Your Complete Buying Guide For Vacuum Packing Machine In 2025

Your Complete Buying Guide For Vacuum Packing Machine In 2025

In case, if you are big business or are into bulk shopping, the long lasting preservation is must, You should invest in the vacuum packing machine to maximize your dollars even more.

Anyone who does not know vacuum packing machine, its a device use for sealing and packing the products so they can be used in the long run. Due to the versatility of the vacuum packing they can be used in the multiple industries. It is way better process of keep the food fresh when compared with the traditional methods. This machine eradicate all the air so mold or anything like that does not occur.

In this guide, we will drive you through all the details you need to know before making your purchase decision. Let’s get started.

1.What Is A Vacuum Packing Machine?

Vacuum packing machine is a machine that packs the products (food, medicines, etc.) in packets by vacuum. This machine works for the removal of the air particles from the product by making it preserved for a longer period of time.

The vacuum Packing machine has the ability to make a vacuum type atmosphere in the bottles which helps the product to remain fresh for longer period of time.

So, the main purpose of this Vacuum Packing Machine is the removal of the oxygen or other gases from the products.

2. What Is A Cryovac Machine?

The Cryovac Machine also works for the drying or removal of air from the products. The method of removing air is also called Vacuum Sealer.

This Cryovac Machine is also used for the long preservation of food. So, this machine efficiently works in the storing of food.

Cryovac Machine Credit: amazo.com

3. What Type Of Technology Are We Using In Vacuum Packing Machines These Days?

The types of technologies we are having these days are:

Nozzle Type

The Nozzle Type Vacuum Packaging is easier to use than the other types of packaging machines. The function of this type is to remove the air from the products.

There is a heater present in this Nozzle type packaging machine which dries the product and makes the product air free. In this process air is expelled out from the nozzle present in the packaging machine.

This type of packaging machine is specially built for the drying of the meat products. But other products can also be made air free from this Nozzle type packaging machine.

There are bags present in the Nozzle type packaging machines. These bags are made of aluminum wires.

The process of vacuumizing the products is done automatically. So, there is no need for any labor to do that. Also sealing of the product is done automatically.

Chamber Type

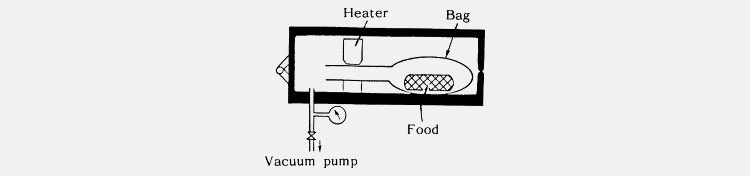

The Chamber type vacuum packaging machine is also used to put out air from the products. There is a vacuum pump, heater and a bag is present in this type of machine.

The product is being placed inside the bag and after that the heater works for the drying of that product. The vacuum pump removes all the air from the product. The air is expelled out through the vacuum pump.

The Chamber type vacuum packaging machine uses the degree of vacuum is almost 0.5 torr to 8 torr. This machine is not fully automatic. It is a semi-automatic machine. The food in this machine is loaded manually.

At the same time dozens of the food is being loaded in the Chamber type packaging machine and also being sealed.

Skin Type

The Skin type packaging machine is also used to remove the air from the products by vacuum present in it. The machine softened the food products. It also gives heat to the food to make it dry.

The Skin type packaging machine also increases the value of the product or food. It also affects the display of food and makes it perfect for the customer.

Mainly this type of packaging can be completed by loading the food or product into the machine and also applying the lid over it.

Skin Type Credit: vacuumpacker.en.made-in-china.com

Deep Draw Type

The Deep Draw type of vacuum packaging machine has a heating plate in it which dries the food. The product is also kept in bags for removal of air. There is a pump through which the air is expelled out of the machine.

There are two films present in the Deep Draw type packing machine. The one is the upper film and the other one is the lower film. And these films are being sealed in the vacuum chamber.

The upper film covered the bag in making the air free product or food. The machine is fully automatic. Every process is controlled by the computer. From loading to trimming everything is done automatically. There is no need for any labor.

Deep Draw Type Credit: jawfeng.com

External Type

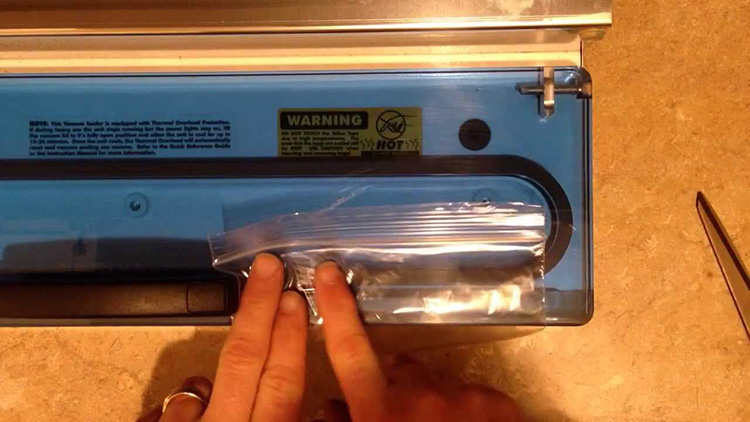

There is a bag attached with the External type Vacuum packaging machine. The external type packaging machine removes all the air from the food or the product and seals the bag.

This all process is done outside of the machine. The component that is used to seal the products is the heater sealer.

External Type Credit: okchem.com

Single Vacuum

In the Single Vacuum machines bag is used for the packaging process. The whole product is placed in the machine in the Single Vacuum Chamber Machine.

The removal of air is done when the lid is closed after placing the product in the equipment. After that, the heat produced by the heater seals the bag. Then again, the air is produced in the sealing process but the bag sucks all the remaining air in the machine.

In the next step the lid is open and the product is carried out from the machine.

The low and medium volume packaging is done by the Single Vacuum Chambers. The liquid products can also be sealed by this equipment. The bag sucks all the liquid from the product.

Single Chamber Credit: jawfeng.com

Double Vacuum

In this type of Packaging machine, the product is placed in the bag not in the machine. And the same process continues when the lid of the machine is closed, the removal of air starts.

Then the product is again sealed in the bag. And the pressure of air created in it is sucked by the bag. And the product is removed from the machine.

This type of packaging machine is used only for medium volume packaging. This also increases the rate of production and the speed. This machine has the special function that the lid is fully automatic.

We can do this type of packaging of the products such as meat, cheese, chocolate and candy.

Rotary Belt Type

The Rotary Belt Type Machine has the same functions as the Double Chamber Vacuum Packing Machine. The Rotary Belt Equipment is the more convenient one than the other machines.

The movement of the belt in this machine is done automatically to complete the process of the sealing. The loading and unloading of the product are also done automatically in this equipment.

By the adjustable packaging plate, the packaging of liquids and soup can also be done by this machine. The plate is almost adjustable to 4 degrees.

The machine is mainly used in the packaging of SeaFood, Pickles, Cheese, Meat.

Rotary Belt Type Credit: jawfeng.com

Automatic Belt

In the Automatic Belt Chamber Packaging Machine, the whole product or food is kept in the bag of plastic and wrapped within it. The product then starts working on the belt. All the methods of removal or air are automatic. The belt changed its position automatically too.

These types of packaging machines work very fast and at a very high speed. The large items can be packed easily from this packaging machine. It also seals the liquids.

This Machine is capable of packaging food like Meat, Large Sausage Logs and Cheese.

Automatic Credit : indiamart.com

Thermoforming Packaging

The Thermoforming Packing Machines can be used at the large scale. Large production can be done by this equipment. These machines have some rolls of packaging film.

The food or the product is kept into the thermoformed pockets. Thermoformed Plastic present in the machine is used to modify the size, shape, color, and the clarity of the product. This machine works perfectly.

This machine is very capable of packing the products like fresh and marinated meat, sausage, cheese, chocolate, candy and grains.

Thermoforming Credit: jawfeng.com

4. What Are The Benefits And Purposes Of Vacuum Packing Machine?

There are amazing benefits to using your vacuum sealer, including storing and preserving food for a long time. Take a look at the many benefits of vacuum sealing below.

Vacuum Packing Machine Credit: levapack.com

Protect from freezer burn

Vacuum sealing foods protect them from freezer burns and dehydration. Freezer burns occur when air comes in contact with water crystals around food. Vacuum sealing helps prevent air from escaping from food.

Freezer burns are not a threat to your health; however, it can ruin the taste and texture of food.

Fresher food for longer

Lack of air exposure allows for long-term protection and safety in the refrigerator or cabinet. Vacuum sealing protects food by stopping the growth of mold, fungus and bacteria.

This is great when buying seasonal items and food that spoils as fast as vegetables, lettuce and meat. It also works for nuts, pasta, crackers, other pantry items that become soft / stale when exposed to oxygen and moisture in the air.

Year-Round Fresheners

Another great use of vacuum sealing is to store seasonal items, such as tomatoes or berries, for winter use. This way you can get items all year round and when they are out of season, they taste amazingly fresh.

Increase Cabinet Space

Whether in the pantry or in the refrigerator and freezer, the place to eat can determine what is at hand. By vacuum sealing items and stacking or stacking them together, it saves space for more food items such as cans and cans.

Improve Taste, Marinating

Another major advantage of vacuum sealing is that it can be used for food and seasoning for extra flavor. Add pickles or spices to chicken, fish, or beef and then vacuum seal for a quick, amazing boost to your cooking experience.

Save Money on Bulk or Family Packs

There is no question that buying food in family packs or in bulk will give you a better value for your dollars. With vacuum sealing parts, you can save your family a lot of money throughout the year.

Shelf Life

Moreover, the shelf life of most of the food items is increased by the vacuum packaging. It always depends on the product, temperature, atmosphere and the barrier properties of the package.

By vacuum packaging you can increase the shelf life of metals also with the help of the adjustable atmospheric temperature.

Sous-vide

The next advantage of vacuum packaging is that it gives a special cooking method called Sous-vide cooking method. In this method the bag sealed the product in the poaches.

Vacuum Packing Machine Credit: levapack.com

5.How Do You Compare Chamber VS Suction Vacuum Packing Machines?

There are two types in terms of packing.

Chamber Vacuum Packing

The chamber vacuum sealers are utilized to store strong and fluid things. Chamber vacuum sealers utilize standard vacuum sealer pouches and full lattice vacuum sealer bags.

The vacuum sealer bags are utilized within the chamber machine. Chamber vacuum sealers can handle the measure of the vacuum.

Chamber vacuum sealers clear air from the chamber, leaving the gaseous tension equivalent both inside and outside the pouch and keeping fluids safely inside the pouch.

The chamber vacuum sealer doesn’t utilize any suction, which permits you to vacuum bundle soups, stews, marinades and different fluids. When utilizing this sort of vacuum sealer machine, you place the vacuum sealer pouch or container you are fixing inside the vacuum chamber.

Without utilizing pull the entirety of the air is emptied from the whole chamber. There are some small machines for home use just as commercial vacuum sealer sized machines for the businesses of the restaurants and the caterings.

Chamber Packing Machine Credit: indiamart.com

Suction Vacuum Packing

Suction food vacuum sealers suck out the air from the front of the bag and when the air is sucked out totally toward the finish of the cycle, the vacuum sealer bag is fixed and the process of the suction is completed.

All vacuum sealer bags and vacuum sealer pouches might be utilized with a chamber vacuum sealer machine. The chamber pouches, which must be utilized with chamber machines, don’t have the cross-section lining needed for suction bags.

Suction Packing Machine Credit: wellymachinery.en.made-in-china.com

6. What Food Should Not Be Packed By Vacuum Packing Machine/ Seal Machine For Food?

There is some food that should not be packed by the Vacuum Packaging Machine.

Vegetables, Fruits and Dairy

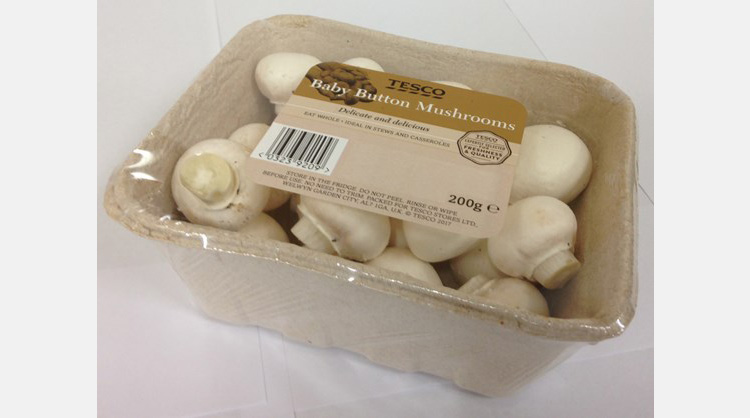

The mushrooms should not be packed by the vacuum packaging machine because of their natural ripening process. The fresh mushrooms can decay faster if packed by vacuum packing machine.

You can pack only the cooked mushrooms by the vacuum packaging Machine.

Mushrooms Packing Credit: nspackaging.com

The vacuum packaging machine makes the ripening time of bananas quicker than the normal one. So only the frozen bananas can be packed by the vacuum packaging machine.

This food also should not be packed by the vacuum packaging machine because the food creates a natural gas in the vacuum that can spoil the food.

Onions should also not be packed by the vacuum packaging machine. It has the same reason as the garlic. It can be spoiled if packed by the vacuum packaging machine.

Dairy Items

The hard cheese can be packed by the vacuum packaging machine but the soft cheese is not a safe food product to be packed.

Cheese Packing Credit: trendhunter.com

Vegetables

The freshly cooked vegetables should not be packed by the vacuum packaging machine because of its high temperature.

These vegetables may be lost in the vacuum. So, the hot vegetables should be packed when their temperature come equals to the room temperature.

Vegetables Packing Credit: landpacking.com

The whole apple should not be packed by the vacuum packaging machine because of its color. So, if you want to prevent it from discoloration, make slices of apple before packaging.

Apples Packing Credit: nnz.com

7. What Are The Different Components Of The Vacuum Packing Machine?

The different components of the Vacuum packaging Machines are as follows:

Vacuum gauge

The vacuum gauge is used to measure the pressure of the vacuum. It is mainly a pressure measuring instrument. It gives us information about the pressure of the vacuum.

Vacuum gauge Credit: rs-online.vn

Emergency Stop

Emergency stop is the component of the Vacuum Packaging Machine that works in case of any emergency. The equipment will stop automatically if any emergency occurs during the removal of the air.

Emergency Stop Credit: dreamstime.com

Set Key

Another component of the Vacuum Packing Machine is the set key. It used to set the temperature of the vacuum.

Increase Key

Moreover, an increase key is the component of the Vacuum Packing Machine which mainly used to increase the temperature of the vacuum inside the equipment.

Decrease Key

In addition, the decrease key is the component of the Vacuum Packing Machine which is used to decrease the temperature of the vacuum of the equipment.

Temperature Controller

The other component of the Vacuum Packing Machine is the temperature control. It is used to control the temperature inside the vacuum

Air Bag

The very main component of the Vacuum Packing Machine is the airbag. So, it is very important to choose the right one for the Vacuum Packing Machine. The bag should be chosen which has an open end that is shorter than the seal bar.

Air Bags Credit: webstaurantstore.com

Heating Element

The heating element of the Vacuum Packing Machine is used to provide heat to the product. So, it should be chosen wisely.

Filler Plates

So, the filler plates are used to take up the whole space inside the chamber. These plates are used to reduce the vacuum time also.

Filler Plates Credit: webstaurantstore.com

8. How Does A Vacuum Packing Machine Work?

A vacuum packaging machine is usually available in two designs:

- Automatic design

- Semi-automatic design

Both designs work with the same principle, the only difference is in the operations

Automatic Vacuum Sealing Machines

Automatic vacuum packing machine working principle:

- Filled containers are inserted into the machine by the operator.

- Parameters are set by the operator through the control panel. ( touch screen interface)

- Vacuum pump of the machine sucks out all the air from inside after containers enter the vacuum chamber.

Semi-Automatic Manual Vacuum Sealing Machines

Semi-automatic vacuum packing machine has almost same functions like automatic vacuum packing machines, the difference lies in the operating process as the operator needs more effort in the sealing process. The sealing process is manual as the operator has to manually fill each container in the machine and seal the container with the finger, pressing the switch. This sealing process is repeated for each container.

The Double Seaming Process

Once the air is removed from the containers the double seaming process starts:

- Compression

Can body is compressed by the machine in the direction of the seaming head holding the lid.

- First Roller Operation

The first seaming roller interconnects the can body’s projection with the lid’s whorl to form a slack seam.

- Second Roller Operation

The first seaming roller hideaways and therefore the second seaming roller advances and presses the seam from the primary roller operation to supply an enclosed seal

9. What Is The Size Of The Vacuum Packing Machine?

Depending upon the size of vacuum packing machines, it comes in different sizes. The below-mentioned table describes the size of different vacuum packing machines:

- Chamber dimension

- External Dimension

Thermoforming machine

This type of vacuum packing machine is fully automatic with high-speed thermoforming machine air pressure. It is feasible for using plastic sheets for example PS, HIPS, PVC, PET, PP etc. it is used to made different types of boxes, trays and dishes.

(Thermoforming machine-Photo credits: Foodbev media)

|

Vacuum Packing machine |

Chamber dimension (L*W*H) (mm) |

External dimension (L*W*H) (mm) |

|

Thermoforming machine |

284* (200-400) |

5200*950*1960 |

Table Vacuum Packaging Machine

This vacuum packaging machine is mostly stainless steel made and is preferable to food hygiene and safety buyers. It can be moved from place to place by using steel trolley. It has a very simple design and is easy to use. Multiple tasks can be run from these vacuum machines at the same time. Height is adjustable which makes packing easy. It has the smallest chamber of all other types of vacuum packing machines. it often provides a transparent top lid for visibility in the packing process. Simple to operate with multitasking options.

(Table Vacuum Packaging Machine-Photo credits: envasadoravacio)

| Vacuum Packing machine | Chamber dimension (L*W*H)

(mm) |

External dimension

(L*W*H) (mm) |

| Table Vacuum Packaging Machine | 210*275*70 | 305*445*240 |

Single Chamber Vacuum Packaging Machine

A single chamber vacuum packing machine is a small inflatable machine. Like others, it is also made from stainless steel and a transparent lid making the packing process more comfortable. With high and fast vacuum packaging speed, sleek and beautiful structure it is one of the simplest vacuum machines used. It also has digital control panels with many options available.

(Single Chamber Vacuum Packaging Machine -Photo credits: PAC Machinery)

| Vacuum Packing machine | Chamber dimension (L*W*H)

(mm) |

External dimension

(L*W*H) (mm) |

| Single Chamber Vacuum Packaging Machine | 550*550*140 | 600*650*1000 |

Double Chamber Vacuum Machine

A double chamber vacuum machine is used in packaging almost every type of food e.g seafood, fruits, meat etc. main feature of this device is it can adjust thickness settings and air volume of food storage bags. It is easy to operate and s good for long-term use. It has a very unique design and is easy to install.

(Double Chamber Vacuum Machine-Photo credits: UnionMachinery)

| Vacuum Packing machine | Chamber dimension (L*W*H)

(mm) |

External dimension

(L*W*H) (mm) |

| Double Chamber Vacuum Machine | 510*500*150 | 1070*685*930 |

Household Vacuum Sealer

These sealers are very easy to use and are low in cost. It can be operated without any hassle. Special vacuum pattern bags and folding bags are used in these machines. Ordinary bags cannot be vacuumed and sealed in this achiness. Folding bags with a thickness of 20 threads are suitable for household vacuum packing machines. The maximum width of the bag is limited to 28cm. it is not used on a large scale or heavy products.

(Household Vacuum Sealer-Photo credits: FUDOVA)

| Vacuum Packing machine | Chamber dimension (L*W*H)

(mm) |

External dimension

(L*W*H) (mm) |

| Household Vacuum Sealer | 280*110*40 | 390*148*72 |

Automatic vacuum packaging machine

In this type of machine the vacuum chamber is also transparent which makes the machine comfortable to use. It also works as an automatic rotary packing machine. It has a graphic touch panel and microcomputer display which makes this machine user-friendly and easy to maintain.

This machine is known for its high performance and quality. The width of the handle can be changed by the motor by a single adjustment. Although not all grippers are required to adjust this machine. This machine is fully automatic from loading the product, filling, packing, vacuum sealing to the finished product. This machine is also made from stainless steel that makes it durable and hygienic in the production line. This machine is easy to maintain, chambers can be cleaned by washing with water and by maintenance it can reach the goal of food production safety.

(Automatic vacuum packaging machine-Photo credits: Alibaba)

| Vacuum Packing machine | Chamber dimension (L*W*H)

(mm) |

External dimension

(L*W*H) (mm) |

| Automatic Vacuum Packaging Machine | 1080*500*80 | 1580*1770*1100 |

Vacuum Gas Flushing Packaging Machine

This machine is considered one of the highest-rated and top qualities. This multi-functional machine has many functions including vacuum packing, sealing and vacuum & inert gas filling. Auto control digital program, two types of heating options: single or double side options are available. Gas flushing, vacuum and sealing time are fully adjustable. The production rate is also high as compared to others.

(Vacuum Gas Flushing Packaging Machine-Photo credits: Indiamart)

| Vacuum Packing machine | Chamber dimension (L*W*H)

(mm) |

External dimension

(L*W*H) (mm) |

| Vacuum Gas Flushing Packaging Machine | 700*800*850 | 920*1100*1200 |

10. What Is The Production Rate Of The Vacuum Packing Machine?

Depending upon the production rate of vacuum packing machines, it is also available according to usage. The below-mentioned table below describes the production rate of different vacuum packing machines:

- Production Rate (m3/h) (meter cube/hour)

- Production Rate (Times/Minute)

| Vacuum Packing machine | Production Rate

(m3/h) or (Times/Minute) |

| Thermoforming machine | 100-200 (m3/h) |

| Table Vacuum Packaging Machine | 4 (m3/h) |

| Single Chamber Vacuum Packaging Machine | 20 (m3/h) |

| Double Chamber Vacuum Machine | 20 (m3/h) |

| Household Vacuum Sealer | 6-12 (times/minute) |

| Automatic Vacuum Packaging Machine | 4-8 (times/minute) |

| Vacuum Gas Flushing Packaging Machine | 20 (m3/h) |

(Control panel in Vacuum Packaging Machine-Photo credits: Dreamstime)

11. How To Choose The Right Vacuum Packing Machine?

One of the most basic questions is which vacuum packaging machine is the right choice. The answer to this question is the requirements of the consumer. A consumer should evaluate different parameters and select the right choice. It also depends on the consumer purpose behind vacuum packing machine buying. Some of them are discussed below:

1. Vacuum packing machine for household

2. Vacuum packing machine for small businesses

3. Vacuum packing machine industrial production

4. Vacuum packing machine for larger products

Vacuum packing machine for household

One of the simple and easy-to-use vacuum packing machines. Household machines are lightweight and can be operated easily. It can be used to preserve small quantity products for a longer time. They are not very much efficient but the best use for houses. They require very little space and are easy to handle.

Vacuum packing machine for small businesses

Machines used for small businesses usually adapt to tight places like shops. They have very small dimensions with a sleek design. Machines used for small businesses have control panels with special features. An automatic labeling system is also a fine feature of this category.

Vacuum packing machine industrial production

As a high production rate is required, all of its characteristics are available in chamber closure. Multiple customized programs can be run at the same time from the digital control panel. For its durability, its structure is stainless steel made.

Vacuum packing machine for larger products

For medium and larger-sized products specially designed automatic vacuum packaging machines are available. It is usually used for meat packaging. It has specific programming. Vacuum packaging machine for larger products works efficiently and methodically, lessening the packaging timer and increasing productivity.

12. What Are The Most Common Problems With Vacuum Packing Machine?

Vacuum packing machines can face several problems, some of the most common are discussed below:

1. Low vacuum:

Sometimes the set pumping time is too short, it stops before the vacuum makes an impact. If the problem still occurs after increasing pumping time, then look at vacuum pump oil. Add or replace the oil.

2. Noise:

Usually, the noise of the vacuum packing machine is very less. If the noise is high it is due to the leakage in the valve of the solenoid. Cleaning and replacing the filter can overcome this issue.

3. Heat not working:

Heating bars are burnt most of the time in this case. Find the fault location and replace the bars of heat.

4. Heating does not stop:

Sometimes heating is not stopped or adjusted; it is also the case of the heating relay in bad condition or burnout. Replace them with new ones.

5. Short circuit:

An internal short circuit is also a common problem in vacuum packaging machines. In this case, proper maintenance is required from the required company.

(Problems in Vacuum Packaging Machine-Photo credits: SEALERSALES)

13. Can I Pack Vacuum Seal Zip Lock Bags With Vacuum Packing Machine?

Zip lock bags make it easy to close or open bags. They are useful for short time storage. Zip lock bags seal is not durable for long time storage. A vacuum sealer is recommended allowing the food to stay fresh for a long period of time. The following process should be followed while sealing zip lock bags by a vacuum packing machine

Choosing a Zip lock Bag

Suitable size and quality are required while choosing a zip lock bag. Two bags are required, one small and one large in size for a handheld machine.

Preparing the Zip lock

Zip lock preparation mainly depends on the type of vacuum sealing machine. For automatic machines, just cut off the zip lock part. For semi-automatic machines, poke 1*1 inch hole at each end of both bags.

Sealing

In the sealing process, the zip lock part is cut off from both ends. The two layers are peeled off apart and are placed inside the bag on both ends to support the bag’s seal. In the last step, the bag is placed inside the machine and turn on the machine; the rest of it will do its magic.

(Zip Lock Bags in Vacuum Packaging Machine-Photo credits: bigfunforus)

14. Are There Any Other Ways To Extend The Lifespan Of Food?

Following are the ways other than vacuum sealing that can increase the shelf life of the food:

Improving Treatment and Handling Procedures

After harvesting fruits and vegetables, post-harvest handling must be ensured to increase its life span e.g treatment with bad water, store in hot places or contaminated boxes. To increase life span their treatment should be done with clean water, handle with care and store in a cool dry place. Its shelf life will automatically increase. For example, apples can be store for up to 8 months in cold storage.

(Cold Storage-Photo credits: Triburg)

Finding Temperature Weaknesses in Cold Chain

Another way to increase the shelf life of the product is by minimizing the depletion of cold chain temperature differences. If the cold chain is compromised the product’s life span will be reduced.

For example, after harvesting four-hour delay in precooling strawberries resulted in almost 50% of the loss. Some methods can be used to observe the temperature of the cold chain throughout the process.

Monitoring Humidity to Identify Improvement Areas

Controlling humidity also increases the shelf life of food. Humidity monitoring avoids moisture loss thus preventing food from spoiling. Refrigeration most of the time’s loss moisture content of food which is not acceptable. Proper monitoring increases the shelf life.

(Monitoring room-Photo credits: Triburg)

Individual Item Coverings

Proper covering of each food item increases the shelf life of the product. Food degrades when it loses its water after oxidation. Individual covering of food items is recommended, avoid plastic coverings as they are not good for the environment.

(Individual Item Covering-Photo credits: Dreamstime)

Absorbent Food Trays and Pads

Absorbent food trays and pads are recommended to increase the shelf life of the food as these trays decrease the product’s respiration rate.

(Absorbent Food Trays and Pads-Photo credits: Ali Express)

Natural Antimicrobials

Use antimicrobials because they help to prevent spoilage and increase shelf life. The customer nowadays demands natural ingredients so it is compulsory to use natural ingredients not chemicals. Use herb, spice or plant extracts as antimicrobials.

15. What Happens If You Use The Wrong Vacuum Back Bag During The Process?

There are a variety of vacuum bags used in the vacuum packing process. They differ in types, thickness and permeability. While choosing a vacuum bag, one must ensure the bag thickness according to the product; otherwise, there is a possibility of being negative effects. The standard vacuum bag thickness is around 3mm which is used for almost most of the products, but some products need more thickness.

1. If the thickness of the bag is not suitable for the product might become not consumable and become sticky to the product.

2. If the bag is of low-quality wrinkles appear on the bag after sealing and the seal will be burnt, it will look like low-quality sealing.

3. If the bag is bigger in size and the product is small it will take more time and electricity to seal the bags and it would look inappropriate.

4. Sometimes choosing the wrong bag results in spoiling food, ripples and low-quality sealing.

(Effects of using wrong bag pack-Photo credits: INDIAMART)

16. How Do You Use A Vacuum Packing Machine?

A vacuum packing machine can be used by following the steps listed below:

1. Open the lid of the vacuum packing machine

2. Insert the food in the bag. Make sure that the open end of the bag is clean and straight. Clean means there should be no ripples, dust or wrinkles. An A25-50 mm margin should be given on the top to ensure a good seal.

3. Put the open side of the bag under the sealing bar, fix this end with the bag fixer.

4. Then close the lid of the vacuum packaging machine and set the seal or vacuum time.

5. After pressing the “Vacuum and Seal” button the machine runs the vacuum cycle. Pay clear attention to the digital screen when vacuuming and press the seal button which will override the timer and will complete the sealing process.

6. First step is the vacuum cycle and when this process is done, the countdown shows to 0, then the sealing process starts, when sealing is done, its countdown also shows 0.

7. Upon completing both steps whether vacuum cycle or sealing process, indicator lights flash for few seconds.

8. After sealing, open the lid and remove the bag.

9. Inspect the vacuum and seal. A good seal will always be clear without and dust or wrinkles. If there are any spots or wrinkles discard the seal portion and run the process again.

10. “Cancel” button can be pressed to stop the machine at any time.

17. How Long Does Food Last In Vacuum Packed Bags?

Different foods have different lasting time periods. Each category is discussed below:

Dry foods

Dry foods like pasta, cereal, flour and other items have already larger shelf life without being sealed and stored conventionally. They last up to six months without being sealed. When sealed with a vacuum packing machine these items last up to 2 years

(Dry Food In Vacuum Packaging Machine-Photo credits:smackpack)

Frozen foods

In the freezer, frozen meats, fish and poultry survive six months in conventional packaging. When sealed with a vacuum packaging machine they can stay fresh for up to 3 years in the freezer. Vacuum sealed vegetables stay fresh for up to four months.

(Frozen Food In Vacuum Packaging Machine-Photo credits: Amazon)

Raw foods

A vacuum packaging machine is also very helpful for raw foods, cheese takes only 2 weeks to spoil but vacuum-sealed cheese can be used up to 4-6 months. Fruit are spoiled after a week but when vacuum sealed their shelf life is doubled to 2 weeks.

(Raw Food In Vacuum Packaging Machine-Photo credits: potatochipsmachinery)

Cooked foods

Most of the cooked food remains 1 to 3 days fresh in the refrigerator. Vacuum packing machines can increase the shelf life of your leftover cooked or meal prepping food to up to 2 weeks.

(Cooked Food In Vacuum Packaging Machine-Photo credits: Ali Express)

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide

Tell us your material or budget, we'll reply you ASAP within 24 hours

Your Complete Buying Guide For Vacuum Packing Machine In 2025 Read More »

Tell us your material or budget, we'll reply you ASAP within 24 hours

Tell us your material or budget, we'll reply you ASAP within 24 hours