinary Industry

Applications in Veterinary Industry

We all love pets! When it comes to taking care of their health. Every one of you goes and picks the brand that offers quality products. This is the responsibility of the manufacturer to provide you with correct and safe medicine with the proper information mentioned label. The veterinary industry mostly utilizes bottling and labeling machines for dispensing antibiotics, pills, supplements, painkillers, etc.

Herbal Industry

Application in Herbal Industry- Picture Courtesy: pixel.com

This industry is concerned with the making of organic tablets, capsules, granules, bars, beans, and related products that are dispensed into bottles and labeled well by using a bottling and labeling machine.

Stationery Industry

Sharpeners labeled bottle in the Stationery Industry

Various stationery products are filled and packed in bottles with catchy and beautiful labels by using a bottling and labeling machine. The products include erasers, sharpeners, pins, toppers, small tools, clips, and related products.

4.How do Bottling and Labeling Machines work?

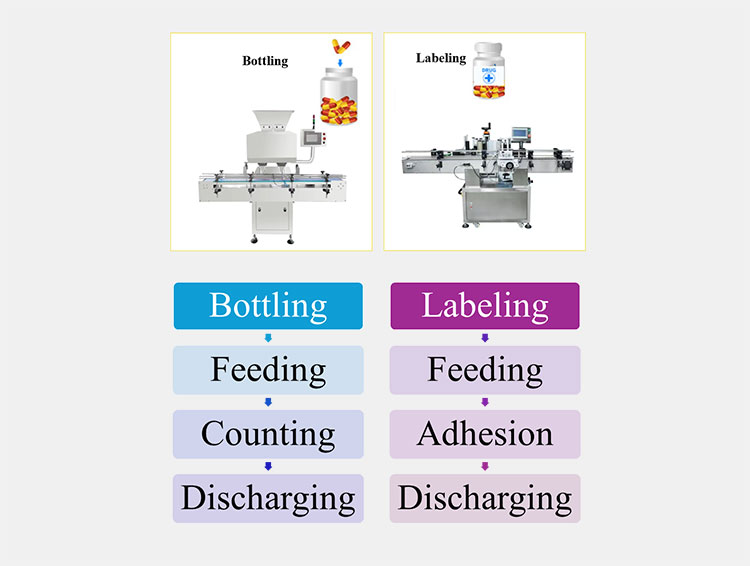

The bottling and labeling machine working is categorized into two basic sections, bottling and labeling.

Let’s talk about bottling first.

Bottling

This is the first step that follows a few major steps mentioned below:

Bottling- Picture Courtesy: Huizhou Pingfang Trading Co., Ltd.

| Step 1: Bottle & Product Feeding | For bottling, the machine is integrated with other units such as bottle unscrambler, this is suitable for those machines that are semi-automatic and automatic in feature.

The properly aligned positions of the bottles are fed inside the machine and are ready for filling. However, the counting products are fed into the hopper either manually or mechanical feeder. |

| Step 2: Counting and Filling | The vibratory channels help the flexible movement of counting items to transfer toward the counting section.

This is an extremely important procedure where the presence of bottles is sensed by the machine and allows the unit to introduce a defined number of tablets inside them. If there’s no bottle, there won't be filling. The bottles come and leave the section at high speed without any error. |

| Step 3: Discharging | Once the bottling has finished, the PLC screen displays the final interface to you. It includes the number of counted items and the correct condition of the final product. This means you’ll be pretty sure that the throughput is high quality and promising. It's time to move towards a labeling machine. |

Labeling

Allpack Labeling Machine- Picture Courtesy: MUSE AI

This is the second step of bottle packaging where a labeling unit serves the application of desirable labels over the bottle surface. Let’s see how it works.

| Step 1: Feeding | A pre-printed label roll is affixed to a specific part of the machine for unwinding. This machine is basically integrated into the last section of the production line for label application. |

| STEP 2: Adhesion | The conveyor of the labeling machine acts as a circulatory system that ensures the steady movement of the bottles into and out of the labeling unit to carry the seamless flow.

The mechanical fixtures allow the appropriate application of labels over the surface and the presser is responsible for accurate and uniform adhesion of the labels. This function is modulated by a driver roller (dragging label strip), and a reel (maintains strip tension) to ensure the exact application you want. |

| STEP 3: Discharging | The filled and labeled bottles leave the unit once entirely catered by the bottling and labeling machine. |

5.What Is the Composition of the Bottling and Labeling Machine?

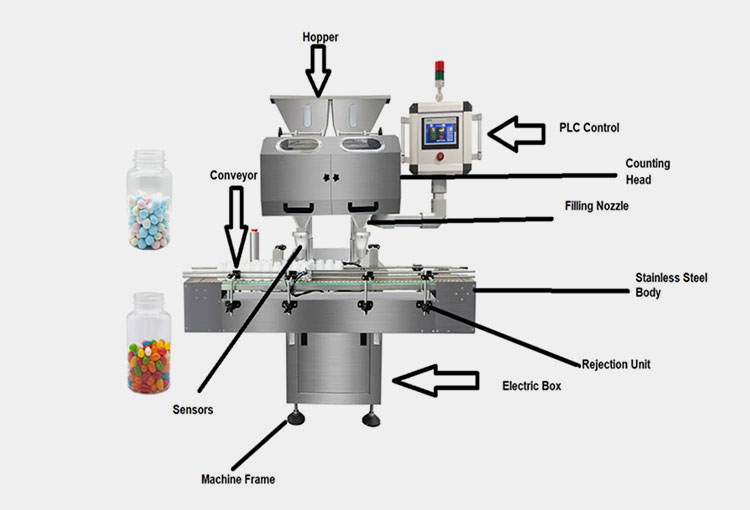

Parts of Bottling and Labeling Machine

To understand the basic parts, we have displayed a labeled image of the bottling and labeling machine. The function of each component is discussed below:

| Part | Description |

| Hopper | The material to be filled in the bottles is stored in a large container of the machine known as a hopper. This is mostly equipped in the upper position which helps in the easy flow of the material implementing the force of gravity. |

| PLC Control | This component of the machine is best described as a brain, which means you can put values and protocols using the touchscreen interface. Click and Enter allows the machine to interpret and send messages and produce desirable jobs. However, it is also able to store and memorize old programs and notify you about major alerts such as alarms, maintenance, or any malfunctioning. |

| Counting Head | Counting heads allows a clear way for counting items to move from vibratory channels toward filling nozzles. this is mostly equipped with transparent glass to visualize the procedure. |

| Filling Nozzle | This narrow passage allows precise and accurate filling of items into the bottles. |

| Conveyor | Bottles come toward the filling nozzles, fill, and leave the unit toward labeling with the help of a conveyor. It is an important component that facilitates the smooth carrying of bottles in and out of the machine respectively. |

| Rejection Unit | If any item is damaged, for example, a tablet with an irregular surface, chipped or sticky capsule, incorrectly coated surface, etc, such material can not be dispensed as the machine senses and sends them directly toward the rejection unit. This unit prevents your final product from mixing with unwanted material. |

| Sensor | According to our analysis, the sensor is the major unit that performs remarkable functions in bottling and labeling machines. It detects the presence of tablets or capsules and displays them as counted on the screen. This is also responsible for important notifications by detecting problems happening inside the machine. |

| Stainless Steel Body | The bottling and labeling machine is constructed with a stainless steel body that is beneficial in minimizing cross-contamination as it cleans the surface easily. |

| Electrical Box | The electrical components of the bottling and labeling machine are enclosed in an electrical box to protect the user and the environment. |

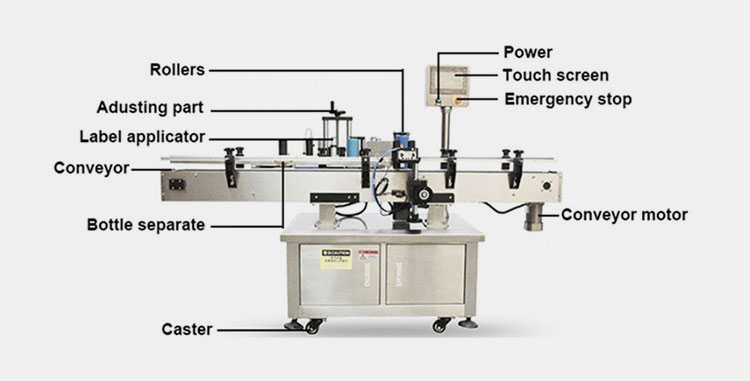

| Rollers | This is the component of the labeling unit that allows adjustment, fixation, and movement of the labeling roll. |

| Touchscreen | Both units, bottling, and labeling machine are equipped with a user-friendly touchscreen. You can operate the machine by pressing the simple key options on the screen. It allows reading and incorporation of the messages and alerts. |

| Emergency Stop | If there is an unwanted situation, do not worry., bottling and labeling machine are featured with an ‘emergency stop’ that halts the machine once you press them. |

| Adjusting Part | The fine-tuning and alignment of the machine can be done by using this option. This is mainly required for precise and perfect sticking of labels. |

| Label Applicator | The application of labels is done by using this component. This can be followed by either a roll-on label, hot glue, pressure-sensitive, or other different ways. |

| Bottle Separator | The proper distance between bottles is maintained by this component which prevents jamming the process. |

| Conveyor Motor | The conveyor of the unit is driven efficiently by a conveyor motor. |

| Caster | Bottling and labeling machines can easy to move install and re-adjust by simply a caster. This component not only helps in adjustment but also supports the entire framework. |

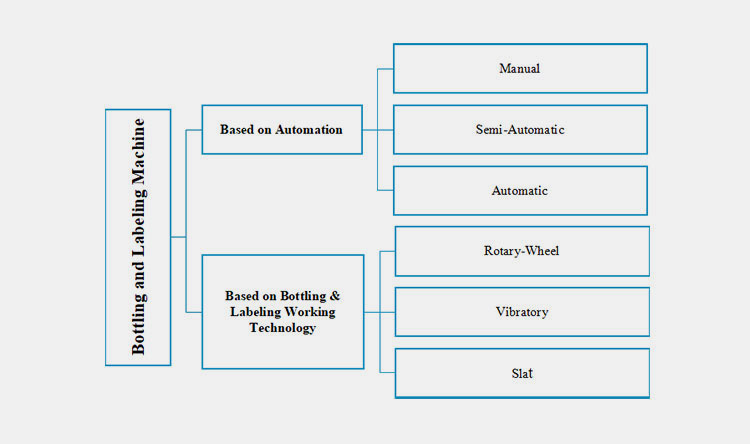

6.What Is the Classification of Bottling And Labeling Machine?

The classification of bottling and labeling machine is so extensive. The game is still not stopped here, in the coming days, you will also see more. This is all due to more production demand and the need for new advancements that are implemented in every new model. We have classified a comprehensive chart below related to available types of bottling and labeling machine.

Based on Automation

The bottling and labeling machine is classified into the following categories:

Manual Bottling and Labeling Machine

Manual bottling and labeling Machine

This is the simplest machine known for easy application and portability. This machine is ideal for small businesses, because, you can fill bottles with optimized quantities and label them by manual handling. A counting machine has a simple tray with small holes to pour and adjust counting items.

Once counting is done, you can dispense items into bottles.

A labeling machine is designed with a handwheel, handle, and adjusting roller for the labeling die. You can manually apply the label by holding a bottle and pressing the button to stick the label on the bottle's surface.

Semi-Automatic Bottling and Labeling Machine

Allpack Semi-Automatic Bottling and Labeling Machine

This is a modern and more advanced type that operates following automatic functions with somehow manual handling. For instance, you can place the bottle for filling and remove it when the process is done. In the same way, you can position and remove the bottle to be labeled whereas the remaining task can be performed by the machine automatically. This machine is suitable for running small to moderate batches.

Automatic Bottling and Labeling Machine

Automatic Bottling and Labeling Machine- Picture Courtesy: Aipak Pharmaceutical

This is the most efficient and fast machine that ensures rapid and reliable counting and labeling of the bottles and is helpful in the running of large production batches. As its name shows, the entire work takes place automatically, which means feeding, filling, labeling and discharging procedures do not require any human intervention though it is carried out automatically.

This machine is suitable for long-term running without risk of errors and long-standing operators for monitoring and dealing with the work. You just need to feed in the necessary procedure steps in the machine system and the rest of the job is performed by an automatic bottling and labeling machine.

Based on Bottling & Labeling Working Technology

According to working technology, the bottling and labeling machine is divided into the following types:

Rotary Wheels Bottling and Labeling Machine

Bottling and Labeling Machine- Picture Courtesy: Aipak Pharmaceutical

This type of technique is mostly observed in semi-automatic and automatic equipment which is commonly used for various shapes, production capacities, and materials.

The machine features rotary wheels that ensure movement of the pills or filling material to push toward respective bottles. This machine follows precise and accurate working which is not the only way to cheap but suitable for dispensing large production setups. Hence, you can achieve high productivity with an effective budget.

Vibratory Bottling and Labeling Machine

Vibratory Bottling and Labeling Machine- picture Courtesy: Aipak Pharmaceutical

As compared to the rotary wheel bottling and labeling machine, this equipment offers fast working technology. The presence of vibratory channels allows fast movement of the pills, tablets, or filling items. The scanners and detectors reduce the chances of error and provide fast filling. This machine is mostly used in large industrial manufacturing sectors where packaging demand is almost very high.

Slat Bottling and Labeling Machine

Slat Bottling and Labeling Machine

This is the fastest bottling and labeling technology. The machine is designed with a specialized structure where slats or cavities are presented throughout the counting area allowing tablets, pills, or related items to be fixed in each cavity. So, there won't be any chances of double or miss-counting.

This machine ensures that you can process thousands of tablets each hour. However, the machine is hooked to some limitations, for example, frequent changeover for items with different shapes.

7.What Is A Bottling And Labeling Machine Production Line?

There are various other important machines are included in the production line of bottling and labeling which helps in the final production of packaging. The execution of every unit plays an important role in bringing quality results.

Allpack Bottle Unscrambler |

Bottle Unscrambler

An upright and uniform supply of bottles is often supplied by a bottle unscrambler machine. This machine receives bottles of various shapes and sizes randomly. Using a pressurized air blower and movement of a vibratory disc helps them to acquire an upright position and sends them to the next machine with the help of a conveyor. |

Bottling Machine |

Bottling Machine

This is the main unit that helps in the correct filling of products inside every bottle. |

Desiccant Inserter |

Desiccant Inserter

To avoid the progression of moisture inside every bottle, a small packet of desiccant is inserted with the help of a desiccant inserter which captures the moisture content and makes your product completely safe and long lasting. |

Allpack Capping Machine |

Automatic Capping Machine

Bottles are secured by placement and twisting a cap around the bottleneck by using the automatic capping machine. once they’re capped, it will assure you that the product inside will be in the secure form till it reaches and is used by end-user. |

Allpack Induction Sealing Machine |

Induction Sealing Machine

Professionally tamper evident and high safety properties are attained by using an induction sealing machine. This machine radiates electromagnetic waves that melt the inner seal of the capping and create a hermetic bond upon cooling that can only break once the user removes it deliberately. |

Allpack Labeling Machine |

Labeling Machine

Labels over each bottle are applied by a labeling machine, and this procedure is known as the final packaging step of the production line. |

8.What Are the Problems and Solutions Related To Bottling And Labeling Machine?

