Bottle Capping Machine: The Complete Buying Guide In 2025

Bottle Capping Machine - Picture Courtesy: SUNHAN PACK

Are you interested in buying a bottle capping machine? Are looking for a suitable bottle capping machine for your process? Do you want to gather more information regarding a bottle capping machine? This platform will sort all your queries and will help you in finding the best suitable bottle capping machine for your process. This buying guide will assist you in finding what a bottle capping machine is and how its operation performed. For getting a complete overview read the complete blog in detail and gets the possible knowledge from it.

1.What Is A Bottle Capping Machine?

A bottle capping machine is a highly versatile machine that is used to apply caps on different types of bottle for making them airtight. The basic requirement of these machines is to prohibit the entrance of particles and microorganism into the bottles so that it can be secured for a longer period. Bottle capping machines are mostly used in food, pharmaceuticals, beverages and chemical industries where the material is packed and delivered in different sizes of bottles.

2.What Are The Industrial Applications Of A Bottle Capping Machine?

Bottle capping machines are widely used in different industries to increase the productivity of that industry and also to make the product look presentable. Some of the industries that mostly uses bottle capping machine are

Beverages Industry

Bottle capping machines are abundantly used in beverages industries as large number of bottles are manufactured there in a single day. The bottles contain both carbonated and non-carbonated drinks that are efficiently secured for a longer period by application of bottle caps. Materials freshness lives the same by maintaining its purity.

Pharmaceutical Industry

Bottle In Pharma - Picture Courtesy: Healthcare Packaging

Bottles in pharmaceutical industries are used for filling of medicines, liquid syrups, ointments and etc. These bottles are filling of material undergo capping process by a highly efficient bottle capping machine. Material spillage and wastage during its transportation can be avoided while applying caps using a bottle capping machine.

Food Industry

Glass And Plastic Food Packaging - Picture Courtesy: Imperial Packaging

Food industry also uses bottle capping machine during packaging of liquid and viscous products like jams, ketchups, milks, dairy products, sauces, oil and etc. Bottles of different sizes and shapes can easily be sealed airtight so that any type of contamination can be avoided and the freshness remains same.

Cosmetic Industry

Cosmetic Packaging - Picture Courtesy: TricorBraun

In some places of cosmetic industry where products like shampoos, creams, lotions and other personal protective products that are filled in bottles are capped using a bottle capping machine. These caps allow the product to remain safe and secure while shipping and movement.

3.What Are Advantages Of A Bottle Capping Machine?

Some of the advantages of a bottle capping machine are

Efficient Capping

Productivity And Efficiency

Bottle capping machines are highly efficient in their process. The machines are available in both manual and automatic modes depending upon the requirement of process. Each of the product gives identical capping result with maximum output rate.

Quality

Quality Bottle Capping Machine - Picture Courtesy: SureKap

The quality of sealing done by a bottle capping machine is of high quality and precision. The turning effect on each type of bottle can be adjusted according to its cap size and can be changed of required in a bottle capping machine.

Customization

Custom Caps - Picture Courtesy: SKS Bottle

One of the most unique benefits of a bottle capping machine is that it allows process to variety of bottles and their types. Customization can be done by just changing the bottle holder and its turning speed.

4.What Is The Working Principle Of A Bottle Capping Machine?

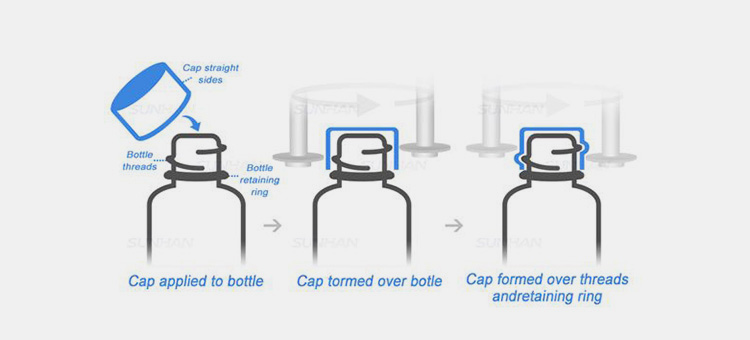

Capping Machine & How Does It Work - Picture Courtesy: SUNHAN PACK

Bottle capping machine has a simple working principle in which bottles are capped to secure materials so that it can be used for longer period. Some of the basic working steps in the operation of a bottle capping machine are

Initially the setting parameters are installed in the machine according to the size and shape of the bottle. The parameters include speed, height, width, angle, gripping adjustment and filling rate.

In the next step the filling process gets started in the bottle filling machine and the required material is entered into the bottles.

The caps are on the same time inserted in the hopper from where they are then supplied to the capping area through feeding mechanism.

Once the bottles gets filled, it is then moved forward to the capping machine where the capping head moves downward and holds the head of bottle.

The cap chuck header rotates on the head of bottle with a certain pressure and tightens the cap in term of rotating, screwing or direct implementation.

The torque of these caps is checked by highly sensitive sensors and their quality is maintained according to it.

Finally, the filled and capped bottle is moved towards the offloading side by a conveyor and here they are packaged for transportation.

5.What Are The Main Components In A Bottle Capping Machine?

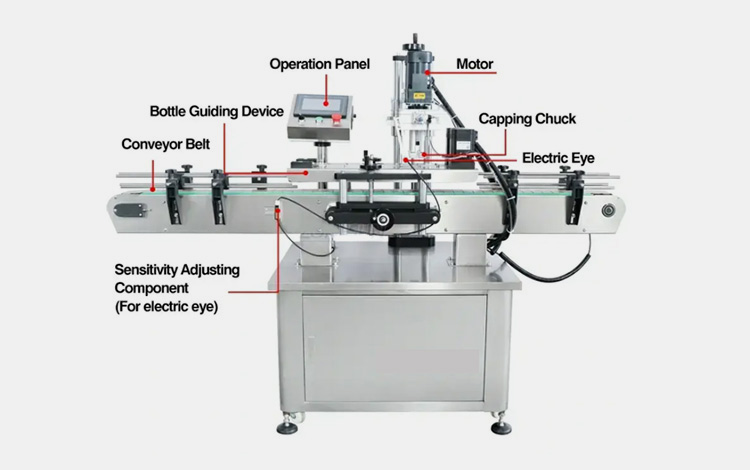

Full Automatic Bottle Capping Machine - Picture Courtesy: ZONESUN TECHNOLOGY

Some of the main components of a bottle capping machine are

Conveyor Belt

This is the feeding mechanism of a bottle capping machine that inserts the filled bottles into the capping process. Speed of a conveyor can be adjusted according to the requirement and productivity.

Hopper

A hopper or a feeding head is the place in which the caps are inserted. Like feeding mechanism of other machines, a hopper can also hold thousands of caps in it and moves them into the system as and when required.

Bottle Guiding Device

In a bottle capping machine, a bottle guiding device is usually connected on the conveyor where guides are used to direct the bottles towards capping process. These guides are mostly made up of rubber and metal part. Any irregularity in movement of bottles can be avoided through these bottle guiding devices.

Capping Chuck

This is the place that holds the caps inserted by the cap feeding mechanism. A capping chuck moves vertically down and up during the capping process. Once the bottle reaches below this capping chuck, it moves down and places the cap on the top of bottle. It also screws, torques and tights the cap so that no spillage of material occurs.

Motor

Mostly servo motors are used in a bottle capping machine due to its highly precise movement and angle detection. It continuously monitors and sends the feedback back to the system. The motor is responsible for the movement of capping chuck in vertical direction and also while the torque is applied on it.

Operational Panel

The operational panel of a bottle capping machine contains all the processing operation control in it. It includes conveyor speed control, system emergency, capping speed, material flow, flow rate, feeding mechanism and systems performance monitoring and display feature. The operator can easily control and monitor the operation through this operational panel.

Electric Eye

The electric eye of a bottle capping machine holds the overall sensing equipment of the process. It detects starting from the movement of bottles throughout the system to the final detection of capping that whether it is properly inserted or not. Complete sensors of the machine are connected with this so that quality capping can be performed.

6.What Types Of Bottle Capping Machines Are Available Globally?

Some of the types of a bottle capping machines are

Screw Bottle Capping Machine

A screw bottle capping machine is one of the mostly used type of bottle capping machine used globally. It rotates the cap on the top of a bottle and tights it to its maximum thread and limit. This type of bottle capping machine is present in all type of bottle processing industries.

Working Principle

Initially, the bottle is loaded on to the conveyor and moves in forward direction.

Once the bottles are filled they enter the capping process and the capping chuck places cap on the top of bottles.

The capping chuck contains rotating head that rotates in a way that the screw threads completely get in contact with the threads on bottle and tights it accordingly.

Finally, the capped bottles are then removed from the offloading side of the bottle capping machine.

Snap Bottle Capping Machine

Automatic Press Snap Bottle Capping Machine - Picture Courtesy: VKPAK

The capping mechanism of this type of bottle capping machine includes engagement of bottles neck with the grooves and applying a snapping fixture. No screwing is required and by only pressing the cap can also be enough in a snap bottle capping machine.

Working Principle

Firstly, bottles are loaded on to the conveyor and are moved in forward direction.

Bottles after getting filled enter in the capping process where the capping chuck places cap on the top of bottles.

Here the capping chuck just fixes the caps on the top of bottle and then applies a low pressure to press it on the bottle neck.

Finally, the capped bottles are then removed from the offloading side of the bottle capping machine.

Cap Placer Bottle Capping Machine

Fully Automatic Press Cap Placer - Picture Courtesy: Rhino-Pak

A cap placer bottle capping machine is somehow a traditional method of applying caps on the bottles as it is only responsible to place caps. Cross threading is applied in this type of bottle capping machine to tight the bolts and threads.

Working Principle

Firstly, bottles are loaded on to the conveyor and are moved in forward direction towards the filling process.

After getting filled, these bottles enter in the capping process where the capping chuck places cap on the top of bottles.

The cross threading mechanism of a cap placer bottle capping machine fixes the caps on the top of bottle and then tights the nut to its maximum required torque.

Finally, the capped bottles are then removed from the offloading side of the bottle capping machine.

In-line Bottle Capping Machine

In-line Bottle Capping Machine - Picture Courtesy: Pharmaceutical Packaging

An in-line bottle capping machine is highly capable of adjusting different sizes and types of bottles in it. Pneumatic processes are used in an in-line bottle capping machine to cap thousands of caps in just a small duration.

Working Principle

In the first step the bottles are loaded on to the conveyor and are moved in forward direction.

Once the bottles are filled they are entered in the capping process where the capping chuck places cap on the top of bottles.

The capping chuck of an in-line bottle capping machine with the help of air pressure applies the caps on different sizes of bottles and containers.

This air pressure air tights the caps so that no spillage or material leakage occurs while travelling hundreds of kilometers.

Finally, the capped bottles are then removed from the offloading side of the bottle capping machine.

7.Which Material Is Suitable For Performing Capping Through A Bottle Capping Machine?

This has been the most asked query that what actually be the capping material to check its suitability. The bottle caps should be made up of

Metal Caps

Metal Bottle Caps - Picture Courtesy: Recycle Caps

One of the widely used types of material is metal. Metals like tin, aluminum or alloys are affective when it comes to stop external air and moisture involvement. Metals caps are used in bottles containing wine, carbonated drinks and other types of chemical spirits and can also be recycled. The seal applied though metal caps are of strong strength and it is precisely placed by a bottle capping machine.

Plastic Material

Plastic Bottle Caps

Most of the plastic caps are made up of polystyrene, polyethylene and polypropylene. These materials are hard and of low cost that makes the product look pleasant and cheaper respectively. Most of the plastic caps are installed by a bottle capping machine on juice, beverages and medicine bottles where the products are directly consumed by human beings.

Rubber Stoppers

Rubber Stopper - Picture Courtesy: Etsy

Stoppers made up of chlorobutyl and bromobutyl class of rubber are resistant towards entrance of any type of environmental material. The materials that are filled in bottles and then sealed using rubber stoppers are mostly related to pharmaceutical industry where high class sealing is required.

8.What Is The Difference Between A Cap Inserting Machine And A Bottle Capping Machine?

Both of the types of machines are mostly used in pharmaceutical, packaging and food industries where large numbers of products are produced on daily basis. Some of the basic differences between both of the machines are

Purpose Of Use

A cap inserting machine mostly refers to just placing the caps the on to the neck of a bottle. It does not involve any type of tightening or torque activity. It is done in the further steps.

Whereas in a bottle capping machine, complete implementation of caps from its placement to its tightening is performed by the capping chuck of the machine. The machine does not rely on any further step.

Operation

In a cap inserting machine, once the bottles are placed beneath the capping head, a vacuum suction mechanism gets started and the caps are precisely placed on the top of the bottle neck. It is then further tightened and sealed on further steps.

On the other hand, as the bottle reached the capping head of a bottle capping machine comes downward, installs the cap and then tights it according to the mechanism of machine. Complete required torque is applied so that the bottle remains air tight and resists any interference.

Applications

Cap inserting machines are widely applied in pharmaceutical, chemical and food industries where large number of products is produced.

A bottle capping machine is a highly precise machine that is used according its automation level and production required. Mostly beverages, chemical, pharmaceutical, food and cosmetic industry uses a bottle capping machine.

Caps Variety

Variety of cap types can be used in a cap inserting machine and they can be further installed on different sizes of bottles.

A single bottle capping machine accommodates single method of capping and the whole system can be changed according to its requirement. But one type of capping is performed at a certain period of time.

9.What Auxiliary Machines Are Associated With A Bottle Capping Machine In A Processing Line?

A bottle capping machine has many auxiliary machine associated with it to perform its process and some are

Bottle Unscrambler

Bottle Unscrambler - Picture Courtesy: Pharma Packaging Systems

A bottle unscramble is basically used to identify and sort different sizes and types of bottles and caps. They align these bottles on the conveying mechanism so that they are moved in a proper way towards the filling and capping process.

Bottle Filling Machine

Bottle Filling Machine

A bottle filling machine is the most important auxiliary machine present in the system as it is primarily used for the filling of material into the bottle that has to be capped. This machine precisely fills the bottle in a way that no spillage can occur afterwards.

Bottle Sealing Machine

Automatic Bottle Sealing Machine

Once the caps are applied mostly rubber and plastic, bottle sealing machines are used further to seal them and form an airtight surface. Sealing machines are set at a certain temperature so that the caps may not get overheat.

Pressing Machine

Pneumatic Cap Press - Picture Courtesy: Adelphi Group

In some of the bottle capping machine processes, pressing machines are also used to press the caps that are inserted previously. These can be rubber stoppers or plastic stoppers.

Labeling Machine

Bottle Sticker Labeling Machine- Picture Courtesy: Secondary Packaging

Once complete sealing is done, labels are applied on these bottles using a labeling machine. These labels contain all products and manufacturer related information so that the customer can easily get aware of it.

Bottle Cartoning Machine

Automatic Bottle Cartoning Machine- Picture Courtesy: Cartoning Machines

In the last step, a bottle cartoning machine is used that packages all the bottles in a single carton. This makes easy handling of bottles and also helps them in traveling long distances.

10.How Different Sizes Of Caps Can Be Processed In A Single Bottle Capping Machine?

Bottle Capping Chuck- Picture Courtesy: Precision Tork

The basic principle of a bottle capping machine adjust variety of cap sizes and cap types in a single machine. It precisely can handle variety of caps just by adjusting the capping head and its feeding mechanism. In a bottle capping machine, easy changeovers can be carried by adjustment of tool and different types of tools can be interchanged at a same level. In this way the required capping tool can be used easily in a bottle capping machine.

Conclusion

Have you got all about a bottle capping machine and its process? Now are you familiar with different types of bottle capping machine? If still you have some queries related to “Bottle Capping Machine” and finding more facts about it, feel free to contact us. We are always here to support, assist and deliver you the best type of machine for your processing setup. Our customer representatives are active 24/7 and can help sorting your concern regarding any type of process and packaging machine.

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide