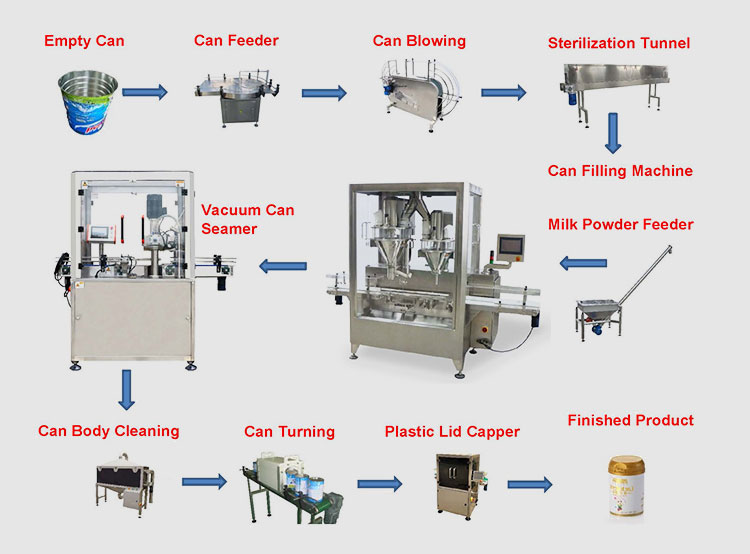

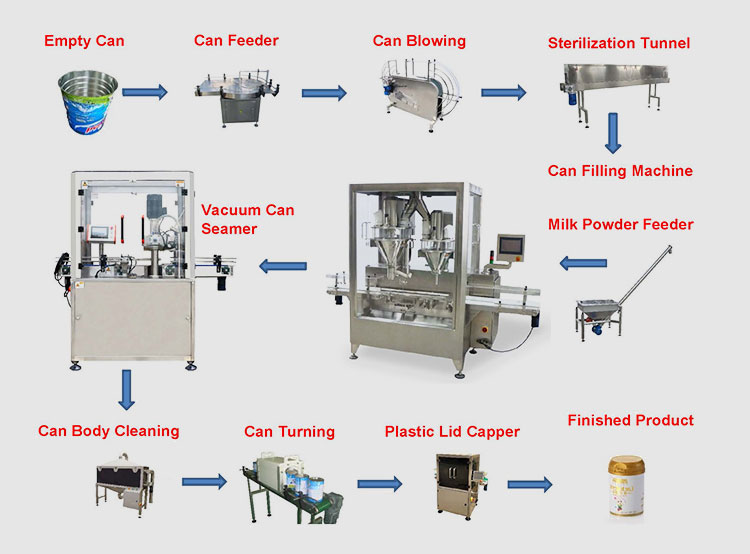

1. What Are Powder Filling and Liquid Filling?

In daily life, from powder capsules and oil capsules you take, to the milk powder that your baby needs to take every day, and the milk tea and beverages you often drink.

These items are filled into capsule shells, jars, and bottles before being delivered to you. So how are these powders and liquids filled?

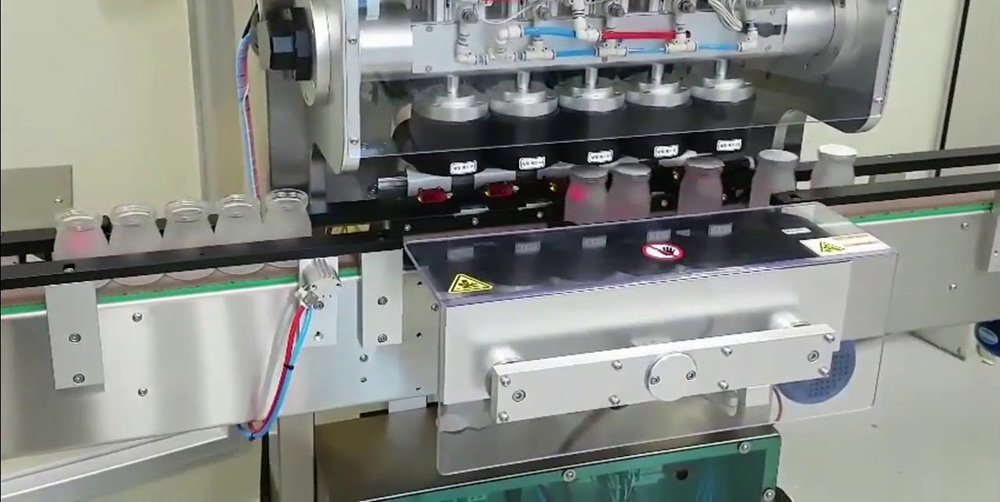

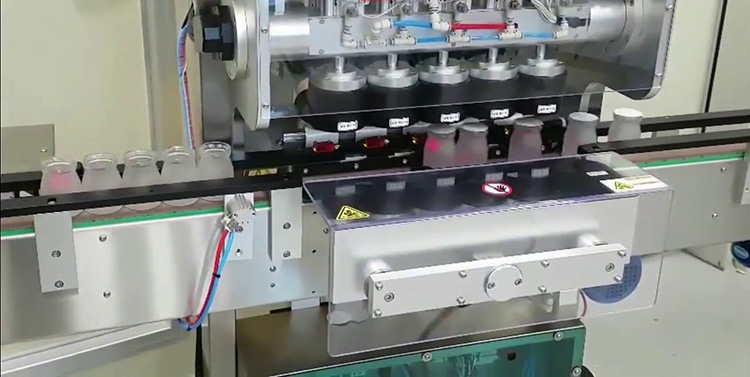

How Do Liquid Filling Machines Work -photo credits: assetpackaging

Super food Powders -photo credits: eatthis

Powder Filling refers to a process that especially fills powdery and granular materials with certain fluidity into a designated container.

This process is suitable for the quantitative packaging of powders in various packaging containers such as bags, cans, and bottles.

There are many types of powders that can be filled in this process and involve various industries and fields.

And there are many types of machines that can be applied for powder filling.

Sugary Drinks -photo credits: healthyfoodamerica

The liquid filling refers to a process that specifically fills a liquid with a certain fluidity into a designated container.

This process is suitable for the quantitative packaging of liquids in various packaging containers such as bags, cans, and bottles.

There are many types of liquids that can be filled in this process, and they involve various industries and fields.

Filling Chains -photo credits:cvctechnologies

And there are many types of machines that can be applied for liquid filling.

What are the things you have in your life that are filled and packaged before being delivered to you?

2. What Are the Common Powder Fillers and Liquid Fillers?

Whether it is daily life items, chemicals, food, etc., there are countless materials of powders and liquids that can be filled.

Food Service Chemicals -photo credits: webstaurantstore

Types of Powders That Can Be Filled:

Protein Powders -photo credits: tonal

There are many types of powders that can be filled and can be roughly divided into four types. Powder seasonings, powder drinks, powder medicines, and other powders.

Powder Seasoning -photo credits: brodandtaylor

Seasoning powder, seasoning bag, pepper powder, chili powder, medium powder, five-spice powder, spice powder, flavor powder, chicken powder, monosodium glutamate powder, powdered sugar, powdered sugar, powdered rock sugar, mixed seasoning powder, and other types of powder filling, and so on.

Powder Drinks -photo credits: foodbusinessnews

Soy milk powder, soybean milk powder, lotus root powder, coffee powder, walnut powder, sesame powder, peanut powder, soybean powder, Pu’er tea powder, kudzu root powder, milk tea powder, konjac powder, ginger powder, red date powder, wheat germ powder, Almond powder, buckwheat powder, bee pollen, tea powder, black tea powder, green tea powder, Ganoderma lucidum powder, colostrum powder, children’s food powder granules, baby rice powder, additive powder, nutritional powder, powder, and other powder fillings, and so on.

Powder Capsules -photo credits: moringapowder

Powder, traditional Chinese medicine powder, powder, other powder fillings, and so on.

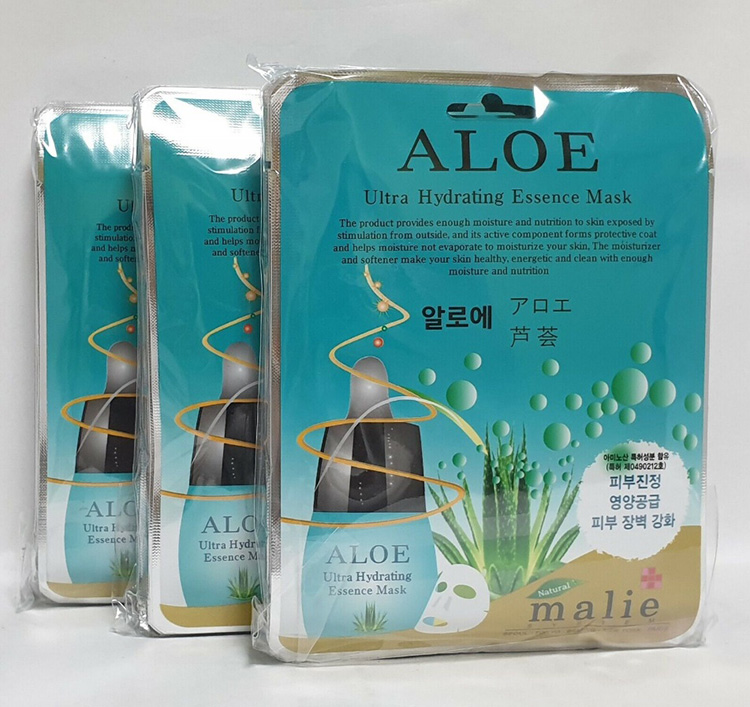

Daily necessities powder, disinfection powder, washing powder, skin care powder, facial mask powder, chemical powder, and other powder filling, and so on.

Facial Mask Powder -photo credits: 100percentpure

Types of Liquids That Can Be Filled:

Usually, flowable liquid materials can be filled. Usually, they are divided into four categories, food, medicine, cosmetics, and chemical.

It is subdivided into beverages, medicinal liquids, cosmetics, lotions, nursing liquids, oral liquids, disinfectants, eye washes, nutritional liquids, wines, injections, pesticides, medicines, perfumes, edible oils, lubricating oils, etc.

Skin Lotions -photo credits: nytimes

Water, beverages, seasonings, sauces, alcohol, etc.

Alcohol, care solution, disinfectant, oral solution, eye wash, nutrient solution.

Toilet water, skin lotion, essence, perfume, makeup remover, etc.

Pesticides, glass water, 84 disinfectant, disinfectant, antifreeze, etc.

Chemical Liquids -photo credits: sawgrassnutralabs

These materials require special means and machines for filling and processing.

3. Why Do Some Powders and Liquids Need to Be Filled?

Some materials do not need to be filled, but some items must be filled before they can be used. Can you name some powders and liquids in your life that can be filled?

There are various powders and liquids that need to be filled.

Medicines -photo credits: memontraders

Medicines:

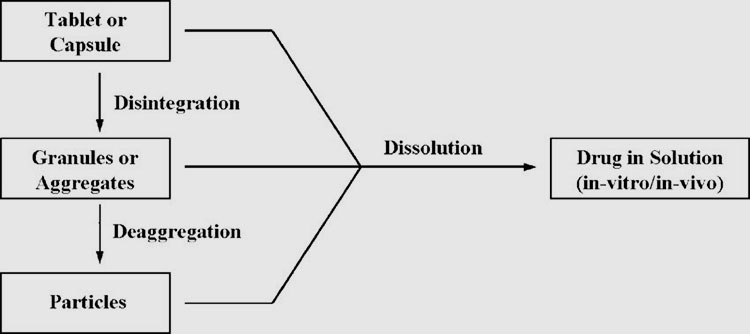

Capsules and Tablets -photo credits: rand

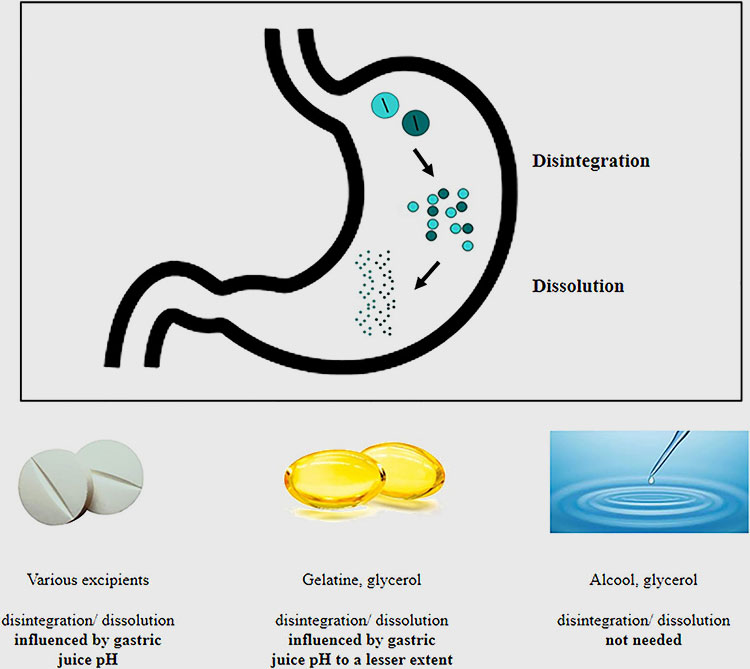

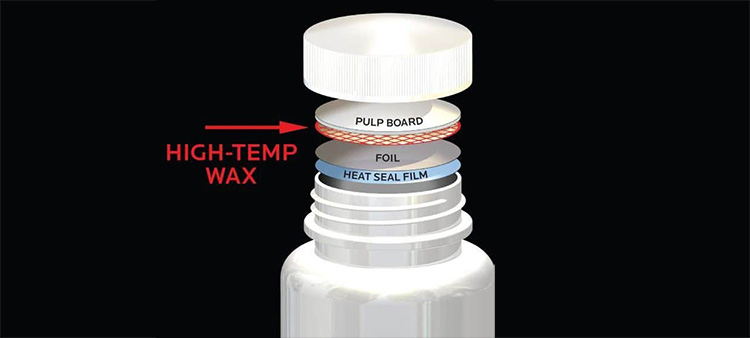

Some medicines need to be filled in capsules before being given to patients. Such as pharmaceutical powders and oily liquids. The most typical one is fish oil.

The medicine itself is bitter or smells difficult to swallow. After encapsulation, this disadvantage can be reduced.

The drug may be irritating to the esophagus and gastric mucosa. Some drugs have bad taste, are easy to volatilize, are easily decomposed by saliva in the mouth, and are easily inhaled into the trachea.

Liquid Medicine -photo credits: greatpetcare

First of all, liquid medicines can be divided into mixtures, oral emulsions, syrups, enemas, and the like. These medicines are all solution-type medicines. It has the characteristics of easy deterioration, easy rancidity, easy volatility, and easy pollution.

Therefore, liquid medicine needs to be bottled to preserve its quality. This prevents deterioration, rancidity, volatilization, and contamination of the liquid medicament.

Medications -photo credits: stock.adobe

Chemical Liquids:

Some chemical liquids need to be filled in fixed containers for their own reasons. Such as glass bottles, and dark containers.

It can prevent some medicines from being decomposed by light. Some agents will undergo photochemical reactions when exposed to light.

laboratory chemicals -photo credits: cen.acs

- Sensitive Volatile Chemicals

Therefore chemicals need to be filled in brown bottles for preservation.

Some chemicals are corrosive and need to be filled in fixed containers for storage.

The nature of glass is very stable, and most chemical substances will not chemically react with glass, nor will they dissolve glass. Therefore, some chemicals need to be filled in glass bottles.

Chemical Liquids -photo credits: knowledge.carolina

Food Powders:

Food Powders -photo credits: drinkhappyviking

There are several considerations for food-grade powder filling.

- For Better Differentiation of Doses

Different powder materials, such as milk powder, starch, etc., need to be better differentiated by grams in the commercial sales process. Because different clients and populations require different or specific dosage requirements.

- For Better Stable Material Quality

Good Quality -photo credits: lstmed.ac

When the powder material is filled, different additives or preservatives will be appropriately added according to different materials to ensure better quality.

- For More Convenient Transportation

After the powder is filled in different doses, it is more convenient to transport and store.

Food Beverages and Liquids:

Powder Beverages -photo credits: daganghalal

Some beverages or dairy products with a short shelf life need to be filled into small bottles to facilitate the needs of buyers and avoid waste.

Beverages and Liquids -photo credits: fiberstar

- For Better QualityMaintaining of Materials

Some beverages with “gas”, such as Coke or Sprite, must be filled with a certain amount of carbon dioxide during the production process.

If the Coke bottle is transparent, it is easier to be exposed to light to produce a chemical reaction, which will greatly reduce the taste.

Therefore, certain “gas” beverages need to be filled into cans.

Gas Beverages -photo credits: eatthis

The materials that must be filled will undergo certain processing and inspection. The whole process is very clean and safe.

4. What Are the Filling Methods for Powders and Liquids?

Once you understand the types of filling materials, you may be very curious about how these materials are filled into fixed containers.

In fact, both powder and liquid filling will be manual and automatic respectively.

Manual Liquid Filling Machine

Manual Filling Machine refers to completely manually separating, classifying, dividing the materials, and filling the powder and liquid into fixed containers.

- Automatic Filling Machine

Automatic Powder Filling

Automatic refers to the completely automatic filling of different powders and liquid materials into fixed containers with the help of machines.

According to different needs, you can choose different ways to complete the fill.

From the Point View of Filling Principles:

There are 3 types of filling methods.

Pressure Bottles Filling Machine -photo credits: fillmore

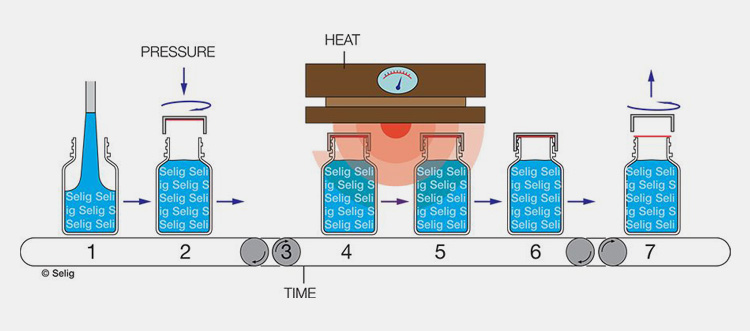

A pressure filling machine is a filling mechanical equipment for filling at higher than atmospheric pressure.

It can be divided into a high-pressure filling machine and an isobaric filling machine. It is widely used in liquid filling containing gas. Products such as beer, cola, champagne, etc.

- Atmospheric Pressure Filling Machine

Atmospheric Pressure Filling Machine -photo credits: szsdwater

Atmospheric pressure filling machine is a filling mechanical equipment that fills by the liquid’s own weight under atmospheric pressure, including constant volume filling and timing filling.

It is mainly used in filling low-viscosity and gas-free liquid products, such as milk, wine, and other products.

Vacuum Filling Machine -photo credits: winemakersdepot

The vacuum filling machine is a filling machine mechanical equipment for filling under the pressure in the bottle lower than the atmospheric pressure.

The main advantages are simple structure, high working efficiency, and a wide range of adaptability to product viscosity. It is commonly used for products including filling oil, syrup, fruit wine, and other products.

Adaptability -photo credits: askingletterresume

Adaptability -photo credits: askingletterresume

From the Point View of Filling Types:

- Diluted Liquid Filling Machine

The diluted liquid filling machine is mainly a liquid product that is relatively rare in filling machines. It is commonly used for products such as filling mineral water, purified water, and potions are common.

- Concentrated Liquid Filling Machine

The liquid filling machine is mainly for the liquid products that are relatively thick in the filling machine, and It is commonly used for juice, skin care, chemical products and other common products.

Oil Filling Machine -photo credits: vkpak

Oil Filling Machine -photo credits: vkpak

The oil-filling machine mainly fills various oil products, and it is commonly used for products such as edible oil, lubricating oil, motor oil, and so on.

From the Point View of Operation Mode:

- Fully Automatic Liquid Filling

Fully Automatic Liquid Filling -photo credits: aquapacksolutions

The automatic piston-type liquid filling machine has been improved and designed on the basis of the original filling machine series, and some additional functions have been added.

It makes the product more simple and convenient in operation, accuracy error, installation adjustment, equipment cleaning, maintenance, and so on.

It is widely used in daily chemical, oil, and other industries, and can be used for filling different high-viscosity fluids.

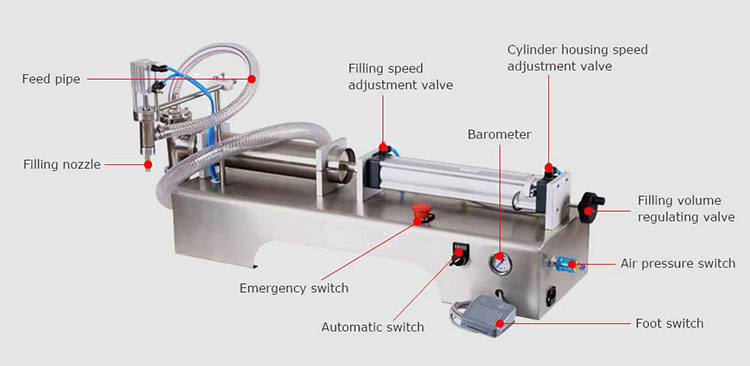

- Semi-automatic Liquid Filling

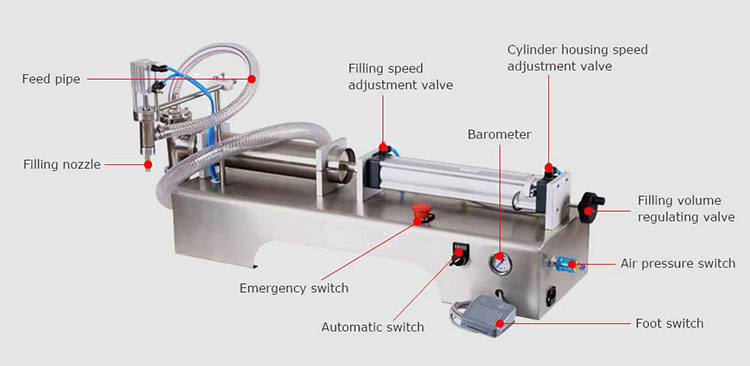

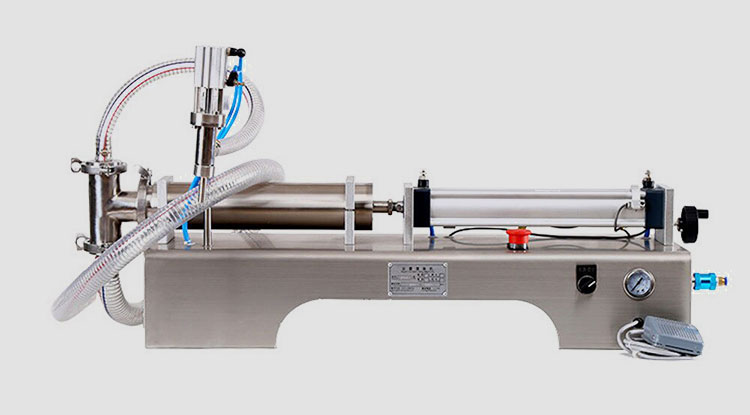

Semi-automatic Liquid Filling

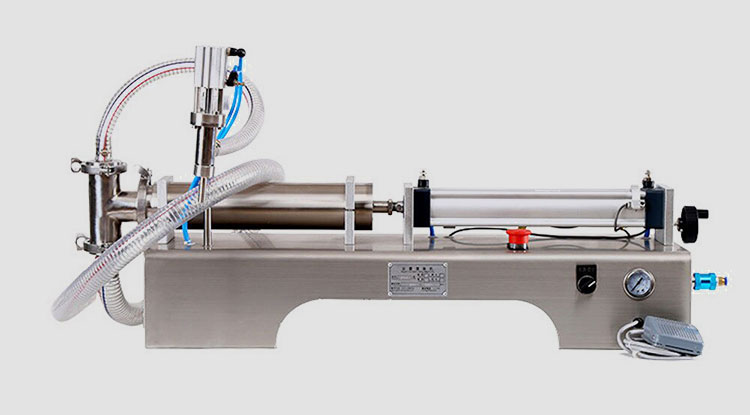

Semi-automatic liquid filling are called liquid single-head automatic filling or semi-automatic piston filling. The structure of this filling is simple and reasonable.

Semi-automatic Liquid Filling machine is made of 316L stainless steel, and uses German FESTO and Taiwan AirTac pneumatic components as pneumatic components.

The fully pneumatic device guarantees safety. The filling volume and filling speed can be adjusted at will. It is a very practical small liquid quantitative filling machine.

The automatic filling machine is more efficient than the semi-automatic filling machine, but the cost of the automatic filling machine is higher than that of the semi-automatic filling machine.

5. What Are Powder Filling Machines and Liquid Filling Machines?

Both powder-filling machines and liquid-filling machines can bring great convenience to your life and work.

Good Life -photo credits: thegoodlifepath

Now, we will introduce to you the types of machines, application industries, machine features, types of components used, precautions for machine use, and machine maintenance.

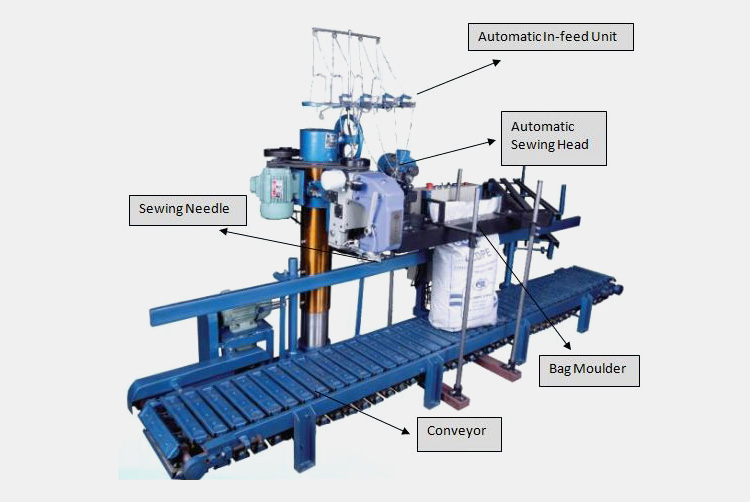

Single Head Automatic Powder Filling Machine

The powder filling machine is a kind of equipment specially used for filling powder and other materials.

The powder filling machine is suitable for quantitative filling of powdery and granular materials such as pesticides, veterinary drugs, premixes, additives, milk powder, starch, flour, condiments, enzymes, feeds, dyes, chemicals, food, etc.

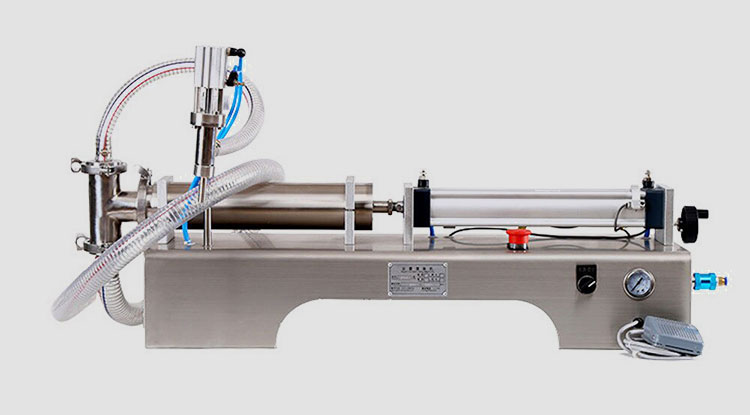

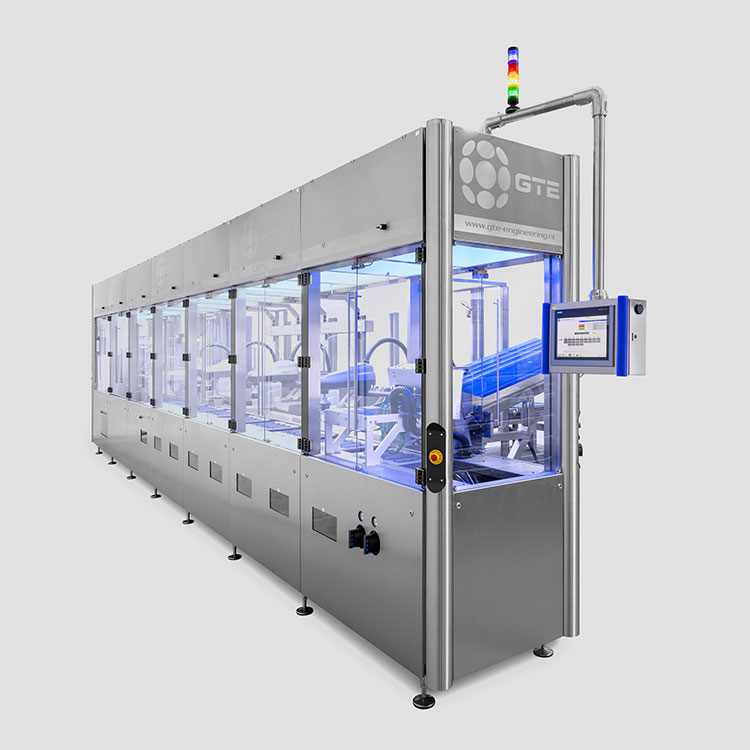

Pneumatic Liquid Filling Machine

A liquid filling machine is a machine specially used for filling various liquids. It is widely used in daily chemical, oil, and other industries, and can be used for filling different high-viscosity fluids.

Application Industry:

Application Industry -photo credits: geeksforgeeks

The powder filling machine is mainly used for quantitative packaging of powdery materials in the fields of food, medicine, microorganism, the chemical industry, etc.

The liquid filling machine is mainly used for liquid filling of lotion, nursing liquid, oral liquid, disinfectant, eye wash, nutrient solution, wine, injection, pesticides, medicine, perfume, edible oil, lubricating oil, and special industries.

Machine Features:

- Main Features of Powder Filling Machine

Main Features of Full Automatic Powder Filling Machine -photo credits: shipute

The whole machine is made of stainless steel, which meets the requirements of GMP specifications, is easy to clean, and is corrosion-resistant.

With a touch screen interface, stable work, anti-interference, and convenient and intuitive operation, the packaging weight can be adjusted at any time. The working state can be changed at any time, and the operation is convenient.

- Main features of Liquid Filling Machine

Main Features of Pneumatic Liquid Filling Machine -photo credits: taizypackaging

The product is simple and convenient for operation, precision error, installation adjustment, equipment cleaning, maintenance, and so on.

The design of the machine is compact and reasonable, the appearance is simple and beautiful, and the filling volume adjustment is convenient.

- Powder Filling MachineVS Liquid Filling Machine

Powder Filling -photo credits: messoessence

The filling way of the two is different: A powder filling machine is filling equipment for powder and granular materials with poor fluidity liquid filling machine is generally water-like, with a lower concentration than solids and fewer impurities.

Liquid Filling -photo credits: vxppharma

The quantitative methods of the two are different: Liquid filling machines have quantitative methods such as piston, negative pressure, and DC. Powder filling machines are generally quantitative methods such as screw and combination weighing.

Types of Components Applied:

- Components Used ForPowder Filling Machine

The intelligent temperature controller is used to control the horizontal and vertical sealing temperature so that the sealing is firm, the sealing performance is good, the bag shape is flat and beautiful, and the filling efficiency is high.

It adopts a programmable controller and is equipped with Chinese and English fonts and a human-machine interface, so that the equipment is easy to operate, easy to adjust, and has a high degree of automation.

Human-machine Interface -photo credits: packagingdigest

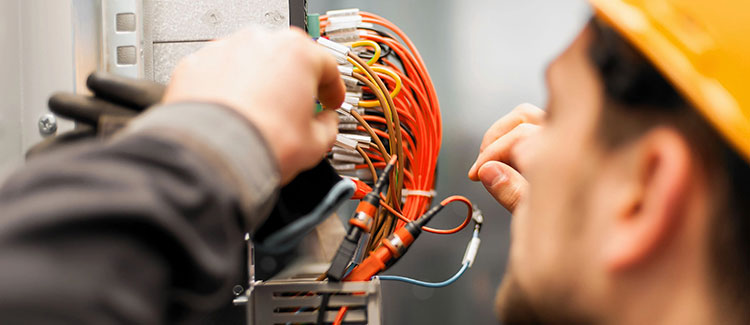

- Components Used ForLiquid Filling Machine:

Using German FESTO, Taiwan AirTac, SHAKO pneumatic components, and Taiwan Delta electronic control components, stable performance.

Material contact parts are made of 316L stainless steel. Adopt Korean photoelectric devices, Taiwan PLC, and French electrical components.

Delta Electronics -photo credits: wbdg

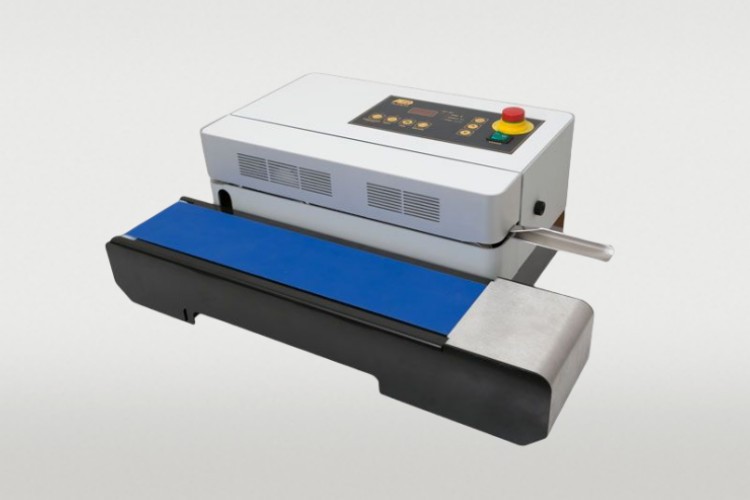

Precautions for Use:

Regulations -photo credits: coe.int

You need to set the parameters of each part of the equipment according to the instructions of the powder filling machine and liquid filling machine to ensure the accuracy of filling after the operation starts.

In the process of powder filling machine and liquid filling machine, the operation of each process must be carried out according to strict standards.

When the machine is running, it is strictly forbidden for the body, hands and head to approach or touch the running parts.

Before each startup, check and observe whether there is any abnormality around the machine.

Machine Operation -photo credits: spherion

Banned -photo credits: skipprichard

When the machine is running, it is strictly forbidden to put hands and tools into the sealing knife seat.

When the machine is working normally, it is strictly forbidden to switch the operation buttons frequently, and it is strictly forbidden to change the parameter setting values at will.

Safety First -photo credits: digvijaymalhotra

The foreign matter must not be mixed in the filling, otherwise, it may cause inaccurate discharge or damage to the machine parts.

When you are operating, if you find foreign objects at the hopper mouth, you should stop the machine to take out the foreign objects.

Recommendations -photo credits: martech

It is recommended that you do not take foreign objects with your hands before shutting down, and avoid damage to the body caused by the rotation of the photoelectric spiral.

If the powder filling machine is not used for a long time, if there is no regular application of lubricating oil, and you need to be sure to apply lubricating oil to the junction of each gear and part before use to prevent serious wear and tear caused by insufficient lubrication after the equipment is started.

Maintenance of the Machine:

Maintenance Equipment -photo credits: seekpng

You need to clean the equipment once a week, remove the dirt, and do maintenance every three months.

When the equipment fails during operation, the first thing to do is to cut off the power first, stop the equipment from running, avoid damage to the filling machine, and restart when the maintenance personnel removes the fault.

Maintenance of the Machine -photo credits: bluefolder

The filling machine needs to be maintained and inspected on a regular basis. You need to see if the machine is loose or unusual.

You need to check whether the lubrication state of the conveyor belt and gear is good.

When the leakage of the working power supply occurs, it needs to be eliminated in time. I hope you pay attention to the usual maintenance of the equipment and extend the service life.

Electrical Safety -photo credits: beardconstructiongroup

After knowing so much about powder filling machines and liquid filling machines, you must have a certain understanding of powder filling and liquid filling.

But do you know the relative advantages and disadvantages of powder filling and liquid filling?

6. What Are the Advantages and Disadvantages of Powder Filling and Liquid Filling?

Of course, a filling also has advantages and corresponding disadvantages. You can understand the advantages and disadvantages of filling in through the following points.

Advantages and Disadvantages -photo credits: investallign

Advantages of Powder Filling and Liquid Filling:

- From the Point of View of Machine Operation

Automation: The automation of the filling machine can complete all processes, such as filling, weighing, etc. Intelligent PLC controls the speed of the entire production line.

Automation -photo credits: channelfutures

Reduce costs: reduce labor costs, save space, reduce rent, etc., and reduce waste of raw materials.

Simplified Work: The use of the filling machine can simplify the manual process, and the operation is simple and easy to use.

Simplified Work -photo credits: windmillstrategy

Improved Quality: Through mechanization, the hygienic environment inside the mechanical conveying system is very stable, which reduces the risk of contamination.

Increased Production Capacity: Through mechanization, filling accuracy is increased and operating rates are increased.

Flexible Production System: The production line can be adjusted. During the peak season, you can adjust the speed of the production line, and during the off-season, you can adjust the speed of the production line.

Visualize the Production Process: It can improve efficiencies, such as improving product safety and reliability, inventory, and quality control.

Improve Efficiency -photo credits: tabsocal

The above are the advantages of filling from the perspective of machine operation.

- From Point of View of Filling Way

It is suitable for different materials, and different manufacturers involve different filling methods. These include aseptic filling.

Aseptic filling -photo credits: gea

Aseptic Filling: Aseptic filling refers to the process of filling and packaging sterilized food (dairy products, etc.) in an aseptic environment and sterilized containers.

During the filling of the material, without adding preservatives and without refrigeration, the filled material has a longer shelf life.

PET Hot Filling: It refers to the use of ultra-high temperature instantaneous sterilization technology in the filling process, and the heat treatment time of the material does not exceed 30 seconds, which maximizes the taste and color of the product, and maximizes the preservation of vitamins in the material ( A filling technology for the content of heat-sensitive nutrients).

PET hot filling -photo credits: oberk

Advantages of PET Hot Filling:

The filling operation is carried out in a sterile and normal temperature environment, and no preservatives are added to the product, thus ensuring the safety of the product.

Improve the production capacity, save raw materials, reduce energy consumption, and reduce product manufacturing costs.

The advanced technology can be widely used in the liquid filling of various products.

Hot Filling Process -photo credits: tandobeverage

PET Cold Filling: It refers to a filling technology that performs UHT instantaneous sterilization during the filling process, and then quickly cools down to normal temperature (25°C), and enters the aseptic tank for temporary storage.

Secondly, the bottle and cap are sterilized with chemical disinfectant, and then filled in a sterile environment, and will not leave the sterile environment until it is completely sealed.

Cold Filling -photo credits: gea

Advantages of PET Cold Filling:

In the whole process, the heating time of the material is short, the filling operation is carried out in a sterile environment, and the filling equipment and filling area are also sterilized so that the safety of the product can be guaranteed.

Cold Filling -photo credits: blog.drinktec

Disadvantages of Powder Filling and Liquid Filling:

The general filling process refers to the filling process of the filling machine. In this place, we will omit the manual filling process.

Therefore, if you need to complete the filling process, you must first purchase a filling machine.

High Cost -photo credits: stock.adobe

- From the Point of View of Purchasing Filling Machines

Requires Cost and Capital: Ordinary filling machines require a certain amount of capital and cost. Larger or better models require more capital.

Manpower Is Required: Although most of the canning machines are now fully automatic. But even the fully automatic mode requires human supervision and verification.

In order to avoid any unexpected situation during the use of the machine.

Manpower -photo credits: horizon-shores

Requires regular professional maintenance and cleaning: After the machine is used for a certain period of time, if you want to maintain the efficiency and life of the machine, you need regular maintenance and cleaning by professionals.

This greatly increases the cost of the enterprise.

Need Maintenance -photo credits: disruptive-technologies

- From the Point of View of UsingFilling Machines

It is easy to leak or produce dust. Abnormal noise is prone to occur during the use of the filling machine.

The filling machine may suddenly stop working. The filling machine is prone to the problem of inaccurate quantitative and filling volume.

Some cheap filling machines have a relatively short service life.

Thinking -photo credits: betterhelp

After understanding the corresponding advantages, in fact, the disadvantages are not absolutely inevitable.

As long as you choose a suitable filling machine according to your needs, these disadvantages can be avoided.

7. How to Choose a Suitable Filling Machine According to the Powder and Liquid to be filled?

Different types of filling machines have different functions and models. How to choose a filling machine, of course, needs to be based on your own needs.

Functions -photo credits: shmoop

From the Perspective of Filling:

- Atmospheric Pressure Filling

Atmospheric pressure filling machine, suitable for your needs for filling low-viscosity and gas-free liquid products, such as liquor, vinegar, soy sauce and other materials.

The atmospheric pressure filling machine is filled by the weight of the liquid under atmospheric pressure. This type of filling machine is divided into two types: timed filling and constant volume filling.

gas-free drinks -photo credits: freepik

- Negative Pressure Filling

The negative pressure filling machine is suitable for your needs for filling fruit juice drinks, toxic pesticides and chemical reagents and o,ther materials.

The isobaric filling machine is suitable for your filling needs of carbonated beverages and carbonated alcohol, such as soft drinks, cola, beer, and other materials.

Soft Drinks -photo credits: cntraveler

- Atmospheric Pressure Filling VS Negative Pressure Filling

The Pressure Applied Is Different: Atmospheric pressure filling machine is a machine that fills liquid materials into packaging containers under normal pressure.

A negative pressure filling machine refers to a machine that first draws air to the packaging container to form negative pressure, and then fills the liquid into the packaging container.

The Filling Materials Are Different: Atmospheric pressure filling machine is only suitable for filling low-viscosity and gas-free liquid materials, such as milk, soy sauce and daily chemical products.

Liquid Packaging Containers -photo credits: husky

The Negative pressure filling machine is suitable for filling beverages containing vitamins, toxic pesticides and chemical reagents with good fluidity and non-gas liquid.

The Packaging Containers Are Different: Atmospheric pressure filling machine can adapt to packaging containers made of various materials, such as glass bottles, plastic bottles, metal cans, plastic bags and metal barrels.

The Negative pressure filling machine is most suitable for glass bottle filling. This machine can ignore manufacturing errors of packaging containers.

Glass Bottles -photo credits: allegrobeverage

From the Perspective of Fillers:

The filling of liquid materials usually adopts normal pressure filling, negative pressure filling, and pressure filling. Such as DC filling, piston filling, vacuum filling and so on. Mineral water can be filled with direct current, piston filling of oil, vacuum filling of liquid medicine, etc.

Of course, depending on the output, some materials can be applied to any kind of filling.

Powder materials are usually filled with screw type and container type.

Piston Filler

There are several affordable and practical powder and liquid filling machines that we recommend.

Recommended Filling Machines:

Screw Blanking Powder Filling Machine / FLG-1000A

There are 3 types of powder filling machines are recommended. Allpack Screw Blanking Powder Filling Machine / FLG-1000A and Single Head Automatic Powder Filling Machine.

Allpack Screw Blanking Powder Filling Machine: This equipment is suitable for powder filling in the fields of food, daily chemicals, medicine and so on.

The equipment is designed with a PLC-controlled screw filling system and can meet specific custom specifications.

Custom Made -photo credits: pixelweavefabrics

Allpack Single Head Automatic Powder Filling Machine: This equipment adopts the spiral metering method. It is suitable for the filling of powdered materials such as milk powder, glucose, protein powder, cocoa powder, coffee powder, rice flour, and solid beverages.

The equipment adopts a single-head automatic powder-filling machine designed according to the national GMP standard.

Single Head Automatic Powder Filling Machine

High-Precision Double-Head Automatic Screw Feeding Powder Filling Machine: This equipment is designed according to the national GMP standard.

The screw filling machine can form an assembly line with bottling machines, capping machines, labeling machines and other equipment, and is suitable for the filling of milk powder, glucose, protein powder, cocoa powder, coffee powder, rice flour, solid beverages and other materials.

High-Precision Double-Head Automatic Screw Feeding Powder Filling Machine

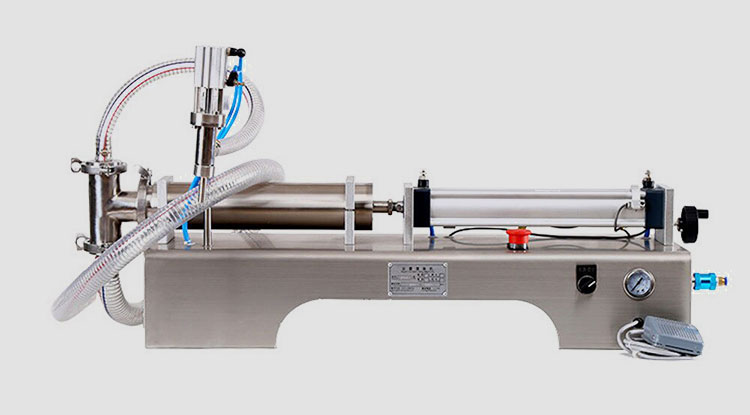

Pneumatic Liquid Filling Machine: It is suitable for cosmetics, oil, alcohol, washing supplies, oral quantitative liquid filling and packaging.

Pneumatic Liquid Filling Machine

There are 7 models available: 5-100ml, 30-300ml, 50-500ml, 100-1000ml, 250-2500ml, 300-3000ml, 500-5000ml.

This liquid filling machine is only for liquid filling, not for paste filling.

Conclusion

The biggest difference between powder filling and liquid filling is the powder and liquid. However, the filling procedure of powder is slightly different from that of liquid. Ultimately, you need to choose the appropriate filling machine based on the material to be filled. If you have needs in this regard or want to know more, you are welcome to consult us.

Tell us your material or budget, we'll reply you ASAP within 24 hours

Tell us your material or budget, we'll reply you ASAP within 24 hours

Adaptability -photo credits: askingletterresume

Adaptability -photo credits: askingletterresume Oil Filling Machine -photo credits: vkpak

Oil Filling Machine -photo credits: vkpak