Back Sealing Powder Packing Machine: The Complete Buying Guide In 2025

Powders are ground materials that are easy to use and apply, and have more stability and rapid action. Due to their incredible benefits, its market is continuously growing and it’s a daunting task to package the powders in multiple packages effectively.

As technology advances, the instruments used for powdered goods packaging have also evolved, offering value and ease to your business. What if a device precisely packages powdered materials with surgical accuracy, guaranteeing that each gram is precisely measured?

Imagine a tool so flexible it could accurately measure everything from coarse pharmaceutical powders to fine spices. Enter the world of the back sealing powder packing machine, where efficiency and creativity blend seamlessly to provide flawless automated packaging.

I know choosing the right back sealing powder packing machine can be a difficult task without proper knowledge. In this guide, we will explore the fundamental aspects of the back sealing powder packing machine.

So if you want a better understanding of the back sealing powder packing machine, read this guide.

1.What is a back sealing powder packing machine?

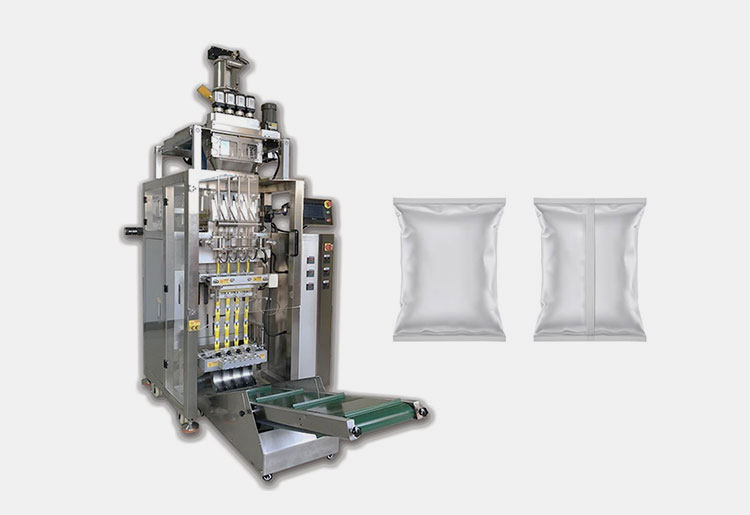

Back Sealing Powder Packing Machine

The back sealing powder packing machine is a packaging technology designed to form, fill, and seal the individual powder sachets. The device is widely employed in the food, pharmaceutical, and cosmetic sectors, making it easier to package a wide range of powdered goods, such as protein powders, flour, spices, powdered drugs, and powdered milk.

A back sealing powder packing machine can automatically complete the whole operation of measuring, filling, sealing, and cutting. It can be an excellent addition to your business.

2.How can a back sealing powder packing machine be utilized for different applications?

The powdered goods are difficult to package manually, therefore, a back sealing powder packing machine is designed, which has been adopted by many industries due to its prodigious benefits. The common industries that are utilizing the back sealing powder packing machine are:

Food and Beverage Industry

Applications in the Food and Beverage Industry

The back sealing powder packing machine is the most popular equipment in the food sector, efficiently packaging items in various packages. Some usual products include flour, powdered milk, coffee powder, salt, spices, and protein powders.

Chemical Industry

Applications in the Chemical Industry

In the chemical industry, the back sealing powder packing machine is utilized for packaging items, such as detergents, pesticides, dyes, and powder coatings efficiently.

Pharmaceutical Industry

Applications in the Pharmaceutical Industry

The back sealing powder packing machine is used in the healthcare industry to package powdered drug products into sachets accurately and in uniform dosing.

Cosmetics Industry

Applications in the Cosmetics Industry

Some notable cosmetic products that can be efficiently packaged using a back sealing powder packing machine are skincare powders, baby powders, and makeup powders.

3.What are the benefits of a back sealing powder packing machine?

Owing to heightened rivalry in the market, several manufacturing firms need to conceive a strategy that separates their brand from that of their rivals. Customers could choose a product whose packaging is more attractive and effective.

Hence, the back sealing powder packing machine is a good choice for businesses looking to expand brand exposure and awareness through effective packaging. Apart from sparing you from the tedious process of manual packaging, an automatic back sealing powder packing machine will offer the following benefits.

Cost-Effectiveness

Cost-Effectiveness

Installing a back sealing powder packing machine undoubtedly requires a huge investment, but if you consider the long-term benefits, it is a worthy investment. It can lessen labor expenses and processing time. Additionally, it can exclude potential human errors.

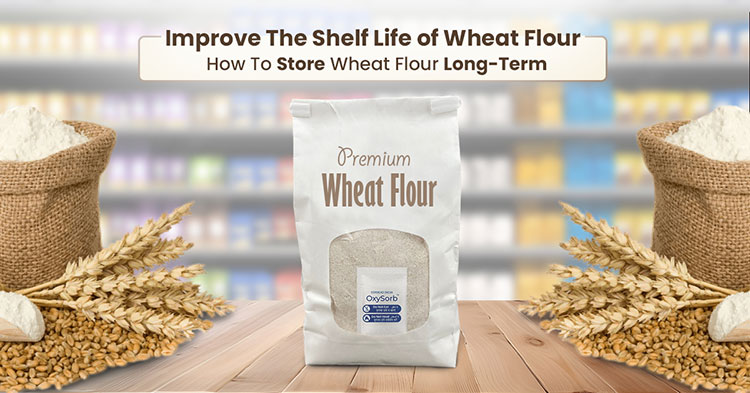

Extended Shelf-Life

Extended Shelf-Life

The back sealing powder packing machine is crucial for maintaining the product’s freshness, eventually increasing its shelf-life while maintaining its inherent qualities.

Enhanced Functionality

Enhanced Functionality

The multi-tasking property of the back sealing powder packing machine allows you greater productivity in a limited time frame with preserved accuracy and efficiency. It can accomplish various tasks utilizing advanced technologies, such as sachet formation, filling, sealing, and cutting with minimal human labor.

Increased Brand Worth

Increased Brand Worth

The back sealing powder packing machine offers flexibility in powder packaging, making it simpler to develop several product designs to establish brand recognition because the product presentation is a key factor in drawing potential customers.

Adaptability

Versatility

One of the key benefits a back sealing powder packing machine provides is versatility in various product processing and packaging designs. It can handle different forms of powders effectively.

Improved Product Quality

Improved Product Quality

Automated processing of the back sealing powder packing machine minimizes the intervention of human labor, resulting in hygienic operation and protecting the product from cross-contamination, ultimately resulting in improved product quality.

4.What are the key components of a back sealing powder packing machine?

The back sealing powder packing machine consists of multiple parts that play a crucial role in its functioning. In this section, we will focus only on the major parts and their description.

Components of a Back Sealing Powder Packing Machine

| Components | Description |

| Packaging Roll Film | The packaging material film roll from which sachets of desired dimensions are fabricated. |

| Material Hopper | The container of powdered material allows a specific amount of powder to be filled in each package. It is an enclosed space located at the top of the machine. Its size and capacity vary with different models. |

| Control Panel | The regulatory screen through which process parameters are monitored and adjusted accordingly. |

| Sachet Molding | The section where packaging film is molded into specified length and width of sachets. |

| Power Switch | It connects the device to the main power supply which is required for machine operation. |

| Heat Sealing | The area where the filled sachets are sealed effectively via heated sealing bars or clamps. |

| Filling Funnel | The component that is responsible for the accurate filling of sachets. It contains a nozzle for the material to ooze out and a filling mechanism, either auger or volumetric cup. |

| Separator | The section where the sealed sachets are separated from the continuous film. |

| Universal Wheel | The wheels are responsible for the easy transport of the device. |

| Exit | The outlet point that expels individual sachets outside the device. |

5.How does a back sealing powder packing machine work?

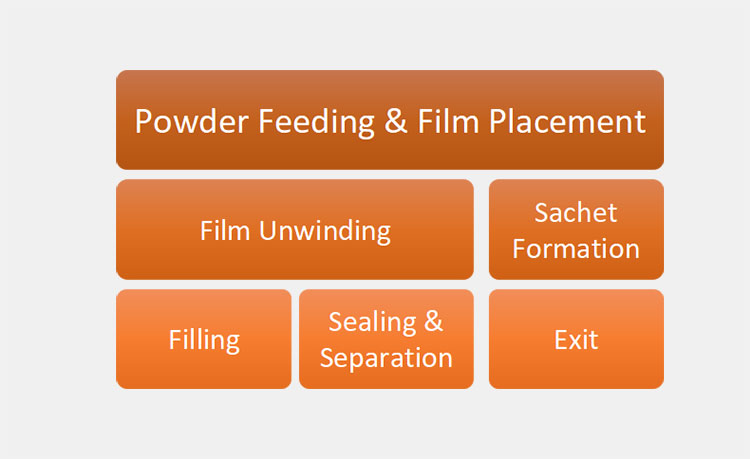

Working on the Back Sealing Powder Packing Machine

Despite the new advancements, the basic operational protocols of the back sealing powder packing machine continue to be the same. Here are the basic steps involved in the working process.

Working Steps of the Back Sealing Powder Packing Machine

Powder Feeding and Film Placement: It is the first step of the process that involves the recommended packaging material film roll placement in particular order to ensure smooth feeding of film. Furthermore, a significant amount of powdered material is poured into the hopper.

Film Unwinding: In this step, the film roll gets unwound to feed the film to the machine for sachet fabrication.

Sachet Formation: This step has the involvement of the shaping or packing molding section where the film is folded into desired dimensioned sachets.

Filling: Here the formed sachets are placed under the filling nozzle to be filled from the precise dose powder.

Sealing and Separation: In this step, the filled sachets are heat-sealed through sealing clamps/bars and separated from the remaining film.

Exit: This is the last step in which the ultimate filled and sealed sachets get an exit from the device.

6.What are the different types of back sealing powder packing machines?

Looking at the heft of options of the back sealing powder packing machine in the market can be overwhelming at times. Research and a comprehensive understanding of the device are important in selecting the right variant for your business.

Here we are enlisting some of the common device variants, classified on multiple aspects.

Orientation-Based Classification

Vertical Form Fill Seal (VFFS) Back Sealing Powder Packing Machine

Vertical Form Fill Seal (VFFS) Back Sealing Powder Packing Machine

The vertical form fill seal (VFFS) back sealing powder packing machine is a widely employed variant in many industries, including food and cosmetics. It is an automated assembly designed to produce filled sachets of powdered goods. It is structured in a vertical orientation and occupies less space comparatively.

The device offers numerous benefits and operates at a high speed with accuracy and efficiency.

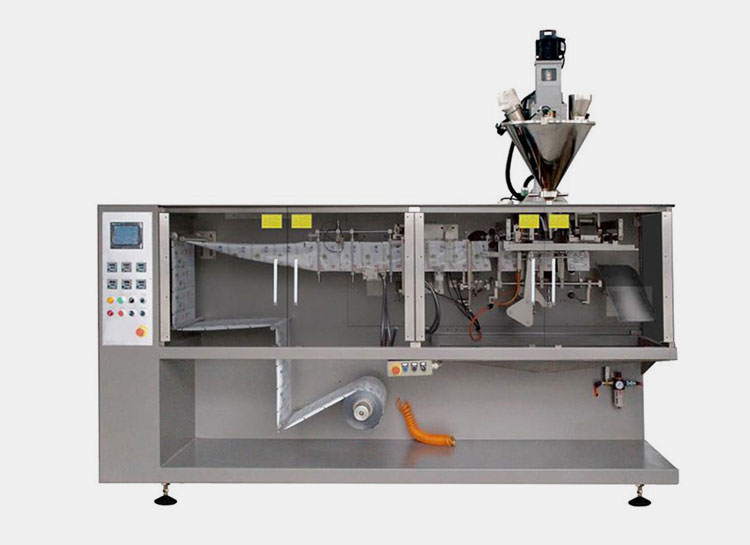

Horizontal Form Fill Seal (HFFS) Back Sealing Powder Packing Machine

AIPAK Horizontal Form Fill Seal (HFFS) Back Sealing Powder Packing Machine

The horizontal form fill seal (HFFS) back sealing powder packing machine is a popular device in large manufacturing sectors, differing in configuration. It operates with the same principle as VFFS but in the horizontal direction. It has a more compact and complex structure.

Packaging Format-Based Classification

Sachet/Pouch Back Sealing Powder Packing Machine

Sachet/Pouch Back Sealing Powder Packing Machine

This type of back sealing powder packing machine is specifically designed to automatically produce filled powdered sachets. The dimensions of the sachets can be adjusted as per requirements.

Stick Pack Back Sealing Powder Packing Machine

Stick Pack Back Sealing Powder Packing Machine

The stick pack back sealing powder packing machine efficiently produces powdered-filled stick packs. Stick packs are popular packages in the food industry and can be utilized for the instant use of powders.

Automation Based Classification

Semi-Automatic Back Sealing Powder Packing Machine

Semi-Automatic Back Sealing Powder Packing Machine

In this type of device, an operator is required to perform a few steps of the process, such as loading of the material, film placement, and discharging of filled sachets. The remaining process is automatically done by the machine.

Fully Automatic Back Sealing Powder Packing Machine

Fully Automatic Back Sealing Powder Packing Machine

This is an advanced form of equipment, utilizing the latest technologies to speed up the process without sacrificing the product’s quality. It only needs instructions from the operator, followed by the automatic functioning. It is equipped with sensors and automated mechanisms, allowing for efficient, accurate, and rapid production.

Filling Mechanism Based Classification

Auger Filler Back Sealing Powder Packing Machine

Auger Filler Back Sealing Powder Packing Machine

This type of back sealing powder packing machine utilizes an auger screw as the filling mechanism. The auger screw rotates and directs the precise amount of powder into each sachet. The amount of powder to be dispensed can be regulated by adjusting the screw rotations.

Volumetric Weigh/Cup Filler Back Sealing Powder Packing Machine

Volumetric Weigh/Cup Filler Back Sealing Powder Packing Machine

The volumetric weigh filler back sealing powder packing machine is an accurate device that can dispense precisely dosed powders into the sachets by measuring them.

7.What do you mean by free-flow and non-free-flow powders in the back sealing powder packing machine?

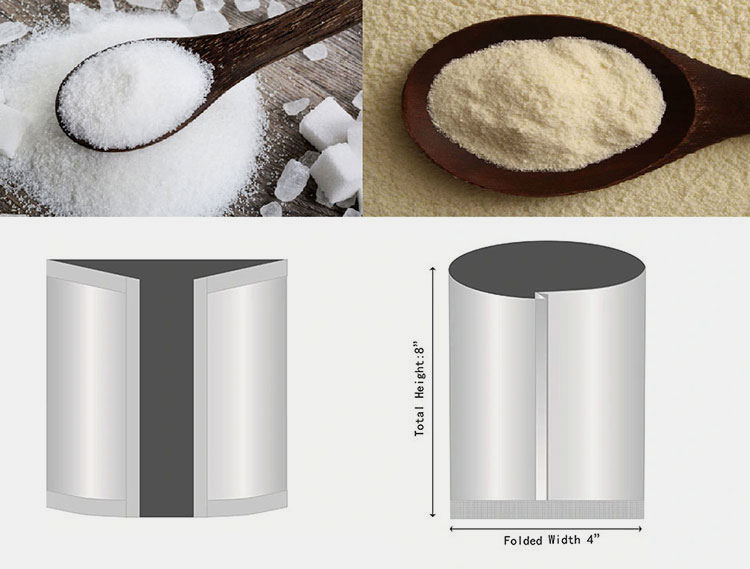

Free Flow Powder (Granulated Sugar) vs Non-Free Flow Powder (Powdered Milk)

Free-flow powders have non-cohesive particles, like in granulated sugar. It implies that they will flow easily while dispensing and no additional pressure exertion can compress or manipulate them.

Non-free-flow powders have cohesive particles, like powdered milk. They do not flow easily. Moreover, extra pressure can be applied to manipulate their structure into any desired form.

There is an unorthodox way to determine the nature of the powder (free-flowing or non-free-flowing), and that is the “Finger Test”.

Finger Test

Poke a finger into the vessel containing the powder. A non-free-flow powder will remain indented after finger removal (after initial pressing). On the contrary, in free-flow powder, the indention will not sustained.

This property determines the filler type you would need for your product’s efficient dispensing. For free-flow powder, an auger or volumetric cup filler will be preferred while for non-free-flow powders, a special auger filler can be utilized capable of handling the sticky products.

8.Why is it important for the back sealing powder packing machine to have suitable packaging material?

The correct packaging process is vital for maintaining the freshness and quality of your product. You can satisfy your consumer’s demands by selecting the appropriate packaging material and device.

Not convinced?

We are enlisting the primary reasons why choosing the right powder packaging and the back sealing powder packing machine is so important:

Airtight packaging prevents the product from humidity, air, and light which are the primary factors involved in the reduction of the product’s quality and freshness.

The packaging must be moisture-proof to avoid bacterial growth which can result in the degradation of the product, ultimately affecting its safety.

Light-resistant packing aids in the protection of products from UV rays: which can cause the degradation of certain products.

The right packaging and efficient processing help extend the product’s shelf-life.

So, it is important to ensure the right packaging material for each product type, but it will not be enough in case of the wrong selection of the device. It means that both the right packaging material and the back sealing powder packing machine are crucial for effective packaging.

9.What are the different filling techniques in the back sealing powder packing machine?

There are several filling techniques applied in the back sealing powder packing machine. The common ones are:

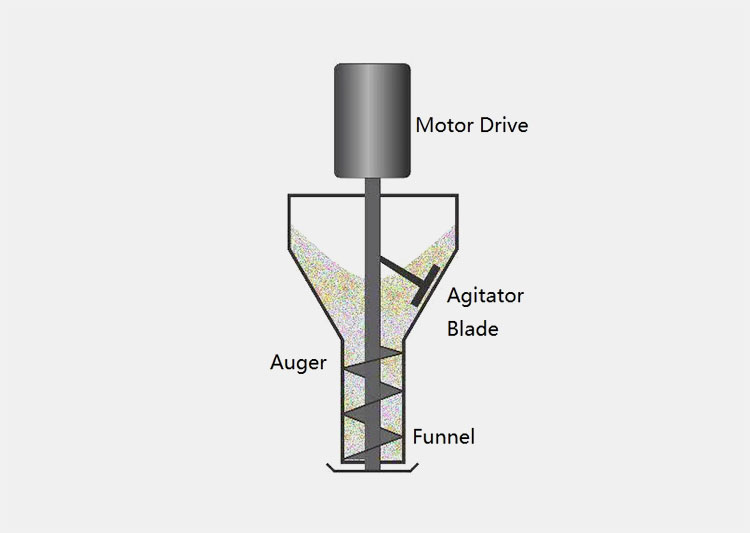

Auger Fillers

Auger Filling Mechanism

The powdered material is poured/kept in a cone-shaped hopper. The powder gets filled into the sachets using an auger screw/conveyor. The amount of the product to be dispensed can be controlled by regulating the number of rotations of the screw.

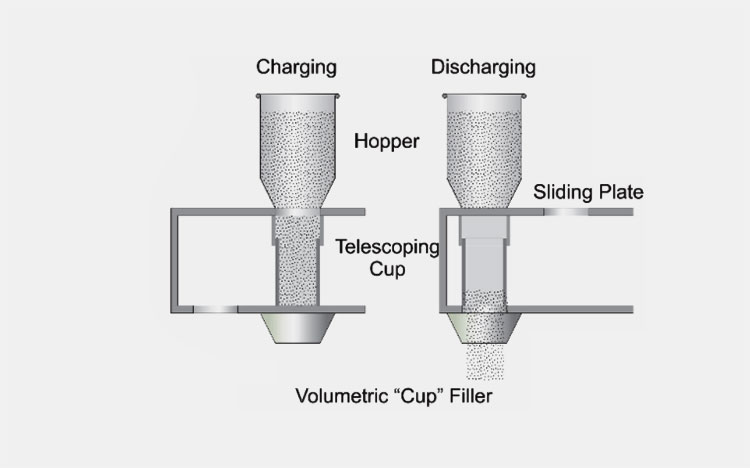

Volumetric Weigh/Cup Fillers

Volumetric Weigh/Cup Filling Mechanism

This is a suitable filling technique for linear feeders. It is flexible, accurate, and has a rapid speed. This type of filler measures the powders in precise weights and then fills them into pouches.

10.What should be done to extend the life of your back sealing powder packing machine?

Maintenance of the Back Sealing Powder Packing Machine

Continuous operation without proper maintenance can reduce the life expectancy of the device, ultimately resulting in a huge loss, both in terms of investment and production halt. It is therefore advised to develop and follow the scheduled maintenance programs for the device to keep it in optimal condition for a longer period.

Here are some tips that can be considered in developing a maintenance schedule that can help extend the life of your back sealing powder packing machine.

- Regularly clean the equipment with a soft cloth or a suitable cleansing agent.

- Determine a time frame for the deep cleaning of the entire device.

- Disassemble the machine and have a thorough cleaning of all the components periodically, particularly the parts in direct contact with the powdered goods.

- Sanitize the elements for food and drug products.

- Moving parts can reduce their movements due to friction after a specific period, therefore, keep lubricating all the moving components to ensure a smooth operation.

- Conduct a routine inspection of all the components of the device under the magnifier. It is done to detect any damaged or worn parts and in case there are; consider timely replacement or repair to avoid major issues.

- Calibrate the device regularly to ensure uniform procedure.

- Remember to conduct the maintenance through trained personnel.

- Document all the tasks performed in terms of maintenance for the record.

11.What are the causes and countermeasures for sealing defects of the back sealing powder packing machine?

Sealing Defect/Failure

“Sealing Failure” is the most common issue encountered in the back sealing powder packing machine. They are frequently caused by improperly adjusted settings. Seal failure can be referred to as various forms of sealing defects, like incomplete seal, wrinkled seal, etc. It not only has an impact on the product’s quality but also creates a negative image of the brand, leading to adversely affecting sales.

Cause and Countermeasures

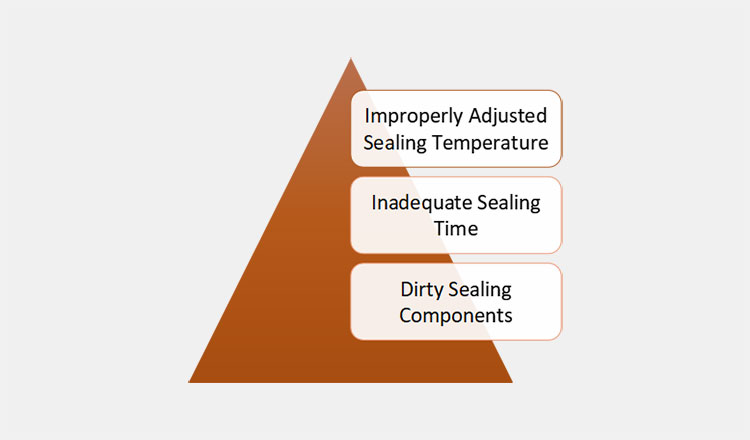

The packaging films are of various types, each differing in characteristics and requiring proper processing settings, otherwise, a defective sealing can result. The main causes are:

Causes of Sealing Failure

Improperly Adjusted Sealing Temperature

The packaging films vary in thickness. Each of them has a suitable temperature setting for sealing. In case of non-adjustment of the temperature, a defective sealing will be the outcome.

Countermeasures

Always check and validate the suitable temperature setting for the respective packaging film to avoid shrinkage or unevenness in sealing.

Inadequate Time of Sealing

For efficient working, a rapid production speed is required. However, the inadequate sealing time will result in the sealing failure, the frequent one is the seal peeling. The inadequate time with high temperature results in a broken seal. Moreover, as the strength of the seal becomes weak, it can burst on impact.

Countermeasures

Adjust the sealing time to be sufficient for an effective seal. Select a device that allows flexibility in sealing time.

Dirty Sealing Components

It is a common defect in which a foreign matter or the product gets entry into the seal part. It is usually caused by the lack of maintenance of the device.

Countermeasures

Thorough cleaning of the sealing components is necessary. Inspect that no film particles/residues are remaining on the sealing station.

12.What are the limitations of a back sealing powder packing machine?

Limitations of the Back Sealing Powder Packing Machine

The limitations of a back sealing powder packing machine are:

- It is compatible with the powders of flow properties to a certain level.

- Some variants are versatile, while others are suitable only for specific applications.

- Buying an advanced fully automatic back sealing powder packing machine demands a huge amount of money.

Automatic devices function through digital settings which are set before the process starts. In case of incorrect instructions, the device has no developed feature to distinguish the problem and will follow them. It is advised to validate the settings before pressing the start button.

The limitations of a back sealing powder packing machine vary as per the model type depending on the:

- Packaging Mechanism.

- Design of the device.

- Operational Principle.

13.What to look for when choosing a back sealing powder packing machine?

There are a large number of variants of the back sealing powder packing machine available in the market. It is therefore difficult to choose the best option for your business. Are you planning to invest in the back sealing powder packing machine, then here are some primary considerations that must be taken into account.

Cost

Assess Your Budget & Machine Overall Cost

Every manufacturer aims for profit. So, assess your budget and cumulative costs of the device and then choose the right option that should satisfy your needs efficiently.

Product Type

Product Type & Characteristics

You must know about the characteristics of your product and research about the features of different variants. Select a device that is compatible with your products.

Versatility

Flexible in Handling Multiple Product Types

If you have the required budget, you should choose a versatile device that can handle different kinds of powders and can package them in several package designs. It may help you achieve future objectives with a single investment.

Operational Mode

Semi-automatic or Fully Automatic Operational Mode

Based on your needs and budget, you can opt for either a fully automatic or a semi-automatic back sealing powder packing machine.

Regulatory Standards

Regulatory Specs

To guarantee safe and effective operation, always select the device that meets the requirements of all the regulatory standards, such as FDA, CE, cGMP, etc.

Device Efficiency

Efficient Device with High Productivity

The productivity rate determines the device’s efficiency. It varies with different variants, depending on several factors. Buy one that could satisfy your production demands smoothly.

Operational and Maintenance Ease

Operational & Maintenance Ease

Select a device having a user-friendly interface so that can be operated with ease. Additionally, it should be maintained with ease as well and the spare parts must be readily available to avoid machine breakdown.

Conclusion

Okay, so you have reached the end of this comprehensive buying guide, and by now, you should have a better understanding of the device. In short, the back sealing powder packing machine is a reliable equipment, ensuring the safe and effective packaging of powdered goods. Many food and non-food industries have adopted this amazing equipment due to its efficiency, high speed, and accuracy. If you are looking to invest in this amazing device or need any further assistance, contact Allpack, you will be guided to a better selection.

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide