High Performance Automatic Weighing Machine

- Multi-mouth Feeder

- High Precision & High Efficiency

- Accurate Control of Feeding Time

Automatic Weighing Machine

Allpack automatic weighing machine is designed to weigh a wide range of small-sized products, both solid or granulated. It is suitable for all kinds of granules, such as grains, tea, spices, etc. All Allpack automatic weighing machines can auto complete the bag-making, filling, sealing, cutting, and counting. The machine adopts high precision servo film transport system, PLC program control and developed touchable human-machine interface, is easy to operate. The appearance of the whole machine is made of stainless steel, which make it durable.Equipped with touch screen display, the packaging weight can be adjusted steplessly at any time, the working state can be changed at any time, and the operation is convenient. This machine has a wide range of applications such as food, agriculture, electronic,chemical, hardware, PET food, medicine industries,etc.

Automatic Weighing Machine

CJS-25IH Automatic Weighing Machine

Allpack CJS-25IH automatic weighing machine is suitable for weighing snack foods such as candy, melon seeds, jelly, frozen, pistachio, peanuts, nuts, almonds, raisins, etc, and is suitable for puffed food, hardware, plastic compounds, and other granular, flaky, strip, round and irregular shape material. The machine adopts a high-precision servo film transport system, PLC program control, developed a touchable human-machine interface of advanced automatic positioning, photoelectric tracking, digital temperature control, etc. This is a multi-functional intelligent assembly machine with strong performance. Low energy consumption, low power, more environmentally friendly.

Operation is simple

High precision&high efficiency

Higher precision

CJD-25IIZ Granule Powder Automatic Weighing Machine

Allpack CJD-25IIZ automatic weighing machine, the filling speed, and filling volume are easy to adjust by the automation control system. When the machine is working, the feeding of materials is driven by two different vibration frequencies, which can ensure accuracy, and improve the feeding speed at the same time. The whole body is made of stainless steel, which is stable and reliable performance. This automatic weighing machine can be applied to various materials, such as hardware accessories, powder, granules, tea, trinkets, medlar medicine, specialty products, rice grains, etc. This is a multi-functional intelligent assembly machine with strong performance.

Simple operation&high accuracy

High stability

Save time for multiple feeding

EWM-5000 Electronic Weighing Filling Machine Automatic Weighing Machine

Allpack EWM-5000 automatic weighing machines mainly consist of feeding equipment, weighing hoppers, and electronic control systems. It can complete feeding, weighing, and packing work independently. Suitable for various packaging containers(bags, cans, bottles, etc.) of various sizes, the packing weight varies from 500g to 5000g by changing amounts of its hopper. It is suitable for many kinds of material packaging, such as rice, nuts, tea, essence spice, corn, gourmet powder, sugar, coffee beans, sunflower seeds, chemicals, wash powder, solid drinks, and so on. It is made of full stainless steel with food grade and energy saving.

High speed&accuracy

Quick&easy weighing hopper

Quick&small vibration

EWM-3000 Electronic Weighing Filling Machine Automatic Weighing Machine

Allpack EWM-3000 electronic automatic weighing machine adopts the use of microcomputer control of optical technology, high accuracy, fast, good quality, and solves precisely the traditional tea packaging tedious process. Suitable for tea, food, food, seeds, fruit, grain shape chemicals, and pharmaceuticals, micro and small components such as general non-sticky solid materials. With intelligent control, it can do fully automatic packaging, more and fast. It is made of full stainless steel with food grade and energy saving.

High precision, high speed

Long life, good stability, manual bagging

Automatic measurement

EWM-2000 Electronic Weighing Filling Machine Automatic Weighing Machine

Allpack EWM-2000 electronic automatic weighing machine consists of a feed hopper, vibratory feeder, lightweight weighing device, weighting hopper, door opening mechanism, etc. The machine is used to weigh objects in grain or powder shape with good fluidity, then to deliver rationed products to the packaging machine for packing. It can be used either alone or equipped on the production line. With intelligent control, it can do fully automatic packaging, more precisely and fast. It is made of full stainless steel with food grade and energy saving.

Small size, lightweight

Minimal power, energy conservation

Oblique throwing feeding

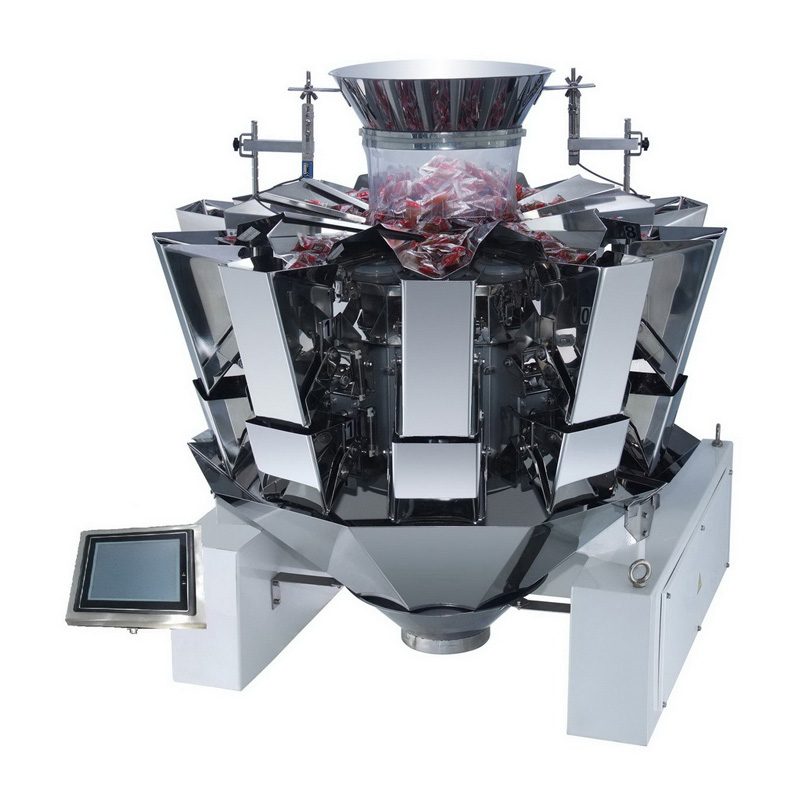

Multi-head Automatic Weighing Machine for Weighing Rice/ Seeds/Nuts/Hardware/Snack /Pet Food Filling Machine

Allpack multi-head automatic weighing machine adopts high precision and high accurate load cell of famous brand, resolution is improved up to 2 decimal. With the program recovery function, it can reduce operation failures and support multi-segment weight calibration. There is no product auto pause function that can improve weighing stability. The 100 programs' capacity can meet various weighing requirements and the user-friendly help menu contributes to easy operation. Linear amplitude can be adjusted independently. Many languages are available for global markets.

Multi-mouth feeder

Specially designed U-shaped linear feeder pans can avoid leaking problem

Can make accurate control of feeding time

Automatic linear Weighing Machine for Granule

Allpack linear type automatic weighing machine is suitable for weighing of granule, slice shape such as cereal, pasta, candy, seed, chips, coffee bean, nut, puffy food, biscuit, chocolate, pet food, frozen foods, etc. It is also suitable for non-food industry such as screws, bolts and plastic components.With modular electronic system makes the machine expanding and maintenance easier and at lowest cost.PLC control system applied in the weigher and it makes machine more stable and low fault rate.

High accuracy and stability

Interchange is available

PLC control system

The Buyer's Guide

Automatic Weighing Machine: The Complete Buying Guide In 2025

Weighing machines are an essential part of any industry, as they help to ensure accuracy and consistency in measurement. However, manually weighing products can be time consuming; that’s why automatic weighing machines have become such a valuable asset for many businesses.

Automatic weighing machines provide efficiency and reliability in an easily manageable package; with their ability to quickly gather data on materials helping keep operations running smoothly. This versatile device can measure all types of material – from food items to medications or pieces of jewelry, giving you accurate results quickly and easily.

In this blog post we will provide an overview of what an automatic weighing machine is and how it can improve your productivity. We’ll also explore the various types available on the market, their advantages and disadvantages, so that you can find the right device for your needs. Keep reading to learn more!

1.What Is An Automatic Weighing Machine?

An automatic weighing machine is a type of industrial equipment used to accurately measure the weight of different packages and products. This device uses automatic scales and electromechanical systems to detect and record weights quickly.

This type of machine is typically found in warehouses, factories, distribution centers, and other business settings where accurately weighing products is important.

Automatic weighing machines are highly accurate and can be programmed with specific weight limits so that only items within the appropriate range can be packaged or shipped out. This helps businesses ensure that their customers receive exactly what they ordered without any surprises.

In addition, automatic weighing machines are efficient since they reduce manual labor in packing processes since it can package multiple products simultaneously with minimal human intervention required.

2.What Are The Components Of An Automatic Weighing Machine?

Load Cells

Load cells are the most important component of automatic weighing machines as they measure the weight of objects placed on them. They work by converting a load force into an electrical output signal that is then processed by a microprocessor to generate an accurate weight reading.

Feeders

Automatic weigh feeders are used to provide automatic feeding of materials into the machine, allowing for consistent and accurate measurements with less manual labor or maintenance required.

Weighing Platforms

Weighing platforms provide a stable surface for weighing items, ensuring accuracy and repeatability in measurement results.

Indicators/Scales

Indicators and scales are used to display measurement readings from automatic weighing machines. These indicators and scales can be either digital or analog, depending on preference.

Controllers

Controllers are used to control the automatic weighing machines by managing signals from the load cells, feeders, weighing platforms and indicators/scales in order to ensure accuracy of measurements.

Software

Weighing software is used to store automatic weight measurements taken from automatic weigh machines for further analysis or reporting purposes. This software can also be configured with other components like printers and computer systems for enhanced functionality.

Printers

Printers are typically connected to automatic weighing machines and allow users to print out records of automatic weight readings taken during certain time periods or intervals.

3.What Are The Advantages Of An Automatic Weighing Machine?

Improves Customer Satisfaction

Automatic weighing machines can accurately detect and record the weight of a product or item, thus eliminating any guesswork. This ensures that customers get exactly what they pay for, leading to increased satisfaction levels.

Accuracy

Automatic weighing machines provide accurate and precise measurements of the weight of an object with minimal user intervention. This is valuable for industries that require exact measurements for production or shipping processes such as food, pharmaceuticals and chemicals.

Reduces Waste

Automatic weighing machines measure the exact amount of product or item needed, helping reduce waste. This means that less materials are used and fewer resources are wasted in production processes.

Enhanced Product Quality

Automatic weighing machines are designed to provide accurate measurements for each package. This helps to ensure that the product is consistently of a high quality, as the packaging process can be tightly monitored and controlled.

4.What Are The Applications Of An Automatic Weighing Machine?

Pharmaceutical Industry

Automatic weight packaging machines are used in the pharmaceutical industry to accurately measure and package medicines. This helps ensure that the right dose of medication is dispensed each time, reducing the risk of overdose or underdose.

Food Industry

Automatic weighing machines can be used to measure the weights of food products such as fruits, vegetables, dairy items, grains and other processed food items for packaging or sale purposes.

Agriculture Industry

Automatic weighing machines are beneficial in measuring animals’ body weights for tracking their health progress over time or evaluating their living conditions. They can also be used to determine the weight of crops for harvest purposes.

Cosmetic Industry

Automatic weighing machines can be used to weigh chemicals, ingredients, and product packaging materials in the cosmetic industry. This ensures that the products produced are of a consistent quality and accurate weight.

Industrial Applications

Automatic weighing machines provide accurate measurements of raw materials, semi-finished products, and other components needed for industrial production processes. This ensures that the produced products meet quality standards and prevent wastage from occurring due to incorrect weights being used in production lines.

5.What Are The Working Principles Of An Automatic Weighing Machine?

The automatic weighing machine works by first calculating the exact weight of an item or product based on data stored in its memory. This data is then compared against predetermined parameters that are programmed into the automatic weight packaging machine’s computer system.

If an item matches all criteria set out by these parameters, it will be packaged and sent off for dispatch automatically. If certain criteria are not met, the automatic weight packaging machine will reject the item. This process is repeated until all items are correctly weighed and packaged accordingly.

6.What Are The Different Types Of Automatic Weighing Machines Available On The Market?

a) Automatic Weighing and Packaging Machine

This type of automatic weighing machine is designed to accurately weigh items, package them into pre-defined size containers, and label the packages with information such as weight, date and time. The automatic weighing and packaging machines can be used for small or large scale production in industries such as food processing, medicine production, chemical processing, etc.

Components

Automatic Weighing System

This system is used to weigh the product accurately, as well as adjust for any inaccuracies in weight due to environmental changes or accidental mishandling. This part typically consists of scales, load cells, conveyors, and other weighing components.

Automatic Feeding System

This system helps to ensure that products are correctly fed into the packaging machine at a consistent rate. It includes vibratory feeders, hoppers, elevators and transfer belts.

Automatic Wrapping System

This system wraps each package with a predetermined amount of material such as plastic film or paper. It typically consists of a wrapping machine, film distributor and conveyor system.

Automatic Labelling System

This system helps to identify each package for tracking or barcode scanning purposes. It includes labelers, label printers and label applicators.

Automatic Filling System

This system is used to fill packages with predetermined amounts of product either manually or automatically depending on the needs of your company. This system can include hoppers, scales, mixers and conveyors.

Automatic Sealing System

This system seals the packages once they’re filled with product either manually or automatically depending on the needs of your company. Automatic sealing is usually used for high-volume applications, while manual sealing is suitable for lower volume or smaller orders. This system typically includes heat sealers, vacuum sealers and ultrasonic sealers.

Quality Control System

This system helps to ensure that all packages produced by the automatic weighing and packaging machine meet predetermined quality standards before being shipped out for delivery. This system can include vision cameras, x-ray scanners and metal detectors.

Automatic Storage System

This system helps to ensure that all packages produced by the automatic weighing and packaging machine are properly stored and organized until they’re ready for shipment. It includes storage systems such as pallet wrappers, carton sealers, stretch wrappers and conveyors.

Working Principles

Automatic weighing and packaging machines integrate various technologies, such as computer vision and robotics, to accurately weigh and package products. The process starts when the product is placed on the weighing machine’s platform, where it is weighed and then transferred to a robotic arm for packaging.

The robot then packages the product according to pre-defined instructions (such as size or weight). Once packaged, the product is sent down a conveyor belt for further processing or storage.

Applications

Automatic weighing and packaging machines are used in a wide variety of industries, from food and beverage, pharmaceuticals and cosmetics. In the food and beverage industry, automatic weighing and packaging machines can be used for packaging items such as cereals, snacks, tortillas, confections and other foods.

In the pharmaceutical industry, automatic weighing and packaging machines are often used to package medicines, tablets and capsules. Also, automatic weighing and packaging machines can be used in the cosmetic industry to package ointments, creams and lotions with accuracy.

b) Check weigher Automatic Weighing Machine

A checkweigher is an automatic weighing machine used to accurately weigh various products such as food, medicines, and other items for quality control purposes.

This type of automatic weighing machine includes a conveyor belt which transports the items onto a scale platform where they are weighed automatically before being released from the system.

The checkweigher also features sensors that detect product weights and can alert operators if any discrepancies are detected between expected weight and actual weight.

Components

Checkweigher Conveyor System

This is the primary component for checkweigher automatic weighing machines. It consists of a conveyor belt and rollers which are used to move items along the line for weighing. The speed can be adjusted depending on the weight and size of items being weighed.

Checkweigher Platform

This is a platform that is used to weigh items placed on it accurately and with precision. It has sensors that detect the changes in weight as well as measure how long an item takes to pass through an area, allowing precise measurements of item weights and speeds that pass through the checkweigher machine.

Checkweigher Control Panel

This is the main control unit for checkweigher automatic weighing machines. It allows users to set parameters and adjust the checkweigher’s functions such as conveyor speed, product weight tolerances, and data logging.

Checkweigher Scales

The checkweigher scales are used to accurately measure the weight of items placed on them. They come with a variety of features including digital readouts, low-profile designs and adjustable accuracy settings that help ensure accurate measurements every time.

Checkweigher Printer

This component is used to record all measurements taken by the checkweighers for reference later or for analysis purposes. It can print labels in various formats, allowing users to easily identify each item that has been weighed and measure its weight accurately.

Checkweigher Reject System

This is an optional feature for checkweighers and helps automate the process of sorting out items which do not meet weight tolerances set by the checkweigher control panel. It can be used to reject underweight or overweight products from entering the rest of the production line.

Working Principles

Checkweigher use a combination of weight, speed and length measurements to analyze the weight of an item. They measure these three parameters to assess if a product meets its predetermined weight range. Checkweigher machines are typically composed of four main components: tension rollers, weigh bridge, rejector and controller.

Tension rollers feed products through the checkweigher at a constant rate, allowing for precise measurement. The weigh bridge is the device that physically measures the items’ weights as they pass over it.

As soon as it senses the item is outside of its pre-set range, the rejector removes it from production line and stores it in a designated area until further inspection or repackaging is required. The controller records the weight readings and analyzes it to calculate the final result.

Applications

Automatic checkweigher weighing machine is widely used in a variety of industries and applications. Checkweighers can be used for anything from food and beverage items, to pharmaceuticals, industrial parts, and other objects.

c)Automatic Bench Top Scale Weighing Machine

A bench scale is an automatic weighing machine that is usually mounted on a stand or bench top for easy use. This type of automatic weighing machine has a wide range of uses including measuring small quantities of ingredients or products for industrial or laboratory purposes. It also offers highly accurate readings regardless of the load size.

Components

Weighing Platform

The weighing platform is the base of bench scale and it consists of a large flat surface on which the items are placed for weighing. These platforms are typically constructed from stainless steel or aluminum to provide stability and accuracy when weighing.

Load Cell

This component measures weight, converting it into an electrical signal. The load cell consists of a strain gauge on a small metal platform. When weight is applied to the platform, the strain gauge measures the amount of force exerted on it and converts this information into an electrical signal.

Digital Display

This component displays the weight measurement in digital form. It is typically a LCD display that can also be used to change settings or enter data.

Digital Interface

This component enables the bench scale to communicate with a higher level of system, such as computers and other equipment connected through USB or Ethernet cables. The interface allows for easy integration of bench scales into larger systems.

Keyboard and Keypad

The bench scale may include a separate keyboard and keypad which allow the user to enter data or change settings.

Power Supply

This component provides power to the bench scale and is typically an external power adapter that plugs into a wall outlet or other source of power.

Enclosure

This component is optional and is typically used to protect the bench scale from dust, dirt and other harmful elements. It consists of a metal frame or plastic case that encloses the bench scale components.

Working Principles

An automatic bench scale machine works by relying on a series of load cells, which detect changes in force or pressure and convert them into electrical signals that can be read by the machine’s electronics. The bench scale then calculates this data to determine the size and weight of the object.

Applications

An automatic bench scale machine is a great tool to have in many businesses.They are used in many industries ranging from retail, food processing and manufacturing to packaging, logistics and research.

d) Automatic Crane Scale Weighing Machine

A crane scale is an automatic weighing machine that is attached to a hoist or crane hook for measuring large items with ease. This type of automatic weighing machine can be used in industries such as transportation, construction, agriculture, etc., to weigh heavy items without having to move them manually.

Components

Load Cell

This is the main component of an automatic crane scale and is responsible for measuring weight. It works by converting the mechanical force of a load into an electrical signal which can be read by a controller.

Controller Unit

The controller unit receives and processes data from the load cell to measure, display, and record the weight of the load. It is typically equipped with a display and keyboard for user input.

Display Unit

The display unit displays the output from the controller unit and allows users to easily view measurements such as weight, tare weight, gross weight, etc.

Power Supply

An automatic crane scale requires a power supply to provide electricity to the load cell, controller unit, and display unit. This is typically provided by either an internal battery or external AC power source.

Support Structure

The support structure provides stability for the automatic crane scale, allowing it to safely handle heavy loads without tipping over or moving around. It also houses the load cell, controller unit, and display unit.

Weighing Hooks

Weighing hooks are used to securely attach the automatic crane scale to a load or object that needs to be weighed. Typically, they are designed to quickly and easily attach and detach from the automatic crane scale’s support structure.

Weight Indicator

A weight indicator is an optional component that allows users to view the weight of a load remotely. It receives and displays data from the automatic crane scale, typically via cable or wireless connection.

Working Principles

An automatic crane scale works by using a hook attached to a steel cable, which is connected to the scale’s controller. Once the object is hooked onto the scale, an automatic reeving unit (ARU) takes the slack out of the cable, and then the scale automatically records the weight of the object.

Applications

An automatic crane scale machine can be used in a variety of industries including mining, transportation, construction and engineering. It can be used to measure the weight of goods or materials that are being transported or lifted by a crane like structure.

7.What Is The Difference Between Automatic Weighing Machine And Manual Weighing Machine?

Automatic Weighing Machine

b) Manual Weighing Machine

The automatic weighing machine uses automatic measuring technology, which provides a fast and accurate method of measuring weight. This type of machine is typically used in industrial settings and can weigh items quickly in large quantities.

Its accuracy depends on the precision of the sensors used as well as on the calibration of the machine itself. In contrast to manual weighing machines, automatic ones are usually highly expensive due to its complex components and design.

Manual weighing machines, on the other hand, are generally simpler devices with fewer parts involved. They use mechanical systems or levers to indicate weight values that result from balancing pans attached to arms placed over a scale beam.

Manual scales offer improved accuracy relative to automatic machines but require more time for data entry and lack automated features for processing data. They are also less expensive than automatic weighing machines, and can be used in home or laboratory settings.

