Clamshell Vs Blister Packaging:The Complete FAQ Guide In 2025

Clamshell Vs Blister Packaging:The Complete FAQ Guide In 2025

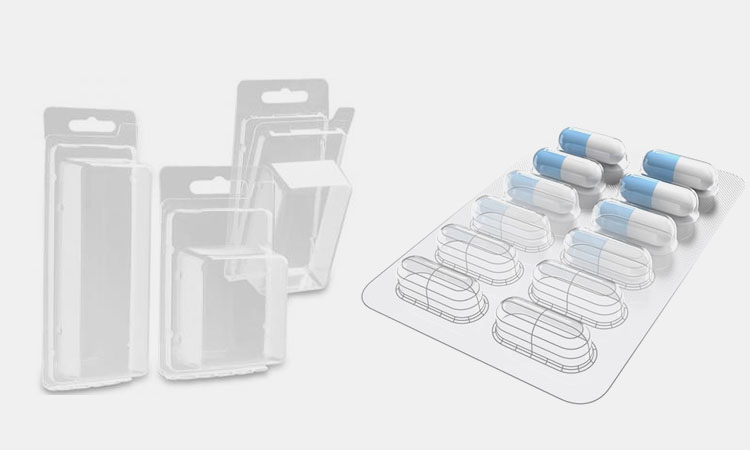

Are you feel unfamiliar with clamshell and blister packaging? Clamshell packaging and blister packaging may be the strange words for you. But you have the frequent use of capsule blister package, battery clamshell package and so on. The wide application of the two types of packaging benefit our society greatly.

What are the types of clamshell packaging and blister packaging? What are the difference between clamshell packaging and blister packaging? Are there any disadvantages of the two packaging way? How to choose your suitable package between clamshell packaging and blister packaging? Here is the complete FAQ guide in 2024 for clamshell and blister packaging.

1.What Is Clamshell Packaging And Blister Packaging?

Clamshell Packaging And Blister Packaging-Sourced:kpfilms

Clamshell packaging or clamshell is a type of blister packaging. With plastic back, it can make the nice sealing and protection for products inside. The two halves of it are hinged together or can be stuck tightly. It can form the various shape and size for the protection of various products. You can also open and close it for second use.

Blister packaging or blister pack is the traditional packaging way. With cardboard or plastic as its back, it can have products showed and information printed well. The heating can contain and protect your products. Usually, you cannot reuse it and the unpacking of machine cannot be recovered. The size and form of it can also be adjusted for product need and type.

2.What Are The Types Of Clamshell Packaging And Blister Packaging?

There are various clamshell packaging and blister packaging type. And here are the typical types of clamshell packaging and blister packaging which is distinguished according to type.

Clamshell packaging

Tri-fold clamshell

Tri-flod Clamshell-Sourced:clamshell-packaging

Tri-flod clamshell is the creative clamshell type. The tri-fold design makes your products stand up and can better show the products. The hole of this package can also benefit hanging.

Two piece clamshell

Two Piece Clamshell-Sourced:xylomatrix

Two piece clamshell has two pieces of clamshell which formed tight and protective packaging. It is usually two pieces of plastic board. And for different products and different products type, it can make the relative suit.

Fold-over clamshell

Fold-over Clamshell-Sourced:fold-over clamshell

The fold-over clamshell is the typical clamshell which usually has dashed hinge or U hinge. The hinge makes the strong connect and makes the smooth opening and closing of the products.

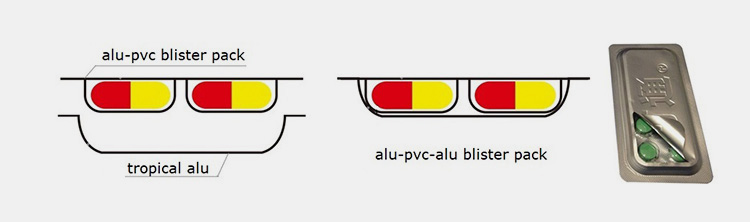

Blister packaging

Face seal blister

Face Seal Blister-Sourced:visipak

Face seal blister is the widely used blister pack. The heating process made the tight stick of back board and plastic sealing cover. It is cheap and applied widely. For the light and small products, it is the ideal products.

Full face seal blister

Full Face Seal Blister-Sourced:clamshell-packaging

Full face seal blister has the sealing manner same with face seal blister. The difference lies in that it has plastic covered the all place. It is more durable and can protect your products better.

Trapped blister

Tapped Blister-Sourced:indepak

Tapped blister is composed by three parts. Besides the backboard and plastic cover, there is also a cardboard between the two which has the same shape of blister. It has the lower cost price as it didn’t apply the heat sealing way. And it also has the tamper-proof function.

Full card blister

Full Card Blister-Sourced:gzhheng

Full card blister also has no application of heat forming process. The flanges wrapped around blister can make the smooth drawing of the products. And it can be used for second time.

3.What Products Can Apply Clamshell Packaging And Blister Packaging?

The clamshell packaging and blister packaging have the wide application. And here is the products where they can be applied.

Clamshell packaging

Food

Food-Sourced:pinterest

Clamshell packaging is the first choice of food packaging. For cake, fruits, vegetables and so on, clamshell packaging makes the delicate and careful protection for the fragile products.

Light bulb

Light Bulb-Sourced:sparex

Light bulb is the delicate products. And for the careful protection, you would better to adopt clamshell packaging for light bulb. It benefits protection and opening for customer’s use.

Cosmetic products

Cosmetic Products-Sourced:elsepack

Clamshell packaging makes the outstanding packaging for the various cosmetic products. It can make the nice job for protecting of bottle, can, tube and various cosmetic products.

Tool sets

Tool Sets-Sourced:task-tools

For various parts, tools, hardware, you would better to try clamshell packaging. It can protect the tool sets which have the fragile and breakable feature. This pack can help the tool sets a lot.

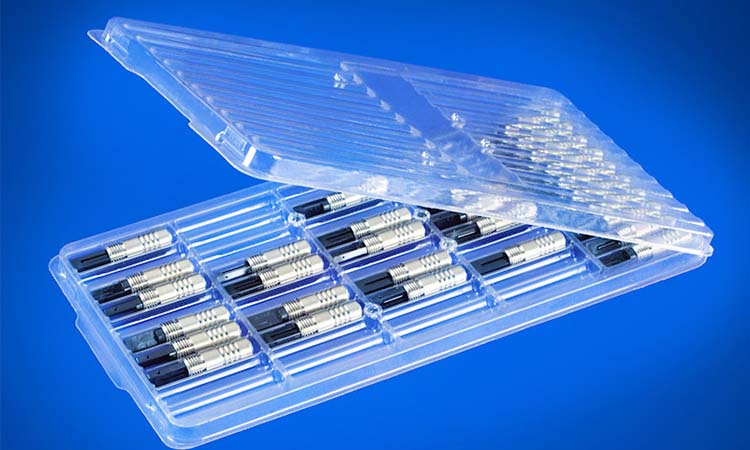

Electronic goods

Electronic Goods-Sourced: greatriverplastics

You may find the various electronic goods and accessories like headphones, cables, earphone and so on all packaged in clamshell packaging. It can hanged and better showed for you.

Sporting goods

Sporting Goods-Sourced:visipak

Sporting goods like badminton, shuttlecock, jumping rope and so on can all have great protection from this types of packaging. The clamshell packaging is the first choice of sports industry.

Toys

Toys-Sourced: sixpoints

The plastic and mechanical toys need the nice protection to prevent themselves from the outside attack. The clamshell packaging makes your toy packaging attractive and qualified.

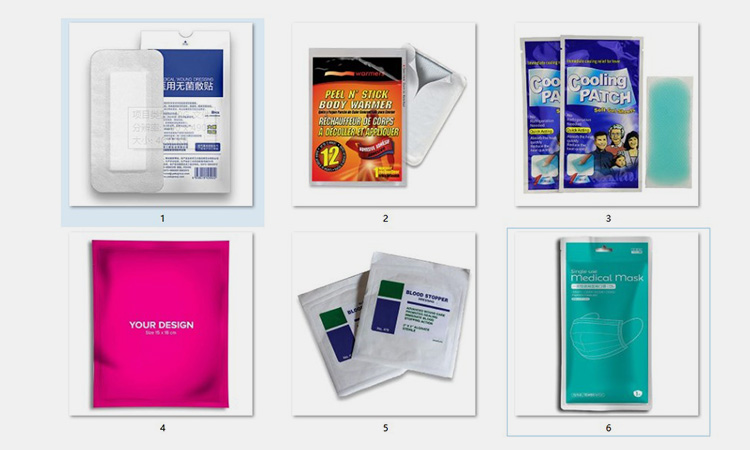

Blister packaging

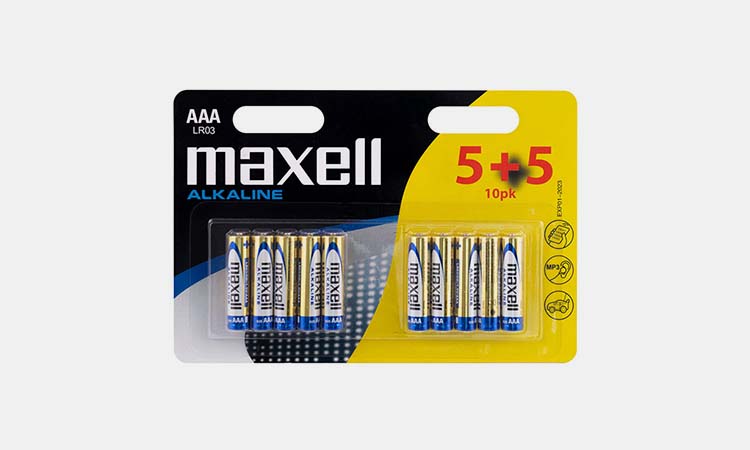

Batteries

Batteries-Sourced:laval-europe

Batteries are the representative products which made the wide application of blister packaging. For battery, blister packaging can make the airtight sealing and prove the quality of batteries.

Fishinglures

Fishing Lures-Sourced:blisterpackaging

Blister packaging has the outstanding use in products like fishing lures. For many fishing relative products on market, you may find its blister pack type.

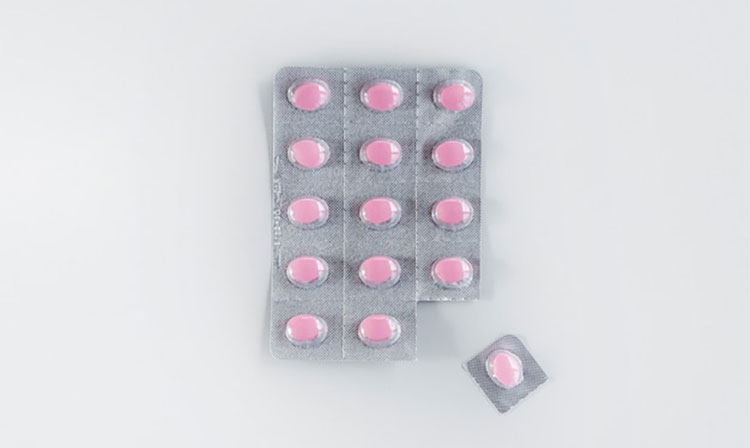

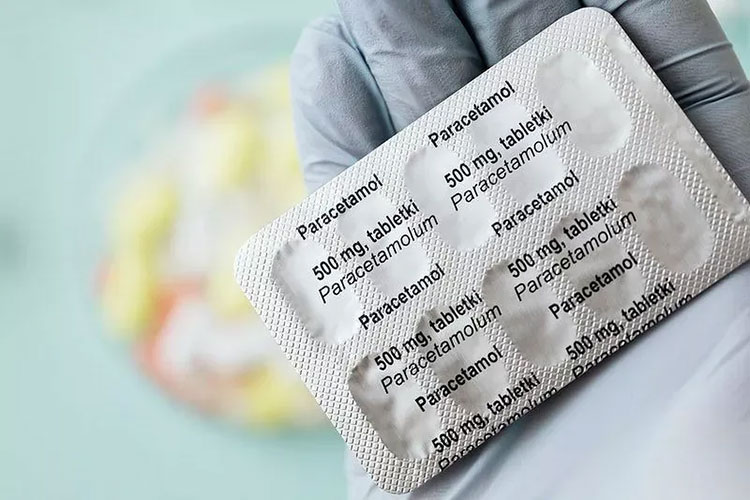

Pharmaceutical products

Pharmaceutical Products-Sourced:toplastics

For various products like tablets and capsules, blister packs are the first choice. It can make the protection of your products with higher sanitary standard.

Toothbrushes

Toothbrushes-Sourced:greenstarsproject

Toothbrushes also adopt blister packaging frequently. You may have found its wide use. It can better prove the sanitary of toothbrushes and also makes the better showing of products.

Stationery

Stationery-Sourced:blisterpak

Stationery has wide products range and you may find pens, erasers, drawing pins, superglue, paper clips and so much products all need the blister packaging for selling, transporting and protecting.

4.What Are The Difference BetweenClamshell Packaging And Blister Packaging?

What are the difference between clamshell packaging and blister packaging. Here is the detailed difference.

Clamshell Packaging VS Blister Packaging-Sourced:topclearance

| Difference | Clamshell packaging | Blister packaging |

| Cost | Clamshell packaging is more expensive compared with blister packaging as it applies more material and more complex technology. | Blister packaging costs less compared with clamshell packaging. But you should also consider the labor and equipment in it. |

| Merchandising way | Clamshell packaging can usually hang on shelf, set on table or display place. | Blister packaging is usually used in hanging on shelf or walls. |

| Assembly | Clamshell packaging can assembled by human hand and also by machine. | Blister packaging should be assembled by requirements. |

| Flexibility | Clamshell packaging is more flexible which adopts functional sealing design and heating sealing. | Blister packaging is less flexible as it adopts most slide blisters and plastic cavity sealing. |

| Industry application | Clamshell packaging can be used to many industries including toy, cosmetic, electronic and so on. But for fresh food packaging, it is not a great choice. | Blister packaging can be applied mostly in battery, toothbrush, pharmaceutical products and so on. |

| Sealing | Locking mechanisms, adhesive and heat sealing are its frequently used sealing way. They are usually rail sail and button sail. | Blister packaging usually adopts heating sealing and adhesive. You may find the various sealing way from different sealing material. |

| Visibility | Clamshell packaging is more attractive as it helps show the products in an all around way. | Blister packaging is lack in visibility and protection compared with clamshell one. |

| Compact | Clamshell packaging is less compact compared with blister packaging. | Blister packaging is more compact and can deal with the products of small size. |

| Environment impact | Clamshell packaging has the larger use of plastic and makes larger and worse impact to environment. | Blister packaging applies less plastic and can replace cards with plastic. |

| Openness | You need to cost more energy in opening clamshell packaging. | For blister packaging, the openness is much easier. |

5.What Are The SimilaritiesOf Clamshell Packaging And Blister Packaging?

After the viewing of differences, you may wonder the similarities of clamshell packaging and blister packaging.

Protection

Protection-Sourced:wilkes

Clamshell packaging and blister packaging can both make the outstanding job in protecting products from the hurt of others. The strong and protective packaging method of the two make the great protection for products.

Displaying

Displaying-Sourced:americanretailsupply

The high visibility of both clamshell packaging and blister packaging can make the great displaying of products. You can place them on market shelf and also make the products hanging.

Decorating icon

Decorating Icon-Sourced:assemblies

You can always find the label or cards of propaganda and introducing on the clamshell packaging and blister packaging. They typically use cards, labeling or printing for the packaging.

Assembly

Assembly-Sourced:colamark

Both clamshell packaging and blister packaging require the help of labor or machine for the assembling of products. The different type of machine requires the same road of filling cavity with products.

6.What Are The AdvantagesOf Clamshell Packaging And Blister Packaging?

Clamshell packaging and blister packaging both have many advantages. And here you can check.

Clamshell packaging

High visibility

High Visibility-Sourced:goodnaturedproducts

Clamshell packaging has high visibility. You can have your products shown in the various angle and can benefit the people who is trying to know the products deeply.

Great protection

Great protection-Sourced:oliverinc

Clamshell packaging is tough and can protect products well. The tough plastic shells can also protect the fragile products in transporting and storing.

Convenient storing

Convenient Storing-Sourced:gecos

Clamshell packaging is light and nestable which means the less space taking of products. It is thus more convenient in storing and displaying.

Water proof

Water Proof-Sourced:protoolreviews

Clamshell has packaging material mostly plastic. The tight clicking of products make it water proof and can deal with the various condition in storing and transporting.

Environment friendly

Environment Friendly-Sourced:amprodmfg

Clamshell packaging is deemed as more eco-friendly as it can be recycled. And the transporting and storing cost of this packaging is lower too.

Better display

Better Display-Sourced:nbeads

Clamshell packaging has high visibility and the various types of displaying method makes it better displayed on market for selling.

Blister packaging

Security prove

Security Prove-Sourced:kaatimex

Blister packaging makes the nice security prove. It keeps the products clean and can also prevent the information tampering.

Multi functional

Multi Functional-Sourced:oliverinc

Blister packaging is multi functional and can make the nice suiting for various types of products. The allowing of single packaging solution help reduce the packaging cost.

Customization

Customization-Sourced:blisterpackaging

The high customization of blister packaging manufacturing makes the special design for various blister packaging type and style.

Quality prove

Quality Prove-Sourced:laetus

Blister packaging avoids the condition of air or moisture affect product quality. For medical products or food, the blister packaging can better prove quality and dosage.

Child protect

Child Protect-Sourced:expertspackaging

Some blister packaging has the special design of child proof. For some medicines or products which is dangerous for children, the design is super practical.

Tamper

Tamper-Sourced:jochamp

The blister packaging can help customers find the tamper easily. And the products quality, reliability and genuine can be proved.

7.Are ThereDisadvantages Of Clamshell Packaging And Blister Packaging?

Nothing is perfect, here you may check the disadvantages of clamshell packaging and blister packaging.

Clamshell packaging

Hard to open

Hard To Open-Sourced:thekitchn

The clamshell packaging apply various sealing manners. Besides the adhesives, you may also find the rail sail and button sail. The sealing of clamshell packaging may make the problem for you to open.

Not Tightly Contain

Not Tightly Contain-Sourced:haoboxuo

For some clamshell packaging, the cavity is bigger and may make the tight containing a little difficult. The fragile products may get damaged in the shaking of transportation or storing.

Unsuitable for meat

Unsuitable For Meat-Sourced:kpfilms

For fresh vegetables and meats, clamshell packaging is not the most preferable choice though it makes the tough protection for products.

Blister packaging

Less durable

Less Durable-Sourced:freepik

Blister packaging has also wide type. And for some blister packaging type, the plastic bubble is thin and breakable. You should make the extra packaging to protect them and make the reliable protection.

Recycle difficulty

Recycle Difficulty-Sourced:ecobliss-pharma

Blister packaging makes much more difficult in recycling. For environment protection and recycling, you should consider the clamshell packaging.

8.How To Choose Your Suitable Package BetweenClamshell Packaging And Blister Packaging?

How to choose your suitable package between clamshell packaging and blister packaging. Here is the points you should consider seriously for the choose.

Product type

Product Type-Sourced:codexbiosolutions

What is your products? Toy, electronics or fresh meat? For the fresh meat or vegetables, you should choose blister packaging. And for the toy, electronic products or cosmetic products, you should choose clamshell packaging.

Packaging material

Packaging Material-Sourced:watersciencesinc

Clamshell packaging is made from various plastic material and you may find the applying of polystyrene, PVC and so on. There are also clamshell packaging which apply the cellulose, styrofoam, wheat and other recyclable material. Blister packaging apply the combination of plastic material and cardboard.

Cost

Cost-Sourced:sagacitysolutions

Clamshell packaging costs more compared with blister packaging. Clamshell packaging applies the thicker plastic material and has the technique more advanced.

Products protection

Products Protection-Sourced:clamshell-packaging

Clamshell packaging and blister packaging can both make the nice protection for products. But the clamshell packaging has the better protection for your products.

Visibility

Visibility-Sourced:naturpac

Clamshell packaging and blister packaging make the nice displaying of products. Clamshell packaging has the better visibility as it displays the products in the more comprehensive angle.

9.What Material Are Used In Blister Packaging And Clamshell Packaging?

What material are used in blister packaging and clamshell packaging? The applying material is similar. And here are the material which is used frequently.

PVC

PVC-Sourced:millerplastics

PVC which has the full name of polyvinyl chloride has the low cost and great resisting ability. It is widely used in the packaging of blister and clamshell.

PCTFE

PCTFE-Sourced:m-seals

PCTFE which has the full name of polychlorotrifluoroethylene is the typical plastic material. It is the form of laminate for blister packaging.

COP

COP-Sourced:ksukzemm

COP is the abbreviation cyclic olefin polymers and cyclic olefin copolymers. This kind of plastic material can be used for medicine packaging and so on.

PET

PET-Sourced:sybridge

PET is the plastic material which is widely used for blister packaging and its backing boards making. It is more expensive but it is not suitable for the packaging of all medical products.

HDPE

HDPE-Sourced:polymershapes

HDPE which has the full name as high density polyethylene is the plastic material which can be used for food packaging. The great safety of this kind makes it have the wide application.

Paperboard

Paperboard-Sourced:bioandchic

Paperboard is used for both clamshell packaging and blister packaging. For the back part of blister packaging and some types of clamshell packaging, it makes the environment friendly work.

Plant fiber

Plant Fiber-Sourced:brheez

Plant fiber has wide application. It is usually made with wheat grain and chaff. You can apply them to make the clamshell packaging for food.

Styrofoam

Styrofoam-Sourced:industrialpackaging

Styrofoam clamshell packaging is the widely welcomed packaging way which make the long time applying on market. It is used for the food packaging usually. But the bad environment influence makes it less welcome on market.

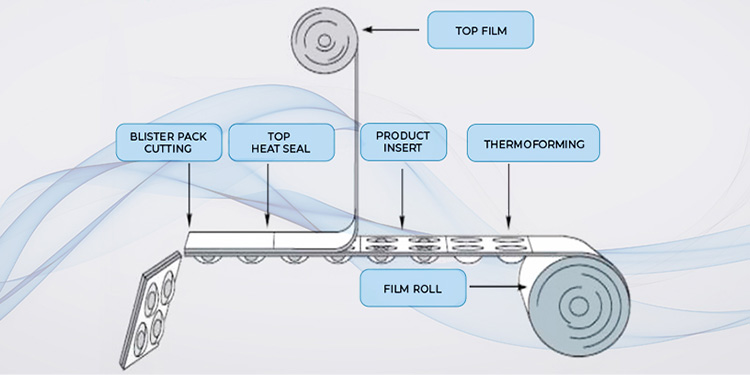

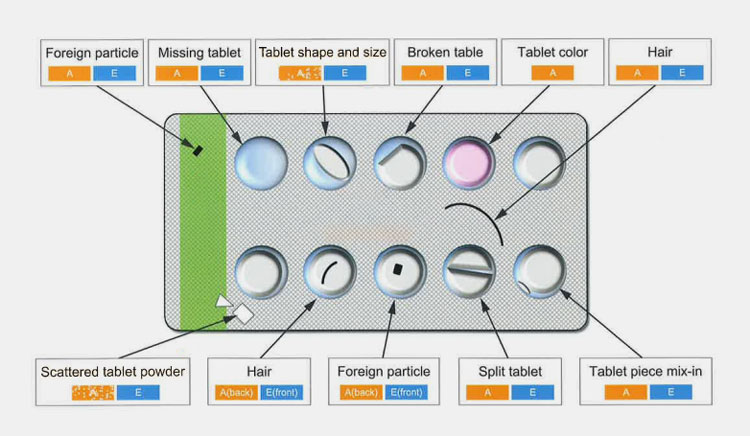

10.What Are The Machines Used For Clamshell Packaging And Blister Packaging?

Have you ever wondered the machines used for clamshell packaging and blister packaging? Here are the machines used for it.

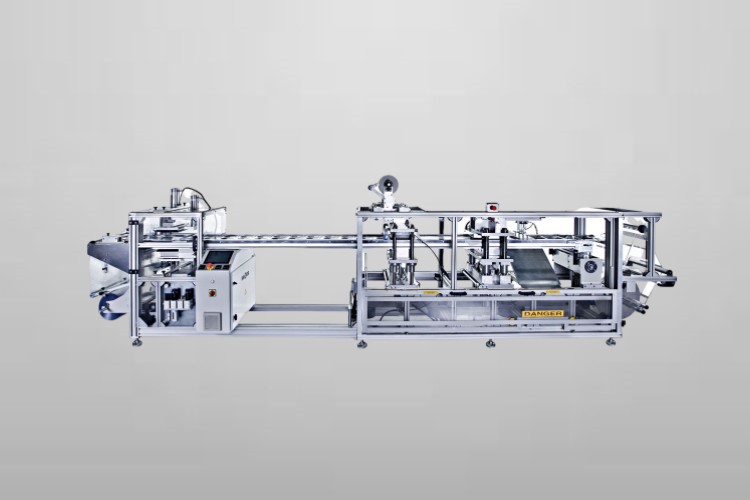

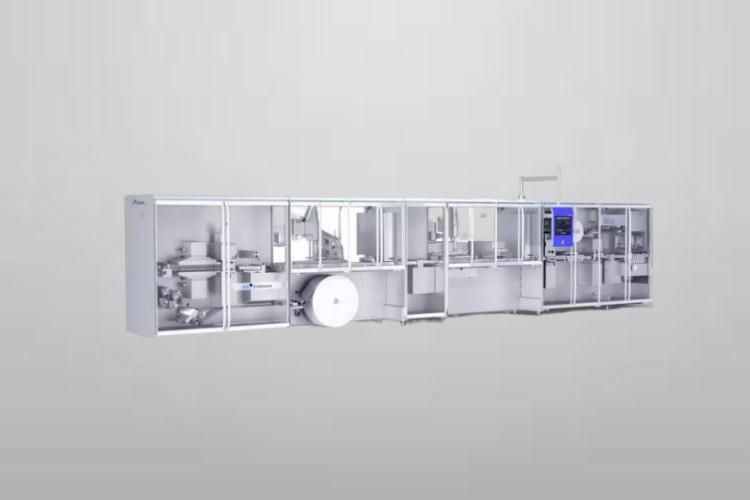

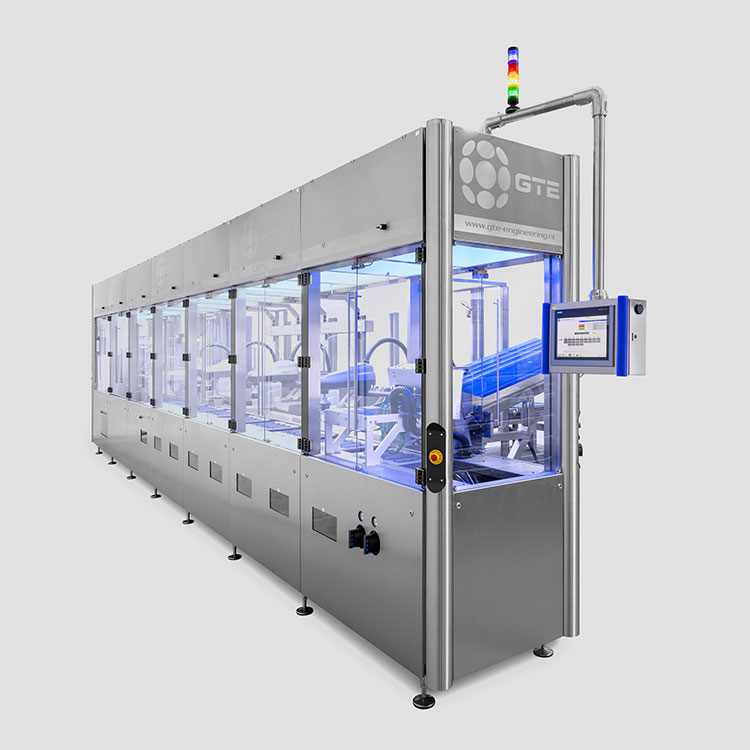

Blister packing machine

ALLPACK Blister Packing Machine

Blister packing machine has various types and for different kinds of products, it can make the great packing work. The high efficiency, accuracy, stable function ability and large production make it widely welcomed in food industry, pharmaceutical industry, supplementary industry and many other industries.

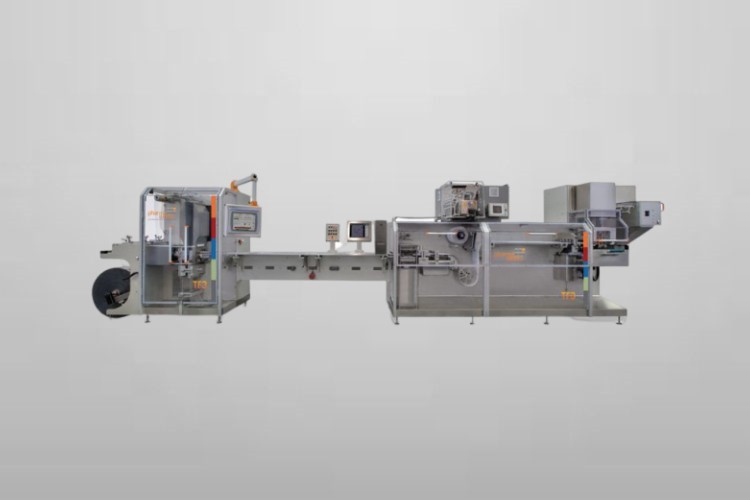

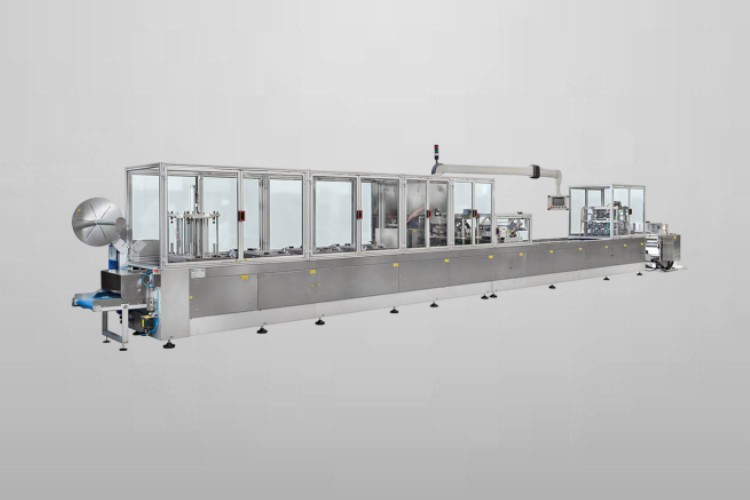

Clamshell packaging machine

Clamshell Packaging Machine-Sourced:volmcompanies

Clamshell packaging machine is the machine which makes the clamshell package for products of various size and type. The clamshell sealer can make the stable sealing and packaging for products. It is durable and flexible. You may find its use in toy industry, food industry, sports industry and so on.

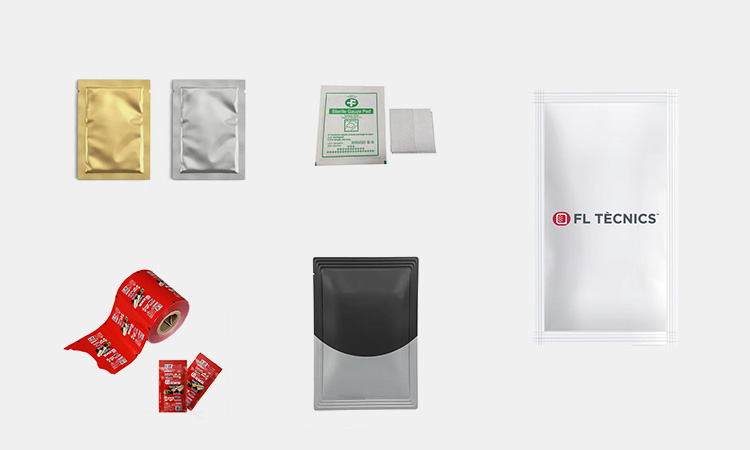

11.How Does Clamshell Packaging And Blister Packaging AreMade?

How does clamshell packaging and blister packaging are made? Here are the precise manufacturing process of clamshell packaging and blister packaging.

Clamshell packaging manufacturing

Clamshell Packaging Manufacturing-Sourced:peoriapros

Clamshell packaging can apply plastic, paperboard and many other material to make its shape. Clamshell packaging can get thermoformed too. And it has the various sealing way, you can seek the help of machine and labor to fill products and make the locking and sealing.

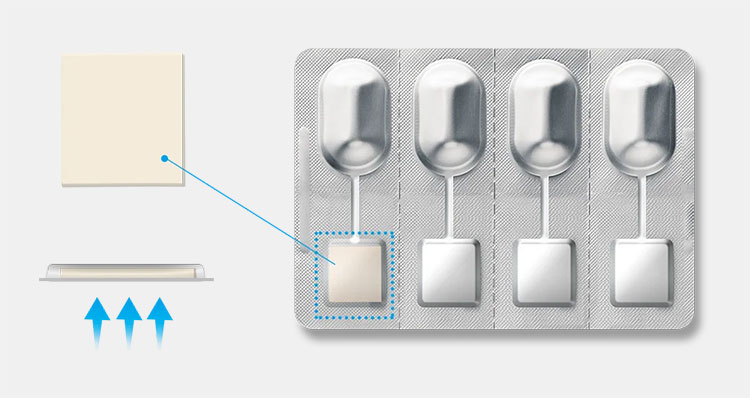

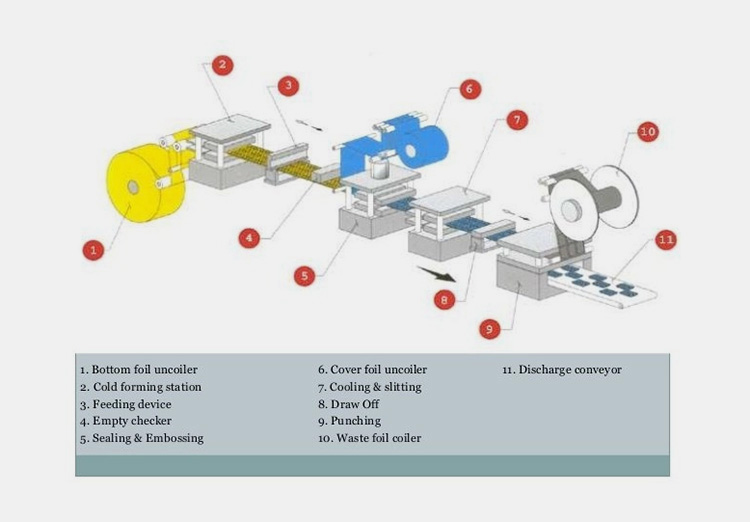

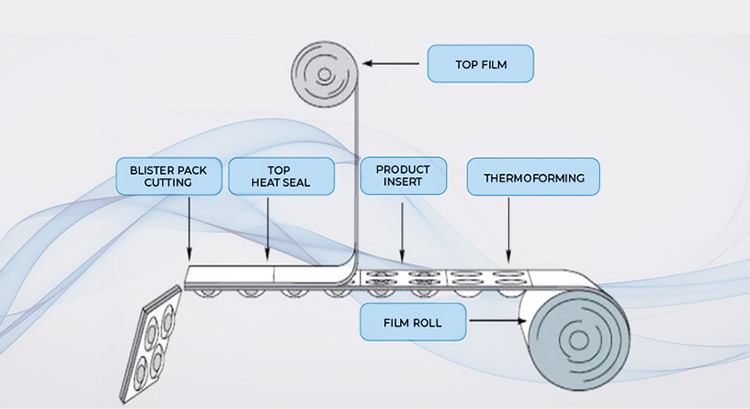

Blister packaging manufacturing

Blister Packaging Manufacturing-Sourced:istockphoto

Blister packaging is usually made with the thermo forming process. The plastic material are made with the according shape by mold with heating process. And after the filling of products in the cavity, you can then apply the adhering or other glue for the tight sticking of blister packaging products.

12.Are There Other Packaging TypeBesides Clamshell Packaging And Blister Packaging?

Are there other packaging types besides clamshell packaging and blister packaging? Of course there are!

Skin packaging

Skin Packaging-Sourced:halopack

Skin packaging is just like blister packaging. But instead of filling products in the thermoforming cavity, skin packaging applies two pieces of plastic film for the holding of products. You may see its frequent use in meat products. This type of packaging makes the clear and direct products displaying.

Header cards

Header Cards-Sourced:rapidcustomboxes

Header cards is the kind of packaging which filled products in plastic bag and has the open part sealed with staples or adhesive. To make the better looking, you should usually adhere header cards on it. The header cards can help decorate the products, seal products and convey the important information.

Hanging carton

Hanging Carton-Sourced:pixartprinting

Hanging carton is the kind of packaging type which makes the eco-friendly and protective packaging for various products. It is usually used for stationary products, cosmetic products and so on. This kind of packaging can also help show the products information and look which help customer’s purchase.

13.Does Clamshell Packaging And Blister Packaging Makes Environment Impacts?

If you are environmentalists, you may wonder the way to protect our environment. And for clamshell packaging and blister packaging, does they make the influence to environment?

Clamshell packaging

Clamshell Packaging-Sourced:cen

The plastic material applied for clamshell packaging may make the irreversible impact for environment. And to avoid this condition, you can apply the other material for clamshell packaging. The paperboard, plant fiber and such degradable material can also apply on the clamshell packaging.

Blister packaging

Blister Packaging-Sourced:scrapbuk

Blister packaging applied also plastic material a lot. And it has also the large application of paperboard, aluminum and other material. If you make the less applying of plastic material in blister packaging, blister packaging can be more eco-friendly.

14.What Innovation You May Find On Clamshell And Blister Packaging?

What innovation you may find on clamshell packaging and blister packaging? Here are the innovation for the two packaging.

Smart packaging

Smart Packaging-Sourced:meyers

Smart clamshell and blister packaging will be applied to medical products. For example, it will help to detect the taking frequency, medication adherence and the relative food information for you. The smart packaging will help improve the patients’ health and treating feeling.

Eco-friendly packaging

Eco-friendly Packaging-Sourced:roocreate

Sustainability and eco-friendly are the points which get great focus today. And in future, there is the continuous trend of adopting the eco-friendly material to clamshell packaging and blister packaging.

Customized packaging

Customized Packaging-Sourced:medteclive

Customized packaging can make your products more attractive and has the shining points of your products more outstanding. This is the new trend, and more and more packaging can be customized.

Conclusion

After the reading of the complete FAQ guide of clamshell packaging and blister packaging, you may have the deep and clear understanding of the two different packaging manner. And for any problem or question, you should just be relaxed and contact ALLPACK.

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide

Clamshell Vs Blister Packaging:The Complete FAQ Guide In 2025 Read More »

SEPHA EZ Blister Tabletop Blister Packaging Machine

SEPHA EZ Blister Tabletop Blister Packaging Machine

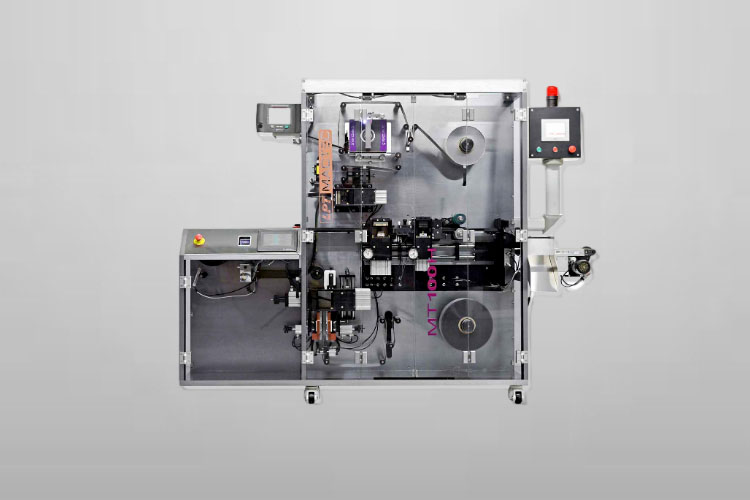

MT-100 Blister Packaging Machine

MT-100 Blister Packaging Machine

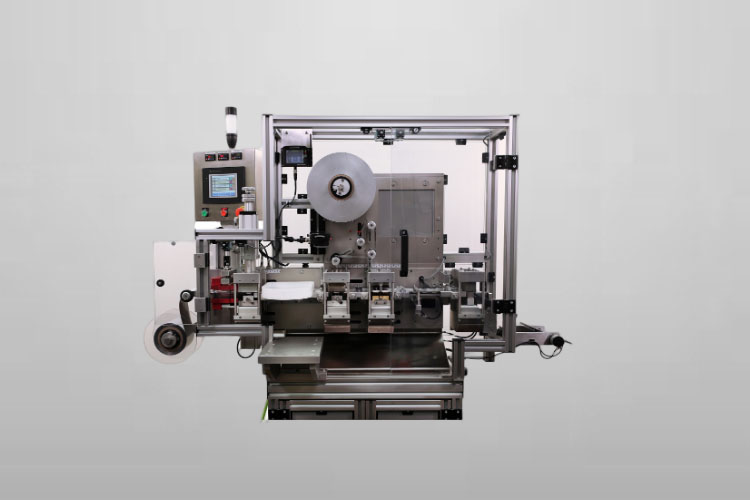

BPC 23 Blister Packaging Machine

BPC 23 Blister Packaging Machine

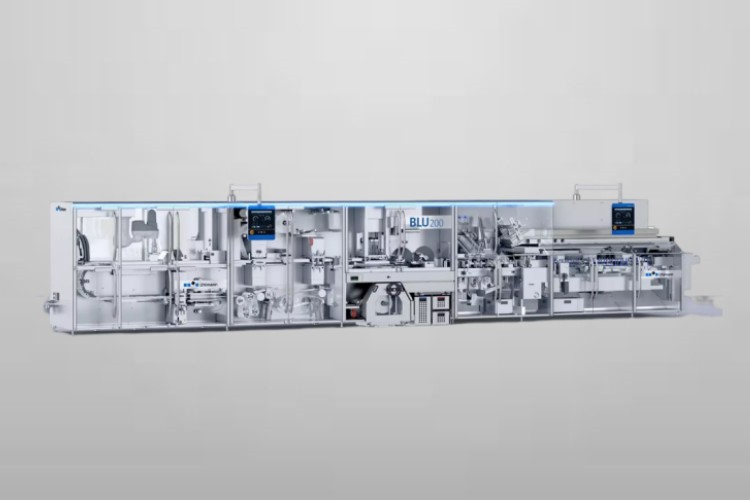

BLU200 Blister Packaging Machine

BLU200 Blister Packaging Machine

BLIMAR® 3050 AITT Blister Packaging Machine

BLIMAR® 3050 AITT Blister Packaging Machine

Tell us your material or budget, we'll reply you ASAP within 24 hours

Tell us your material or budget, we'll reply you ASAP within 24 hours

Tell us your material or budget, we'll reply you ASAP within 24 hours

Tell us your material or budget, we'll reply you ASAP within 24 hours