Blood Collection Needle Counting Machine: The Complete Buying Guide in 2025

Do you know that blood collection needles are so common in identifying your ailment? We understand it looks scary and many of you have needle aversion and skip routine checkups! But this method is almost the same with minor changes since 1955.

Today, for your safety and health concerns, biomedical sciences and engineering have emerged with modern counting machines in order to bring the packaging process with extra care. Suppose there’s no counting machine; the picture would be drastically horrible as manual counting is really impossible to meet your requirements. Despite of fact, it would be unsafe for patients as manual handling can be a source of unclean and wrong packaging. Therefore, a blood collection needle counting machine is a tremendous solution.

Picture Courtesy: MLS

How this robust machine can bring this tiresome job in a fraction of a seconds, you will get to know in this post. If you are planning to buy this equipment, then don't go anywhere and read the complete blog, we promise you will find it fruitful, once you conclude because it will help you to find the right unit selection best for you.

1.What is a blood collection needle counting machine?

Allpack Blood Collection Needle Counting Machine

This is a versatile and straightforward machine that is used to count the pre-determined quantity of blood collection needles and fill them into their packaging material as ordered by the unit. it is ideal for moderate to large quantity blood collection needle batches as it offers a hygienic and safest way to your product.

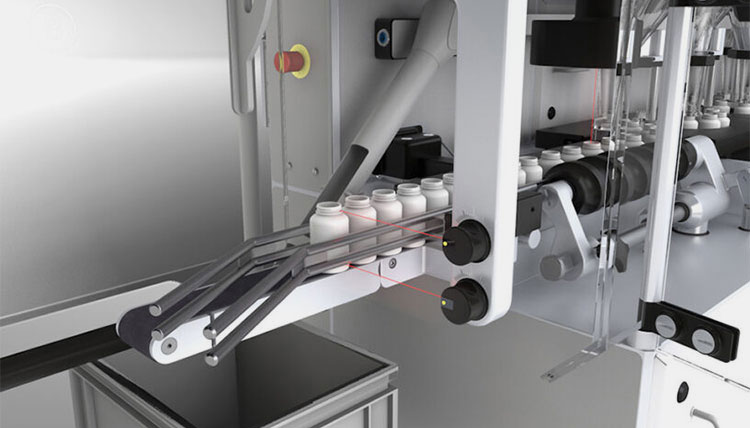

This is designed with a compact footprint with an automatic control system that allows self-feed of bottles, pouches, or boxes. It has adopted a high rail speeding unit for its transportation and a sophisticated electrical system allows counting by utilising multiple counting heads that save your time simultaneously increasing your productivity in handling sharp needles.

2.What benefits do blood collection needle counting machine offer to their customers?

When it comes to knowing the needs of this machine; you will be surprised to understand its unlimited advantages that every manufacturer dreams of. For running a production line related to blood collection needles counting, there are some important benefits that you must know about:

Booming Your Productivity

Greater productivity

Nevertheless, this machine works mainly depending on a computerized system where an entirely smart design is responsible for interpreting your requirements and ordering the mechanical section to bring the counting of blood collection needles timely. So if you have daily greater requirements, then this machine is for you, as it is capable of running multiple items in the blink of an eye.

No Chances of User Injury

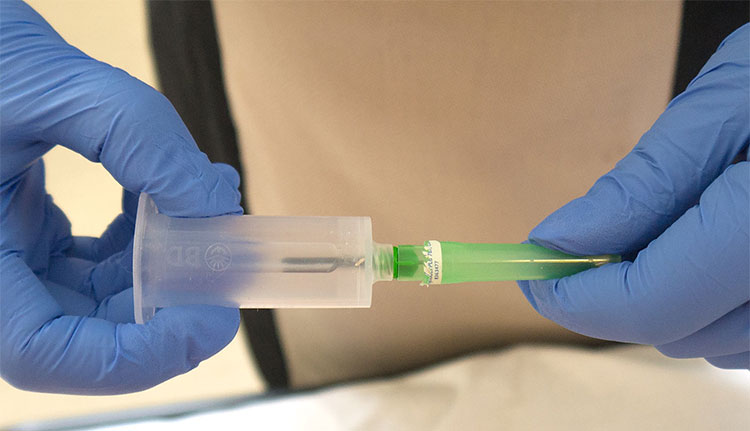

User safety- Picture Courtesy: Universal Biosensor

Here, you have minimal contact with blood collection needles except to load them in a hopper. Just press the button, and the machine will start its job. This is a promising solution with significant user safety in the workplace.

A containment Unit Against Dust Emission

Anti-dust operation- Picture Courtesy: Medshop

It is pretty normal that during count, many items produce some quantity of dust, i.e., movement of items. Therefore, the blood collection needle counting machine has an excellent recovery and containment system that helps in the prevention of dust. It is equipped with a vacuum extraction unit that helps in the extraction of dust by sieve holes designed in the vibrating plates that collect via internal tubing and eventually remove the possibility of dust and prevent contamination inside the machine and items.

Reliable Addition with Safe Construction

Safe construction- Picture Courtesy: Medisa

When it comes to knowing its make-up; then it is mainly designed with the utilization of FDA-approved food-grade materials which are reliable for blood collection needle counting without worrying about cross-contamination or product damage.

Customer satisfaction

Customer satisfaction- Picture Courtesy: Hume City Council

This is so true that customers will complain if they get the wrong blood collection needles or any incorrect number. Therefore, you may recall the whole batch sometimes, which is not only tiresome for you but for the whole supply chain. However, this is not a problem if using a blood collection needle counting machine as it is the most effective solution for medical item counting and packaging competitively.

3.What are the market applications of blood collection needle counting machines?

The blood collection needle counting machine offers huge applications in the diversified fields of the production and packaging world. Check it out now!

Pharmaceutical Industry

Pharmaceutical solid dosage medication

In this industry, where accuracy and safety are considered a paramount component, a blood collection counting machine is used for counting and packaging health-related formulations like solid dosage oral tablets, capsules, pills, granular supplements, and related products that require an accurate and safe treatment.

Nutraceutical Supplements Industry

Nutraceutical Supplements- Picture Courtesy: Cool Braces

This industry is also offering formulations that are much like the pharmaceutical industry with slight differences in their indication. For example, their supplements are based on generalized health benefits including the number of probiotics, prebiotics, multivitamins enzyme inducers, and other health-related boosters such as energy dose, mineral balancing supplements that are available in soft or hard gelatin capsules, tablets such as (regular, effervescent, chewable), gummies, and other that are counted and packed blood collection needle counting machine.

Chemical Industry

Chemical Granules

This industry is mainly associated with products available in a raw chemical and are mostly hazardous to users if touched by bare hands. They are basically available in the form of smooth granules, tablets, or pellets, that are quantitively filled by a blood collection needle counting machine safely with much interaction of you and the working environment.

Cosmetic Industry

Cosmetic waxing beads- picture courtesy: salt and paper

Various cosmetics items require frequent counting before their final packaging. This includes skincare formulation in beads, such as waxing products, skin cleaning products, granules related to manicure and pedicure treatments, hair related masks, which are packed in respective containers, jars, and pouches, by blood collection needle counting machine.

Food And Beverages

Food and beverages

This is the major industry where the safety concern ratio is also higher compared to the medical field. The blood collection counting machine is applicable for products like coffee beans, frozen food i.e, chicken drum sticks, cheesy bites, non-frozen food products, several pulses and grains, dried fruits, confectionery, and beverages such as ready-made food, chips, crackers, biscuits, etc ensuring fast counting for accurate packaging in this sector.

Veterinary Industry

Veterinary applications

This industry requires a blood collection needle counting machine for the counting and packaging of products related to your pets in the form of solid dosage formulation, for example, oral antibiotics some over-the-counter drugs, like painkillers, anti-allergy medication, and health-related supplements.

Stationery Industry

Stationery items counting and packing

A blood collection needle counting machine is required in the stationery industry for accurate packaging of items such as pencils, sharpeners, rubbers or erasers, painting brushes, keychains, decorated plugs or tools, pencil toppers, clips, safety pins, and much more.

Construction Industry

Industrial uses

Various products are available in small tools and require precise packaging for your efficient construction work. It is essential to pack an accurate quantity as mentioned in the packaging information to proceed an uninterrupted work. These hardware tools such as plugs, switches, nuts, bolts, pins, needles, and many related items used in construction are mainly packed by using a blood collection needle counting machine.

4.What are the different types of blood collection needle counting machine?

There are certain different types of blood collection needle counting machine that we have discussed below:

Hi-Tech Rotary Blood Collection Needle Counting Machine

Rotary blood collection needle counting machine- Picture Courtesy: Cremer

These machines are specially designed to count needles conjoining to a large quantity production line. It is equipped with a carousel made up of pockets to hold containers and is responsible for filling the counted needles in a consistent circular motion that occurs instantly. Soon after filling, the container leaves the filling section and allows the next. In this way, a large indefinite counting can be done. Consequently, it is considered the most suitable option in major corporations' counting and packing solutions due to its high throughput.

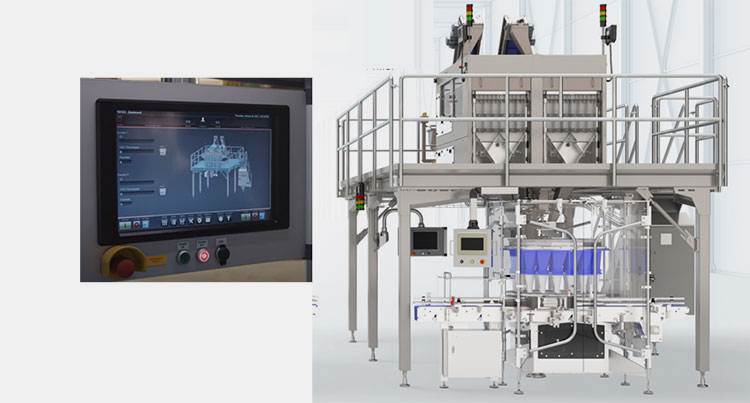

Linear Blood Collection Needle Counting Machine

Linear blood collection needle counting machine- Picture Courtesy: C.E King

This machine linearly counts and fills the number of blood collection counting needles into packaging material with the help of the continuous motion of the conveyor belt. This is the most commonly used type and is used in different industries related to small, medium, and large production sections.

Visual Inspection Blood Collection Needle Counting Machine

Visual Inspection Blood Collection Needle Counting Machine- Picture Courtesy: Cremer

The era has facilitated you with a modern blood collection counting machine as it offers a visual inspection unit where the entire process can be visualized with 3D images in various stages such as blood collection needles carrying from vibratory plates till its final counting followed by discharging of the system.

Apart from its high expense, the machine is quite beneficial for you in terms of attaining accuracy and advanced performance without any discrepancies. This is a flawless option if you are running a high-demand business or a larger manufacturing company.

5.What is the working principle of a blood collection needle counting machine?

The working principle of the blood collection needle counting machine is mainly comprised of the following major steps that we have described below:

Step 1: Product Loading

Product loading

This is the first step where you can start your work by simply loading the blood collection needles into the machine’s hopper manually or by using any supportive unit such as a loading conveyor.

Step 2: System Preparation

Infeed Data- Picture Courtesy: Cremer

This is the second step initiated with feeding your protocol into the machine software simply by using a PLC touch screen. This includes the speed of counting items per minute, the run time, and the number of runs to occur in the whole batch.

Step 3 Detection

Detection in Vibratory Plates

This is a process where transferring or dropping the blood collection needles takes place from the bottom of the hopper and starts moving toward the filling area simply by the movement of vibratory plates smoothly and consistently. during this time, the entire operation is monitored by photoelectric detectors and equipped scanners. if there is any defect in the material, it can be directly sent to the rejection site without interfering with the process.