Nevertheless, a bottling and labeling machine is a perfect packaging solution. However, this is not uncommon that machines may suffer some technical issues. You must know how to deal with them. Let’s see the common problems and their solutions.

Jamming of Bottles

Jamming bottles in the process - picture courtesy: Banner Engineering

The uniform flow of bottles into the machine gets jammed and interrupted.

Solution

To solve this problem, you should schedule maintenance of the machine at regular intervals. Lubricate the moveable components such as the conveyor, regulate the speed of the conveyor, and correct the setting of the machine. Installing a photoelectric sensor in the conveyor system can also reduce the problem of blockage.

By following this, a subtle and smooth flow of bottles will be there during the procedure.

Tearing Off the Label Over the Bottle Surface

Tearing off of label- picture courtesy: pinterest

You may experience that label over the bottle's tears soon after the procedure.

Solution

This problem may occur when you use incorrect labeling material. Also, if your machine is not calibrated properly, it drags the labels which results in tearing. Therefore, you must inspect the quality of labeling material before choosing for the process. Regular calibration and maintenance are the solutions to many interconnected technical issues.

Inaccurate Counting of Products

Bottling and labeling machine

Inaccurate or double marking of counting items takes place when working with a bottling and labeling machine. This ultimately disturbed the entire production batch and affected the brand’s reputation.

Solution

If the surface of the scanner or sensor is not cleaned, it may result in an irregular counting pattern. Therefore, it is recommended to check if any dust particles are present.

Similarly, calibration helps in clearing counting and reduces the chances of errors. Moreover, the counting speed must be properly regulated so the sensor gets an appropriate time to detect the presence and passing of an item.

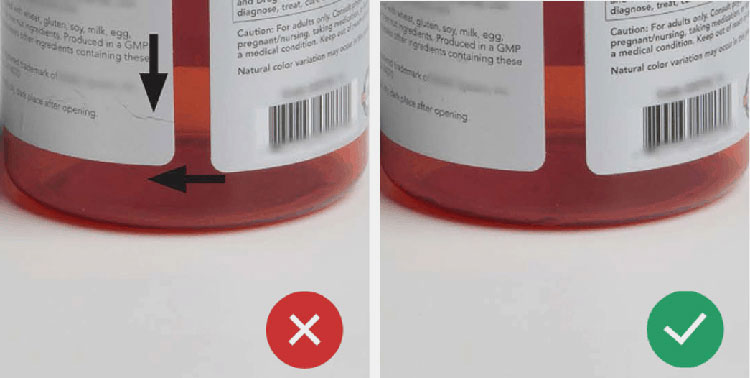

Curling and Wrinkling of the Labels over the Bottles

Defects of bottle labels- picture courtesy: drugplastics

Sometimes, you feel minor or noticeable curling and wrinkling of labels that don’t present a good product.

Solution

This is a pretty common problem that usually occurs in colder climates. Moreover, the cutting die of the labeling machine may not cut the label properly and automate the cutting line.

Asses if your bottles have irregular shapes. Because various bottling and labeling works follow the standard shape of the bottle. in the case of irregularly shaped bottles, it is recommended to go to the setting of the machine and allow operation for random shapes.

Check the label applicator is pressing and adhering to the label properly as recommended.

Correct the label tensioner if needed.

Conclusion

Bottling and labeling machine is a unique combination that is extensively required for every production line. This is not only a cost-effective solution but has the capability to boost your entire business success. Allpack every product is designed with simplicity and versatility that meets quality standards and your demand with customized and unique applications. Our customers trust our products as they are easy to operate and easy to maintain. If you’re planning to buy or want to get some guidance, Allpack is here to support you. Feel free to message us.

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide