Your Most Professional Powder Packaging Machine Manufacturer

- Intelligent Filling System

- Automatic Weighing Function

- Stepless Motor Precision Control

Powder Packaging Machine

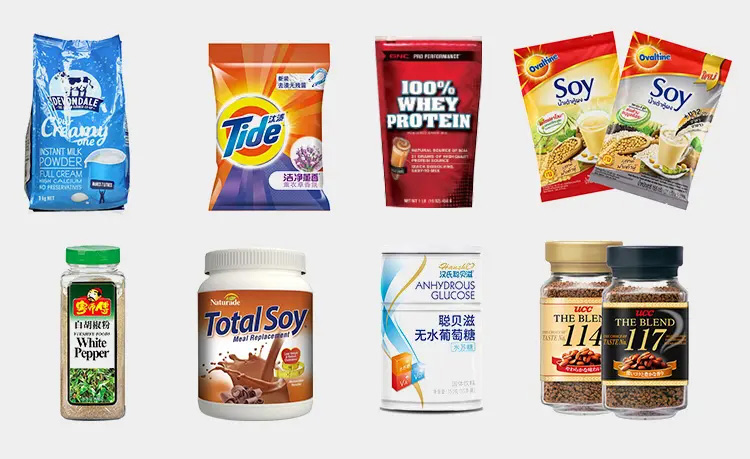

Allpack powder packaging machine is widely applied for food, pharmacy medical, and chemical products in mesh sizes ranging from 120 to 400, such as milk powder, soya powder, cosmetic powder, slimming tea, medical powder, etc. Allpack powder packaging machines can complete the forming bag, measuring, material filling, sealing, counting, date code printing, and all the work automatically. The PLC controller has the such as setting the length of the bag, the output alarm, and the speed and quantity with buttons. The machine can be installed to code the printer for 1-3 lines characters such as production and expiry date according to your special request. With fine packaging performance, all Allpack powder packaging machines have low noise, sealing texture, and strong sealing performance.

Powder Packaging Machine

DXDF-100AX Powder Packing Machine

Allpack DXDF-100AX powder packing machine is suitable for powder zipper bags, standing bags, and pre-made bag packaging such as washing powder, coffee powder, matcha powder, curry powder, seasoning powder, flour, protein powder, etc. The main function of this powder packing machine is automatically weighing according to the setting, and working with the feeding system and filling system to complete the operating cycle repeatedly. The advantages of the machine are to improve working efficiency and reduce production costs, more importantly, machine automation is going to replace manual operation.

Step motor precision control

Intelligent control

Easy operation

The Buyer's Guide

Powder Packaging Machine: The Complete Buying Guide in 2025

As a vital machine, powder packaging machines are now applied in various industries and fields. The power of powder packaging machines is needed for all kinds of milk powder and snacks we eat, as well as various powder medicines and chemical materials. Today let us experience the charm of powder packaging machines together!

1.What Are the Powder Packaging Machines?

Powder packaging machine also called as powder packing machine, is a general term for packaging equipment for packaging powder products. There are many kinds of powder products, which can involve industries such as industry, food, agricultural and sideline products, and various products such as milk powder, starch, pesticides, veterinary drugs, premixes, additives, condiments, feed, and enzyme preparations.

The powder packaging machine is suitable for automatic bag packaging machine products for powder products. General machines can automatically complete all the work of measuring, filling, sealing and cutting.

The powder packaging machine is suitable for small bag packaging of medicine, food, chemical industry, pesticide, etc. It is suitable for manufacturers of powdered medicines, sugar, coffee, fruit, tea, monosodium glutamate, salt, seeds, desiccant, etc.

2.What Are the Types of Powder Packaging Machines Available There?

According to the degree of machine automation, powder packaging machine can be divided into semi-automatic powder packaging machine and fully automatic powder packaging machine.

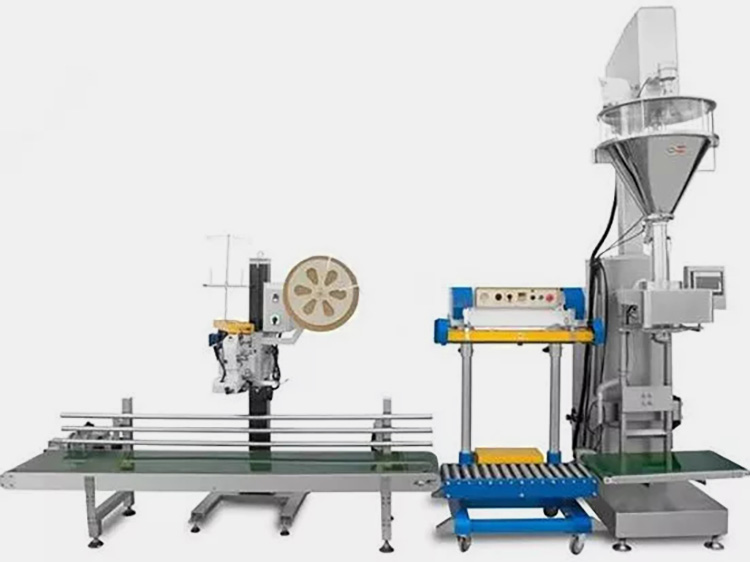

Semi-automatic Powder Packaging Machine

Semi-automatic powder packaging machine has the functions of powder filling, wrapping, labeling, sealing and sitting. This type packaging machines are mostly applied for filling and packaging of food powder, beverage powder, medical powder, chemical powder, etc.

This semi-automatic powder packaging machine shall be applied with a bag sealing sewing machine through the conveyor belt.

Fully Automatic Powder Packaging Machine

Fully automatic powder packaging machines are mostly applied for filling and sealing the flat bag, three-side bags, four-side bags, and stand-up bags. This fully automatic powder packaging machines are consisting of both sealing machine and packaging forming machines.

Fully automatic powder packaging machines are also suitable for automatic packaging lines. This fully automatic powder packaging machines are mainly consisting of a premade bag automatic rotary packaging machine, a screw scale, and a screw elevator.

According to the shape design of the machine, powder packaging machine can be divided into vertical powder packaging machine and horizontal powder packaging machine.

Vertical Powder Packaging Machine

The vertical powder packaging machines have the functions of powder filling, wrapping, and sealing. This powder packaging machine is totally automatic and can conduct the powder back sealing, three-side sealing, four-side sealing, etc.

With the core components of motor, pressure vessel, pump, PLC, gear, bearing, this vertical powder packaging machines are suitable for small scale production.

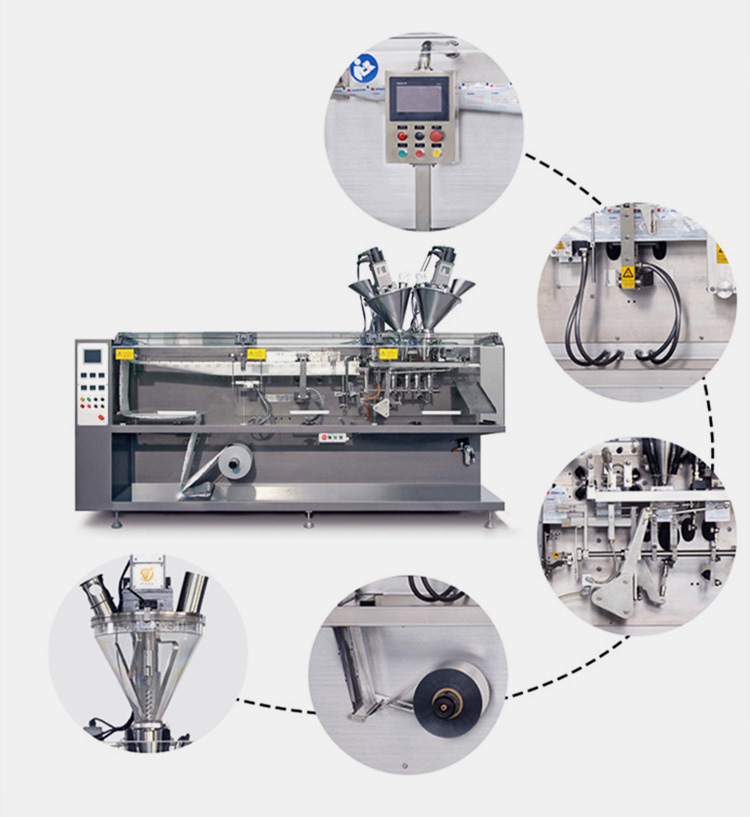

Horizontal Powder Packaging Machine

The horizontal powder packaging machines have the function of powder filling, wrapping, labeling, laminating, capping, etc. It has a various packaging type including stand-up pouch, bags, film, foil, belt, pouch, case, bottles, cans, etc. The horizontal powder packaging machines are suitable for packaging chains and large scale productions with high efficiency.

According to the packaging bags, powder packaging machines can be divided into premade pouch filling machine, sachet machine.

Premade Pouch Filling Machine

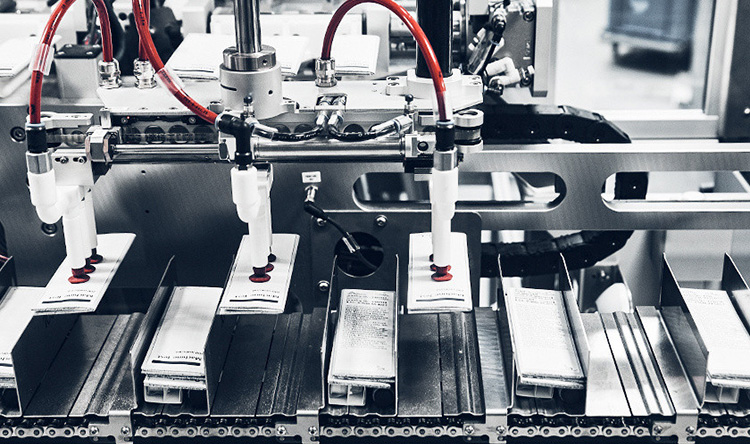

Premade pouch filling machine is suitable for filling and packaging the bags and pouches that are premade. Premade pouch filling machines are mainly divided into two types including horizontal type and rotary type.

Sachet Machine

Sachet Machine also can be called Pouch Packaging Machine, and it is a kind of filling and sealing machine for materials such as granule, powder, and liquids or sauces with little pouches.

According to the filling process, powder packaging machine also includes powder filling machine.

Powder Filling Machine

The powder filling machine is a device which is used in the filling of products that are in the form of powder such as pesticides, veterinary drugs, premixes, additives, milk powder, starch, condiments, enzyme preparations, feed and other powdery and granular materials.

With all these types of powder packaging machines, which one you favor best? And do you know what are the main parts of these powder packaging machines? If you do not know, then let us keep moving on the next part.

3.How Many Parts Do Powder Packaging Machines Have?

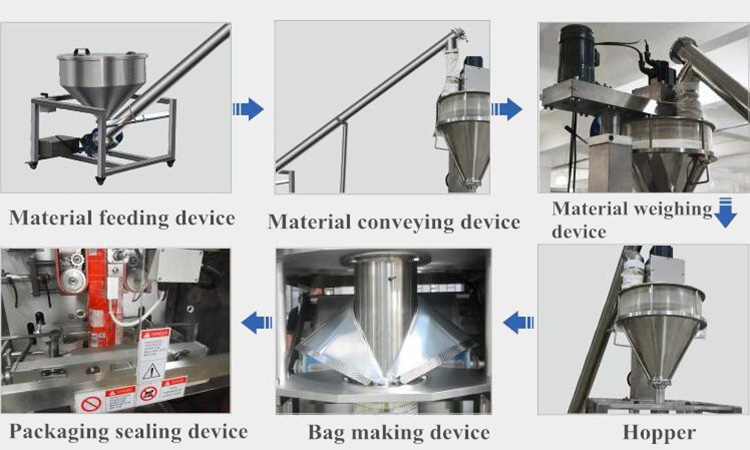

The components of different types of powder packaging machines are similar, but also they have the main same parts. Below we mainly understand the main parts of vertical powder packaging machines and main parts of horizontal powder packaging machines.

Main Parts of Vertical Powder Packaging Machine

There are 6 main parts of vertical powder packaging machines including material hopper, vibrator, auger elevator, auger weigher, packing machine, finished product conveyor.

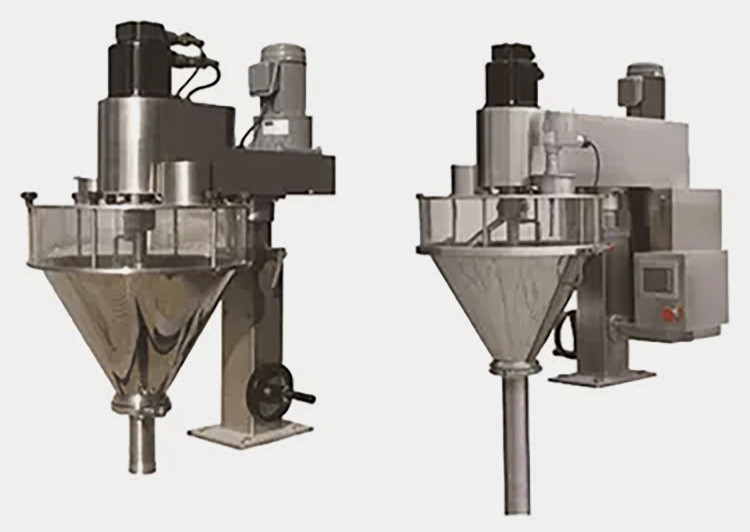

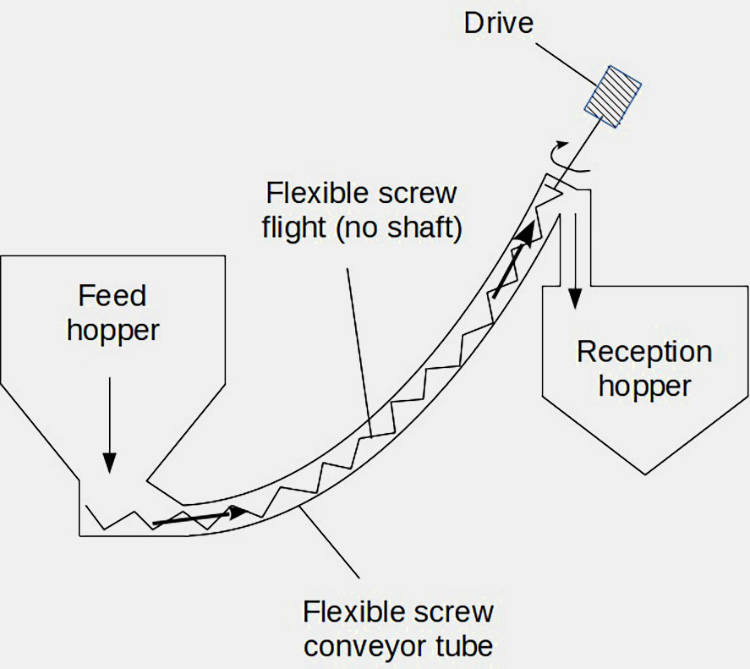

Auger Elevator

Auger elevator consists of the feeding hopper, vibrator, and the auger screw which can help loading the powders into the auger weigher or auger filler. Auger elevator is the first part and the necessary part.

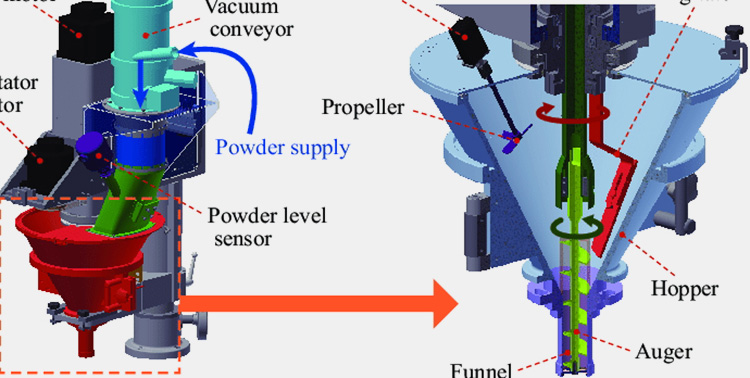

Auger Weigher

The auger weigher also called as auger screw filler, is applied for mixing and weighing the powders with high precision. With the transparent hopper, the auger weigher is working with fast feeding.

Packing Machine of Vertical Powder Packaging Machine

Packing machine fulfills the process of powder filling, bag forming, bag sealing and cutting. Packing machine is the main part of the powder packaging machine and it finished the most work of the powder packaging. Packing machine can connect to the finished product conveyor or the chain.

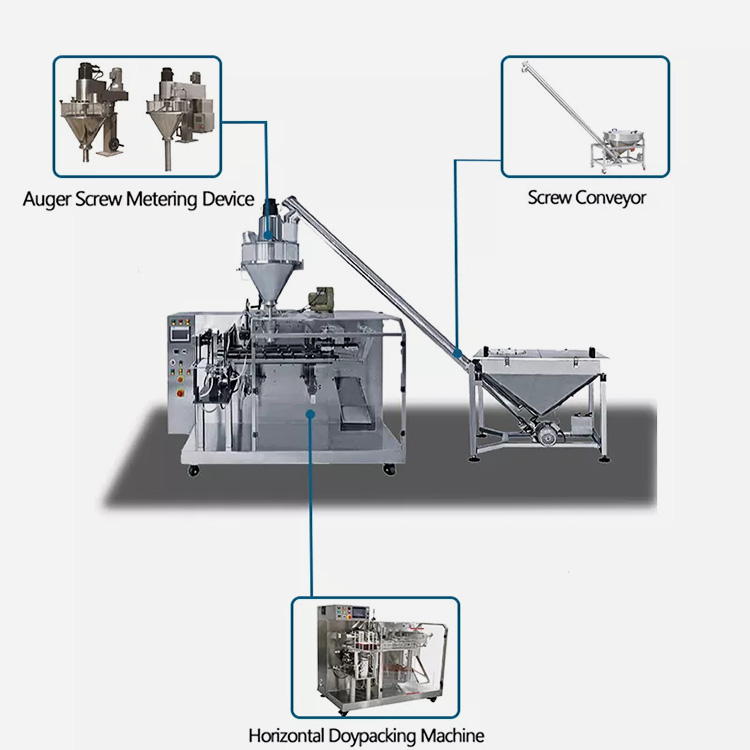

Main Parts of Horizontal Powder Packaging Machine

There are totally three parts of the horizontal powder packaging machine including the screw conveyor also called as auger elevator, auger screw metering device also called as auger filler or auger weigher, the horizontal packing machine.

Screw Conveyor

Screw conveyor also called as auger elevator of the horizontal powder packaging machine is the same with the vertical powder packaging machine. This part can consume the different powders and load the powders in to the auger filler.

Auger Screw Metering Device

Auger screw metering device looks like a funnel shape, it is equipped with advanced load cells. Auger screw metering device can use high-sensitivity sensors to weigh powders, and then use the controller to adjust the speed of ingredients, so as to ensure the correct distribution of quantity and weight.

Other than the auger elevator, auger screw metering device, the most important part is packing machine of the horizontal powder packaging machine. The horizontal powder packing machine is professionally designed for the working chain and large scale production.

Packing Machine of Horizontal Powder Packaging Machine

Powder packaging machine is a combination machine. Each part of the device can be disassembled and assembled separately. Different powder processing processes use the same component functions, but there are differences in details. If you want to learn more about the differences and functions of parts between different models, your consultation is welcome.

With all these parts, the powder packaging machine can work smoothly and safely.

4.What Are the Working Principles of Powder Packaging Machines?

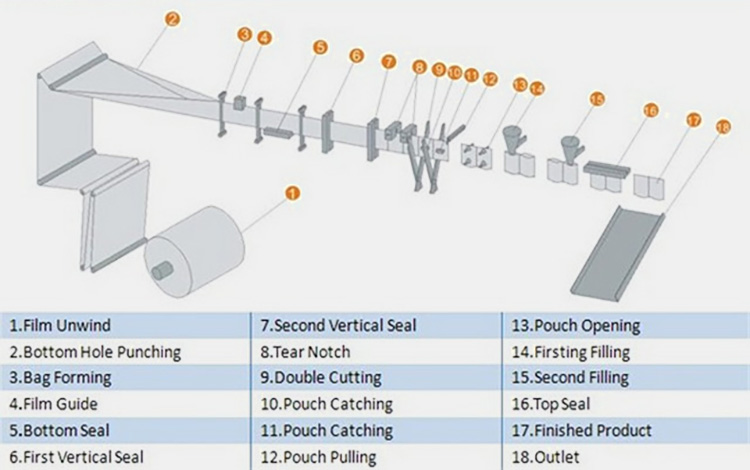

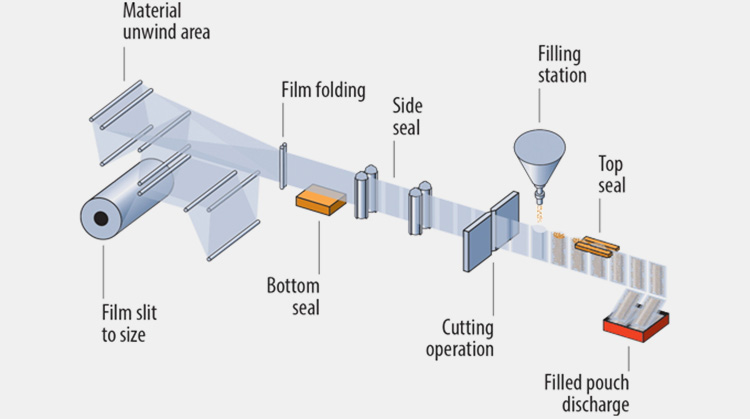

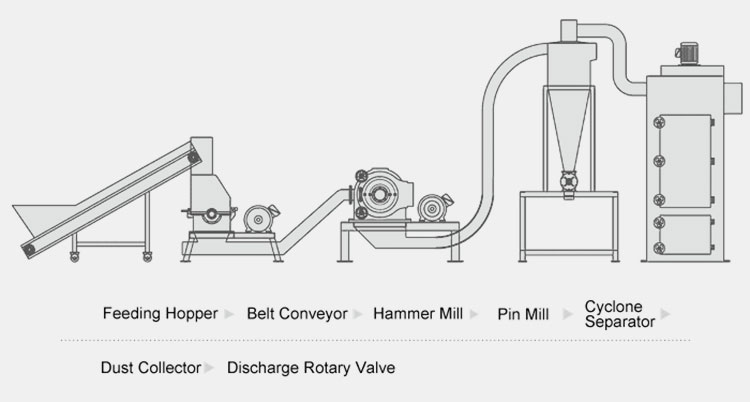

The working principles of all types of powder packaging machines are the same but with little differences. There are 4 working steps of the powder packaging machines including powder dosing, powder filling, bag forming, bag sealing and cutting.

Powder Dosing

Powders will be uploaded into the material hopper first, then the vibration feeder will continue transferring powders into the auger metering machine which also is called as auger filler.

Powder Filling

When powders are uploaded into the auger filler, powders will be mixed again and weighed in this process. The auger filler is equipped with the weighing sensor which can weighing the powders precisely. And the weighed powders will be filled into the bags or films each by each.

Bag Forming

There are total 15 working steps in the vertical powder packaging machines including film unwinding, bottom hole punching, bag forming, film guide, bottom seal, first vertical seal, second vertical seal, tear notch, double cutting, pouch catching, pouch pulling, pouch opening, first filling and second sealing.

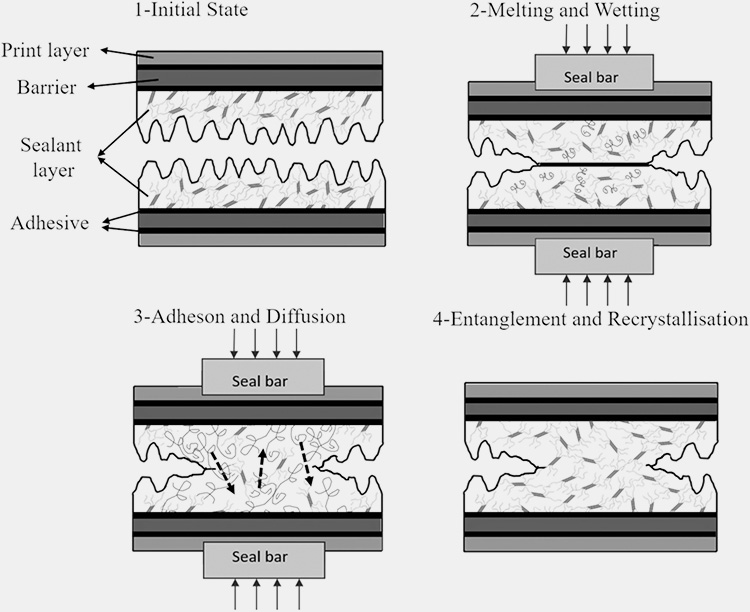

Bag Sealing and Cutting

Bag sealing and cutting is the last step for the powder packaging machines. In this working procedure, filled bags will pass through a heat sealing and pressure device. With this heat-sealed and pressure device, bags will be sealed and cut. Finally, the bags will be transferred to the finished product conveyor belt.

Through the powder weighing or powder dosing, powder filling, bag forming, bag sealing and cutting. The whole working process of powder packaging machine is done.

5.Why Do You Need A Powder Packaging Machine?

Powder packaging machine is a comprehensive machine integrating machine, electricity, light and instrumentation, single-chip control, automatic quantitative, automatic filling, automatic adjustment of measurement error and other functions.

Its advantages include fast speed, high precision, wide packaging range, wide application range, fully automatic control, automatic quantitative, convenient cleaning, etc.

High Speed of Packaging

The powder packaging machine adopts the light control technology and the screw for unloading. The feeding speed is fast, the efficiency is high and it can be controlled.

High Precision of Packaging

Powder packaging machine adopts stepper motor and electronic weighing technology. It is equipped with a high-sensitivity electronic weighing system, with small weighing errors and high precision. The weighing speed can reach 40-60ppm.

Wide Range of Weight Packaging

The same quantitative packaging machine is within 5-5000g, and the feeding screw of different specifications can be adjusted and replaced through the electronic scale keyboard. And the feeding screw is always adjustable. Powders in a wide range of weights can be packaged.

Wide Range of Applications

Powder packaging machine can be applied in various fields and industries, such as food industry, pharmaceutical industry, chemical industry, metallurgical industry, etc. And the powder packaging machine is suitable for packaging various powders and granules with certain fluidity.

Fully Automatic Control

All powder packaging machine models are basically semi-automatic and fully automatic, and there is basically no manual form. The design and development of this machine are very mature, and through fully automatic control, it can save manpower and material resources.

With all these advantages, are you also very excited? There are many models of Powder packaging machine, and different models can meet your needs for filling and packaging different materials.

6.How Many Types of Powders Can Be Filled by the Powder Packaging Machines?

Powder packaging machine has a wide range of applications, including filling and packaging food powders, pharmaceutical powders, chemical powders, agriculture powders.

Food Powders

Food powder can also called powdery food including milk powder, coffee, spices, seasonings, additives, food nutrition granules, solid drinks, various starch powders, etc. such as tea powder, cocoa powder, coffee powder, soybean flour, wheat flour, and chili powder etc.

Pharmaceutical Powder

Pharmaceutical powder also called as drug powder is widely filled and packaged by the powder packaging machine, and it mainly includes cold granules, anti-inflammatory powders for external use include tetracycline, erythromycin, chlortetracycline, ofloxacin, norfloxacin, etc. Chinese medicine powders include Panax notoginseng powder, Chuanbei powder, donkey-hide gelatin powder, etc.

Chemical Powder

Chemical powder includes groin talc powder, urea formaldehyde powder, sodium carboxymethyl cellulose powder, polyaluminium chloride pac powder, hydroxypropyl methylcellulose powder, etc.

Agriculture Powder

Agriculture powder includes plant fertilizer, fish protein powder, biological fertilizer, chitosan chitin powder, amino acids powder, kelp seaweed powder, gypsum powder, humic acid powder, etc.

There may be more types of powders that can be filled and packaged by the powder packaging machine, but the main types are all can be filled and packaged by the powder packaging machines.

7.What Should You Do If the Sealing bythe Powder Packaging Machine Is Not Tight?

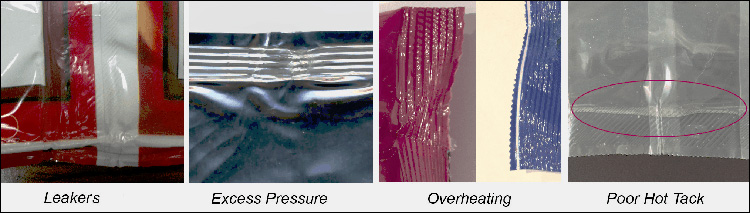

When using a powder packaging machine for work, if the seal is often not tight, it will not only affect the normal progress of production, but also cause a lot of cost waste.

Therefore, when the seal is not tight during the product packaging process, you’d better take the procedure of stopping production, checking the fault and dealing with the fault.

Reasons for Poor Sealing:

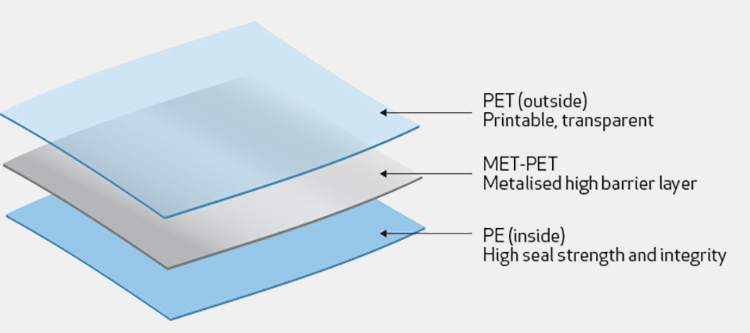

Uneven Inner Layer of Packaging Material

If the seal is often not tight, you should first check the packaging bag for problems. First of all, you should check whether there is a difference in thickness between the bag that is not tightly sealed and the bag that is tightly sealed.

Second, check the quality of the bag. During the production process, some packaging bags may be damaged or the workmanship is not rigorous. In this case, you should replace the good quality packaging bag in time.

Insufficient Temperature of Heat Sealing Device

If the powder packaging machine is not tightly sealed continuously, it may be the problem of insufficient heat-sealing temperature. During the sealing process, the packaging bag needs to pass through a heat sealing device, that is, the packaging mouth is heated and then sealed.

If the temperature of the heat sealing device is insufficient, it will not be enough to melt the seal of the packaging bag. At this time, you need to increase the temperature of the seal.

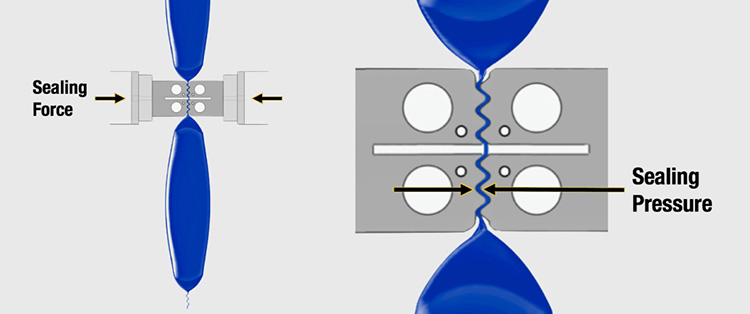

Insufficient Sealing Pressure

If there is no problem with the heat sealing temperature but there are still a lot of loose seals, it is likely that the sealing pressure is insufficient. After passing through the high temperature of the heat sealing device, the sealing device will press the packaging bag tightly.

If the pressure is insufficient, it will cause the bag to not be sealed tightly. Packaged products are prone to material leakage. In this case, you should adjust the sealing pressure. The sealing pressure cannot be too large or too small, and should be adjusted to a moderate strength.

If you encounter such similar problems in the production process, you can follow these countermeasures to solve the problems you encounter. Of course, if you buy a similar machine, you will definitely get professional guidance and after-sales maintenance services.

8.What Are the Packaging Forms of Powder Packaging Machines?

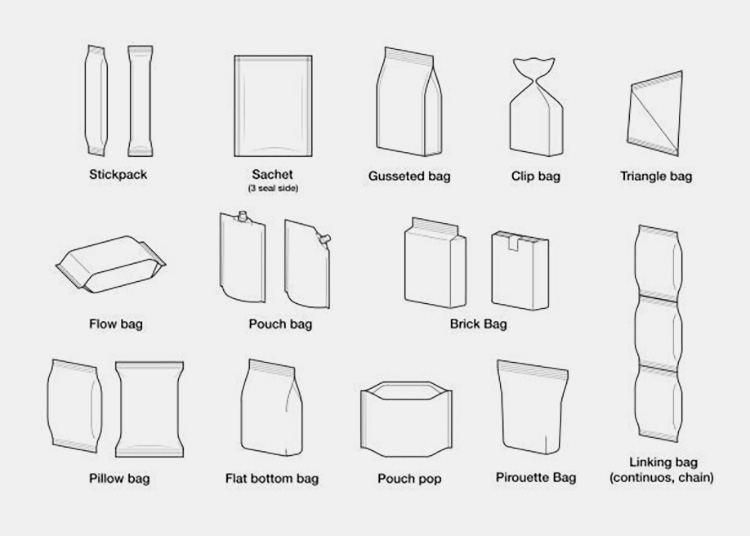

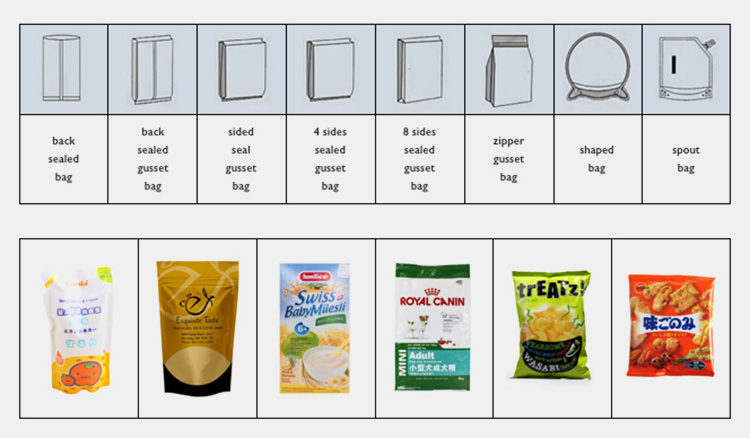

There are two main packaging forms of powder packaging bags including bags types, and bag sealings.

From the View of Bag Types

Different materials may require different bag forms. However, currently the most mainstream bag forms include 13 forms. These include stick bag, clip bag, triangle bag, flow bag, pouch bag, pillow bag, gusseted bag, stand-up bag or pouch, pouch pop, brick bag, flat bottom bag, pirouette bag, linking bag, sachet.

From the View of Bag Sealing

There are various sealing ways of powder bags including back-sealed bags, back-sealed gusset bag, sided-sealed bag, 4 sides-sealed bags, 3 sides-sealed bags, 8 sides-sealed bags, zipper-sealed bags, shape-sealed bags, and spout bag.

Different products are suitable for different packaging and sealing methods. For products with large demand, such as protein powder and milk powder, manufacturers generally use larger packaging bags for packaging.

Generally, the demand is small, such as condiments or additives, etc., for materials that require a small dose at a time, manufacturers will choose sachet or pouch packaging. You can refer to the advice given by the manufacturer to choose a suitable packaging and packaging form for your product.

9.What Are the Differences Between Powder Packaging Machines and Powder Filling Machines?

Powder packaging machines and powder filling machines are totally different machines but with similar functions and parts. The main differences lie in machine design, machine function, machine parts.

Machine Design

The machine design of powder filling machine and powder packaging machine is different. The design of powder packaging machine is more complicated than the powder filling machine.

Powder Filling Machine

The powder filling machine is a device which is used in the filling of products that are in the form of powder such as pesticides, veterinary drugs, premixes, additives, milk powder, starch, condiments, enzyme preparations, feed and other powdery and granular materials.

Powder Packaging Machine

The powder packaging machine is suitable for small bag packaging of medicine, food, chemical industry, pesticide, etc. It is suitable for manufacturers of powdered medicines, sugar, coffee, fruit, tea, monosodium glutamate, salt, seeds, desiccant, etc.

Machine Function

The main functions of powder filling machine are powder weighing, and powder filling. The main functions of powder packaging machine are powder weighing, powder filling, powder bag packaging, powder bag sealing and cutting.

Powder Filling Machine Working Process

There are two main working steps of powder filling machine are powder weighing, powder filling. So the machine parts of powder filling machine are quite simple and less which is easy for you to operate and are suitable for small business.

Powder Packaging Machine Working Process

There are four main working steps for powder packaging machine including powder weighing, powder filling, powder bag packaging, powder bag sealing and cutting. So the machine parts of powder packaging machine are quite complicated and more which are all automatic controlled and are suitable for large scale business production and chain production.

Machine Parts

The main parts of powder packaging machines are more complicated than the powder filling machines.

Main Parts of Powder Filling Machine

There are 10 main parts of the powder filling machine including servo motor, feeding material, material hopper, filling nozzle, leakage material, feedback scale, power switch, touch screen, level sensor, mix motor.

Main Parts of Powder Packaging Machine

There are 6 main parts of vertical powder packaging machines including material hopper, vibrator, auger elevator, auger weigher, packing machine, finished product conveyor.

Though there are various differences between powder filling machines and powder packaging machines, these machines are designed for fulfill different filling and packaging needs.

Conclusion

Powder packaging machines have various applications in different industries and they are the vital machine for all industries. If you have any need of these kind of machine or you want know more other types of machines, you are always welcome to come to us and we will give you our best opinions.

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp:+86 18171018586

Tell us your material or budget, we'll reply you ASAP within 24 hours

Tell us your material or budget, we'll reply you ASAP within 24 hours