Best Price Semi-Automatic Labeling Machine

- Hot Stamp Ribbon

- Sensor Control or Step Control

- Structural Combinations and Label Winding

Semi-automatic Labeling Machine

Allpack semi-automatic labeling machine is used for labeling PET bottles, plastic bottles, glass bottles, and metal bottles. This labeling machine is suitable for labeling round bottles of different sizes. Semi-automatic labeling machines are widely used in food, beverage, rice oil, medicine, daily chemical, and other fields. The semi-automatic labeling machine improves the labeling speed and labeling quality. Operation process: product delivery - labeling (automatic) - take out the labeled product. All Allpack semi-automatic labeling machines are small labeling machines and very easy to operate. The conveyor parts are fully enclosed to avoid abnormal conditions and make them safer to use. The labeling device can be replaced on uneven surfaces such as concave and curved surfaces.

Semi-automatic Labeling Machine

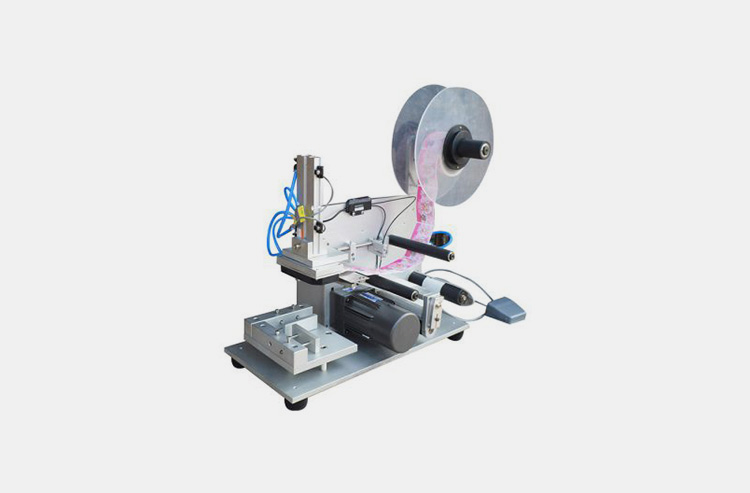

MT-50 Semi-automatic Round Plastic PET Bottle Sticker Labeling Machine

MT-50 semi-automatic round plastic PET bottle sticker labeling machine is suitable for self-adhesive labels or self-adhesive films of different sizes on various round bottles, high-precision, high-speed, automatic dispensing, and labeling. The ingenious design allows you to mechanically adjust some structural combinations and label winding, and you can easily and freely adjust the label position. All of this makes it easy to change products and labels.

Semi-automatic Control

Sensor Control Or Step Control

Structural Combinations And Label Winding

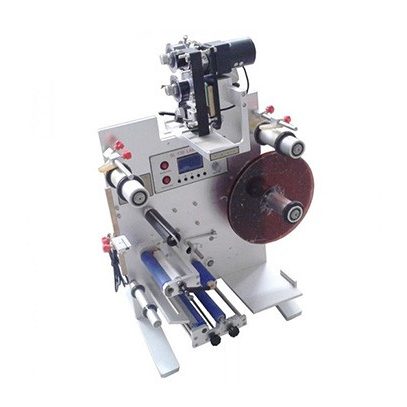

MT-50D Semi-automatic Plastic Round Bottle Labeling Machine With Coder

MT-50D semi-automatic plastic round bottle labeling machine with coder is an ideal equipment for semi-automatic labeling of round bottles on the packaging of daily chemicals, food and beverage, medicine, chemical, and other light industrial products. This machine is suitable for the production of round bottles of various specifications and small batches of multiple varieties. It can only be used for stand-alone labeling. This machine adopts a hot stamp ribbon instead of liquid ink.

Hot Stamp Ribbon

Semi-automatic Labeling

Convenient Maintenance

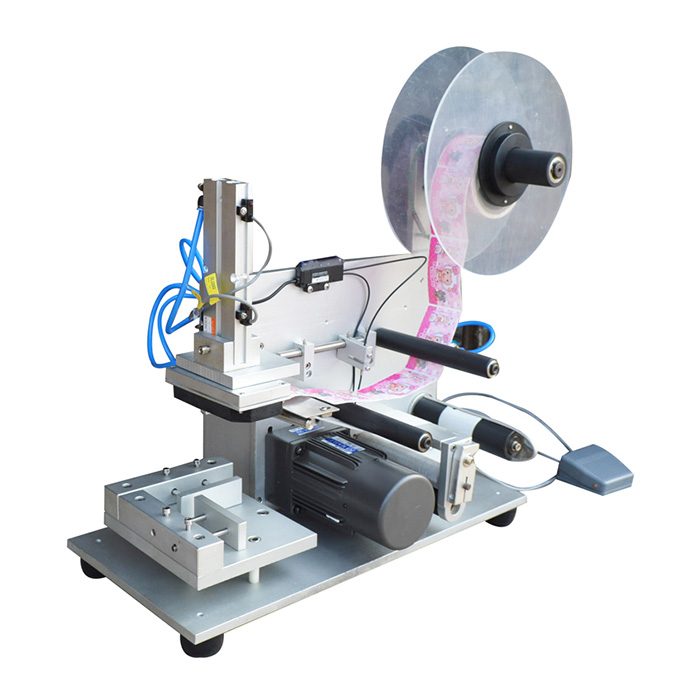

MT-60 Semi-automatic Square Rectangle Flat Bottle Labeling Machine With Pedal Switch

MT-60 semi-automatic square rectangle flat bottle labeling machine with the pedal switch is suitable for self-adhesive labels, self-adhesive films or electronic barcodes, etc. labeling and is widely used in cosmetics, toys, electronics, medicine, and other fields. This semi-automatic labeling machine applies the suction method to stick the label on various square workpieces, such as cosmetic flat bottles, packaging boxes, plastic covers, etc. The labeling device can be replaced on uneven surfaces such as concave and curved surfaces. With high precision and good working performance, it can be used on any regular or irregular surface.

Convenient Maintenance

Used On Any Regular Or Irregular Surface

High Precision And Good Working Performance

LT-80 New Type Semi-automatic Adhesive Film Round Bottle Labeling Machine

LT-80 new type semi-automatic adhesive film round bottle labeling machine is suitable for self-adhesive labels or self-adhesive films of different sizes on various round bottles, high-precision, high-speed, automatic dispensing, and labeling. It is mainly applied in round bottles, round cans, PET bottles, plastic bottles, glass bottles, metal bottles, etc. With good labeling accuracy and stability, this machine can offer you high-quality labels without wrinkles and bubbles. With powerful functions, circumferential positional and non-positional labeling can be easily achieved.

High-speed

High-precision

Labeling Accuracy And Stability

SL-130 Semi-Automatic High Efficiency Labelling Machine Double Labeller For 2 Labels With Printer

SL-130 semi-automatic labeling machine double labeler for 2 labels with the printer is suitable for labeling round bottles of various sizes, such as glass bottles, plastic bottles, metal bottles, shampoo bottles, small conical bottles, round cosmetic bottles, etc. It is especially suitable for labeling and coding products with small quantities and many varieties. It is an ideal equipment for semi-automatic labeling of round bottles on the packaging of daily chemicals, food, beverage, pharmaceutical, and chemical.

Reliable Performance

PLC Control System

Sensor Electronic Control System

YT-30100 Semi-automatic Irregular Plane Round Bottle Sleeve Labeling Machine

YT-30100 semi-automatic irregular plane round bottle sleeve labeling machine is suitable for irregular bottle sleeve labeling. It can be used for labeling various workpiece planes, arc surfaces, and concave surfaces, and can be used for labeling irregular workpieces. This plane labeling machine applies a PLC control system and subdivision stepping motor to drive and send labels. The feeding mechanism is equipped with a brake function to ensure that the label tape is tensioned and the label detection is accurate.

Bottles Sleeve Labeling

Sturdy And Durable Structure

Used For Labeling Irregular Workpieces

YT-31200 Semi-automatic Round Bottle Square Bottle Sticker Labeling Machine

YT-31200 semi-automatic round bottle square bottle sticker labeling machine adopts high-precision labeling technology, that the labeling accuracy can reach within ±0.5mm and meets the requirements of high-precision labeling. This labeling machine supports taper labeling and circular labeling. The operation is simple and convenient. All the peeling, feeding, labeling, and labeling can be completed automatically. The labeling process can be completed by manual loading and unloading. The operation is safe. The transmission parts are wrapped, and the circuit and gas circuit is arranged separately to avoid abnormal occurrences that make it safer to use.

Manual Loading And Unloading

High-precision Labeling Technology

Supports Taper Labeling And Circular Labeling

YT-41300 Semi-automatic Desktop Plastic Bottle Labeling Machine For Self-adhesive Label

YT-41300 semi-automatic desktop plastic bottle labeling machine for the self-adhesive label has the function of single sticking and double sticking, which can be switched on the touch screen. It can be used for labeling cylindrical objects of various specifications, such as xylitol and cosmetic round bottles. The desktop labeling machine can print the production batch number and other information on the label.

For Self-adhesive Label

Print Production Batch Number

Be Switched And Positioned Arbitrarily

The Buyer's Guide

Semi-Automatic Labeling Machine: The Complete Buying Guide In 2025

Do you run a business that requires precise labeling such as food, pharmaceuticals, or other items? If so, the semi-automatic labeling machine could be just the answer. Increasingly popular among manufacturers, semi-automatic labeling machines offer a fast and accurate way to apply labels across various surfaces quickly with minimum labor input.

Not only can this technology help save both time and money but it also supports higher product accuracy in terms of labeling placement every time. Keep reading to learn more about how this advanced technology can revolutionize the way you label products!

1. What Is A Semi-Automatic Labeling Machine?

A semi-automatic labeling machine is a type of automated machinery used to apply labels to products. This type of machine typically uses advanced technology such as computer vision, precision robotics, and image recognition systems in order to accurately apply labels in an efficient manner.

Semi-automatic labeling machines can be used for many different types of labelling applications, including barcodes, date codes, product identification and brand labeling. Semi-automatic labeling machines are a great way to boost production efficiency while ensuring accuracy and quality control.

Also, these machines can be used in conjunction with other automation processes such as packaging and palletizing to further improve productivity. Ultimately semi-automatic labeling machines provide an easy, cost effective solution for businesses everywhere who need to apply labels quickly and accurately.

2. What Are The Components Of A Semi-Automatic Labeling Machine?

Conveyor

The conveyor moves the products through the semi-automatic labeling machine and allows them to be labeled in an assembly line fashion.

Label Dispenser

This component holds the labels that are used to apply onto products. It typically comes in roll form and can have variable speeds according to product type and label design.

Labeler

The semi-automatic labeling machine has a mechanical or pneumatic arm which takes the label from the dispenser and applies it to the product.

Inkjet Printer

This component is used to print labels with specific information that needs to be put on products, such as barcodes or expiration dates.

Label Verifier

This is a camera system that reads the barcode and verifies its accuracy before the product moves on in the semi-automatic labeling machine. It can also detect if there are any problems with the label placement and quality, as well as any discrepancies between labels and products.

Controller

A semi-automatic labeling machine is usually operated by a controller, which can be manual or automatic depending on the system’s requirements. The controller makes sure that all components are working properly and will give alerts if there are any issues with the labeling process.

Label Rejecter

This component is used to detect any labels that were misapplied and reject them from the semi-automatic labeling machine. It can also be used to reject products with incorrect labels or labels that are missing information.

3. What Are The Pros Of A Semi-Automatic Labeling Machine?

A semi-automatic labeling machine offers a range of benefits over manual labeling, including:

Cost Savings

Semi-automatic labeling machines can help to reduce labor costs, as they require less manpower than manual labeling. Additionally, semi-automatic machines are typically more cost-effective than fully-automatic machines due to their smaller scale and complexity.

Adaptability

semi-automatic machines can be adapted to various sizes of products and containers, meaning that only one machine is needed for multiple types of products. This can save time and money as well as increase production efficiency.

Versatility

Semi-automatic labeling machines are also able to apply different types of labels with ease, such as heat transfer labels, self-adhesive labels, pressure-sensitive labels and others. This allows for greater flexibility in labeling solutions.

Accuracy

Semi-automatic labeling machines are highly reliable and accurate, resulting in fewer errors than manual labeling. This can help to ensure that products are appropriately labeled and properly accounted for.

4. What Are The Applications Of A Semi-Automatic Labeling Machine?

Food Industry

Semi-automatic labeling machines are widely used in food industry for labels attached to food packages, such as frozen foods, snack packaging and cans. The semi-automatic machine can help improve the efficiency of food production by automatically attaching labels to product containers with accuracy and speed.

Medical Industry

In the medical industry, semi-automatic labeling machines are used to accurately attach labels to medicine bottles, medical devices and equipment, such as surgical instruments and laboratory containers.

Cosmetic Industry

Semi-automatic labeling machines are used to quickly and accurately label products such as lipstick, foundation, and other cosmetics. The semi-automatic machine is equipped with a top-down camera that can scan the product to ensure its exact dimensions before applying labels.

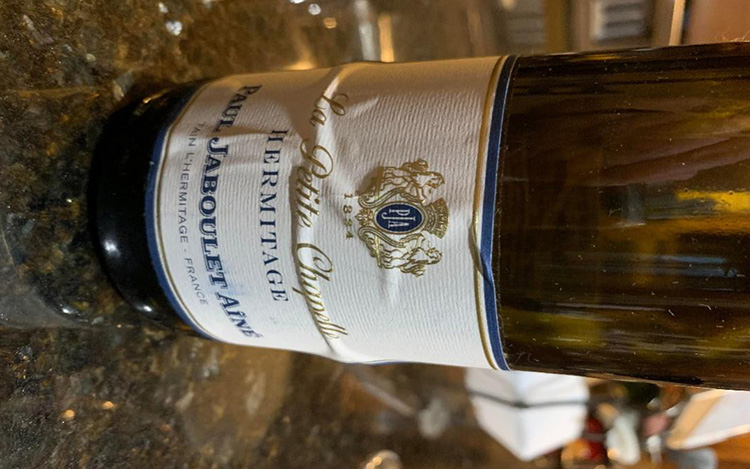

Beverage Industry

Semi-automatic labeling machines are also useful for labeling beverages such as beer, soda, and water bottles. The semi-automatic machine can accurately apply labels to each bottle quickly and efficiently.

Chemical Industry

Semi-automatic labeling machines are used in the chemical industry to label containers with hazardous materials and chemicals. These semi-automatic labeling machines help ensure that labels are accurately attached to containers by automating the process.

5. How Does A Semi-Automatic Labeling Machine Work?

The semi-automatic labeling machine operates on a few general principles:

a) Feeding labels into the machine

The semi-automatic labeling machine requires labels to be fed into it before it can start the labeling process. It uses either a continuous roll of labels or a stack of pre-cut labels. The semi-automatic labeling machine is designed to smoothly feed the labels into the machine and start the labeling process.

b) Pressurizing and heating

Once the semi-automatic labeling machine has been loaded with labels, it will then apply pressure and heat to adhere the label to the container. The semi-automatic labeling machine has a mechanism that can be adjusted to ensure the correct amount of pressure and heat is applied to each label.

c) Dispensing

At the end of the labeling process, the semi-automatic labeling machine will dispense the labeled container and move on to apply labels onto another container. This is done in a continuous process, allowing the semi-automatic labeling machine to label multiple containers without any downtime.

6. What Are The Different Types Of Semi-Automatic Labeling Machines?

a) Semi-Auto Pressure Sensitive Labeling Machines

Pressure sensitive labeling machines use a roll of adhesive labels to apply self-adhesive labels to containers or packages. The label is dispensed onto the product and then pressure is applied to ensure that it adheres properly. This type of semi-automatic labeling machine is ideal for small to medium sized products, such as bottles, cans, jars and other containers.

Components

Labeling Head

The labeling head is the most critical component of pressure sensitive labeling machines, as it consists of a mechanism that applies pressure to attach the pressure-sensitive label onto the surface of the container or product.

Label Dispenser

The label dispenser is used to dispense pressure-sensitive labels from a stack onto the container or product.

Unwinder

The unwinder is responsible for winding and unwinding pressure-sensitive labels from its roll as it feeds the label through the labeling machine.

Label Sensor

The label sensor detects pressure sensitive labels to ensure that each item is labeled accurately and consistently with the correct pressure.

Product Handling System

The product handling system consists of a conveyor belt, gripper arms, and other components that move the product through the pressure sensitive labeling machine and accurately position it for labeling.

Label Rewinder

The label rewinder is responsible for winding up any waste pressure-sensitive labels which have not been used.

Electrical Controls

The pressure sensitive labeling machine also includes electrical controls and connections for controlling the pressure, speed, and accuracy of the labeling process.

User Interface

Finally, pressure sensitive labeling machines include a user interface such as a touchscreen that allows operators to easily program and adjust the pressure, speed, and accuracy of labeling jobs.

Working Principles

Pressure sensitive labeling machines work by combining pressure and pressure-sensitive adhesives to accurately label a variety of containers.

The pressure is applied by a power roller and the pressure-sensitive adhesive is dispensed onto the container.

When pressure is applied to the adhesive, it bonds quickly to the container’s surface while simultaneously releasing from the machine.

Applications

Pressure sensitive labeling machines are used in a variety of industries and applications, ranging from food packaging to labels for industrial machinery. In the medical field, pressure sensitive labels are often used on pharmaceuticals and medical products such as syringes and vials.

Beverage labeling is another common use for pressure sensitive labeling machines, typically applied on cans, bottles, and pouches. Pressure sensitive labeling machines also find use in cosmetics, and other consumer goods industries.

b) Hot Melt Semi-Automatic Labeling Machine

Hot melt semi-automatic labeling machines use hot glue or adhesives to apply labels to packages and containers. The applicator dispenses the adhesive onto the container, where it is then heated to create a bond between the label and the product. This type of semi-automatic labeling machine is most often used for food and beverage products that require high levels of durability.

Components

Label Applicator

This is the main component of hot melt semi-automatic labeling machines. It applies the label onto the product with hot melt adhesive, usually at a high speed.

Dispensing Arm

This arm connects to the applicator and dispenses labels from a roll mounted onto it.

Label Printer

This component prints labels for the machine to apply onto products. It can be a direct thermal or thermal transfer printer depending on the type of hot melt semi-automatic labeling machine.

Controller

The controller is responsible for controlling all functions of the hot melt semi-automatic labeling machines, including printing and applying labels at the correct speed and accuracy.

Computer Interface

A hot melt semi-automatic labeling machine needs to be connected to the computer in order to control its functions. This is usually done with a USB cable or other communication protocol.

Label Rewinder

The label rewinder winds up the excess labels from the hot melt semi-automatic labeling machine, making it easier for operators to replace the labels when needed.

Hopper

The hopper stores the hot melt adhesive for the hot melt semi-automatic labeling machine, making it easier to refill when needed.

Hot Melt Adhesive

This is what bonds the label to the product and helps ensure that the labels remain in place.

Label Sensor

The label sensor detects if there are any missing or misaligned labels on the hot melt semi-automatic labeling machine, and can adjust accordingly.

Conveyor

The conveyor is used to move products from one station to another for hot melt semi-automatic labeling machines. This helps speed up the process of applying labels.

Air Blower

The air blower is used to cool hot melt semi-automatic labeling machines and keep them operating safely and efficiently.

Vacuum Pump

The vacuum pump is used to remove hot melt adhesive residue from the hot melt semi-automatic labeling machines, preventing clogging and other damage.

Heater Unit

The heater unit is responsible for melting hot melt adhesive so it can be applied to products.

Label Counter

The label counter tracks the number of labels applied by hot melt semi-automatic labeling machines, making it easy for operators to monitor usage.

Working Principles

Hot melt semi-automatic labeling machines work by using hot melt glue to attach labels onto products. The process begins by feeding products onto a conveyor belt and passing them under an applicator head.

The hot melt glue is heated to around 200 degrees Celsius in order to become liquid, before being applied from the applicator head directly onto the product. The hot melted glue then cools and dries within seconds, forming a secure bond with the label.

Once the label is placed, the hot melt semi-automatic labeling machine can then be used to verify that the label has been accurately applied by using optical sensors to detect if the right number of labels have been attached in the correct positions.

c) Semi-Automatic Round Bottle Labeling Machine

A semi-automatic round bottle labeling machine is a specialized piece of equipment used for applying labels to round bottles. This type of labeling machine offers semi-automation and high efficiency, making it ideal for many types of production lines.

Semi-automatic round bottle labeling machine uses rotating brushes or rollers to apply the label to the bottle, which ensures accurate placement. Also, these machines have adjustable settings for controlling the speed and accuracy of each label application.

Components

The components of semi-automatic round bottle labeling machine consist of the following:

Labeling Head

This is the main component which applies labels around the containers. The labeling head can be adjusted depending on the size and shape of the containers and it also controls how far apart labels will be placed on them.

Bottle Indexer

This component moves the containers through the labeling process at a consistent rate which prevents them from overlapping or jamming.

Label Dispensing System

This is used to feed labels into the labeling head so they can be applied to the containers. It may include either manual or automatic feeding systems depending on the requirements of your system.

Conveyor System

This is the belt or other type of conveyor that moves containers through the labeling machine.

Control Panel

The control panel is used to operate and monitor the semi-automatic round bottle labeling machine. It includes inputs for speed, label length, and timing adjustments for different parts of the process.

Print Heads

Depending on the type of semi-automatic round bottle labeling machine, there may be one or more print heads used to apply additional information such as barcodes or text onto the labels.

Labeling Software

This is used to control and monitor the labeling process from start to finish. It includes features such as label design, print previews, and data management.

Safety Equipment

This includes guards, sensors, and other components which keep operators safe from hazards such as moving parts or chemicals.

Accessories

Accessories such as label holders, re-winder, and un-winder can be added to semi-automatic round bottle labeling machines depending on the needs of the system. These accessories help make the process more efficient and accurate.

Working Principles

The semi-automatic round bottle labeling machine works by feeding labels from a roll or fanfold stack into the machine and placing them on the container in precise positions. The process begins by transferring the label from a stack to the machine’s applicator.

Once in place, an adjustable guide bar helps ensure that the label is placed accurately on the bottle. A sensor then reads the label and sends it through a print head where it can be printed with information such as batch numbers, expiry dates, or product information. Finally, the label is applied to the container and ejected, ready for packaging.

Applications

Semi-automatic round bottle labeling machines are used in a variety of industries, including food and beverage processing, cosmetics manufacturing, pharmaceutical production, and chemical packaging. They can be used for labeling bottles with labels such as barcodes, text information, images, nutritional facts, or other information.

d) Semi-Automatic Flat Labeling Machine

A semi-automatic flat bottle labeling machine is a type of machine used to apply labels to flat bottles. This semi-automatic labeling system is designed to provide quick and accurate label application with minimal operator involvement.

The semi-automatic system features an adjustable speed conveyor, allowing it to accurately place labels on almost any size or shape container.

The semi-automatic flat bottle labeling machine also includes a sensor that detects the presence of product, ensuring labels are applied accurately and consistently.

Components

Label Dispenser

The label dispenser is the part of the semi-automatic flat bottle labeling machine that dispenses labels one by one, ready to be applied to the bottles. It has an adjustable gap between the rollers so that it can accommodate different sizes of labels.

Bottle Indexing Conveyor

The bottle indexing conveyor is a conveyor belt that moves the bottles through the semi-automatic flat bottle labeling machine. It has adjustable speed settings so that it can accommodate different sizes of bottles.

Label Placement Mechanism

This is the part of the semi-automatic flat bottle labeling machine that applies labels onto each bottle. It has adjustable settings so that it can accommodate different sizes of labels.

Label Plate

The label plate is a metal plate that holds the bottles in place for labeling. The semi-automatic flat bottle labeling machine can be fitted with multiple plates depending on the size and shape of the bottles.

Safety Systems

Some semi-automatic flat bottle labeling machines come with safety systems that are designed to protect the other components of the machine and the operator. These may include emergency stop buttons, sensors, and interlocks.

Control Panel

The semi-automatic flat bottle labeling machine is controlled via a control panel, which allows operators to set parameters such as speed and label placement.

Working Principles

Once the bottles enter the semi-automatic flat bottle labeling machine, they are transported along by the conveyor and then labeled with an adhesive label.

The labels are then detected by the label sensor, applied to the adhesive and firmly secured to the bottles.

Finally, once all of the bottles have been labeled, they are transported out of the semi-automatic flat bottle labeling machine and ready to be shipped.

Applications

A semi-automatic flat bottle labeling machine is an invaluable tool for a variety of applications, such as: food and beverage industry, pharmaceuticals industry, cosmetics industry, and chemical industry.

In the food and beverage industry, semi-automatic flat bottle labeling machines can be used to accurately label bottles of wine, beer, spirits, soft drinks, sauces, preserves and other bottled products.

In the pharmaceuticals industry semi-automatic flat bottle labeling machines are used for applying labels onto small bottles of medication, tablets, creams and other health related products.

The semi-automatic flat bottle labeling machine is also beneficial for businesses operating in the cosmetics and chemical industries. These machines can accurately apply labels onto bottles of shampoo, conditioner, lotion, perfume and other beauty related products.

They are also useful for labeling bottles containing pesticides, detergents and other household and industrial chemicals.

7. What Is The Difference Between A Semi-Automatic Labeling Machine And An Automatic Labeling Machine?

a) Semi-Automatic Labeling Machine

b) Automatic Labeling Machine

The main difference between semi-automatic labeling machines and automatic labeling machines is the degree of automation they offer.

A semi-automatic labeling machine requires manual input from an operator to initiate the labelling process, while an automatic labeling machine can be programmed to complete the entire labelling process without any human intervention.

A semi-automatic labeling machine is typically used for smaller projects as it requires less sophisticated equipment, and is usually cheaper to purchase. It also takes less time to set up than an automatic labeler because the operator must manually input instructions before each labelling job.

On the other hand, an automatic labeling machine is more suitable for larger projects due to its higher automation level. It can be programmed to handle multiple labeling jobs at once, and is also equipped with sensors that detect when an item needs to be labeled. As a result, it takes less time for the machine to complete large labeling projects than semi-automatic machines.

8. What Is The Difference Between A Semi-Automatic Labeling Machine And A Manual Labeling Machine?

a) Semi-Automatic Labeling Machine

b) Manual Labeling Machine

The main difference between Semi-automatic labeling machine and manual labeling machine is the degree of automation. A Semi-automatic labeling machine requires less human intervention than a manual labeling machine.

Semi-automatics labeling machines use motors and sensors that allow them to handle more tasks than their manual counterparts, such as feeding labels into the printer. Semi-Automatic machines can also be programmed to handle more complex labeling tasks.

Semi-automatic machines are faster and more efficient than manual ones because they don’t require as much human input. Manual labeling machines, on the other hand, rely solely on human power and the accuracy of the operator to complete labelling tasks.

Manual labeling machines are often used when labels are used in small batches or labelling is only done occasionally. Semi-automatic labeling machines are better suited for larger jobs where accuracy and speed are important factors.

Semi-automatics can also be used to apply multiple labels with different products, which is impossible with manual labeling machines. In short, Semi-automatic labeling machines offer more automation, speed and accuracy than manual labeling machines, while still requiring some human input.

9. What Type Of Materials Can Be Used With A Semi-Automatic Labeling Machine?

Paper Labels

Semi-automatic labeling machines can be used to apply paper labels quickly and efficiently. The labels can have text, barcodes or other symbols printed on them which makes them ideal for product identification and tracking purposes.

Plastic Labels

Semi-automatic labeling machines are also capable of applying plastic labels which come in a variety of shapes and sizes. These labels are often used for industrial applications, as they can withstand high temperatures, extreme weather conditions and more without fading or peeling off.

Adhesive Tapes

Semi-automatic labeling machines can be used in conjunction with adhesive tapes to apply labels quickly and accurately. This method is most commonly used in the food and beverage industry, as it ensures that the labels stay on securely without needing to be re-applied.

Tag and Label Combinations

Semi-automatic labeling machines can also be used to apply tag and label combinations which are often used in retail environments. This ensures that products are identifiable quickly and easily, as both a tag and label are used to identify them.

Heat Shrink Tubing

Semi-automatic labeling machines can also be used in conjunction with heat shrink tubing to apply labels quickly and accurately. This method is especially useful in the automotive industry, as it ensures that the labels stay on securely without needing to be re-applied.

10. What Type Of Products Can Be Labeled Using A Semi-Automatic Labeling Machine?

Bottles

Semi-automatic labeling machines are designed to label many types of bottles, such as glass and plastic containers, jars, jugs, cans and more. Depending on the machine, these can include vertical wrap labels for round-shaped items or roll-fed labels for flat surfaces.

Boxes

Semi-automatic labeling machines can also be used to apply labels to boxes and other rectangular items, such as cartons. These are typically applied using a label dispense system, which applies the appropriate amount of adhesive and pressure for secure adhesion.

Bags and Sacks

Semi-automatic labeling machines are capable of applying wrap-around labels to bags and sacks of various sizes. This is done using a semi-automatic system that applies the label quickly and accurately to ensure product integrity.

Pouches

Semi-automatic labeling machines are also capable of applying wrap-around labels to pouches, such as those used for food packaging or medical supplies. These are typically applied using a semi-automatic system that applies the label quickly and accurately.

11. What Type Of Labels Can Be Applied To Products Using A Semi-Automatic Labeling Machine?

Self-Adhesive Labels

These are the most commonly used labels applied by Semi-automatic labeling machines and consist of adhesive on one side that adheres to the surface of the product. This type of label is typically printed with text or graphics for branding or information purposes.

Pressure Sensitive Labels

Pressure-sensitive labels are adhesive-backed stickers that adhere to a variety of surfaces when pressure is applied. These pressure-sensitive labels can be used for product identification and tracking, promotional purposes, labeling food products, and much more.

Vertical Wrap Labels

Vertical wrap labels are applied using Semi-automatic labeling machines that wrap the label around a container or product in its entirety. This type of labeling is often used for products with irregular shapes.

Heat Transfer Labels

Heat transfer labels are applied using Semi-automatic labeling machines that use heat to affix the label to a product. The label material is placed on top of the product and then heated, which causes it to adhere to the product surface.

Stretch Wrapping Labels

These labels are applied via stretch wrapping machines that use tension to wrap the label around containers and products. This type of labeling is used for paper or plastic labels with shrink sleeves or film labels.

Shrink Sleeve Labels

These are also applied via a machine that applies heat to shrink the label around a container. This type of labeling is often used for products that have an irregular shape, such as bottles and cans, as it can provide full coverage of the product surface.

Roll Fed Labels

Roll-fed labels are used in Semi-automatic labeling machines and come in pre-printed rolls that can be quickly loaded into the machine. The machine then applies the label to the product surface. This type of labeling is often used for large-scale production as it allows for quick turnaround times.

12. What Are The Maintenance Procedures For A Semi-Automatic Labeling Machine?

Regularly Check the Machine

Before using a semi-automatic labeling machine, it is important to ensure that all components are in good condition and functioning properly. It is essential that you check the labels, conveyor belts, guide rails, tape heads, sprockets and other moving parts for any signs of wear or damage before use.

Clean the Machine

Keeping your semi-automatic labeling machine clean is essential for it to run smoothly and efficiently. Make sure to regularly wipe down the surfaces with a soft cloth, ensuring all dirt and dust particles have been removed. It’s also important to check that any adhesive residue has been removed from the labels or tape heads.

Perform Regular Maintenance

It is important to regularly check and perform maintenance on the semi-automatic labeling machine, such as checking for loose screws or bolts, inspecting the drive belt and lubricating any moving parts.

Troubleshoot Issues

If you encounter any issues with your semi-automatic labeling machine, make sure to troubleshoot the problem before attempting any repairs. This may involve checking the voltage, testing various components or adjusting settings on the machine.

Proper Storage

When not in use, semi-automatic labeling machines should be stored in a safe and secure location that is free of dust and moisture. Keep the machine covered with a cloth or plastic sheeting to protect it from potential damage.

13. What Are The Troubleshooting Tips For Semi-Automatic Labeling Machines?

1) Check the power supply and make sure that it is connected properly. If not, then re-connect it so that the semi-automatic labeling machine can function correctly.

2) Inspect any mechanical parts of the semi-automatic labeling machine for signs of damage or wear and tear. Replace any worn out parts or clean any dirty components to ensure that the semi-automatic labeling machine operates smoothly.

3) Check for any loose screws or nuts and tighten them if necessary. This is important as it ensures that all the components of the semi-automatic labeling machine are functioning properly.

4) Make sure that there is no obstruction in the labeling path, such as a label spool that isn’t properly aligned or a label that is stuck in the machine.

5) Check the settings of your semi-automatic labeling machine and verify that they are all correct. Ensure that labels are loaded, sized, cut and placed correctly with the right temperature and pressure settings.

6) Make sure to check if any of the semi-automatic labeling machine’s software has been updated in order to ensure that it is running correctly.

7) If all of the above steps have been completed, and the semi-automatic labeling machine still isn’t operating properly, then contact a professional service provider for assistance. They will be able to diagnose any issues and provide solutions.

14. What Are The Problems In Semi-Automatic Labelling Machines And Their Possible Solutions?

Clogging

Semi-automatic labeling machines can be prone to clogging due to incorrect setup, poor maintenance and other problems.

Possible Solutions

Ensuring proper setup and alignment of rollers and guides, as well as regularly cleaning the machine to prevent contamination.

Inaccurate Label Placement

Semi-automatic labeling machines rely on the operator to place labels onto bottles or cans which can result in inaccurate placement.

Possible solutions

Use sensors and vision systems to ensure accurate placement or implement a semi-automatic system that holds the label in position until it is correctly placed.

Jamming

Semi-automatic labeling machines are prone to jamming due to incorrect setup, cross-contamination of label stock, poor maintenance and other problems.

Possible Solutions

Ensuring proper setup and alignment of rollers and guides, regular cleaning of the machine to prevent contamination, and regularly checking for signs of wear or tear on critical components.

Wrinkling of Labels

Semi-automatic labeling machines can also cause labels to wrinkle due to incorrect guide settings or friction from the rollers.

Possible Solutions

Adjusting the guides and rollers to reduce friction, as well as regularly checking them for signs of wear or contamination that could be causing problems. Additionally, using a semi-rigid label material will help prevent wrinkles from occurring.

Conclusion

A semi-automatic labeling machine is a key piece of equipment for many businesses. Now that you know more about the features and benefits of a semi-automatic labeling machine, it’s time to take action and get one for your business. Allpack is here to help you find the perfect machine to fit your needs. Contact us today for more information or to start shopping for your new semi-automatic labeling machine.

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp:+86 18171018586

Tell us your material or budget, we'll reply to you ASAP within 24 hours