Bottle Washing Machine: The Complete Buying Guide in 2025

If you’re struggling with rinsing bottles manually then ‘a bottle washing machine’ is worth buying equipment. This is an easy-to-use solution that can work in small and large industrial fields.

Whether your pocket permits or not; this machine is available in various types allowing anyone to grab and achieve effective results. Before planning to invest in the bottle washing machine; we suggest going through this guideline to learn more. Let’s Read.

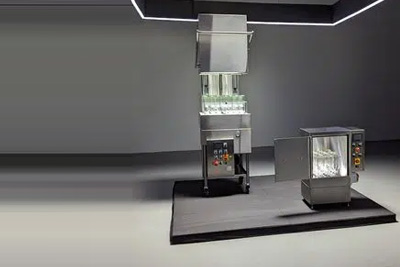

1.What Is Bottle Washing Machine?

A bottle washing machine is an excellent tool that improves the hygiene and cleaning of bottles by clearing and sanitizing bottles to improve the quality of your products.

On industrial basic, a bottle washing machine runs on every production. Not only this but small laboratories are also aimed to produce sterile products using this solution.

A bottle washing machine is designed to clean large, rounded bottles, that involved with automatic feeding of bottles in the system. This is an absolutely perfect device to carry aseptic filling where no chance of fixing foreign residue.

2.Where Do You Use Bottle Washing Machine?

A bottle washing machine has multiple industrial applications. Some of them are:

Nutritional Industry

Picture Credit: Silver Spur

To maintain the cleaning and safety of bottles used for packaging proteins, vitamins, and other nutritional products, a bottle washing machine is highly recommended as it ensures the bottles are 100% safe and clear to sustain the quality of nutritional products.

Pharmaceutical Industry

Whether storing sterile preparations, general preparations, solid dosage forms, liquid dosage forms, or topical preparations; a bottle washing machine always helps in maintaining cleanliness and high-level sterility which is necessary for every pharmaceutical product.

Beverage Industry

Picture Credit: SKS

A bottle washing machine is essential to keep the quality of beverage products like drinking water, juices, sodas, etc., The machine is of prime importance as it cleans and dries the bottles prior filling to beverages.

Food Industry

This is another production industry that is equally required with high sanitization and cleaning of bottles before packaging of products. For example, sauces, spices, cooking oils, powders, and topical dressing. In the food industry, a bottle washing machine ensures product safety and quality.

Cosmetics Industry

A bottle washing machine plays significant role in preparing clear bottles ready to fill with products like foundations, moisturising lotions, shampoos, or products like personal care such as bodywashes, handwashes etc.,

Chemical Industry

Picture Credit: Grainger

For the storing of chemicals like bleaches, acids, alkaline solutions, or any reagent; a bottle washing machine is essential to obtain cleaned bottles before the filling process.

Automotive Industry

Picture Credit: Motor1

This is also another important sector require bottle washing machine for cleaning bottles used for engine oil, brake oil, industrial solvents, etc.,

Research Laboratories

Picture Credit: The scientist

In this facility, a bottle washing machine is required to clean and prepare bottles for storing laboratory samples. For instance, tissues, biological organs, etc.,

3.How Bottle Washing Machine Is Beneficial?

A bottle washing machine offers several benefits to users and businesses. Some of them are:

Automation and Precision: PLC control allows for the automation of the bottle washing process, enabling precise control over various stages of cleaning, rinsing, and sanitization. This ensures consistent and accurate results, reducing the chances of human errors.

Automation & PLC Control

Bottle Washing Machine- Picture Credit: LUNG WEI PACKING CO., LTD.

An automatic bottle washing machine featured with PLC control ensures high automation for the bottle washing process that enables perfect control over various process stages of bottle washing such as rinsing, drying, and sanitizing. It overall ensures highly consistent and accurate results to end users.

High Speed and Various Motions for Washing

Picture Credit: Iven

A bottle washing machine can clean large batches very quickly. Plus, the process of washing from various directions e.g., vertical, circular, horizontal ensures ultra cleaning with the likelihood of human error.

Accurate Metering with Small Error

A bottle washing machine is a cost effective equipment for your production line as it minimizes energy consumption by using optimized water levels during bottle washing process with no chances of any residual left behind.

Recommended for Aseptic Product

Picture Credit: Iven

The body of the bottle washing machine is comprised of stainless steel which offers many benefits. First, this feature is extremely suitable for aseptic filling lines. Secondly, this is very useful for easy maintenance of the machine.

Safe for Users

Picture Credit: Syntegon

All electrical components of a bottle washing machine are integrated into a compact housing that ensures users' safety against electric shock due to its exposure to the physical environment and moisture.

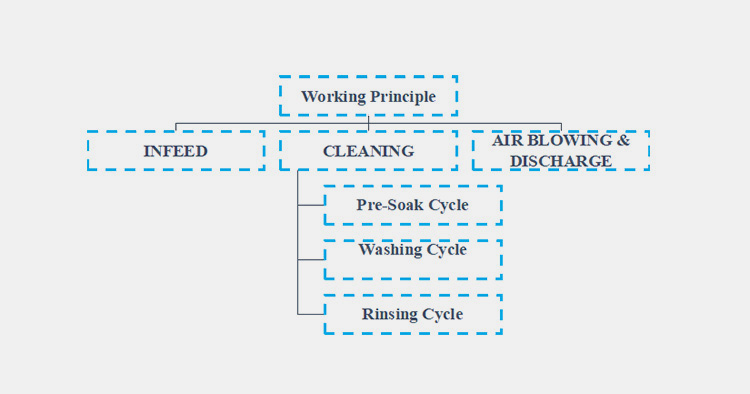

4.How Bottle Washing Machine Works?

A bottle washing machine has primary working theme that is composed of the following steps we’ve discussed below. For understanding, have a look!

STEP 1: INFEED

In this step, bottles are uncovered from caser and transported to the washer via conveyor unit. They are collected on the table for cleaning procedure.

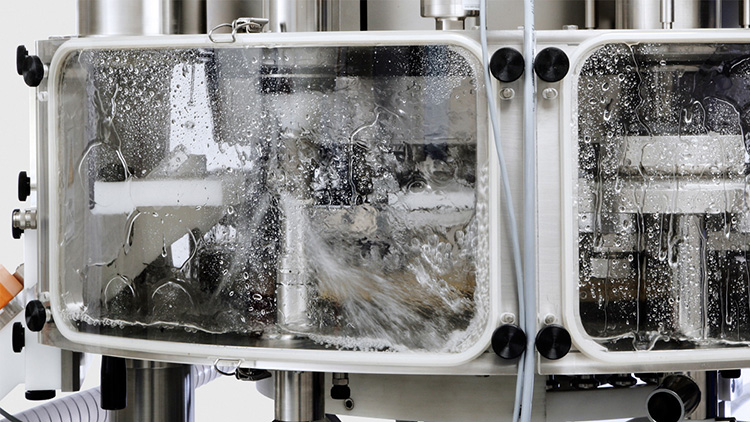

STEP 2: CLEANING

This step is divided into the following sub-stages.

Pre-Soak Cycle- Deionized Water

Just right after infeed section, bottles are subjected to pre-wash cycle which is accompanied by upside down for emptying left residual or any particles out of it. The residual is rapidly discharged out by the machine. This phase typically takes 3 minutes.

Bottles are sub-merged by the machine in the hot water with temperature at35°C. A sieve belt filters the wastewater. The submerged water is removed by turning bottles up-side down and dirty water collected in the tank located below the machine.

Washing Cycle

Picture Credit: AMA Journal of Ethics

This is an actual zone where washing of bottles is being subjected. This section is composed of several identical washer helps in detergent soaking of the bottles. This process follows three steps:

In first step, a long-term soaking of bottles by immersing in caustic solution takes place. This process mostly takes 7 minutes where temperature of caustic bath is kept maintained at 70-85°C.

Here, all sticky particles of chemicals or dirt is removed by the action of caustic soda and high temperature of water. In the second step bottles are emptied and remove dirt and in third steps another deep soak is given to clean the bottles.

Rinsing Cycle- Water for Injection

Picture Credit- Adobe Stock

Now bottles are subjected rinsing process that involved rinsing zone and spray zone which mostly require 3 to 9 minutes. Here, bottles are rinse with cleared water and exposed to spray zone for high pressure spray to internal and external showers. Bottles are given with final exposure of water for injection before air blower.

STEP 3: AIR BLOWING & DISCHARGE

Compressed air is introduced using heat exchangers which are coiled tubes that produce heated air into inverted bottles prior to discharging unit.

This is achieved by an air blower that uses the nozzle to blow a seamless stream of air into each bottle to dry inside bottles and loosen and remove the particle if left over. A set of cleaned bottles are transferred to the outfeed conveyor for the further filling process.

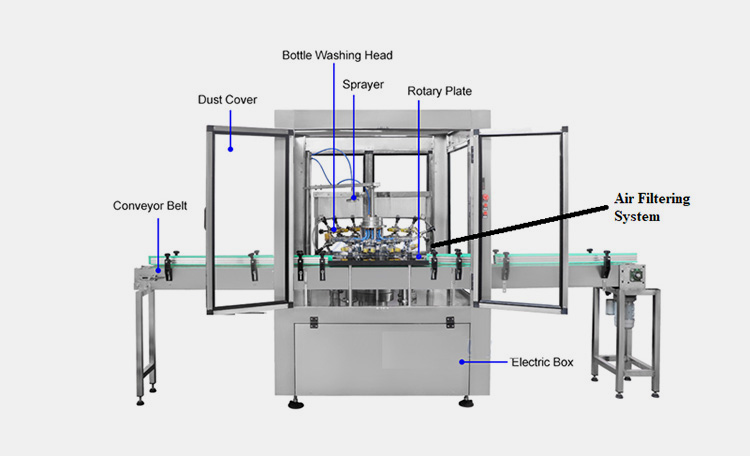

5.What Are the Primary Parts of Bottle Washing Machine?

Conveyer Belt

This system comprises multiple components these including belt, pulleys, rollers etc,. that moves the bottles towards and away from the machine. It is automatic, convenient and completes operations without any hassle. All models of bottle washing machine provided by Aipak comes with a built-in conveyer system that is attached on either side of the machine and if needed can easily be removed and reattached within minutes.

Dust Cover

To protect the bottles from environmental dust particles the whole washing of the bottles is carried behind the protective shield or dust cover. Not only the dust cover prevents the accumulation of dirt on washed bottles it is also durable and made up of plastic to avoid accidental breakage.

Bottle Washing Head

This unit holds multiple nozzles that spray soap and water inside and around the bottles. After spraying soap, the nozzles spray pressurized water jets that effectively remove dirt and soap.

Sprayer

The sprayer is the unit of the machine that holds water and soap separately. Since the machine is automatic the release of soap and water is done entirely without any manual intervention.

Rotary plate

Different manufacturers offer different orientations and working of machine, however, most bottle machines have a rotary mechanism in which a number of bottles are aligned and washed simultaneously. Although bottle washing machine having a rotary plate is costly in the long run it's more productive and economical.

Electric Box

Present in every machine this compartment holds all panels and wires that control the working of equipment. The exact location of the electric box may differ for each model or every machine, but it is usually present on the side or bottom of a bottle washing machine.

Air Filtering Unit

After washing the drying of the bottles is done by blowing air into and around each unit. The blown air should be free from dust particles to avoid contamination. This is done by filtering the air in the filtering unit before being blown into the bottles.

6.What Type of Bottles Can Be Washed Using Bottle Washing Machine?

There are different types of bottles that can be washed using a bottle washing machine. It depends on the various specifications that the design of machine offers.

| Jars

|

Jars are glass bottles of various sizes and shapes that are used usually in food and beverages industry. These bottles are washed employing bottle washing machine to ensure safe and hygienic packaging. |

| Ampoules

|

Ampoules are small glass containers that have liquid medicine stored in them. They require the necessity of washing along with ensuring sterile condition of it, which can be washed using bottle washing machine. |

| Vials | Vials are pharmaceutical glass bottles that are washed using bottle washing machine , with many washes and sterilized air to provide aseptic nature to it. |

| Dropper Bottles | Dropper bottles are intended for pharmaceutical, food industry and cosmetics industrial use. These are washed using a bottle washing machine incorporating air and water to efficiently clean and provide contaminants free bottle such as eye, nose, and ear dropper bottles. |

| Round Bottom Bottles | Such bottles are washed for pharmaceutical purposes to ensure the safety of the medicinal liquid filled in them. |

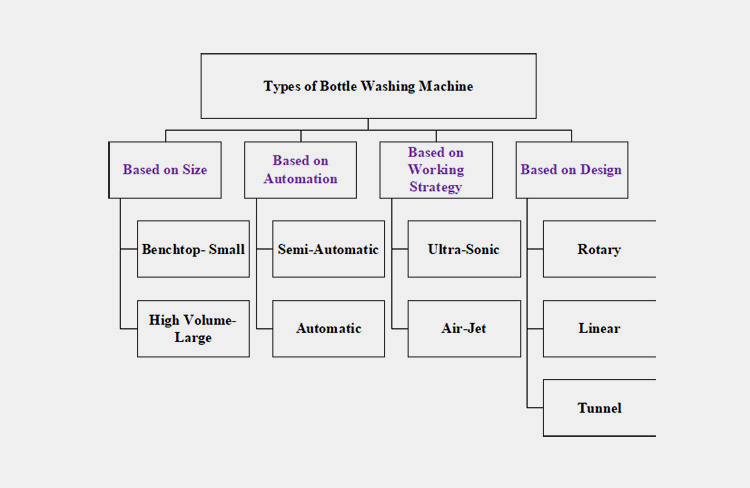

7.What are Different Types of Bottles Washing Machine?

Upon requirements and automation, bottle washing machine is classified into various types. Each type has its specified role and uses in specified industry. Let’s see them one by one.

TYPES OF BOTTLE WASHING MACHINE BASED ON MACHINE SIZE

Benchtop/Small Bottle Washing Machine

A benchtop bottle washing machine can b install on the working table. This machine is designed to operate industrial and laboratory processes where small size bottles are subjected to a bathing tank for high frequency cleaning under constant temperature and sonication. This machine is small in size but performs semi-automatic operations.

High Volume/Large Bottle Washing Machine

High Volume/Large Bottle Washing Machine- Picture Courtesy- Niagara System

This machine is large that can treat the bulk of untreated bottles for washing procedures. You can easily integrate this machine with other equipment of the production line; therefore, this is suitable for large industries where non-stop production processes are carried out. This machine requires a spacious facility for installation.

TYPES OF BOTTLE WASHING MACHINE BASED ON AUTOMATION

Considering automation; the bottle washing machine is divided into the following sub-types.

Semi-Automatic Bottle Washing Machine

This is the perfect solution for washing bottles and jars where the production volume is small to moderate. The machine offers washing procedures for various shape and sizes of bottles with an automatic washer and rinser.

This is a cost-effective and affordable machine as compared to an automatic bottle washing machine that requires the involvement of an operator during handling bottle as certain stages such as loading, unloading., This is also a fast washing device that cleans hundreds of bottles in one hour.

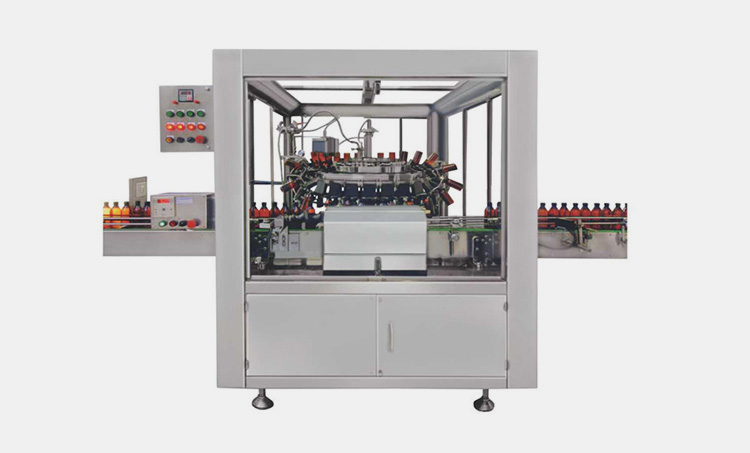

Automatic Bottle Washing Machine

Automatic Bottle Washing Machine- Picture Credit- IC Filling System

When it comes to washing large batches of bottles or considering large industries, of course, an automatic bottle washing machine is used that is involved with the entire procedure automatically.

A very time-economical solution that is involved with automatic loading washing, drying, and unloading of bottles. Yes, you’ll find it expensive when compared to semi-automatic bottle washing machine, but it offers uncountable benefits in term of sterilization, time, automation, large batches, maintenance, and so on.

TYPES OF BOTTLE WASHING MACHINE BASED ON WORKING STRATEGY

Ultra-Sonic Bottle Washing Machine

Ultra-Sonic Bottle Washing Machine- Picture Credit- SED Pharma

This machine offers tremendous cleanliness to bottles. Its working principle includes powerful ultrasonic wave generation that produces bubbles to hit or implode over the surface of the bottles and trap the dirt from each nook deeply. This is a time saving machine that promises the cleaning of foreign particle attached or present inside or outside the bottle.

This is also known as ‘sonicator’, mostly used in research labs and healthcare industries.

Air Jet Bottle Washing Machine

Air Jet Bottle Washing Machine- Picture Credit- AnchorMark

This machine follows an excellent mechanism for cleaning bottles that involves compressed air and vacuum. When bottles are fed into the machine, they’re subjected to positive pressure followed by stage-wise incorporation of compressed air for detaching and loosening of sticky particles. Those dirt, or foreign particles that are removed from the surface are sucked by using negative pressure generated by a suction blower.

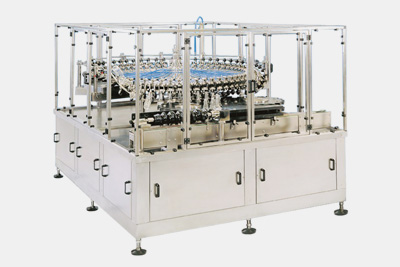

TYPES OF BOTTLE WASHING MACHINE BASED ON DESIGN

Rotary Bottle Washing Machine

Rotary Bottle Washing Machine- Picture Credit- LAXMI Pharma

This machine designed is compact where a circular carousel or turret is meant to support and integrate bottles for washing, drying, and discharging. The machine works by rotating the turret where uncleaned bottles are subjected to washer and air dryer sections. Some machines are equipped with brushes that ensure contamination free bottles in one cycle. This machine is suitable for PET, glass, round, flat bottles of various sizes.

Linear Bottle Washing Machine

Linear Bottle Washing Machine- Picture Credit- Anchormark

You can consider this equipment as a standard bottle washing machine where the entire work process is taken place in a flexible linear fashion. The bottles to be cleaned are fed onto the conveyor belt that transports them one by one toward different washing zones. For example, pre-wash, wash, rinse., This type of machine is recommended for moderate to large batches where medium to high production is carried out. This is mostly preferred for washing small bottles such as vials, and ampoules.

Tunnel Bottle Washing Machine

Tunnel Bottle Washing Machine

This machine is basically suitable for large industries for catering to large production batches in time effective manner. The bottles subjected to cleaning are transferred into the tunnel-like structure where they pass through various cleaning zones like pre-washing, washing, brushing (optional), and drying. This is recommended for washing round as well as flat shaped bottles made up of either glass, plastic, etc.,

The general volume of the bottle includes approx. 30 to 250 millilitres. The machine can wash bottle batches swiftly such as hundreds of bottles per minute.

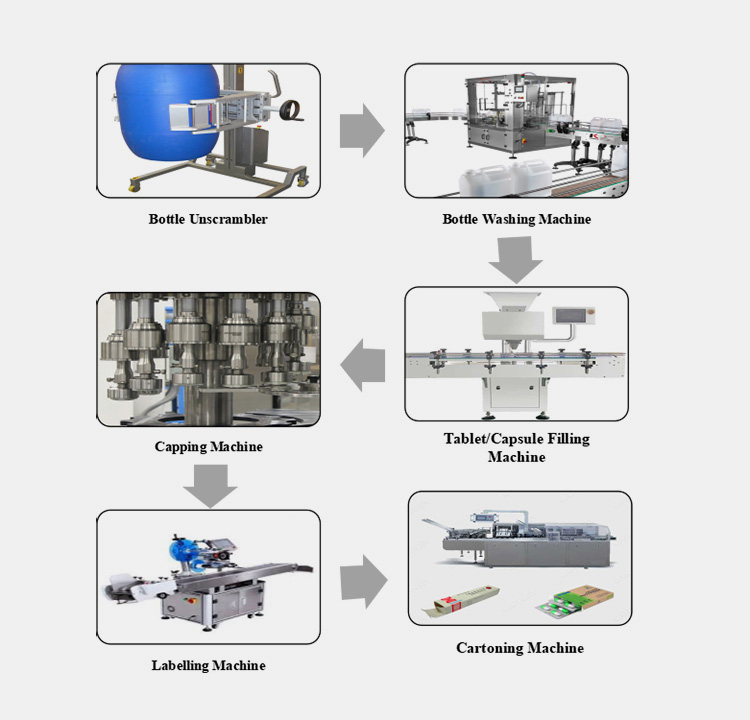

8.Describe a Complete Production Line of Bottle Washing Machine?

The photos show the machine on the auxiliary equipment to form a production line of bottle washing machine.

Bottle Unscrambler

A bottle unscrambler is an essential machine that sorts bottles of various shapes or sizes and feeds automatically into the bottle washing machine for efficient cleaning and eliminating unwanted material out of it. Moreover, this machine ensures the removal of damaged bottles from the batch.

Bottle Washing Machine

A bottle washing machine is an important component of the production line that receives uncleaned bottles and transports cleaned and sterile bottles towards the filling machine. The bottle washing machine has great capability to integrate with other devices for fast and flexible working.

Tablet/Capsule Filling Machine

A tablet or capsule counting and filling machine once receives cleaned bottles from the bottle washing machine are subjected to tablet/capsule counter and filler respectively.

Capping Machine

This is an important part of the production process that secure the bottles by twisting caps automatically over the neck of the bottles. This machine is of prime importance as it ensures 100% protection against entering foreign particles inside the bottles.

Labelling Machine

Once bottles are cleaned and filled with products, they’re positioned for the labeling process. This can be done using of labeling machine that sticks labels and prints them with batch number, production date, expiry date, and other important information.

Cartoning Machine

A final stage of the production line where the entirely secure batch is introduced into respective cartons along with leaflets. This machine has the ability to flip open carton and inserts bottles either vertically or horizontally.

9.How long do the bottles take to dry in Bottle Washing Machine?

Bottle Washing Machine- Picture Credit- AQUATECH

In bottle washing machine temperature the drying time for plastic bottles and glass bottles are

different. The bottles are transported to the drying section where several hot air nozzles blast air inside and outside the bottles ensuring the sets are dried completely in 2 to 4 minutes.

The total heating power used by a bottle washing machine is about 4KW-5KW watts despite no matter how many degrees of water temperature is required. As compared to plastic bottles, glass bottles dry fastly as their washing temperature is mostly higher approx. 200 degrees.

Hence it retains heat for longer and fast to dry. The plastic bottle does not retain heat, so it takes longer time to dry. The commonly used air drying temperature is controlled between 40~90℃ which ensures rapid drying of bottles inside as well as outside.

10.What is Cleaning Solution used for Bottle Washing Machine?

Washing bottles is an essential process required for pharmaceuticals, foods, nutraceuticals, and work, thus in the bottle washing machine in first place washing agents or solutions was used that immerse bottles in the pre-washing phase. The commonly used washing agents are discussed below:

| Types of Washing Agents | Description |

| Deionized Water

|

This is used in pre-washing or washing phase in a bottle washing machine which is an effective option of cleaning as it offers high level of sanitation. This is also known as demineralized water where mineral ions are eliminated from water and purify the bottles by removing contaminants and ions on its surface. |

| Water for Injection

|

Highly purified water is used in pharmaceuticals, biological research, and nutraceutical companies for washing bottles. This water strictly meets criteria regulated by USP and European pharmacopeia means it offers benefits and ensures water is free from impurities and maintains the integrity of your product. |

| Concentrated HCl | This is mostly used for removing industrial scales or sticky substances inside the bottle and some precipitations of inorganic salts. |

| Alkaline Solution | An alkaline solution wash is employed to wipe greasy components or sticky particles around every nook of the bottles. |

| 5-10% trisodium phosphate (Na3PO4- 12H2O) solution

|

This solution is used to wash bottles in order to clean oil stains ins or outside the bottles and make them presentable to the filling section. |

| Organic solvents

|

Organic solvents like xylene are used to wash bottles to clean grease paint particles or stains. |

11.What are Major Technical Problems & Tips Related to Bottle Washing Machine?

Some of the major technical problems that can be faced in a bottle washing machine are:

Breaking or Misalignment of Bottles

During the washing process in a bottle washing machine, often it is observed that glass bottles break within the system. This is due to the misalignment of mechanical gear present in the conveying system.

Troubleshooting

Proper cleaning and maintenance of mechanical gears should be done according to the standards defined by the manufacturer.

Checking of bottle gripper/winch to assess the space between each of the bottles and aligning them if required.

Impurities And Improper Drying

During the washing process, impurities or microbes can be left attached to the bottle due to impure water or detergent quality. Also, sometimes the bottles are not properly dried.

The problem occurs due to a problem in the bottle drying system where the blowers are not properly performing the cleaning and drying process.

Troubleshooting

The efficiency of hot blowers of compressed air should be observed periodically as mentioned by the manufacturer.

Adjustments in the drying duration can also rectify the problem if the blower is working properly.

Inadequate Washing

Picture Credit: SGS

This is the most critical problem that occurs in a bottle washing machine as its primary job is to clean the bottles.

The process of improper cleaning occurs due to various reasons. It can be either clogging of the nozzle opening or due to the wrong rate of pressure.

Troubleshooting

Timely cleaning of nozzles is necessary to remove any blockage or clogging present on its opening.

The flow rate of water is also a concern to be adjusted so that each bottle gets proper cleaning pressure.

Also, the moving speed of the conveyer can be a reason for improper cleaning. The timer of the conveyor system if adjusted can rectify the problem.

Vibration

Picture Couretsy: GEA

With the passage of time, in some bottle washing machine, vibration and sound are observed due to the loosening of parts or reduction in lubrication.

Troubleshooting

Each of the bottle washing machines requires a specific predictive and preventive maintenance schedule to check whether any of the parts are damaged inside the system or any loosening is present.

The friction between the mechanical parts of a bottle washing machine can be reduced if proper lubrication and greasing is applied to those joints.

12.What Need To Consider When Purchasing A Bottle Washing Machine?

Some of the key considerations that are important to think of before purchasing a bottle washing machine are:

| Automation Level The most important factor is to check the level of automation of a bottle washing machine according to the workspace and process level. |

|

| ·Washing Standards The most essential feature to be considered is to verify the washing processes and standards of a bottle washing machine. It must include all three stages like initial pre-rinse, washing as its second stage and finally proper sterilization of bottles. This will allow clean and accurate washing of bottles within the system. |

|

| Noise and Vibration Bottle washing machines are also selected on the basis of noise and vibration produced in it. The machines with greater noise and vibration rates can affect human ears as well as can create atmospheric pollution. So, without going for a cheaper machine, the buyer should purchase a noise-sensitive machine. |

|

| Manufacturers Reputation There is a list of local suppliers and manufacturers for bottle washing machine around the globe. It is important to identify the most reliable and authentic manufacturer that provides assistance, spare parts availability and guidance for a long period of time. Manufacturers without local guidance can cause a lot of hindrance and waste of time. |

|

| Utilities Consumption

In the modern world there are many machines available that operate on low energy consumption throughput. These are the most likely machines to be selected so that no extra burden on utilities may fall on the consumer. This will also allow making economical products for the customer. |

|

Conclusion

In conclusion, the bottle washing machine is an integral component of any business that deals pharmaceuticals, nutraceuticals, beverages, etc., This machine ensures firm quality of your brand by maintaining hygiene and quality that directly increase the consumer satisfaction about your brand. For purchase or knowing different categories of bottle washing machine, please contact our sale team now. We promise to help in order to optimize your business and maintain high standards in a cost-effective manner.

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide