Blister Packaging Problems and Solutions: The Ultimate Guide In 2025

Do you know blister packaging is the most popular method for extending the quality and shelf life of the product? This is mainly composed of two layers of sheets, an upper plastic sheet, and a backing support.

The blister packaging technique is mainly relying on the factor of heat and gluing properties of the machine. When performing such procedures you may encounter challenges, but these challenges are technically capable of troubleshooting if you have proper knowledge.

This article purpose is to provide adequate knowledge related to the problems and the solutions of blister packaging.

1.What is blister packaging?

Blister Packaging

Blister packaging, blister pack, or blister are the names coined to explain various kinds of pre-formed transparent or opaque plastic pockets, usually utilized for storing and securing different consumer items. These plastic cavities are supported by tough and resistant materials, for instance, cardboard, paper board, or aluminum foil.

The blister component of blister packaging is created through heating and melting plastic polymer till it is bendable and is cast around a mold to form a cavity that perfectly corresponds to the consumer good. Immediately after inserting the product, the back part is head-sealed against the blister pack.

It is widely found in the pharmaceutical industry for packing goods like pills, tablets, capsules, and lozenges. It also secures food items, cosmetics, electronics, toys, batteries, hardware, and other tools.

2.Why is blister packaging required?

Blister packaging is the go-to alternative for numerous goods ranging from medications to stationery. However, this adaptable packing is not about aesthetics; it has a vital part in product protection and safety.

Let’s dive deep into the plentiful benefits of blister packaging.

Preserving Product Integrity

Blister packaging with films and lidding materials is effective in protecting the product against moisture, light, and oxygen. For protection purposes, the parts of blister packaging are manufactured with barrier layers, which are vital in preventing the penetration of external agents.

Opaque aluminum in lidding materials acts as a light-blocking agent, therefore, it safeguards product damage by UV radiation.

Convenient Packaging

Convenient Packaging

Blister packaging is designed to keep in mind the convenience of the users. Products are accessed one by one and the remaining products are kept sealed. Also, every product is stored in a separate pocket, resulting in the preservation of product quality.

Moreover, impairment of one component of packaging does not impact the quality of left products.

No Unintentional Drug Misuse

No Unintentional Drug Misuse

Blisters or other backing components are opened and accessed with specific actions or information. They are hard to open without the right kind of handling and, therefore are regarded as child-resistant packing, preventing the risk of unintended ingestion by children and elderly patients.

Tamper Protection

Tamper-Proof Blister Packaging

The preferred advantage of blister packaging is- tamper protection. Opened blisters cannot be returned to their previous state. Due to this feature of blister, displacing lids from blister cavities causes noticeable damage. This inherent characteristic aids in averting manipulation and pilferage, thus rendering blister packaging a suitable option for the pharmaceutical and electronic industries.

Product Aesthetics

Product Aesthetics

Different types of blister packaging like skin, clamshell, and others are widely employed for retailing, as clear plastics allow users to view the inside product without opening the contents, easing the decision-making process. Moreover, lids are usually colored and engineered to catch the eyes of shoppers.

Cost-effectivity

Cost-effectivity of Blister Packaging- Picture Courtesy: Sepha

Although the initial operational cost is high, blister packaging is cost-effective for bulk packaging. The starting materials of blister packs are inexpensive and packaging equipment is efficient and automated.

Reduce Movement Inside Packaging

Reduce Movement Inside Packaging- Picture Courtesy: Dieline

The cavities in blister packaging are tailored to fit the contours of the content. Especially designed molds create accurate pockets that have reduced space between product and packaging. This allows minimal movement to the product, therefore reducing its mechanical damage.

3.What are the blister packaging problems and solutions?

Despite the excellent safeguarding and marketing properties of blister packaging, challenges and problems in blister packaging persist when shelf-life, quality maintenance of end products, and customer satisfaction are considered.

Some potential problems of blister packaging and their solutions are penned below:

Breakage

Breakage of Blister Pack

Generally, blister packaging is formed using durable and long-lasting materials. However, sometimes, packaging breaks after the sealing, bringing about product damage, contamination, and, customer dissatisfaction.

Breakage may be due to poor-quality plastic polymers and backing material. These materials lack robustness and tear resistance. Thus, they damage upon stretching and frictional force. Moreover, they have inadequate thickness and uniformity.

Another reason for breakage is the non-uniform distribution of pressure by the blister packaging machine, resulting in some areas experiencing local breakage.

Solution

With the use of materials with adequate thickness and durability, this issue is prevented. Furthermore, looking into machine settings and fixing pressure problems may prevent the chances of blister packaging breakage.

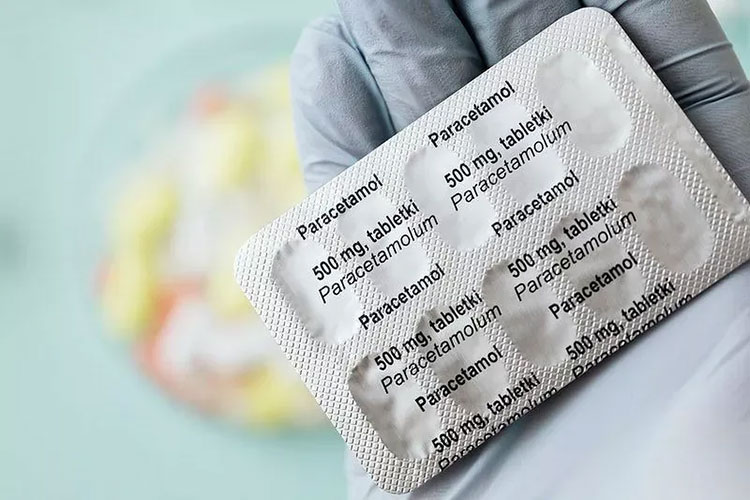

Ink

Ink Blister Packaging- Picture Courtesy: Ninsaúde Clinic

There are several informational instructions on the blister packaging, for example, the name of the product, its weight, expiry period, etc. It is difficult to follow instructions on blister packaging if the ink is not visible.

Ink peels off from blister packaging because of heat or frictional issues. Moreover, if the ink is mixed with impurities, it is difficult to discern information.

Solution

Packaging material must have an affinity for ink. This helps in improving the visibility of ink. Moreover, ink should be heat-tolerant so that it does not disappear from packaging. Check the quality and purity of ink before use to avoid indecipherability of ink.

Inside Foreign Particle

Inside Foreign Particle- Picture Courtesy: Accupack

Blister packaging is usually free of dust and other foreign objects. However, occasionally unexpected foreign particles are seen on the interior and exterior of blisters.

This happens when dust or other contaminants are attracted to static charges, generated during the temperature change of the film, or when a film goes from hot to cold. Static buildup during sealing also attracts dust or debris, resulting in permanent sealing inside the packaging. Furthermore, contaminants are introduced during the creation of polymer film.

Solution

This issue is solved by controlling the static build-up. Always inspect the polymer film before the manufacturing process. Static removal devices like static brushes aid in the off-loading of electrical charges. Packaging films resistant to static charges are also used to prevent this problem.

Printing Issues

Printing Issues- Picture Courtesy: The Times

Clear printing is fundamental to comprehensible product instructions and warnings. However, several people have problems understanding instructions because of spotty and smudgy printing. There are many reasons for this, for instance:

Muted prinks, non-uniform ink transfer, blotchy instructions, whizzing, washboard impression, and image bleeding are due to unclean, damaged, spongy, and, loose sleeves, tubing, and plates in the image carrier.

Improper pH of ink could be the basis for muted or blotchy printing. Additionally, foamy, scratchy, spotty ink particles and the nonuniform appearance of printing are a result of low ink viscosity. Whereas, messy ink, irregular coloring, and dark coloring than desired, ink rings, and, fisheyes are because of high ink viscosity.

Solution

Before prinking, ensure the image carrier is clean and undamaged. Moreover, check the tubing and plates of the image carrier before use. Moreover, ensure the pH of the ink is in the right range for accurate printing. Also, the viscosity of ink should be appropriate for uniform and clean printing.

Incomplete Blister Formation

Incomplete Blister Formation- Picture Courtesy: KAA Timex LR

Sometimes, during blister packaging, incomplete blister formation is observed, leading to product contamination and packaging integrity problems. Low temperature could be the cause of incomplete blister formation because blister material is not melted enough to achieve the required shape.

Also, inadequate pressure can stop the material from entirely conforming to the mold. Non-uniform thickness and impurities in the blister material also impede the blister production. Defects in the molds and their misalignment can affect incomplete blister formation.

Incorrect settings of the blister packaging machine or its damage can also impact the blister shaping.

Solution

It is necessary to adjust the thermoforming parameters like temperature and pressure to ascertain proper material melting and blister formation. Always use blister-forming films having uniform and good thermoforming characteristics.

Routinely inspect the molding devices for wear and tear and misalignment to attain desired blister packaging. Similarly, calibrate, adjust, and maintain the blister packaging machine to avoid breakdowns.

Excessive Heat

Excessive Heat- Picture Courtesy: Sepha

High heat is the reason for several problems in the blister packaging and can contribute to material and product damage and can compromise medication safety. Excessive heat during molding and heat-sealing leads to extreme softening of materials, resulting in material distortion and product exposure.

The high heat could be the cause of the failure of the adhesive to stick with the backing support, thus contaminating and causing product loss. It also leads to discoloration, degradation, and loss of potency of some products. At high temperatures, warping and delamination of blisters occur.

Solution

It is important to store blister packaging in relatively low temperatures and dry environments. Blister packs should be placed away from heat sources and sunlight. Moreover, when selecting blister packaging materials and adhesives, it is recommended to go for heat-resistant materials.

Consider adding protective layers in the blister packaging to protect blisters from high heat.

Uneven Packaging

Uneven Blister Packaging- Picture Courtesy: Hello Pharma

Sometimes, uneven blister packaging is observed when there is non-uniformity in contour, dimensions, and depth of cavities. This could cause the dislodging of the product and its damage. Also, it makes blister packaging unappealing and causes inadequacies in downstream procedures like sealing and counting.

It could be due to malfunctioning of thermoforming equipment, for instance, damaged sealing elements and inadequate pressure input. Differences in the thickness and uniformity of materials can lead to non-uniform blister design.

Defective molding design and improper alignment of molds produce uneven packaging. Changes in the temperature during blister thermoforming can impact the blister evenness.

Solution

This issue is resolved by regularly performing calibration and maintenance of the thermoforming machine and using superior quality materials with suitable thermoformability. Ensure molds are free of damage and other wear and tear and also aligned properly.

Maintain consistent temperature throughout the thermoforming process to get uniform blister packaging. Last but not least, use blister designs that are less prone to packaging irregularities.

Incompatibility of Packaging Material

Incompatibility of Packaging Material- Picture Courtesy: Sierra Coating Technologies

This is a serious issue initiating several problems, for example, the reactivity of materials with each other, leading to product efficacy loss or contamination. The blister-creating materials interact with packed products, resulting in color fading and the development of an unpleasant odor in the product.

Some plastics leak certain chemicals in acidic or basic products. The overwrapping material like foil or paper may interact with blister materials, causing its deterioration and bleaching.

Solution

It is vital to conduct compatibility tests on materials to ascertain there would be no issue in incorporating them together. Get recommendations from material suppliers about different combinations of materials. Furthermore, it is best to opt for materials that are consistent with the chemical structure and pH of the product.

Weak Seal

Weak Seal

Seal of blister packaging is integral in maintaining the shelf-life of the product. Moreover, it also guarantees the potency, clarity, safety, and stability of the product.

The seal of blister packaging is compromised using incompatible packaging materials. Base and lidding materials are unmatched, decreasing seal integrity. Less sealing area is utilized for making seals.

Also, incompatibility between the sealing system and the type of blister packaging leads to poor sealing. Some sealing systems like platen sealing are more suited to Cold Formed Foils. These systems seal at high pressure and low temperature. Whilst, other sealing systems such as rotary sealing systems seal at low pressure, achieving sealing in a shorter time.

Unsuitability between sealing parameters like dwell time, pressure, temperature, and material combination also promotes inadequate sealing. Damaged sealing plates also contribute to this issue.

Solution

Choosing the right combination of materials guarantees seal integrity. Sealing blister packs along the larger surface area and cutting surplus material ensures the absence of weak points. Moreover, it is best to consider the right sealing system that corresponds to the characteristics of the film to avoid this problem.

Optimization of sealing parameters and sealing force ensures the strength of the seal. To achieve a high-quality seal, it is recommended to strip and re-anodize aluminum sealing plates occasionally.

Adhesive

Adhesive in Blister Packaging

Adhesives and glues are employed to adhere films, effectively sealing the materials. Hot melt adhesives are triggered by high temperature, pressure, or cold seals. An optimum amount of adhesive must be applied for correct binding.

A high amount of adhesive can cause sticking out of adhesive from the pack and binding with medication inside the blister. Low adhesive will lead to weak adhesion that increases the chance of spilling of pill during product handling and transportation. Sometimes, the adhesive may become hard or drip, ensuing inadequate binding.

Solution

It is recommended to frequently maintain a blister packaging machine and check the properties of adhesives to solve the problems regarding adhesives. Moreover, inspect the adhesive opening every day for hardened adhesive or leaking.

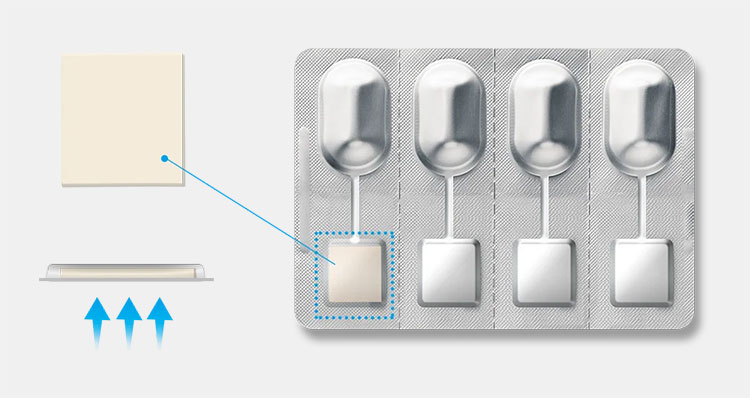

Control of Moisture Content

Control of Moisture in Blister Packaging- Picture Courtesy: WiseNano

It is a well-known fact that numerous medications are highly sensitive to moisture content; even small alterations in humidity can affect their stability and efficacy. Sometimes, moisture control is ineffective due to the poor design of blister packaging. Inherent moisture in capsules and tablets degrades product quality,

Also, the flow of air in the space between the aluminum pouch and blister packaging can lead to the entry of moisture, presenting a significant risk to medication.

Solution

This moisture-related issue can be resolved by allocating designated apace for desiccant sheets in the blister pack. This can be done by connecting each blister cavity with a desiccant sheet. These sheets of varying thicknesses (0.6mm, 1mm, and 2mm) have a superior protective role in maintaining a dry environment while upholding the aesthetics of products.

Additionally, the desiccant is wedged into the interior lining of the aluminum foil pouch to solve the airflow problem between the blister card and the aluminum foil pouch. This placement ensures a completely dry environment.

Conclusion

Blister packaging is not just packaging. It has a role in protecting and safeguarding medications and other products. It also boosts product visibility and prevents tampering risk. Addressing the blister packaging problem is a challenging task. So, for your ease, we have discussed various blister packaging problems and solutions in this blog post. Remember that ensuring material, ink, and adhesive compatibility, checking and maintaining the blister packaging machine, and, setting correct parameters can save you from a great deal of trouble, where blister packaging is concerned. For further details regarding blister packaging or blister packaging devices, please contact us, Allpack through our website.

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide

Tell us your material or budget, we'll reply you ASAP within 24 hours

Tell us your material or budget, we'll reply you ASAP within 24 hours