Automatic Banding Machine:The Complete Buying Guide in 2025

Are you looking to buy an automatic banding machine, but finding it hard to choose from the seemingly endless array of choices on the market? With technology advancing at a rapid pace, buying a banding machine in 2025 can be overwhelming and confusing. But don’t worry, our complete buying guide is here to help! We’ll explain all the essentials that you need to know when selecting your machine.

Additionally, we’ve detailed common features and options for each type of product so you can find the perfect fit for your business needs. So if you’re ready for an efficient solution that will streamline production time and save money in the long run – read on!

1.What Is an Automatic Banding Machine?

An automatic banding machine is an industrial device that is used to automatically wrap and secure bundles of items, such as boxes or packages. It uses a coil of plastic film to wrap around the bundle, which is then cut and sealed with heat or adhesive tape. The machine can be programmed to accommodate different sizes and shapes of bundles, making it suitable for a variety of applications. The speed and accuracy of the machine make it ideal for high-volume operations, such as packaging warehouses and factories.

The automation of the automatic banding machine process helps to ensure a consistent, secure product every time. Because they are so versatile, automatic banding machines can be used in many industries and applications, including retail and food processing. With their ability to handle a wide variety of bundle sizes and types, these machines provide an efficient way to save time and money.

2.What Are The Components Of An Automatic Banding Machine?

The automatic banding machine has several components that work together to form a cohesive unit for efficient and reliable operation. The main components are:

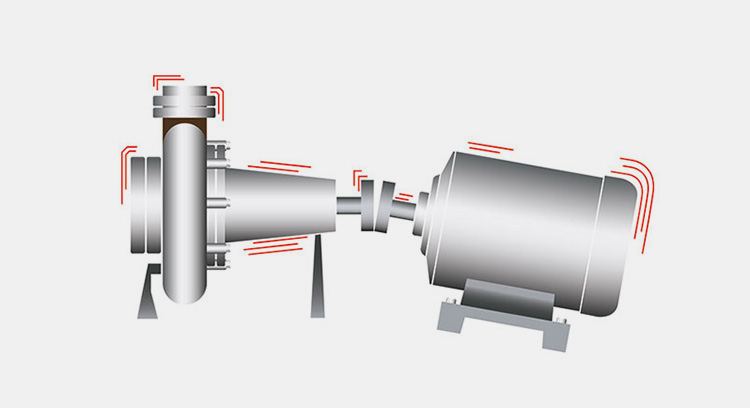

Feed Conveyor

This component is responsible for delivering the objects to be banded onto the belt. It can either be powered manually or by an electric motor, and it also typically features adjustable speed settings for different sizes of objects.

Pressure Rollers

The pressure rollers secure each object by pressing them gently against the belt and keeping them in place. This ensures that each item is securely banded without being damaged.

Banding Head

The banding head consists of a tensioner, which tightens the bands around the objects, and an applicator, which applies the bands to the items. This component also has adjustable settings for different sizes of objects.

Heat Sealer

The heat sealer is responsible for sealing the bands securely around the objects. The heat sealer can be adjusted to different temperatures, so it can be used for materials of varying sizes and thicknesses.

Control Panel

This component is responsible for monitoring and controlling the other components of the machine. It features a user-friendly interface with several adjustable settings for different sizes of objects.

3.How Does An Automatic Banding Machine Work?

The automatic banding machine is an efficient, cost-effective way to wrap bundles of products or materials together. The process begins when an operator places the bundle in a loading station. Next, the machine secures and tightens a plastic strap around the bundle to bind it securely together. The strap is then fed through either a rotating wheel mechanism or an arch type machine, depending on the size of the bundle. The wheel mechanism will wrap the strap several times around the bundle, and the arch type offers tension adjustments to provide a more secure hold.

Once the straps have been applied, they are automatically cut using either a stationary blade or automated cutting system that is built into the machine. The cut straps are then tightened and tensioned, to ensure that the bundle is securely fastened. Finally, the machine will knot the ends of the strap to complete the binding process.

The finished bundles can be placed in a collecting table or onto conveyor belts for further processing before being ready for shipment. The entire process is an efficient way to keep products and materials securely bound, with minimal operator intervention. The automatic banding machine is an ideal solution for any company looking to increase production efficiency and reduce labor costs. With a wide range of models available, there’s sure to be one to fit your needs.

4.What Are The Applications Of An Automatic Banding Machine?

An automatic banding machine is an essential tool in many industries, as it helps to streamline production processes by quickly and easily bundling products together. Here are some common applications of an automatic banding machine:

Food Industries

An automatic banding machine can be used to bind food items such as boxes of cereal, snack bags, and even produce. This helps to ensure that the food items remain secure during transit and storage. It also reduces manual labor time, which can help keep costs down.

Retail

An automatic banding machine is invaluable for retail applications such as securely bundling multiple items together for sale or shipping. It not only saves time, but can also help boost customer satisfaction by ensuring that the items arrive securely packaged.

Agricultural

An automatic banding machine can be used to bundle together plants and other agricultural products for transport or storage. It is also useful for bundling tools such as shovels and rakes for easy handling and storage in an agricultural setting.

Manufacturing

An automatic banding machine can be used to securely and quickly bundle together components that are used in the manufacturing process. This helps to keep costs down and ensures that the components remain organized and secure during transit or storage.

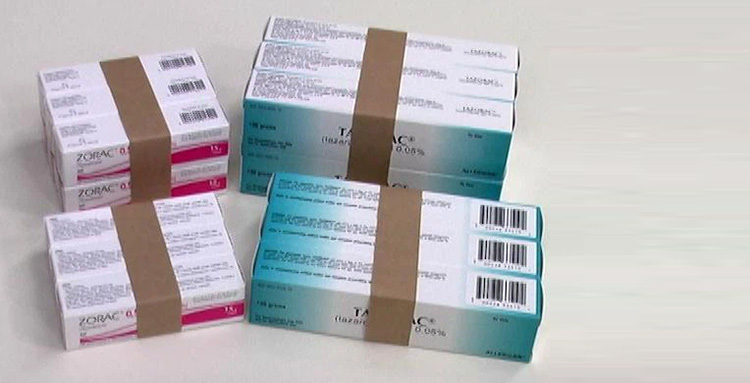

Cosmetic

Automatic banding machines are also useful for securely packaging cosmetic items such as makeup and skincare products. This ensures that the items remain secure during transit or storage, and can help to boost customer satisfaction by ensuring that the items arrive in perfect condition.

Logistics and Warehousing

Automatic banding machines are used to easily manage and move large shipments of goods for transportation, storage, and distribution in the logistics industry. This assists with keeping an accurate record of inventory movement as well as providing efficient packing solutions for customers.

5.What Are The Advantages Of Investing In An Automatic Banding Machine?

As an investor, you may be considering the purchase of an automatic banding machine. This type of equipment offers a number of advantages that can make it an ideal investment choice. Here are seven reasons why investing in an automatic banding machine could be a wise move:

Increased Productivity

An automatic banding machine can increase the productivity of your teams significantly by reducing the amount of manual labor needed for product packaging and shipping activities. This allows for you to package more products in a shorter period of time, enabling greater efficiency and cost savings.

Improved Accuracy

Automatic banding machines are designed to be precise, allowing for a more accurate delivery of packages to customers. This ensures that customers receive their orders on time and in perfect condition.

Improved Safety

Manual banding processes can be dangerous and lead to workplace injuries, whereas automatic banding machines have significantly fewer risks involved. This improved safety allows for a safer working environment for your teams.

6.What Are The Different Models Of Automatic Banding Machines?

There are several different types of automatic banding machines available on the market. Each type offers its own advantages and disadvantages, so it’s important to research each option before making a selection. The most common types of automatic banding machines are:

Continuous-Banding Machines

A continuous-banding machine wraps a continuous length of plastic or paper banding around bundles of items in one quick motion. This type of machine is ideal for large production runs because it requires minimal setup, and can quickly wrap a high volume of items with greater accuracy and consistency than manual methods.

Side-sealing Machines

Side-sealing machines are designed to secure items in place before packing them into boxes. They use a flexible banding material, such as plastic or paper, to wrap around bundles of items and keep them secure. Side-sealing machines typically require more setup than continuous-banding machines but are ideal for small production runs.

Inline Banding Machines

Inline banding machines are designed to wrap bundles of items in a single, continuous motion. These machines are ideal for high-volume production runs, as they can quickly and accurately band hundreds of items at once. They’re also able to wrap irregularly shaped items due to the adjustable tension settings available on many models.

7.What Types of Materials Can Be Used With An Automatic Banding Machine?

An automatic banding machine can be used for a wide variety of items, depending on the size and shape of the material and desired outcome. Common materials that are suitable for use with an automatic banding machine include:

Plastic Straps

Plastic straps are the most common type of material used with an automatic banding machine. They are lightweight, durable, and relatively inexpensive to produce. These straps come in a variety of colors and can be customized based on the size and shape of the item being packaged.

Steel Straps

Steel straps are heavy-duty material used when extra strength is needed for package security. They are more expensive than plastic straps but will provide more security and are harder to break.

Fabric Strapping

Fabric strapping is often used when a banding machine is needed for an irregularly shaped item or objects that need to be tightly secured together. It is lightweight, flexible, and comes in different widths depending on the size of the items being packaged.

Cord Straps

Cord straps are the perfect material for lightweight tasks that involve bundling items like cables, wires, or cords together. They’re made from a durable polyester cord that resists wear and tear, and they can be tightened to the exact needs of whatever task you’re working on.

Paper Board

Paper is a lightweight, versatile material that can be easily and securely held together with an automatic banding machine. It is often used to bundle smaller items together or to keep documents organized.

8.What Types Of Products Can Be Packed By An Automatic Banding Machine?

An automatic banding machine is a highly efficient tool for packaging products. It can be used to wrap various items quickly and securely, providing an economical solution for businesses needing reliable product protection and presentation. Some of the different types of products that can be packed by an automatic banding machine include:

Beverage bottles and cans

Beverage bottles and cans can be securely wrapped with a banding machine. It provides extra protection for the product, helping to reduce damage during transport and storage.

Food products

Many food products such as chips, cookies, and crackers can be quickly sealed in protective packaging using an automatic banding machine. That keeps food fresh and prevents them from becoming stale.

Hardware Items

Hardware items such as nuts, bolts, screws, and washers can be wrapped with a banding machine. This helps to protect against corrosion and other damage that could occur during storage and transport.

Bags and Pouches

Automatic banding machines are an ideal solution for packaging bags and pouches. The machine can easily wrap individual items or bundles of products in film, paper, or plastic to ensure they stay secure during transport and storage.

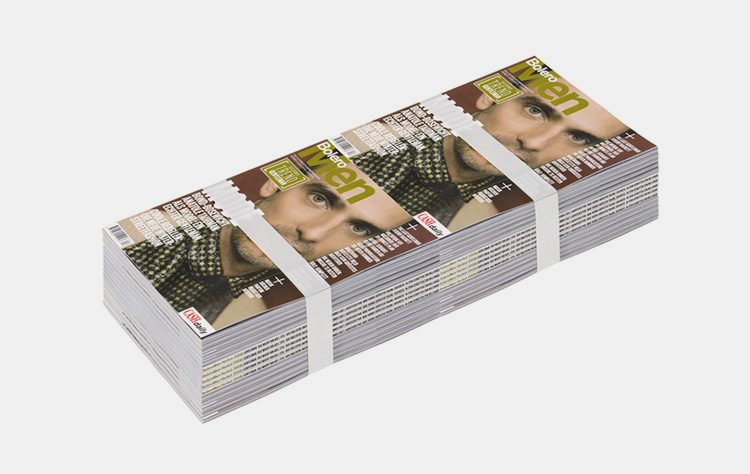

Books

A banding machine is a great asset when packaging books or magazines in bulk. It ensures that each item remains securely bound until it reaches its destination, keeping the contents safe from damage during transit.

Cases

Cases of goods such as electronics, medical equipment, and other fragile items can be securely wrapped using an automatic banding machine. It helps to keep the goods protected and ensures they are properly presented when they reach their destination.

Cartons

Automatic banding machines are also great for packaging cartons of items. That allows businesses to securely secure multiple items while still being able to identify each individual item if needed.

Pallets

Automatic banding machines can be used to package entire pallets of goods at once, making it easier and faster to ship them out to customers or warehouses. The machine can be used to securely wrap the entire pallet in film or paper, ensuring that it remains intact and secure during transit.

Lotions and creams

Automatic banding machines can be used to package lotions, creams, and other liquids. This helps to prevent leakage during transit and storage and keeps the products safe until they reach their destination.

9.What Are The Most Common Issues With Automatic Banding Machines And How Can They Be Fixed?

While automatic banding machines are designed to be efficient, reliable and easy to use, you may find that issues arise from time to time. The most common issues you may are:

Electronic Issues

Automatic banding machines are prone to electronic issues due to their reliance on intricate circuitry, making it more difficult to troubleshoot them than mechanical problems. Common signs of an electrical issue include the machine not powering up, failing to start when commanded, or having unusual noise coming from it.

Solution: The best way to fix an electronic malfunction is to consult the machine’s user manual or contact a professional. DIY repair attempts are not recommended as this can cause further issues.

Misaligned Parts

If the parts of a banding machine are misaligned, it can prevent it from correctly feeding and sealing straps.

Solution: The issue can be resolved by adjusting the alignment of the various components in the machine.

Mechanical Problems

Automatic banding machines can suffer from mechanical issues such as a broken belt, damaged parts, or worn-out components. Common signs that your machine needs a mechanical repair include it stalling during use or having difficulty positioning the banding material properly.

Solution: Depending on the severity of the problem and your experience level, you may be able to carry out the mechanical repairs yourself. If not, seeking help from a professional is recommended.

Jammed Rollers

Automatic banding machines use rollers to feed the banding material into place, but these can become jammed due to a variety of reasons. Common signs of a roller jam include the machine refusing to start or having difficulty positioning the banding material correctly.

Solution: The best way to fix a roller jam is to carefully unjam the roller by hand, or you can consult the machine’s user manual or contact a professional for help.

Clogged Filters

Another common issue with automatic banding machines is the buildup of debris in their filters. This can be caused by a variety of factors such as dust or dirt.

Solution: Regularly inspect and clean your machine’s filters in order to prevent clogs from occurring. You can also purchase replacement filters for your machine if needed.

Inconsistent Band Tension

Automatic banding machines need to apply a consistent amount of tension across the band in order to successfully secure items. If the amount of tension varies from one side of the band to the other, the items may not be properly secured.

Solution: To ensure consistent band tension, you can adjust the amount of tension in the machine’s settings or contact a professional for help. Additionally, regularly checking and replacing worn-out components can also help to prevent this issue from occurring.

Poor Quality Banding Material

If the quality of the banding material is not up to standard, it can cause problems with the machine. Common signs of this issue include bands breaking easily or having difficulty positioning them correctly.

Solution: To fix this problem, you should check that you are using a good quality banding material and replace any damaged or worn-out components. Additionally, regularly checking and replacing the banding material can also help to prevent this issue from occurring.

Incorrect Settings

If you’ve recently changed any settings on your automatic banding machine, it’s possible that they may have been set incorrectly.

Solution: Make sure to double-check all of the settings in order to ensure that they are correct and properly adjusted before attempting to use the machine again. If necessary, refer to your machine’s manual in order to properly set its settings.

10.Are There Any Features That I Should Look For When Buying An Automatic Banding Machine?

When buying an automatic banding machine, there are many features you should look for that can help ensure the product’s success. The following is a list of key features to consider:

Speed

If you need to complete tasks quickly, look for an automatic banding machine that has adjustable speed settings. This way you can adjust the speed depending on your needs and not be limited by the default setting of the machine.

Adjustable Width Settings

Many automatic banding machines come with adjustable width settings, allowing you to tailor the exact size of your bands to the application. This is essential for ensuring your bands are tight, secure and properly formed.

Automatic Feeders

Automatic feeders help to ensure that the machine can keep up with high production runs without manually having to place items into the banding process each time. This not only helps speed up production but also reduces labor costs associated with manual feeding.

Automatic Tension Control

This feature allows for the tension of the banding material to be adjusted automatically, ensuring that your bands are secure and properly formed each time. It is essential for ensuring consistent results throughout production runs.

Safety Features

Many automatic banding machines come with safety features such as emergency stops, guards, and sensors that can help protect operators from harm during operation. This is essential for ensuring a safe working environment and avoiding potential hazards.

Heating Element

Some automatic banding machines come with a heating element that is used to heat the banding material in order to make it more malleable and able to form tightly around items or bundles. This is essential for ensuring secure bands each time.

Quality Control

Some automatic banding machines come with in-line quality control systems that can be used to verify the strength and security of each band applied. This is essential for ensuring consistent product quality throughout production runs.

Warranty

Any automatic banding machine you purchase should come with a warranty, so that in the event of any malfunction or defect, you can rest assured that it will be covered.

These are just some of the features you should look for when buying an automatic banding machine. However, depending on your specific needs and application, there may be other features that you should consider. It is important to do your research and choose the machine best suited for your needs. With the right machine, you can ensure that your production line runs smoothly and efficiently with minimal disruption or downtime.

Conclusion

Automatic banding machines have revolutionized the packaging industry in many ways. If you are considering investing in an automatic banding machine for your business, you should consider all aspects when making your decision. Be sure to research the features and capabilities of each kind of machine, as well as their cost and maintenance requirements. That being said, Allpack has a wide selection of reliable and high-quality machines that can help make packaging easier and faster. Contact them today to learn more about how they can help satisfy your banding needs.

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide

Tell us your material or budget, we'll reply you ASAP within 24 hours

Tell us your material or budget, we'll reply you ASAP within 24 hours