Bottle Sealer Machine: The Complete Buying Guide in 2025

Are you tired of the product spillage packed in bottles? Do you want to get rid of this malady? That’s great! Finding the right sealing machinery at right time can tackle every minor issue of your business but it is sometimes tricky as you have to be attentive and fully understand the entire mechanism of equipment.

Don’t Fret! This ultimate FAQ guide is going to display a bottle sealer machine along with its working principles, major classifications, applications, and many more. You just have to stay hooked and thoroughly analyze this informative review!

1.What Is A Bottle Sealer Machine?

A bottle sealer machine is a machine used to seal various types of bottles to prevent the spillage of contents inside them. These bottles can be filled with various types of liquid, solvents, medicines, dyes, etc. Bottle sealer would be an excellent option for various industries to use to completely close the upper part of the bottles. This machine has numerous benefits as it is a quick, convenient easy-to-use machine that will provide industries with increased productivity and profit margins.

2.What Is The Working Principle Of The Various Types Of Bottle sealer Machines?

The basic working principle of a bottle-sealing machine is based on the heating and cooling process.

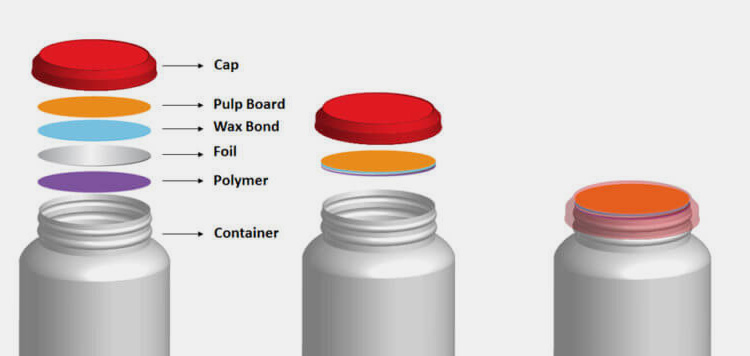

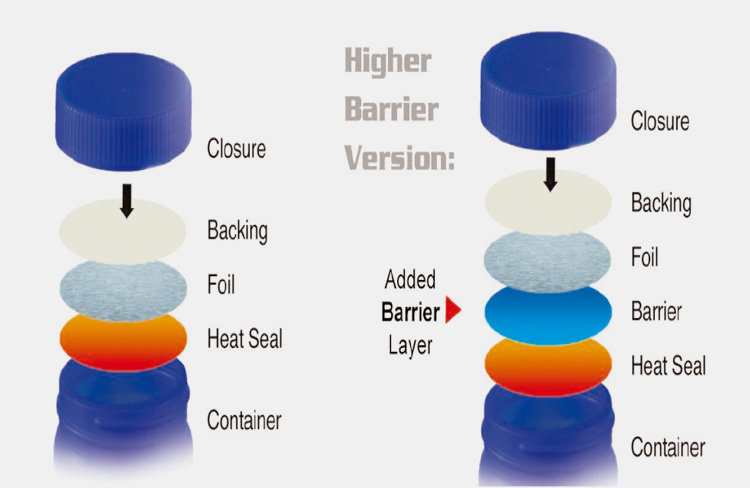

Firstly, the bottle is filled with the desired liquid. Then the bottle goes to the two-piece liner. This liner is made up of paper, wax, polymer covering, and foil. Then the material for the cap which will seal the bottle is chosen. The cap is then placed on the bottle and is made to go through the induction head of the machine where an electromagnetic field is produced. This heats up the foil inside the cap which in turn melts the polymer on the inner seal. After that, cool air comes out, making the polymer stick to the bottle and sealing the lid.

3.What Are The Main Components Of The Various Types Of Bottle sealer Machines?

Bottle sealer machines are made of various components. Let us discuss each component below

Electric Power Supply

This is the main supply that will provide the machine with the power to work and do its job.

Controlling Meter

This part of the machine dictates and decides how the machine is going to work right from the start till the end.

Inverters

Inverters have the ability to control all the ranges required for optimum working of the machine.

Induction Head and Sealing System

This is the main part that does the sealing process of the bottles.

Inductor Sealing Coil

The coil gives enough heat to seal the cap on the bottles.

Touch Screen

The touch screen can be operated by a person who can monitor the whole process of bottle sealer.

Cooling System

The cooling system provides cool air to remove the excess heat from the machine.

Conveyer Belt

The conveyer belt of the machine automatically transports the bottles from one part of the machine to another.

Round Wire Conversion Kits with Blades

These blades decide the dimensions at which the sealing material should be cut.

4.What Is the Purpose of Buying a Bottle sealer Machine?

Someone might wonder the purpose of buying a bottle sealer machine. Well the purpose is quite simple. The bottle sealer machine is a wonderful option to seal the bottles in the best way possible. Sealing them off will protect the bottles from contaminations and will also save the client from any loss and ensure that the bottles are shipped from the factory in a safe and secure manner.

5.What Are The Different Types Of Bottle Sealer Machine?

There are different types of bottle sealer machine that can be used in various industries. These different types which have their own specifications are listed below

Heat Sealing Machine

This type of machine is dependent on the heating process for sealing the cap on the bottles. One of the most important benefits of using this type is that it can increase the shelf life of the bottles since it puts a very good protective seal on the bottles. Thus it can be used by a lot of industries due to the benefits it offers.

Screw Cap Sealing Machine

The screw cap sealing machine is a unique machine because it has the ability to seal various kinds of bottles of different shapes and sizes. Due to its versatility, this machine can be used in various kinds of industries like the pharmaceutical, food, agriculture, and cosmetic industry.

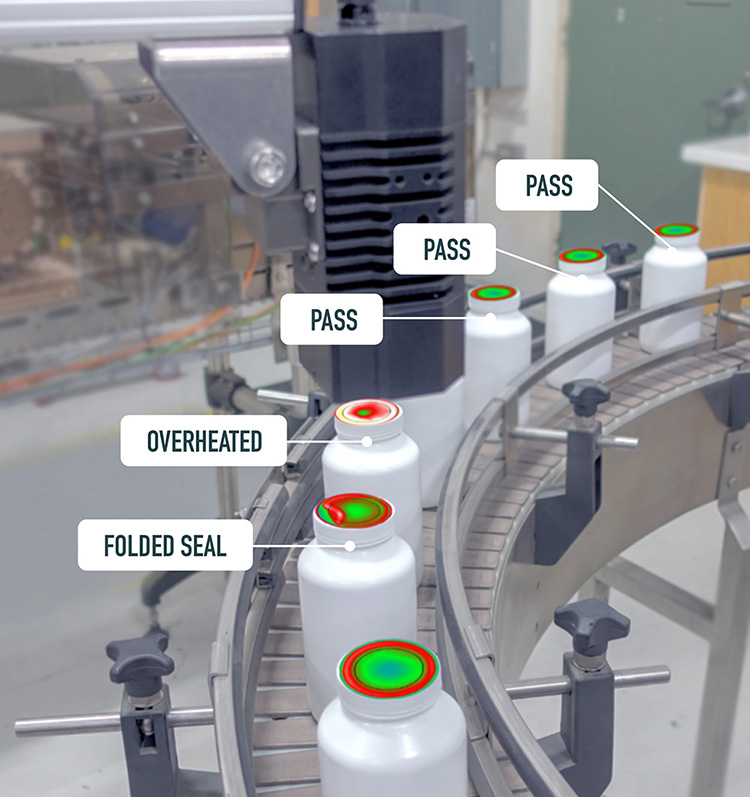

Induction Bottle sealer Machine

This is one of the most popular types of bottle sealer machine. This type depends on the electromagnetic field and the heating process which seals off the cap effectively and securely on the bottle.

Ampoule Sealing Machine

This type of machine is used to seal glass bottles. The top layer is melted by a flame and the ampoule is sealed off by the thermal process. A small space is left at the top of the ampoule which is filled with inert gases like nitrogen so that they do not react with the ampoule.

Crimp Sealing Machine for Vials

This is used for crimping and sealing plastic and glass vials, bottles, jars, and containers. It is suitable for the food, pharmaceutical, and food industry to seal products like spices, jams, vaccines, and serum. You can get 100% perfect sealing without extra pressure hence it assures products safety and potency.

Automatic Rotary or Screw Capping Machine

Screw Capping Machine follows pick and place according to torque adjustment , appropriate for screw or press fit caps. They are used in food and drinks, pharmaceutical, cosmetics, pesticides, distilleries, toiletries, personal care etc products.

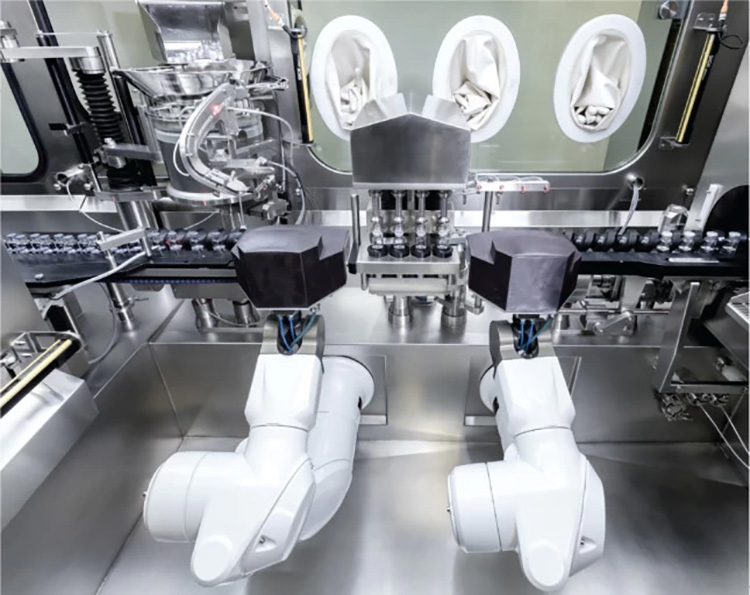

Vial Capping Machine

They are one of special pharmaceutical machinery for filling, stoppering and capping of glass bottles. Vial Capping Machine is designed for operating in a sterile area.

Measuring Cap Placing Machine

Specifically designed to place measuring caps as the lid of sealed bottles

6.Industrial Applications of Bottle sealer Machines

The bottle sealer machine due to its versatility and effectiveness can be used in a number of industries such as pharmaceutical, food, chemical, agriculture, and cosmetic industry. Let us discuss each industry below

Pharmaceutical Industry

The use of bottle sealer machine is extremely critical in the pharmaceutical industry. Since medicines and drugs require safe and secure packaging, the bottle sealer machine seals off the lid of these bottles in the best way possible. This process not only protects the contents of the bottles inside from spilling outside but it also ensures the purity of the drug by preventing them from any contamination.

Food Industry

The food industry is involved in the production of various foods and drinks such as soft drinks and juices. These liquids are filled in bottles that need an effective seal to prevent the spillage of the liquid contents from the bottles. They also need a good protective covering so that they do not get contaminated and make the juices and soft drinks undrinkable. Installing a bottle-sealing machine in the production line of the food industry will cater to all these needs.

Nutraceutical Industry

The nutraceutical industry makes various food tablets and vitamin supplements which are put into bottle shaped containers. Using a bottle sealer machine to seal the caps on these bottles will provide a safe and effective way to protect them.

Chemical Industry

Chemical industry is a highly versatile industry which manufactures various kinds of chemicals such as ink, dyes, paints and solvents which are then used in other industries to make final products. The packaging of these chemicals has to be handled with extreme care since these chemicals need to maintain purity and potency. Bottle sealer machine will ensure their purity since they will prevent the contact of air and bacteria from the contents of the bottles, preventing oxidation.

Agriculture Industry

The agriculture industry is responsible for cultivating crops like wheat, sugarcane, barley and rice and refine them to make products such as cooking oil, non-alcoholic beverages and processed dairy foods. These products are then filled into bottle shaped containers of different shapes and sizes, according to their requirements. Bottle sealer machine can cover the surface of these bottles and ensure their maximum protection during their shipping.