Step 3: Counting And Filling

Counting & Filling

The number of blood collection needles starts dropping from the vibratory plate toward the counting area and is considered as marked simply by blinking the light of the detector and eventually drops down into the packaging material whether it is a box jar or a pouch. It ranges from one to various filling heads so it is capable of counting unlimited objects under a strict monitoring and inspection system. In some machines, every component is properly visualized and scanned automatically to yield large counting per minute.

Step 4: Output

Final product- Picture Courtesy: LAMANSH Lab

When the required number of blood collection needles are filled in the filling material is discharged via the exit unit which is mostly a conveyor. Now the final material is sent to another integrated machine or can be removed manually.

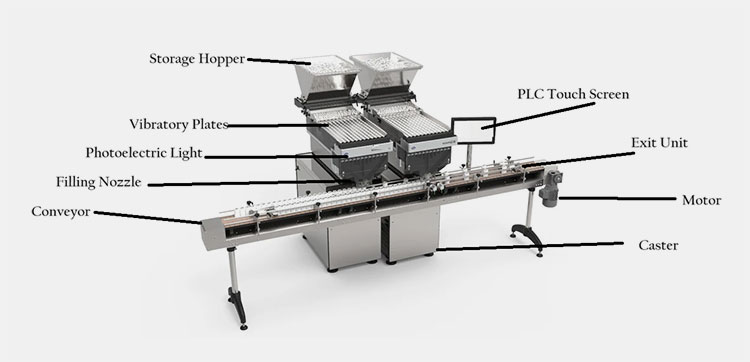

6.What is the machine design of the blood collection needle counting machine?

Blood Collection needle counting machine- Picture Courtesy: C.E King Limited

A blood collection counting machine encompasses various modern components serving you with modern technology in the precise counting of objects, here we have presented a clear picture of the machine highlighting its structure and suitable explanation for your understanding.

Storage Hopper

An important unit equipped with the topmost position where loading of blood collection needles takes place playing a key role in the storage of bulk quantities of items with promising processing without requiring intermittent re-filling. This is kind of a bulk tank for a consistent supply of items once receiving demand from a software processor.

Vibratory Plates

This unit plays a fundamental role in regulating the movement and monitoring of the blood collection needles in a controlled and consistent manner. There are multiple vibratory plates designed in a way that generates a gentle shakiness to the needles to pass them from the hopper to the filling section without chances of jamming or overlapping.

PLC Touch Screen

This unit serves you as a leader of equipment which takes on your command simply by receiving from the screen and simultaneously transmitting them to various parts of the machine. for example, speed, no. items, types of packaging containers, etc., hence you can attain efficient performance with flexible digital coordination.

Photoelectric Light

A photoelectric light performs an elemental role in the identification of the correct and exact presence of blood collection needles by simply striking its rays with the object making the system a ‘marked’ needle and giving a notification on screen. This excellent technology ensures that no double or miss-counting can occur.

Filling Nozzle

This is a fundamental unit equipped with a photoelectric sensor and parallel with a filling container, once it is positioned, the machine senses the presence and drops the pre-determined number of blood collection needles. The quantity and flow of needles can be regulated depending on your choice.

Exit Unit

The filled materials leave the machine once it is catered by the unit smoothly. The conveyor is subjected to consistent flow with optimized configuration to ensure correct and aligned movement of the packing to other units of the system.

Conveyor

It performs a pivotal role in the feeding, positioning, and discharging of the container. It is mainly fixed with the machine as well as integrated to interlink the device with other equipment.

Conveyor Motor

This unit generates mechanical force by utilization of electrical energy to bring movement in completing the tasks related to the regulation of the container’s movement.

Caster

It can be wheels, rollers, and fixed holders to ensure firm stability and offer flexible mobility required for positioning and installation in your facility. moreover, the whole body standing is supported by casters and you can easily move the machine during cleaning and maintenance tasks.

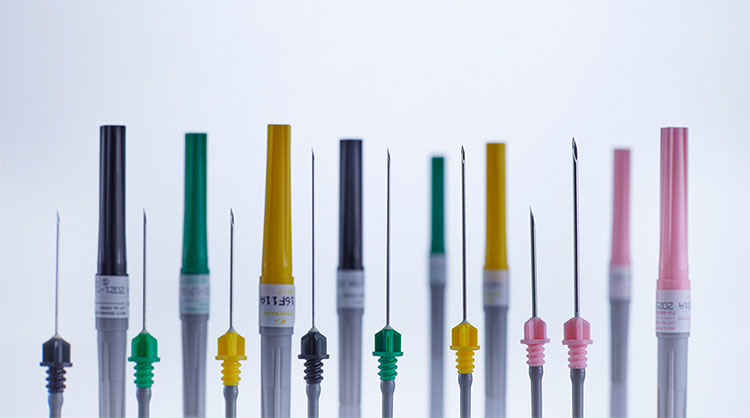

7.What different needle types can be counted by a blood collection needle counting machine?

A blood collection needle counting machine is devised to accommodate a diverse selection of different types of needles. In this regard, the machine has unique features to detect the size and shape of a needle.

Straight Needles

Straight blood collection needles- picture courtesy: CNWTC

A cutting-edge technology of blood collection needle counting machine with advanced sensors allows it to count straight needles. It can be tailored by customizing machine settings to accommodate various needle gauges each time.

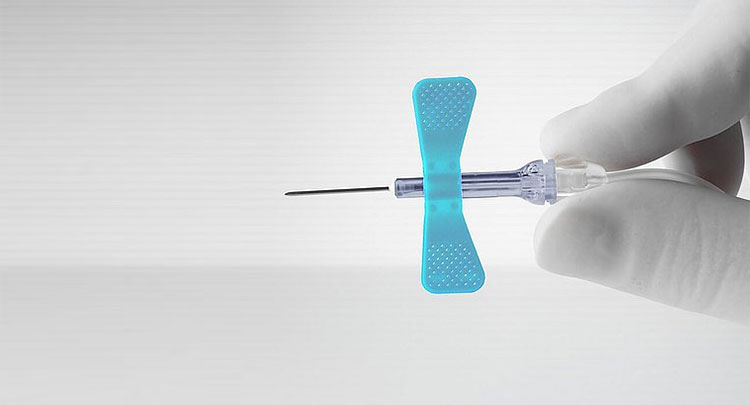

Butterfly Needles

Butterfly blood collection needles- picture courtesy: Greiner Bio-One

The blood collection needle counting machine is engineered with special features of width detective attributes. The width sensors in this device enable it to be the best possible choice for counting butterfly-type blood collection needles.

Acupuncture Needles

Acupuncture blood needles

Owing to its diverse set of functions, the blood collection needle counting machine is tooled with a comprehensive system. Hence it can easily count acupuncture needles used for different therapies. Its innovative features contribute to the steady and constant flow of items toward the vibratory plates of the counting machine.

Lancet Needles

Lancet Needles for glucose monitoring

Blood collection needle counting machine has significant features that go in your favor, in terms of detection channels which consist of separate infrared light that helps in the counting process with 100% authentication.

Venipuncture Needles

Venipuncture- Picture Courtesy: Medistudent

It is one of the ideal solutions for counting venipuncture blood collection needles correctly. The multistage counting gadgets used as sensors make sure that they can spot the dimensions of needles during the counting operations.

8.What packaging materials does a blood collection needle counting machine can fill?

There is a diverse range of packaging materials that can be filled by a blood collection needle counting machine, for example:

| Cartons/Boxes | Blood collection needles are commonly counted and filled in cartons or boxes which is the most economical and handy packaging type. Whether it is for retail purposes or general storage, these boxes are easy to transport and can store bulk items in a smaller space. |

Blood collection needles cartons/boxes- Picture Courtesy: HUSK medical |

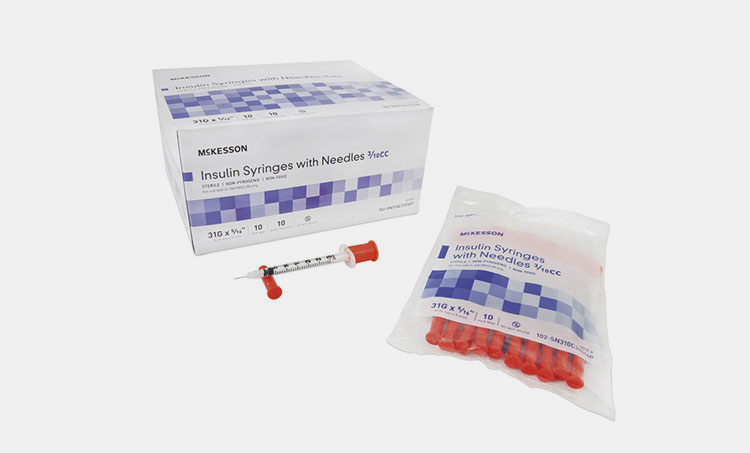

| Pouches | Flexible and transparent pouches are another popular packaging type for storing blood collection needles which is a lightweight and safest option used in medical fields. A blood collection needle counting machine is suitable when it comes to dispensing items in pouches |

1cc Needles- Picture Courtesy: McKesson Medical |

| Bottles | Whether plastic or glass, it is the best and most secure way of storing blood collection needles in an organized manner. This machine is considered a preferable solution for the distribution of these items in bottles/containers/jars. |

Blood collection needle bottles- Picture Courtesy: Cremer |

| Trays | Disposable trays are lightweight and portable packaging types for storing blood collection needles and syringes worldwide. They are secure by a transparent lid and are known as a secure way of carrying medical items. A blood collection needle counting machine is ideal when it comes to counting and filling these trays as it offers various sizes and widths trays easily. |

Blood collection needles in a disposable tray- Picture Courtesy: Farris Lab |

9.What are the tips for cleaning and maintaining the blood collection needle counting machine?

When it comes to dealing with a blood collection needle counting machine, it must be cleaned and maintained to bring health-related tasks professionally well and free from risky practices. Any carelessness can result in the malfunctioning of the machine and reduced product quality in terms of various discrepancies. Rather you should the mentioned below points to extend the machine's life and the product’s accurate counting.

Cleaning Vibratory Plates and Tools

Cleaning machine’s parts

The blood counting needles are the sensitive objects used for healthcare chores including blood collection for diagnostic purposes. The cleaning of the machine is essential in a way any small particle or dust can affect the test results (the patient can be sent for re-checking that harms him in many ways such as mentally, physically, and economically). You should be very careful and punctual in quickly cleaning vibratory channels, hopper, filling nozzle, and those parts that come in contact with a needle to maintain hygienic practices.

- For that disassemble the tool and follow manual cleaning with a clean and dried cloth, For convenience and safety, you can remove the foreign part in the hopper and associated parts.

- Apart from general cleaning, the counting component can be cleaned with warm water and certain cleaning agents such as isopropyl alcohol and related solvents.

- Today, the modern way of dust collection can be done by utilization of vacuum dust collection, which is subjected to a hopper, internal tubing, in-between components, sensors, and vibratory plates.

Maintenance of Blood Collection Counting Machine

It is convenient for every user to schedule maintenance of the machine for various confined periods such as daily, weekly, monthly, and annually to keep up with the equipment’s condition. It will save a lot of time and interruption-free working.

Maintenance

By daily processing of the machine and the utilization of sensors, transmitters, photoelectric light, etc can be interrupted during counting as a continuous number of blood collection needles drop on them; with time their efficiency can be affected and the detection unit may cause inefficient results. For that, it is recommended to calibrate the machine and monitor and clean dust piling. This will help in maintaining the productivity of the machine for longer.

Change or replace the damaged part of the machine for easier working prevent malfunctioning and preserve the life of the equipment.

Frequently lubricate certain or movable parts to avoid vibration, unnecessary voices, or jamming issues.

10.What are the major technical problems you face when using a blood collection needle counting machine? How to manage them?

Without any doubt, a blood collection needle counting machine is a reliable option if you need assistance with equipment in your healthcare production facility. despite that, it may be presented with some malfunctioning that may interrupt your workflow and timely throughput. However, some easy solutions do not require a technician rather you can solve them yourself.

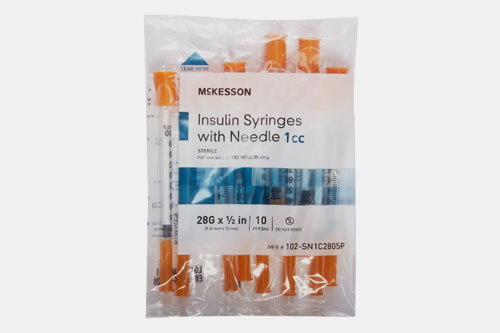

Incorrect number of counted items

Blood collection needle packaging- Picture Courtesy: McKesson

In some cases machine is unable to detect the presence of needles or it shows a higher number of counted items than the actual presence. This can occur due to either fast or slow movement of the vibratory plates, problems in software, or the presence of dust over the sensors, detectors, or scanners.

How to Manage?

To manage this problem,

You should regularly monitor and clean the machine as suggested in the cleaning and maintenance section of this post.

It is recommended to add an optimized protocol related to the number of blood-collecting needles, and the speed of counting items, and calibrate the equipment for sharp detection.

Displaying Software Glitches

Blood collection needle counting machine- Picture Courtesy: CountingLine

This is a common problem when the machine’s PLC touchscreen exhibits problems such as failure in displaying results, unable to feed the protocol, and frequent hanging of the system.

How to Manage?

The automatic machine mostly features counting software which must be updated regularly to acquire fast and latest version.

Correct and update the settings of the equipment and run the process to assess the correct performance.

Overlapping of Blood Collection Needles

Needles overlapping

This is a seldom issue accompanied by overlapping of items during the movement over vibratory plates that results in downtime.

How to Manage?

This problem can be solved by disassembling the vibratory plates and assessing the inside condition, if the tools are required to lubricate then this should be done timely.

Re-assemble the vibratory plate and check if they are settled correctly.

Regulate the counting speed and movement to facilitate a gentle flow of items to be counted.

11.What are the best factors you should know when purchasing a blood collection needle counting machine?

This is quite normal to feel a bit anxious when purchasing a machine. Nevertheless, a little workout can make you confident to decide what is the right machinery for you. Therefore, there are some points you should keep in mind to get a suitable machine to install.

Your Productivity

Percent productivity

What should be your expected productivity per day? This should be estimated prior to going forward. It will help to either go for a small, medium, or large-size blood collection needle counting machine that will absolutely meet your demand.

Automation Level

High Efficiency Blood Collection Needle Counting Machine- Picture Courtesy: Counting Line

What automation can be acceptable in your facility should be decided before. If your working process belongs to day and night procedures, then automatic is undoubtedly the right option for you. In case of moderate production capacities, semi-automatic is a handy option to purchase.

Easy Operating Keys

Easy to use – Picture courtesy: NMJ Packing

You can discuss your vendor and demand for the machine featuring easy operating keys to reduce the likelihood of abnormalities or slow operation. It will definitely help in achieving the target goals related to attaining ease of operation and stress-free working.

Your Area Specification

Allpack blood collection needle counting machine

If your working facility is small and looking for a machine with high features, automation, and integration then it must be in a compact footprint. This is of course tricky but easy to achieve if you know the dimensions of your facility and the required machine’s size during purchase.

Conclusion

In conclusion, a blood collection needle counting machine is a reliable solution for counting and packing items and helps you fill a broad range of packaging materials. The machine is capable of running in a large series of production lines and shows unprecedented performance. Allpack is the world leader in offering you an excellent series of blood collection needle counting machines and packaging machines for such as pharmaceuticals, foods, and related sectors. If you’re interested in looking for a purchase; then contact our team now.

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide