Automatic Bottle Washer: The Complete FAQ Guide in 2025

Automatic Bottle Washer: The Complete FAQ Guide in 2025

As the demand for bottled products continues to grow, the need for efficient and effective bottle-cleaning solutions becomes increasingly important. Automatic bottle washers are becoming a popular solution for industries that require a large number of clean bottles, such as the beverage, pharmaceutical, and food industries. These machines provide a quick and consistent way to clean and sanitize bottles, saving both time and resources.

In this blog post, we will explore the advantages of automatic bottle washers, how they work, and why they are an excellent investment for any business that requires a high volume of clean bottles.

1.What Is An Automatic Bottle Washer?

An automatic bottle washer is a key component in bottle line technology. This machine automatically washes, rinses, and dries the bottles at a very high speed. It is commonly used for bottle-cleaning operations in pharmaceuticals, food, and beverage industries primarily in breweries as well as in various industrial production lines.

An automatic bottle washer is automated and controlled by a computer system that monitors and adjusts various settings throughout the cycle such as temperature, water pressure, and rotation speed. This equipment can handle different types and sizes of bottles depending on the type of model that is being used.

This device is a beneficial piece of equipment for any bottle line production as it ensures that the bottles are cleaned thoroughly and properly before filling or before moving to the next process. With its improved efficiency, both businesses’ time and money are saved in the long run while the production of high-quality products is achieved.

2.What Are The Components Of An Automatic Bottle Washer?

Automatic bottle washers consist of the following components:

Washing Compartment

It is made out of stainless steel and uses jets of water or steam to clean the bottles. This is the main part where bottles are held for washing through jetted water or gases.

Source of Heat

This provides heat for hot water cleaning, sterilization, and drying processes. The heat source can be a boiler, an electric heating element, or even a combination of both.

Filters

These are used to remove any foreign particles or contaminants from the water before it enters the tank.

Control Panel

This is where operators can set the required parameters for the machine for optimal performance. It is also used to monitor and adjust the settings of different processes throughout the washing, rinsing, and drying process.

Injectors

These devices inject hot water or steam into the tank to help clean the bottles more efficiently.

Rinse Tank

This is where the clean bottles are rinsed after being washed in the washer tank.

Sanitation System

Many bottle washing machines are equipped with a sanitation system that utilizes ultraviolet light, ozone, or other methods to keep the bottles free of germs and bacteria. The system ensures that all the bottles have zero contamination therefore fit for packaging.

Dryer

The dryer eliminates any water droplets or any moisture content left on the bottles after they have been rinsed. By this, the bottles’ cleanness and dryness is guaranteed before taken to the next step of production.

Conveyor belts

This is the system that transports bottles from one section of the process to the other. The conveyor system is usually manual or automated, depending on the size and complexity of the machine.

3.How Does An Automatic Bottle Washer Work?

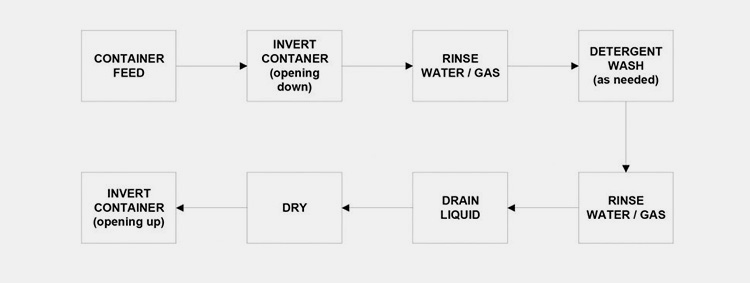

The dirt or contaminations on bottles is eliminated by following these steps systematically:

Loading of the bottles or containers into the machine

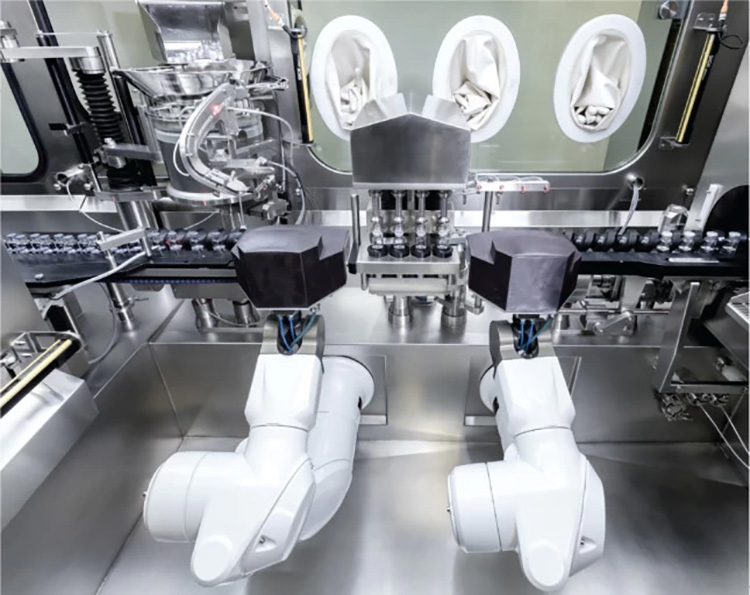

This is done manually by placing them onto a conveyor belt, or automatically via robotics or some other automated method.

Pre-rinse

This step involves spraying the bottles or containers with a stream of water to remove lose any unwanted substance from the surface.

Wash

Detergent and water are sprayed onto the surfaces of the bottles or containers while they are spun at high speeds in this stage.

Rinse

The bottles or containers are then sprayed with a continuous stream of water to rinse off any remaining detergent or debris.

Blow-off

In this last step, the air is used to blow water from the containers or bottles before they are removed from the machine for the next process.

The whole process ensures that the bottles or containers are sparkling clean and sanitized to meet safety and quality standards and are ready for the final stages of production.

4.What Are The Advantages Of Using An Automatic Bottle Washer?

Incorporating this piece of equipment in your production line will increase the efficiency of a bottling process by eliminating manual labor and ensuring that bottles are cleaned quickly, efficiently, and thoroughly. In the long run, it can reduce production costs, improve quality control and ensure consistent results.

These machines require less energy than manual cleaning methods, which can reduce operational costs significantly

There is great minimization of the risks of accidents that are associated with manual cleaning methods, as there is no need for staff to be in direct contact with harsh chemicals or sharp objects like brushes or scrubbers.

Water and detergent usage are highly reduced since excessive amounts won't need to be used in order to achieve the desired level of cleanliness. This also reduces the amount of waste produced from manual methods by eliminating the need for disposable cleaning supplies such as sponges, rags, and towels.

Bottles are consistently cleaned to the same level of cleanliness every time which is an enhancement of desired quality. This is very important, especially for industries where contamination could lead to serious health risks or product defects such as in the pharmaceutical production industry.

5.What Are Some Of The Applications Of An Automatic Bottle Washer?

Automatic bottle washers can be used across a wide range of industries. Here are some examples:

Food and beverage processing industries

These machines are particularly useful for cleaning bottles that contain food and beverage products to ensure they meet health regulations.

Pharmaceutical Industries

Automatic bottle washers are used in the pharmaceutical industry to clean and sanitize bottles for the production of medicines.

Dairy production line

This equipment is perfect for cleaning and sterilizing containers that store milk, cheese, and other dairy products.

Beer and Wine brewers

Breweries and wineries also benefit from automatic bottle washers as these machines help to clean bottles that hold beer and wine in order to maintain the quality of the product.

Chemical Industries

These machines are used by chemical plants and labs to clean bottles that contain hazardous materials.

Water treatment plants

Automatic bottle washers are also useful for cleaning containers that store water for purification purposes, ensuring clean drinking water for communities.

Labs

Many laboratories use this equipment to clean test tubes and other containers used for scientific experiments.

Home use.

These machines are also available for home use, helping to clean and disinfect bottles for personal use.

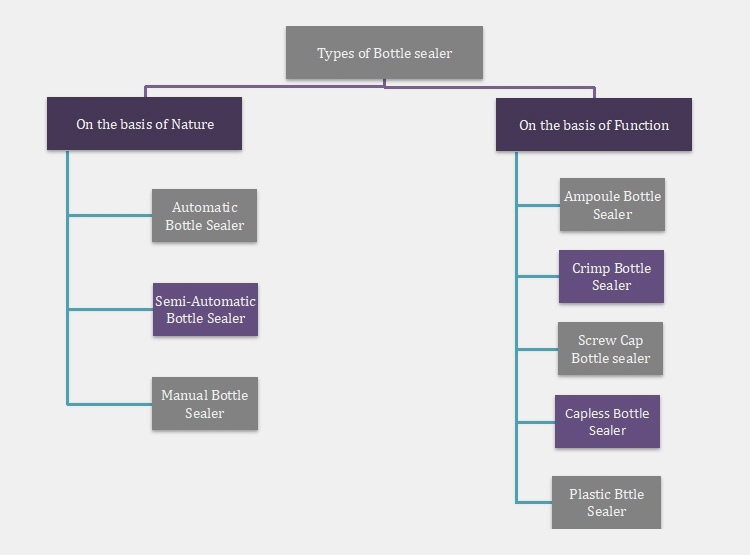

6.What Types Of Automatic Bottle Washers Are Available?

There are a variety of different types of automatic bottle washers on the market, each designed to make the process of cleaning bottles easier and more efficient. The most common types are;

Tunnel washers

These are the most common type of automatic bottle washers and are designed to accommodate a wide range of bottle sizes. Tunnel washers can operate at high speeds and accommodate large production runs.

Rotary wheel washers

These types of washers use multiple spindles to spin bottles through the washing process. It rotates the bottles as they go around a circular chamber, allowing them to be completely submerged in water and detergent for a thorough cleaning.

Conveyor-style washers

This type of tool uses conveyors to move bottles along a track for cleaning.

Spray-style washers

These machines use jets of water to clean bottles.

Ultrasonic Bottle Washer

This type of washer uses ultrasonic energy to create millions of microscopic bubbles that rapidly move around and remove dirt, oils, and other contaminants or unwanted substances from the interior of bottles. It also cleans the exterior surface quickly and efficiently.

7.What Is The Difference Between A Semi-automatic Washer And An Automatic Bottle Washer?

Semi-automatic bottle washers require human labor to operate which is a tedious process for the operator, while automatic bottle washers are self-operating.

Number of bottles handled.

Semi-automatic bottle washers can only clean a limited number of bottles at a time, while automatic bottle washers have the capability to clean hundreds to thousands of patches of bottles in a single cycle.

Time

Semi-automatic bottle washers require more time and effort to clean a batch of bottles, while automatic bottle washers complete the process much more quickly in every cycle.

Consistency

Automatic bottle washers can ensure uniformity in cleaning results, while Semi-automatic bottle washers may have variations in cleaning quality.

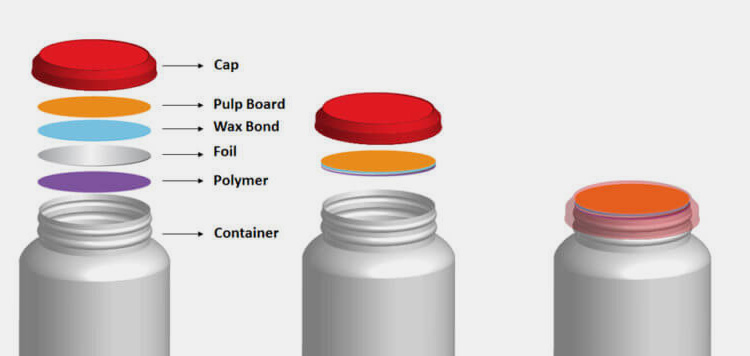

8.What Types Of Bottles Can Be Washed With An Automatic Bottle Washer?

Beer Bottles

Beer bottles are typically made of glass and can be washed in an automatic bottle washer. The machines use high-pressure water jets to deep clean the insides of the bottles and remove any residue that may have built up from previous uses.

Baby Bottles

Baby bottles are usually made of plastic and can be safely washed in an automatic bottle washer. The machines utilize high-pressure water jets to remove dirt, grime, and residue from the inside of the bottles. This helps to make sure that your little one is drinking clean and safe milk or formula.

Water Bottles

Many people like to reuse their water bottles, and this can be done safely with an automatic bottle washer. The machines are designed to thoroughly clean the inside of the bottles so that bacteria and other contaminants do not accumulate over time.

Wine Bottles

Wine bottles typically come in a variety of sizes and shapes, but most can be cleaned in an automatic bottle washer. The machines use high-pressure water jets to reduce any sediment or corkage residue that may be in the bottle, and this helps to keep your wine tasting fresh for longer.

Juice Bottles

Juice bottles are typically made of plastic and can be washed in an automatic bottle washer. This is a great way to ensure that the contents of your juice bottle are clean and free from any bacteria or residue. High-pressure water jets help to reduce the amount of time needed to clean each bottle, making the process faster and more efficient.

Medical Bottles

Many medical bottles are made of plastic and can be washed in an automatic bottle washer. These machines use high-pressure water jets to deep clean the inside of the bottles, removing any residue or contamination that may have occurred from previous uses. This helps to ensure that your medication is safe and free from contamination.

Soda Bottles

Soda bottles are usually made of glass and plastic and can be washed in an automatic bottle washer. High-pressure water jets help to remove any residue or buildup that may have occurred from previous uses, ensuring that the contents of your soda bottle remain fresh and uncontaminated.

Milk Bottles

Milk bottles are also typically made of plastic and can be washed in an automatic bottle washer. The machines use high-pressure water jets to clean the insides of the milk bottles and ensure that any residue or bacteria is removed. This helps to keep your milk tasting fresh and uncontaminated.

With automatic bottle washers, you can be sure that all of your bottles will come out sanitized and sparkling clean each and every time. Some models even come with multiple washing cycles, so you can customize each cycle to the type of bottle being washed, ensuring a perfect clean for all bottles.

9.Can An Automatic Bottle Washer Clean Both The Inside And Outside Of A Bottle?

Definitely yes. An automatic bottle washer can clean the inside and outside of a bottle. Automatic bottle washers are designed to scrub away dirt, dust, and other contaminants from the surface of bottles. This cleaning process typically includes powerful jets of water or air, as well as detergent or chemicals that help to loosen and remove built-up grime.

Some automatic bottle washers also include brushes and other scrubbing tools that can be used to clean the inside of bottles as well. This allows the machine to thoroughly clean not just the outside but also the inside of bottles. The result is a sparkling clean product every time!

10.Can An Automatic Bottle Washer Be Used For Cleaning Other Types Of Containers?

Yes, an automatic bottle washer can be used to clean other types of containers but only under special instructions to the machine and that is if they are compatible.

Some glass and plastic materials require unique cleaning solutions in order to avoid damage during the washing process. If you are not sure whether your automatic bottle washer can be used to clean a certain type of container, it is recommended to consult with the manufacturer for specific instructions.

Literally, automatic bottle washers can be used for cleaning other types of containers and this makes it an effective and convenient tool for a variety of cleaning solutions.

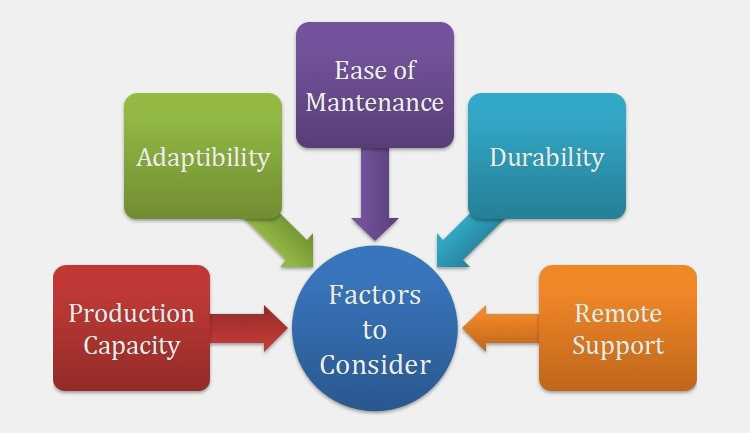

11.How Do You Choose The Right Automatic Bottle Washer For Your Needs?

Choosing the right automatic bottle washer for your needs can be a walk-in-the-park task. Before obtaining one, it is important to consider several factors such as size and capacity, water pressure requirements, drying technology, and energy use. The following guide will provide basic information about these features so you can make an informed decision when selecting an automatic bottle washer for your needs.

Size And Capacity Of Bottles Handled.

It is important to consider the type and quantity of items you will be cleaning when making your selection. Larger machines may come with multiple compartments or adjustable shelves to accommodate different sizes of bottles and containers.

Required Water Pressure For Washing

Different types of automatic bottle washers require different amounts of water pressure in order to operate effectively. Make sure that you understand the requirements of the machine you are considering so you can ensure a successful cleaning cycle.

The Rate Of Drying Bottles

Automatic bottle washers typically use hot air and centrifugal to dry bottles and containers after washing. Hot air drying is a slower, more energy- process but may require more time for bottles to completely dry while centrifugal drying; uses spinning to quickly remove water from the surface of washed items, however, it can also be louder than air drying and may consume more energy in the process.

Energy Use Of The Machine.

When selecting an automatic bottle washer, it is important to consider its energy efficiency rating. Look for models that are rated as Energy Star certified in order to ensure you get the most efficient model available.

Conclusion

In the world of manufacturing, efficiency is key and that's why the automatic bottle washer has become a game-changer for businesses that rely on clean, sanitized bottles. With the ability to wash thousands of bottles per hour, this machine can save businesses time and money while ensuring the highest level of hygiene for their products. But it's not just about convenience - the automatic bottle washer also reduces environmental waste by conserving water and energy. At Allpack, we understand the importance of streamlined production processes. That's why we're proud to offer the latest in automatic bottle-washing technology to our clients. With this innovative equipment, companies can take their operations to the next level and remain competitive in today's fast-paced world.

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide

Automatic Bottle Washer: The Complete FAQ Guide in 2025 Read More »