Weighing Filling Machine: The Complete Buying Guide In 2025

Weighing Filling Machine: The Complete Buying Guide In 2025

A weighing filling machine may be exactly what you need if you want to increase the efficiency of your manufacturing while also improving the way your products are packaged. These machines can help you save time and cut waste while guaranteeing that your products meet the highest quality standards thanks to exact weight measurements and quick filling speeds.

You'll learn everything you need to know about weighing filling machines in this in-depth buying guide in 2023, which including the features and advantages, and what aspects to take into account when selecting the ideal equipment for your business. This buying guide will provide you the facts you need to know about weighing filling machines so that you can make an informed choice, whether you're a tiny startup or a large factory.

1.What Is A Weighing Filling Machine?

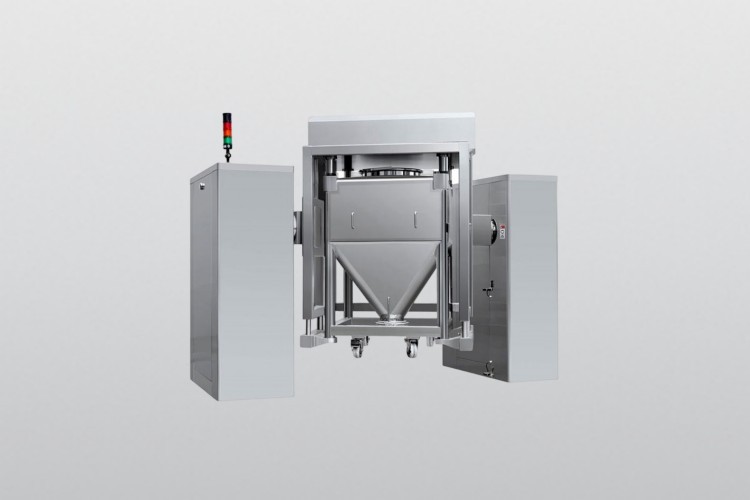

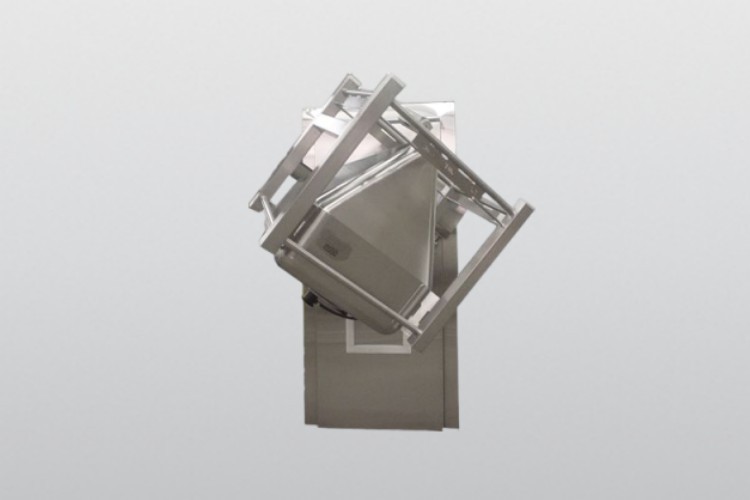

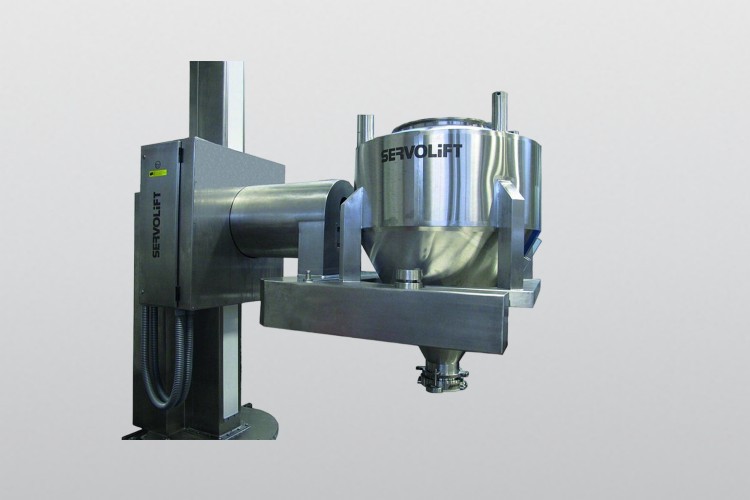

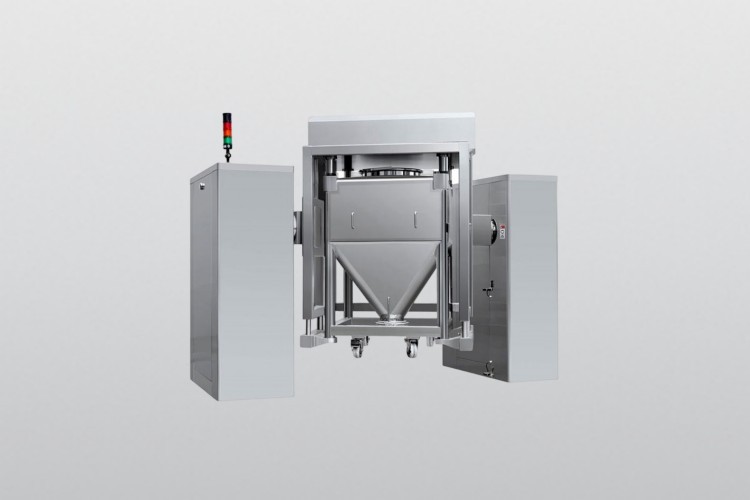

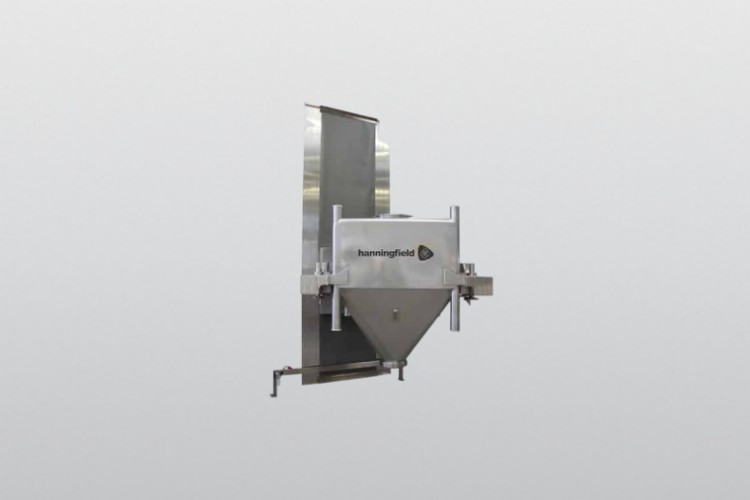

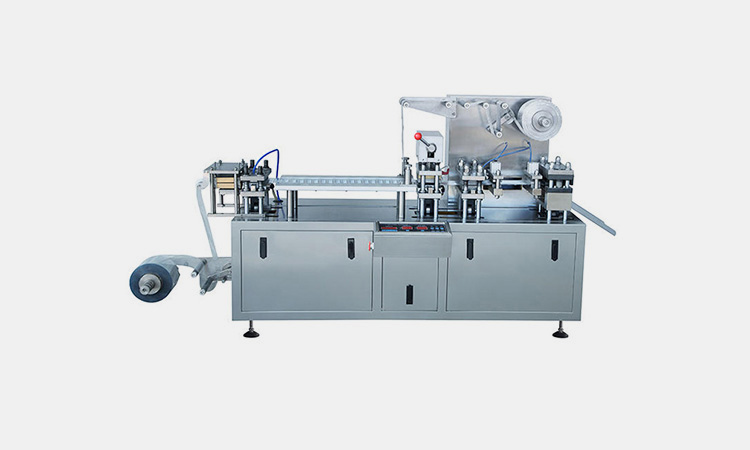

Weighing Filling Machine-Photo Credit:Busch Machinery

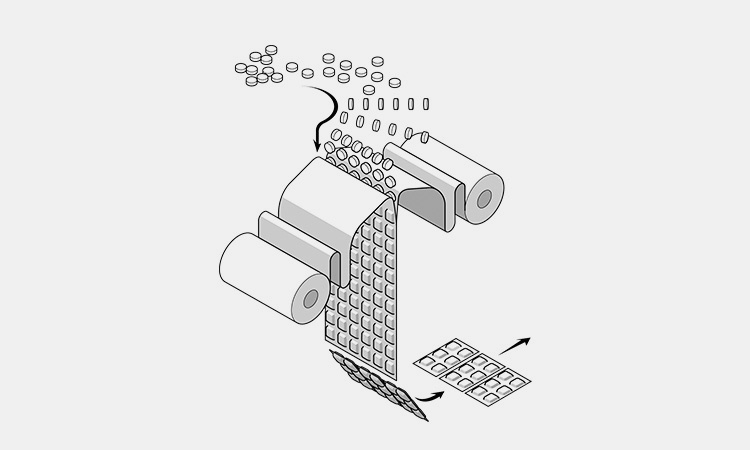

A weighing filling machine is used in many industries to precisely fill containers with product by weight. These devices typically have a reservoir or hopper for keeping the product, a scale or load cell for determining the product's weight, and a dispensing mechanism for distributing the product into the container.

Food and beverage, pharmaceutical, chemical, and cosmetic sectors, among others, frequently employ weighing filling machines. In comparison to conventional filling techniques, they offer more accuracy and precision, especially when filling materials with different densities or viscosity.

2.How Can Weighing Filling Machines Benefit You?

Adding a weighing filling machine to your business can bring significant positive changes and benefits, some of the key benefits include:

Improved Efficiency:

Weighing filling machines automate the filling process, allowing for faster and more efficient production. They can handle high-speed filling operations, reducing manual labor and increasing overall productivity. With their ability to accurately weigh and fill products simultaneously, these machines optimize the workflow, minimize downtime, and improve operational efficiency.

Cost Savings:

By accurately measuring and filling products, weighing filling machines help reduce product waste and minimize overfilling. Moreover, the automation capabilities of these machines can save on labor costs and increase throughput, improving the overall profitability of your business.

Enhanced Product Quality:

Weighing filling machines ensure precise and consistent filling quantities, which is crucial for maintaining product quality. Accurate measurements prevent overfilling, ensuring that each product meets the desired specifications. This consistency enhances customer satisfaction, reduces product returns, and helps build a positive reputation for your business.

Versatility and Flexibility:

Weighing filling machines are versatile and can handle a wide range of products and container types. This versatility allows businesses to diversify their product offerings without investing in multiple filling systems. Whether you're dealing with granules, powders, liquids, or fragile items, weighing filling machines can be adapted to accommodate various products, making them highly flexible for different business needs.

3.What Are The Common Applications Of Weighing Filling Machines?

Weighing filling machines have a wide range of applications due to their versatility and accuracy. Here are some common applications of weighing filling machines:

Food and beverage industry:

Weighing filling machines are often used to fill bottles, cans, and other containers with food and beverage products such as sauces, dressings, oils, and beverages. Weighing filling machines can handle a wide range of fill volumes, from small quantities for sample packets to large volumes for bulk containers.

Pharmaceutical industry:

Weighing filling machines are used to accurately fill containers with pharmaceutical products such as pills, tablets, and capsules.By providing accurate measurements and minimizing waste, weighing filling machines play a vital role in ensuring the quality, safety, and efficiency of pharmaceutical production.

Chemical industry:

Weighing filling machines are used to fill containers with various chemicals, including liquid and powdered chemicals.These machines are designed to handle hazardous and potentially dangerous chemicals with the utmost care, ensuring worker safety and minimizing the risk of spills and accidents.

Agriculture industry:

Weighing filling machines are used in the agriculture industry to fill bags with products such as seed, fertilizer, and animal feed.Accuracy is essential in the agriculture industry, where the proper dosage of products like seed and fertilizer can have a significant impact on crop yields.

Cosmetics industry:

The cosmetic industry is highly competitive, and consumers demand products that are of the highest quality and consistency. Weighing filling machines are used to fill bottles, jars, and other containers with cosmetics and personal care products such as lotions, creams, and shampoos.

Mining industry:

Weighing filling machines are used in the mining industry to fill bags and other containers with minerals such as coal and ore.Weighing filling machines can handle a wide range of bag sizes and types, from small sacks to large bulk bags, allowing mining companies to package their products in a way that is both efficient and cost-effective.

4.What Are The Different Types Of Weighing Filling Machines?

The best type of filling machine for your application will depend on the specific product you are filling, the container size and shape, and the production needs of your operation.

- Vibratory Weighing Filling Machine:

Vibratory Weighing Filling Machine-Photo Credit: Accutek Packaging

Vibratory weighing filling machine is a type of a filling machine that uses vibration technology to fill containers with goods like powders, granules, and small pieces.The product is moved by the machine's vibratory feeder into the weigh hopper, where it is weighed to verify the proper amount is delivered.

The product can flow out of the machine and into the container during the filling operation by vibrating the hopper. As a cost-effective alternative for many firms, vibratory weighing filling machines are also renowned for their dependability, longevity, and little maintenance needs.

- Net Weighing Filling Machine:

Net Weighing Filling Machines-Photo Credit:Liquid Packaging Solutions

Net weighing filling machines weigh the product before dispensing it into the packaging. These machines ensure that each package contains the correct weight of the product. It is used to precisely fill containers with a given weight of product. It works by first determining the empty container's tare weight.

The necessary quantity of product is then dispensed into the container, and by deducting the tare weight, precise measurement is ensured. These devices are frequently used in sectors like food processing, medicines, chemicals, and agriculture where exact measurement and packing are essential.

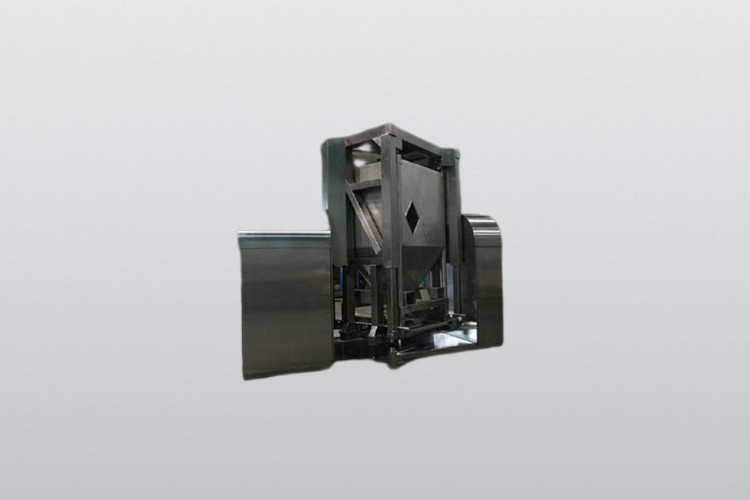

- Auger Weighing Filling Machine:

Auger Weighing Filling Machines-Photo Credit:All Fill Inc

Auger weighing filling machines is made to precisely fill containers with goods that are granular or powdery. The product is dispensed into the containers by use of an auger mechanism, which is made up of a helical screw. Empty containers are set on the apparatus, and a hopper or feeding mechanism is used to hold the product.

To draw the product and move it in the direction of the dispensing outlet, the auger rotates under the power of a motor. A weighing system that controls the filling procedure ensures accuracy in measurement. In industries including food, medicine, chemicals, and agriculture where precise and controlled product filling is crucial, auger weighing filling machines are frequently employed.

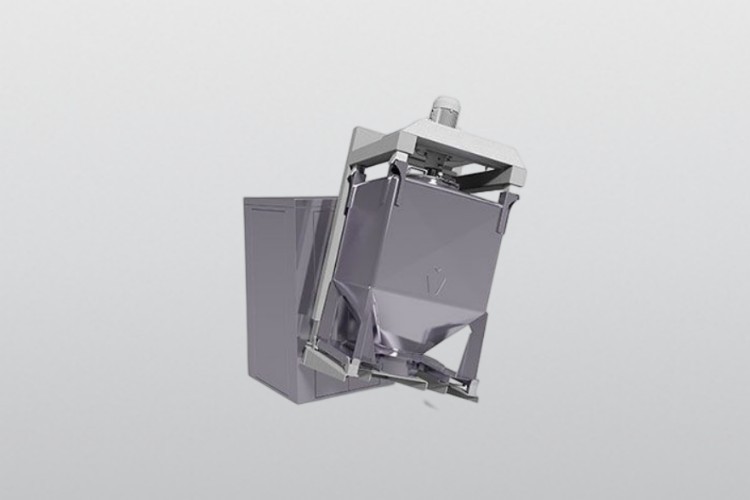

Semi-Automatic Weighing Filling Machine:

Semi-Automatic Weighing Filling Machines-Photo Credit:AUGER ENTERPRISES

Semi-automatic weighing filling machine requires some level of human intervention in the filling process. These machines typically require an operator to manually position the container on the weighing scale and initiate the filling process.

While the weighing and filling operations are automated, the container placement and product commencement processes on these machines require user assistance. A foot pedal or button can be used to start the filling operation after the operator places the container on the machine.

After weighing the container by using load cells or another weighing mechanism, the machine releases the desired quantity of product. The machine stops filling when the desired weight is attained, and the user removes the filled container. Semi-automatic weighing filling machines are appropriate for smaller production because they strike a balance between efficiency and operator control.

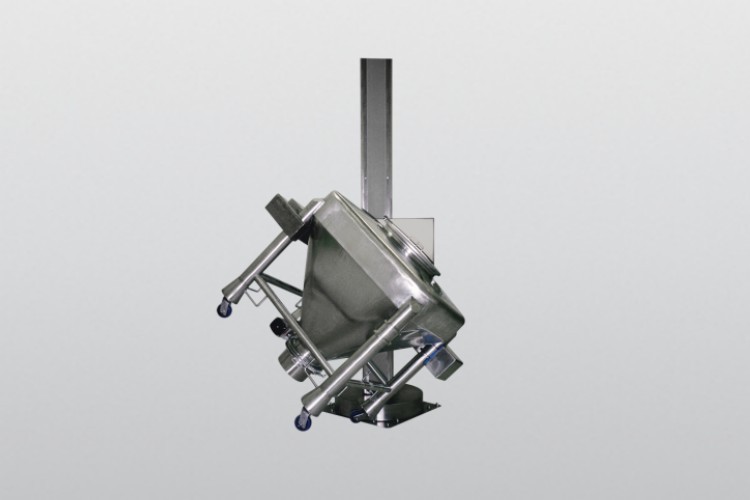

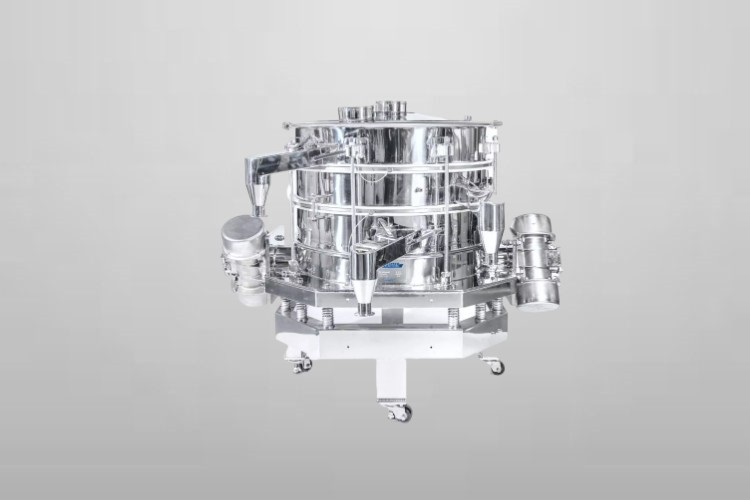

Automatic Weighing Filling Machine:

Automatic Weighing Filling Machines-Photo Credit:NPACK Liquid Filling Machines

An automatic weighing filling machine is a fully automated system that performs all operations automatically, from product dispensing to container positioning, weighing, and filling. The machine can be programmed to fill containers of various sizes and shapes with a precise amount of product, and it can also automatically adjust the filling speed to ensure that the desired weight is reached.

5.How Does A Weighing Filling Machine Differ From A Gravity Filling Machine?

Difference between Gravity Filling Machine and Weighing Filling Machine-Photo Credit:APACKS & Accutek Packaging Equipement

Weighing filling machines and gravity filling machines are two different types of filling machines that operate on different principles.

Due to their excellent accuracy, weighing filling machines guarantee that each package has the proper amount of product. These devices are frequently used to fill containers with liquids, powders, and granules in the food, pharmaceutical, and chemical sectors.

On the other hand, gravity filling machines are more straightforward in design and rely on gravity to fill the packaging with the goods. These devices are frequently employed to fill bottles with liquids like water, juice, and soda.

6.How Does A Weighing Filling Machine Differ From A Volumetric Filling Machine?

Difference between Weighing Filling Machine and Volumetric Filling Machine-Photo Credit:Lodha Pharma

A series of pistons or pumps are used in volumetric filling machines to dispense a predetermined volume of product into the packaging. These devices are frequently used to put liquids, creams, and lotions into containers. Volumetric filling machines are well renowned for their great speed and efficiency and are frequently used for materials that have a uniform viscosity or thickness.

On the other hand, weighing filling machines ensure that each package includes the proper weight of the product and are extremely accurate. Liquids, powders, and granules are frequently packed by using these equipment. Weighing filling machine is renowned for its adaptability, accuracy, and simplicity of use and can handle a variety of product types and container sizes.

7.What Is The Working Principle Of Weighing Filling Machine?

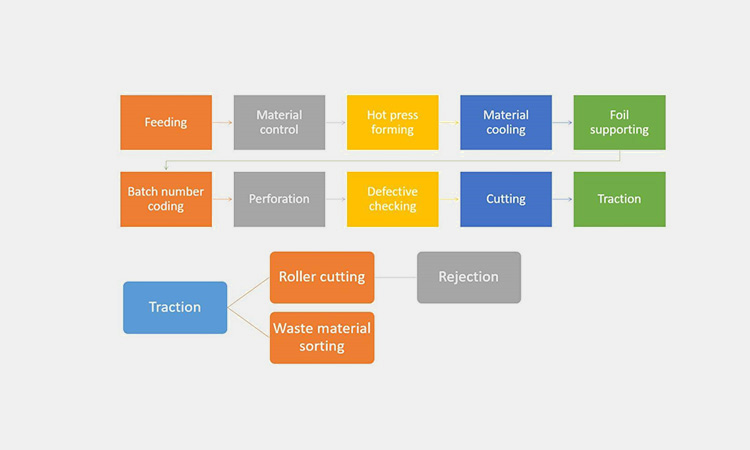

The working principle of a weighing filling machine involves the following steps:

- Product is fed into a hopper or storage tank.

- The weight of the product in the hopper is measured by a load cell, which is a device that converts the weight of an object into an electrical signal.

- Once the desired weight is reached, the filling valve opens and the product flows into the container.

- The filling valve closes when the target weight is reached, and the filled container moves down the conveyor belt.

The weighing filling machine uses a computerized control system to monitor the weight of the product and adjust the filling process to ensure accurate and consistent filling. The control system also stores product and filling parameter settings, allowing for quick and easy product changeovers.

Some weighing filling machines may also have additional features such as automatic tare weighing, which subtracts the weight of the empty container before filling, and automatic capping or sealing of the filled containers.

Overall, the working principle of a weighing filling machine is to accurately measure and dispense a predetermined weight of product into containers, ensuring consistent and high-quality packaging.

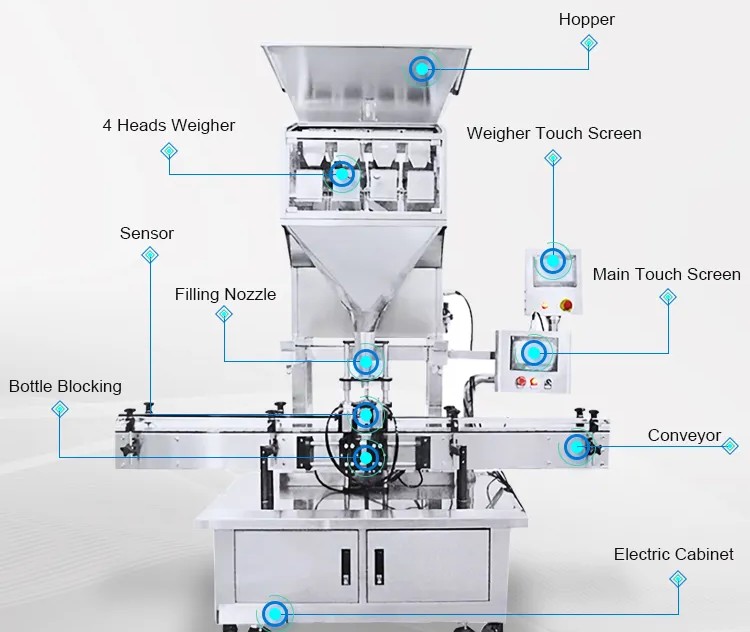

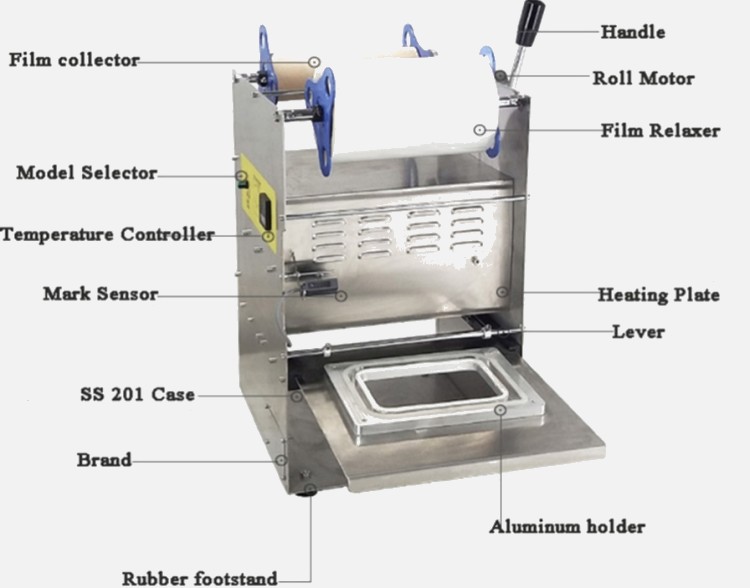

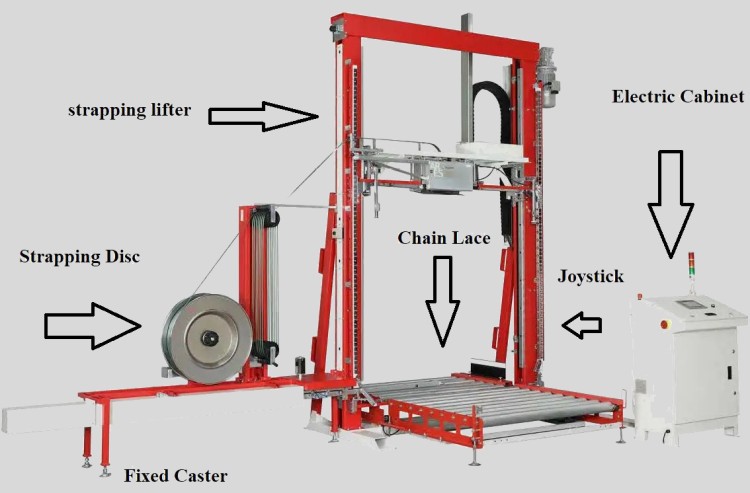

8.What Are The Key Components Of A Weighing Filling Machine?

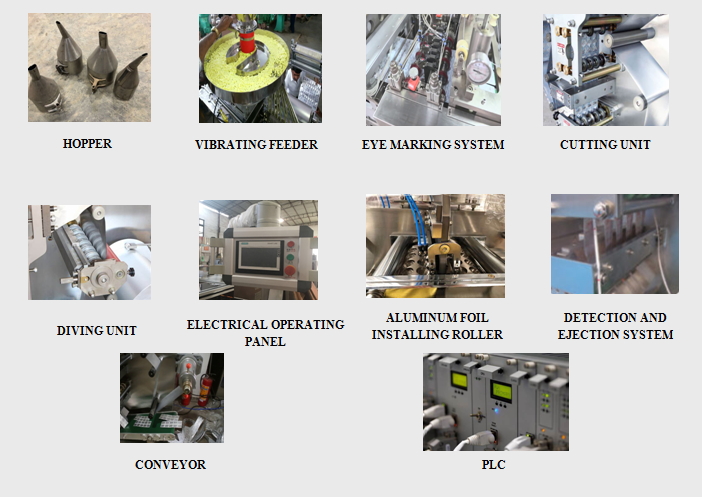

The key components of weighing filling machines include:

- Weigher: This is the main weighing component of the machine that measures the weight of the product in the hopper.

- Sensor:The sensor is responsible for detecting the weight of the product in the hopper and sending this information to the control system.

- Bottle Blocking: This is a mechanism that blocks the container being filled to prevent spillage or overfilling.

- Filling Nozzle:The filling nozzle dispenses the product into the container.

- Hopper: The hopper holds the product to be dispensed into the containers.

- Weigher Touch Screen:This is a touch screen display that provides information about the weight of the product being dispensed.

- Main Touch Screen:The main touch screen is the interface that operators use to control the filling machine and input product and filling parameters.

- Electric Cabinet:This cabinet houses the electrical components of the machine, including the control system and motor.

- Conveyor:The conveyor moves the containers through the filling process, from the filling station to the capping or sealing station.

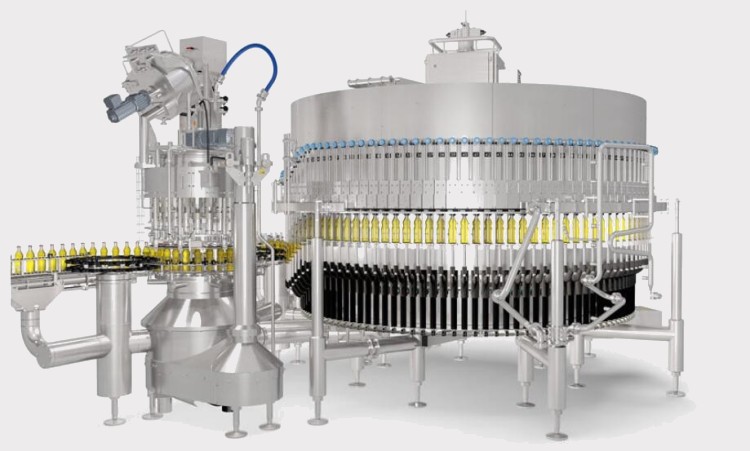

9.Can Weighing Filling Machine Be Integrated With Other Equipment?

Yes, weighing filling machines can be integrated with other equipment in a production line to create an automated and efficient manufacturing process. Here are some machines that can be integrated with weighing filling machines:

Bottle Unscrambler:

Bottle unscrambler: Photo Credit CVC Technologies

A bottle unscrambler is used to orient and feed empty bottles into the production line in an organized manner. It can be integrated with a weighing filling machine to ensure a continuous supply of bottles for filling. The bottle unscrambler aligns the bottles and feeds them onto the conveyor system, which then delivers them to the weighing filling machine.

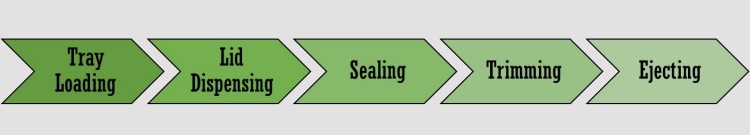

Capping Machine:

After the weighing filling machine dispenses the product into the bottles, a capping machine can be integrated to apply caps or closures to the filled bottles. The capping machine ensures that the bottles are properly sealed, preventing any leakage or contamination.

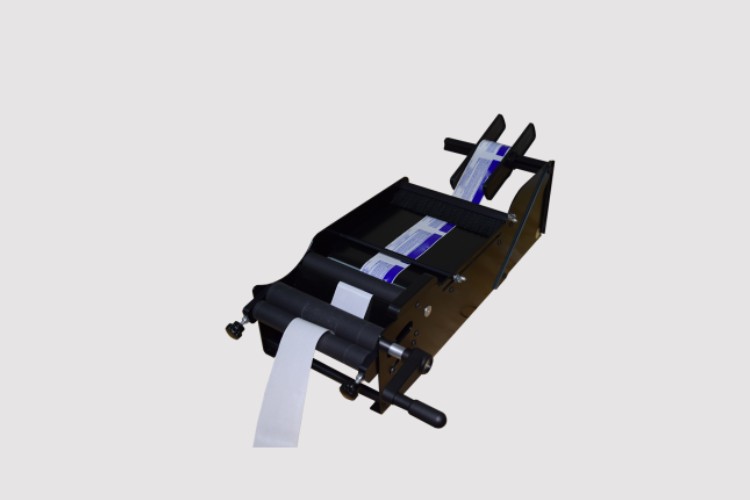

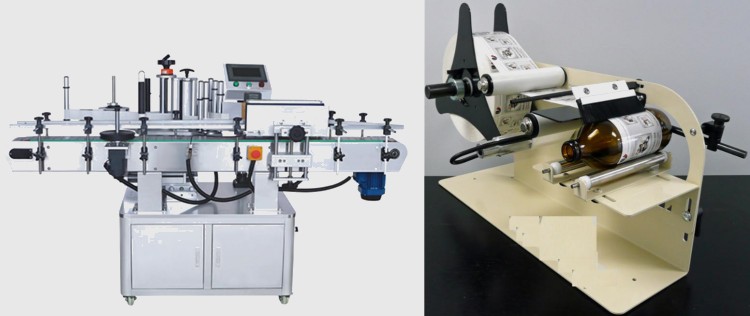

Labeling Machine:

labeling Machine: Photo Credit Wedderburn New Zealand

A labeling machine can be integrated into the production line after the capping machine to apply labels to the filled and capped bottles. The weighing filling machine fills the bottles, the capping machine seals them, and then the labeling machine applies the appropriate labels with product information, branding, or regulatory compliance.

10.How To Maintain Weighing Filling Machine?

Just like every other machine which needs regular check and maintenance to run as efficiently as possible, weighing filling machine too requires proper check and balance to provide maximum results. Let us discuss some of the points on how to maintain this machine.

- Lubricate all the moving parts of the machine which include piston, screws, o-rings to prevent any form of friction which would decrease the overall productivity of the machine.

- Check all the electrical components of the machine and make sure they are properly connected and are not exposed to any wet surface which is quite dangerous.

- Use a microfiber cloth to clean those parts which are covered with dust. Disassemble the moving parts and clean them with regular soap and water appropriately.

- Check the oil level of the vacuum pump and fill them accordingly if the level is not enough to run the machine.

- Check of the air distributor is working properly and add silicon grease regularly so that it works at optimum conditions.

- Keep an eye out for all the components which include hopper, weigher and nozzles and make sure they are working fine. If they show any signs of damage, then repair them immediately or replace them with new components.

11.How To Troubleshoot The Weighing Filling Machine?

When troubleshooting a weighing filling machine, here are some common issues and their potential solutions:

Inaccurate Weighing:

- Ensure that the machine is properly calibrated according to the weight standards.

- Check that the load cells or weighing sensors are clean and free from any debris or obstructions.

- Verify that the weight settings and parameters are correctly programmed for the desired fill volume.

- Inspect the feeding mechanism to ensure that it is delivering the correct amount of product to be weighed.

Slow Filling Speed:

- Check the product supply system, such as pumps or valves, to ensure proper flow and pressure.

- Verify that the machine settings, such as fill speed and timing, are optimized for efficient operation.

- Clean or replace any clogged or worn-out parts that may be hindering the filling speed.

- Ensure that the product being filled has appropriate viscosity and is not causing excessive resistance.

Leaks or Spills:

- Inspect all seals, gaskets, and connections to ensure they are tight and in good condition.

- Check for any damage or wear on the filling nozzles or dispensing mechanisms and replace as necessary.

- Ensure that the bottles or containers being filled are properly positioned and sealed to prevent leaks.

- Adjust the fill volume and speed to minimize the chances of spills during the filling process.

Machine Jamming:

- Examine the feeding system to ensure there are no blockages or obstructions that could cause jamming.

- Lubricate moving parts and check for any signs of wear or misalignment that could lead to jams.

- Verify that the control system and sensors are functioning correctly to detect and prevent jams.

- Ensure that the bottles or containers being used are compatible with the machine and do not cause issues with the feeding or filling process.

12.How To Choose The Best Weighing Filling Machine?

Following are some of the key features which should be considered to choose the best machine.

Type of Weighing Filling Machine:

Depending on the specific product, a buyer may need to consider different types of weighing filling machines such as volumetric, gravimetric, or combination systems. For example, a buyer looking for a machine to fill liquid products like milk or juice may prefer a volumetric system, while a buyer filling granular products like rice or beans may prefer a gravimetric system.

Production Efficiency:

The production efficiency of a weighing filling machine is a critical consideration. Buyers should look at the machine's maximum production speed, the accuracy of the filling process, and the machine's downtime. For example, a buyer who needs to fill a large volume of product per hour may need a machine with a higher production speed and less downtime.

Compatibility with the Material:

The compatibility of the weighing filling machine with the product material is also essential. For example, if a buyer is filling powders or granular materials, they may need a machine with specialized handling features such as dust control or anti-static materials.

Budget:

Buyers must also consider their budget and the overall cost of ownership when choosing a weighing filling machine. Factors such as the machine's purchase price, maintenance costs, and energy consumption should be evaluated to ensure that the machine fits within the buyer's budget.

Conclusion

In conclusion, weighing filling machines are an important asset for various industries that require accurate and efficient filling of products. They offer a wide range of benefits such as increased productivity, reduced labor costs, and improved accuracy. By considering key factors such as the type of product, filling volume, and required accuracy, businesses can make an informed decision when selecting a weighing filling machine that will meet their needs and provide the best return on investment.

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide

Weighing Filling Machine: The Complete Buying Guide In 2025 Read More »

Company Background & Information

Company Background & Information

Company Background & Information

Company Background & Information

Company Background & Information

Company Background & Information

Tell us your material or budget, we'll reply you ASAP within 24 hours

Tell us your material or budget, we'll reply you ASAP within 24 hours