8.What Products Can Be Measured Using An Automatic Weighing Machine?

Food Products

An automatic weight packaging machine is ideal for quickly and accurately weighing food products such as dried fruit, nuts, and cereal before packaging them.

Industrial Components

Components used in manufacturing processes like bolts, screws, washers and other metal pieces can be accurately weighed using automated machines.

Pharmaceuticals

Automated weighing machines are essential for ensuring accurate doses of pharmaceutical drugs are dispensed, especially when dealing with controlled substances.

Chemicals

Accurate chemical measurements can easily be obtained by automatic weight packaging machines during the production process.

9.What Type Of Packaging Materials Can Be Used With An Automatic Weighing Machine?

Pouches and Bags

Pouches and bags are the most widely used type of packaging material with automatic weighing machines. They can be made from a variety of materials, such as paper, plastic, foil, or cloth. The pouches and bags are typically filled with a product and then sealed before being weighed. The automatic weight packaging machine is able to accurately weigh each package for accurate shipping or storage.

Cartons and Boxes

Cartons and boxes can also be used in automatic weighing machines. These types of packaging materials are ideal for larger items that need to be shipped or stored in bulk. Cartons and boxes provide extra protection for products during transit and storage.

Trays

Trays are perfect for automatic weighing machines since they can hold multiple items and keep them organized. Trays also provide extra protection for fragile items and help to prevent damage during transit or storage.

Cans

Cans are commonly used with automatic weighing machines due to their durability and stability. Cans can be made from a variety of materials, such as plastic, metal, or cardboard, depending on the product being packaged. The automatic weight packaging machine will accurately weigh each can before it is sealed and shipped out.

10.What Are The Maintenance Procedures Of An Automatic Weighing Machine?

Cleaning

Automatic weight packaging machines should be cleaned periodically to ensure they are free from dust and debris. This will help them work more efficiently and accurately.

Calibration

Automatic weight packaging machines should be calibrated regularly to ensure the readings are precise and accurate. Calibration can be done using a calibration weight or other reference equipment, depending on the type of machine used.

Regular Inspection

Automatic weighing machines should be inspected for any damage or wear & tear that may affect its performance and accuracy. Any worn out parts should be replaced as soon as possible to prevent further problems from occurring.

Troubleshooting

If automatic weighing machines are not working properly, it is important to troubleshoot and determine the cause of any issues before making repairs or replacing parts. A qualified technician should be contacted for assistance if necessary.

11.What Are The Common Challenges Associated With Automatic Weighing Machines And Their Possible Solutions.

Automatic weighing machines are an excellent tool for accurate measurement but common issues may occur if they are not properly maintained or used correctly. They include:

Jamming

Automatic weighing machines are prone to jamming problems due to dust, dirt and other elements that get stuck in the mechanism.

Possible solutions

Regular maintenance of the machines and frequent cleaning.

Power Outages

Automatic weighing machines are powered by electricity and when there is a power outage, the automatic weighing machine can go offline, preventing it from producing accurate readings.

Possible Solutions

Having an uninterrupted power supply (UPS) system installed and using a generator to provide backup power.

Data Loss

An automatic weighing machine may suffer data loss if it is not properly backed up or if incorrect settings are used during operation.

Possible Solutions

Backing up all data on an external hard drive or cloud storage, as well as setting automatic backups at regular intervals.

Mechanical Malfunctions

Automatic weighing machines can experience mechanical malfunctions due to wear and tear or improper use, leading to inaccurate readings and incorrect measurements.

Possible solutions

Regularly inspecting the automatic weighing machine for signs of damage, keeping it well-maintained and ensuring that only authorized personnel are allowed to operate it.

CONCLUSION

An automatic weighing machine is a great investment for businesses in all industries from food processing to manufacturing. Not only do they help cut costs but they also help increase the speed of operations by making the weighing process more efficient and user-friendly. Furthermore, with customizable features such as LCD displays and integrated control units, it provides ease of control over the entire system. With all these benefits, an automated weighing machine can revolutionize any business. In addition, Proper use and maintenance will ensure reliable operation, safety and security for many years. Therefore, if you have been considering purchasing an automatic weighing machine for your business, contact Allpack today for more information about the perfect machine for your needs. With their experienced team of experts ready to answer any questions you can be rest assured of a perfect solution. Make the switch today!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp:+86 18171018586

Tell us your material or budget, we'll reply you ASAP within 24 hours

Tell us your material or budget, we'll reply you ASAP within 24 hours