Cosmetic Industry

Many beauty products such as creams, body lotions, serums, and hair products are packaged in bottles. These products are very sensitive to light, temperature and air and will degrade if they come into contact with them. Thus bottle sealer machines can provide these products with a good quality seal, ensuring that they are well protected from any damage.

7.Quality of a Safe Bottle Sealer MachineMechanism

Whenever you invigilate the quality of any operating procedures , you assure it’s safe and GMP compliant services. In order to deliver best and secure efficiency of any products undergoing Bottle sealing mechanism you should consider:

- Making of a regulatory affairs team to supervise packaging and sealing of pharmaceutical products.

- What product are you intending to pack and seal?

- What process shall be followed for packing and sealing?

- There must be some policies of the manufacturer for safety of pharmaceutical products.

- Validation and verification to ensure integrity and safety of the product without any spillage or breakage.

- All Quality Control testings both in process and after process ,should be done prior to sending out the product to the markets.

- Trained personnel , adequate facilities and maintenance of proper record should be there concerning bottle sealing mechanism to achieve good quality.

8.How Will You Benefit From The Various Types Of Bottle sealer Machines?

Bottle sealer machine is one of the best machines out there to seal bottles. The design of this machine is simple and has a lot of benefits to offer. Let us discuss some of the advantages of this machine below.

Tamper Proof Seal

This machine provides the bottles with an ultra-protective seal which prevents the contamination of the bottle from the outside environment, ensuring its purity.

Cost Effective

Installing this machine in the production line can reap huge profits since it is not highly expensive and give productive results.

Quick Results

Since this machine doesn’t require much manual labor and almost effectively works on its own, it has the ability to seal thousands of bottles in a single day. Thus generating quick results.

User Friendly

The working principle of this machine is simple and doesn’t require complex methods to operate, making it user friendly for anyone who wants to use it.

Low Space Requirement

This is because the machine doesn’t require a lot of space as compared to other machines used in large scale industries. Thus it can be fitted anywhere in the production line.

Low Maintenance

This machine requires general cleaning and maintenance just like the other standard machines.

Versatility

Due to the number of different types this machine has, it can be used to seal bottles of various designs, shapes, and sizes. Thus it gives a number of industries an option to install it in their factories.

Precision and accuracy

Due to the presence of a touchscreen system, this machine has the ability to operate perfectly, thus ensuring accuracy.

9.Are There Any Drawbacks Of The Various Types Of Bottle sealer Machines?

As you have read the advantages of bottle sealer machine covers all areas of functioning. There are a lesser number of disadvantages as,

- You need a high investment capital as the machine is expensive and the installation cost is also high.

- Moving the machine from one place to another is a difficult task because it is heavy. In case you manage to move the machine, you might experience a lot of damage thus limiting the movement.

- The size of the machine also requires a bigger installation space thus increasing the cost of investment

10.Maintenance Of Bottle sealer Machine

The maintenance of the bottle sealer machine is quite simple. These are the points that one should keep in mind to ensure that the machine is working as efficiently as possible.

- The power supply including the current and the voltage should be checked to see if appropriate levels of power are being given to the machine.

- Every component of the machine such as the conveyer belt, controlling meters, inverters, inductor sealing coil, inductor head, and the system should be inspected to ensure that all the parts are working fine.

- Lubrication such as oil should be used in different parts of the machine such as the conveyer belt and bearings to prevent friction between the parts.

- The machine should be checked for any leakage of the compressor to ensure the safety of people working around the machine.

11.How To Troubleshoot Common Problems Of The Various Types Of Bottle sealer Machines?

| Problems | Solutions |

| 1) The seal is either too tight or broken. | Adjust the pressure system to ensure that appropriate levels of pressure are being put on the cap. |

| 2) The power supply is disrupted, affecting the whole process of the machine. | Check all the parts of the power supply to see where the fault is and replace them with new ones. |

| 3) The conveyer belt has broken down. | Replace the belt with a new one. |

| 4) Some parts of the machine such as the inverter, controlling meter, and induction sealing coil are not working properly | Replace these parts with new ones which are easily available in the market or online. |

| 5) The heating temperature is too high. | Adjust the heating temperature till it reaches the desired level. |

| 6) The cooling system is not producing cool air. | Inspect the cooling system to check where the fault lies to ensure it produces cool air. |

12.Is There Any Difference Between Bottle Sealer Machine And Cap Sealer Machine?

A bottle sealer machine is usually an automatically operated machine to seal bottle caps onto the individual and various kinds of bottles along with sealing a protective barrier that prevents spillage of the content inside. Whereas, a Cap sealer machine fixes caps or lids on different types of bottles and containers.

The difference arises only in the mechanism employed in both types of closure applications either it is about fixing or twisting a cap on any container, or it is about sealing and closing the bottle mouth through any process.

13.How to select the Best Bottle Sealer Machine?

For being able to choose the best bottle seal you must know the answers to the following questions regarding your bottle as well as the content inside for which you’re using the sealing mechanism.

- What level of tamper-evident protection do you need to provide? This would look into type of sealing liners required according to respective consumer demand or how your products need to be ensured safe and hygienic.

- There are two types available clean peel seal and tamper evident seal.

- What is your product type? Aggressive products may require a strong barrier layer for protection from environmental degradation factors while inert contents might not.

- Does the packaging needs to be leakproof? For ensuring this you might require air and waterproof seals.

14.Marketing Strategy Of Bottle sealer Machine

A bottle sealer machine can be used very effectively to promote your brand. Due to the number of advantages and benefits this machine has, it can be easily used by the customer to effectively strategize their brand and bring in huge profit margins.

This machine is very quick and gives productive results in a very short amount of time. Thus it promises huge profits for customers hoping to reap as many benefits as they can. It doesn’t require much manual labor to operate. So the customer doesn’t have to worry about employing expensive manual labor.

This machine also doesn’t require much space for its installation, thus the customer can easily fit it anywhere in his factory. The protective covering of the seal on the bottles ensures that the bottles won’t get damaged or contaminated during the shipping process, thus providing a huge relief to the customer who wouldn’t have to worry about the damage costs.

15.Considerations Before Purchasing Bottle Sealer Machine

You need to make sure you take few important things into your notice before you buy a Bottle Sealer Machine, these are:

- One should be aware of the user manual related to the equipment. However most of the machines are automatic and has easy operability it is also necessary to make sure it is kept maintained and cleaned timely to increase the machine’s durability.

- Before buying the bottle sealing machine you’ve the option to choose whether you’d prefer manual, semi automatic or fully automatic system. Recommended choice is selection of automatic system as it has an inbuilt human machine interface and PLC software ,even though that might be costly but it comes convenient.

- Safety should be prioritized concerning the equipment as well as yourself. The machine should have sensors to detect any danger and stop by itself to prevent further harm.

- Ensuring ergonomic design of the equipment might help you to cut down too much noise levels and minimal air pollution through less smoke , giving you an efficient working environment.

- Construction material of the machinery should improvise integrity of the contents to be put inside the equipment such as stainless steel is strong, durable, aseptic and convenient for cleaning.

- Your selection of type of bottle sealer machine should make sure it has all kinds of sealing available such as induction and screw cap sealing.

- Production capacity which is highly achieved by such type of machine should be your go-to choice for purchasing.

- Your machine should be flexible enough to adapt to variety of bottle sealing mechanisms and so change their parts on response accordingly.

- The machine should have installed inkjet printing system to automatically label the seals.

- For the purpose of security and safety, machine should have inbuilt sensors to detect any error in the process of operating system.

Conclusion

After discussing all the details above, it is safe to say that a bottle sealer machine is the perfect choice for anyone who is looking for a fast, effective, economical, and safe way to seal their bottles. It is not only an excellent choice to install in the production line of the factories but also the best machine to include it in a workshop environment. Thus making it an all-rounder machine!

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide