V Type Blender: The Complete Buying Guide In 2025

V Type Blender: The Complete Buying Guide In 2025

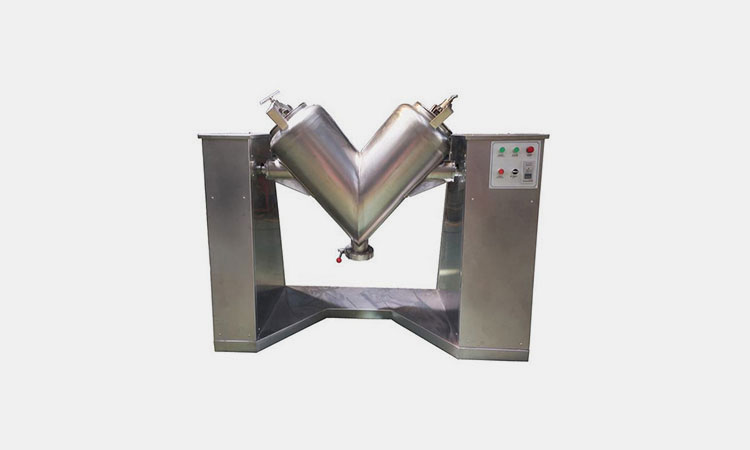

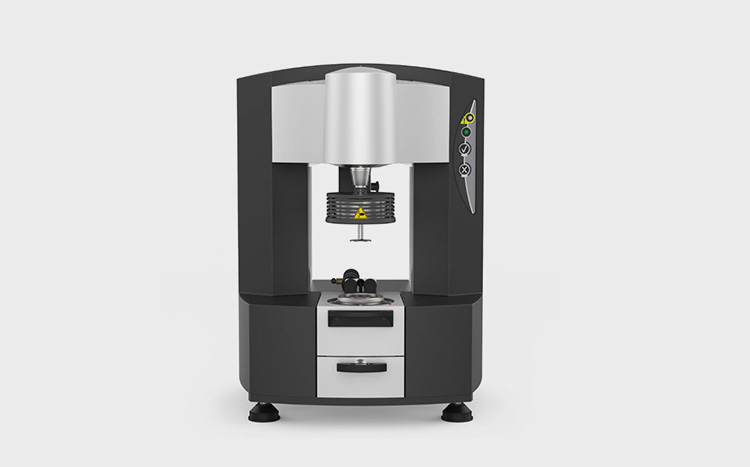

Food, pharmaceutical, chemical, polymer and other industries are always in concern for blending of heavy particles into small size. As the name explains, it consists of v type shape that is used to blend granules and powder to form perfect mixture. Materials can be blend to fine particles once they are experienced in a v type blender.

There is variety of v type blenders available in the modern world. Each of industry is using it for blending and mixing purpose. Allpack in this regard also manufactures variety of v type blenders and its accessories. This buying guide is designed for providing more information to the customers. So take the most of it!

1. What Is A V Type Blender?

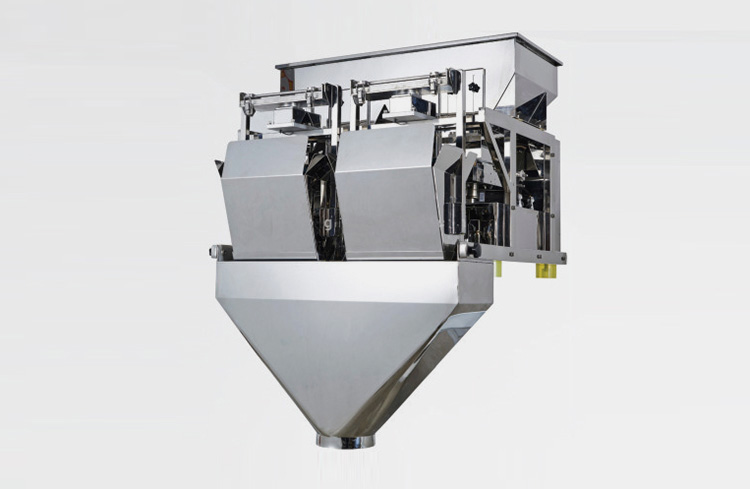

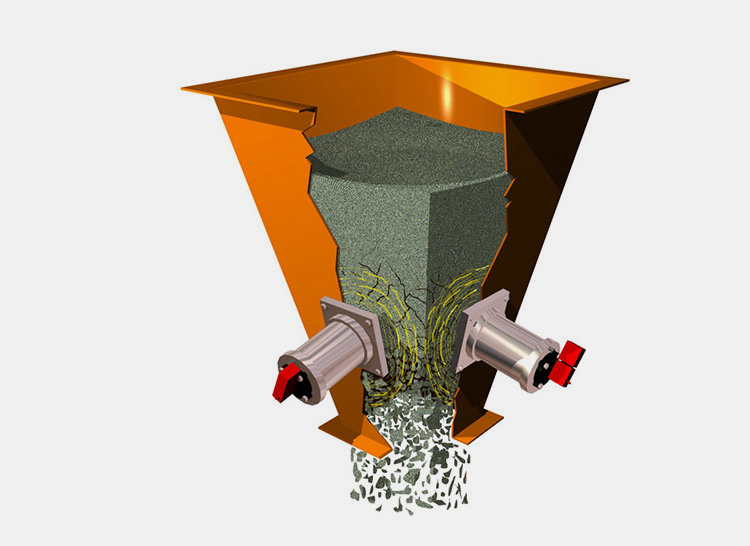

Industries prefer v type blender for efficient and accurate blending of heavy materials to fine and powdered form. The blend is high capable of mixing and blending these heavy particles used in chemical, powder, plastic, pharmaceutical and food industry. The motion of centered v shaped container helps in cutting and mixing of particle when they pass through the agitators.

The material is poured from one side of the blender and its three dimensional moving effects give highly precise results. Once the particles are blend into desired form they are taken out of the other side or lower part of the container.

2. What Are The Applications Of V Type Blender?

It has various types of application and some of them are in

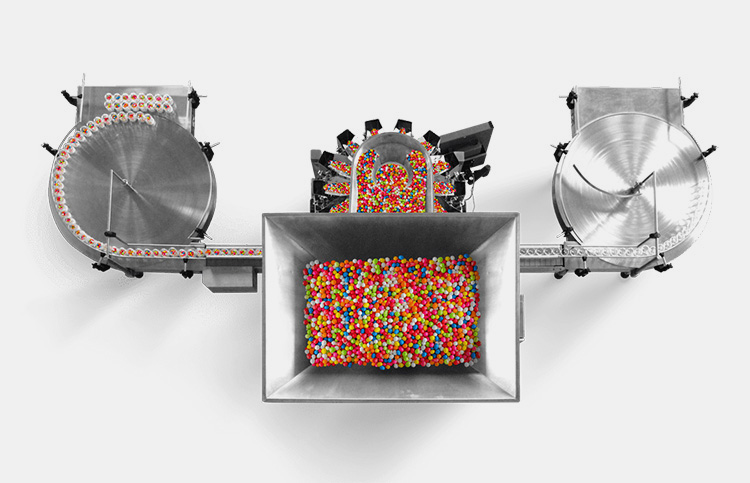

- Food Industry

The food industry is the highest consumable of v type blenders as it blends vast number of products into fine particles. Food industry also uses type blenders as mixers for mixing of different compounds. The final products are hygienic and highly secure to use in the preparation of food products. Some of the foods including cocoa powder, flour, wheat flour, wet flour and fresh meat are blended in a v type blender.

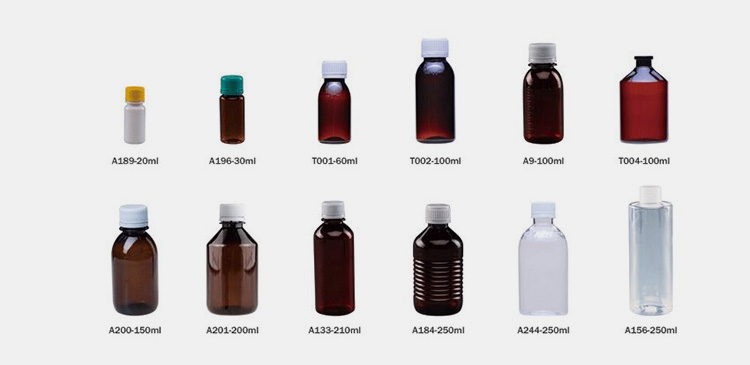

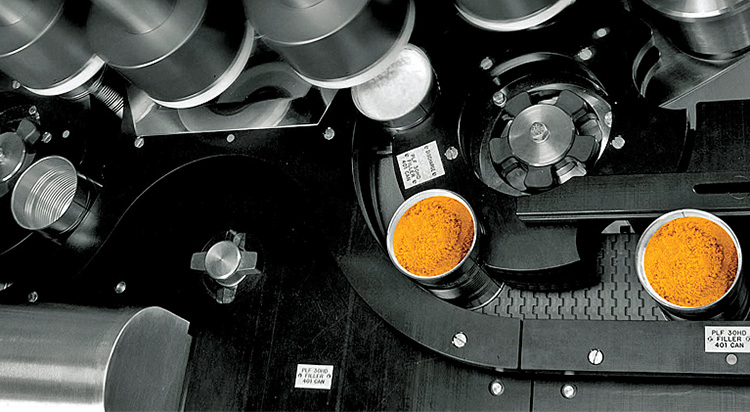

- Pharmaceutical Industry

The pharmaceutical industry is the second biggest user of v type blenders. Medicines are poured and mixed at a high accuracy using a v type blender. By products of medicines and supplements that are hard and heavy in size are then further blended and used for making of tablets, syrups, suspensions, antibiotics, anti bacterial medicine and capsules. All active ingredients including cellulose, starch, gelatin and lactose are blended into fine powdered particles using a v type blender.

- Chemical Industry

The chemical ingredients including dyes, pigments, powders and substances are uniformly distributed and mixed to form single processing products in a v type blender. Paints, detergents, plastic granules, resins, fertilizers granules, agrochemical seeds, fillers, minerals, crystal form of salt and sugar and other chemical products uses these mixtures as their byproducts.

- Agricultural Industry

The raw materials of agricultural industry are efficiently blended and processed in a v type blender. Blending process is done in both semi-automatic and manually according to the machine specifications. This process requires lot of farmers and also consumes too much of time. V type blender has reduced both time and labor cost at a distinct level.

Agricultural feed, proteins, vitamins, enzymes, meal, supplements, pallets, bio control agents, anti-insecticides, nitrogen, phosphorus, zinc, organic material, potassium, minerals and oats are some of the agricultural products that are blend in a v type blender.

- Cosmetic Industry

The cosmetic industry also uses v type blenders for mixing and uniform production of chemicals that are applied on human body. Proper mixing of these products is necessary as it has a direct consent with human body. Creams face and eyes talc, blushes and oils are some of the cosmetic products that are blend in a v type blender.

- Plastic Industry

The plastic industry also uses v type blenders for accurate mixing of plastic polymers and other type of resins. These units consistently mix these substances for better compounding results.

3. Does A V Type Blender Perform Mixing Or Blending Of Different Particles?

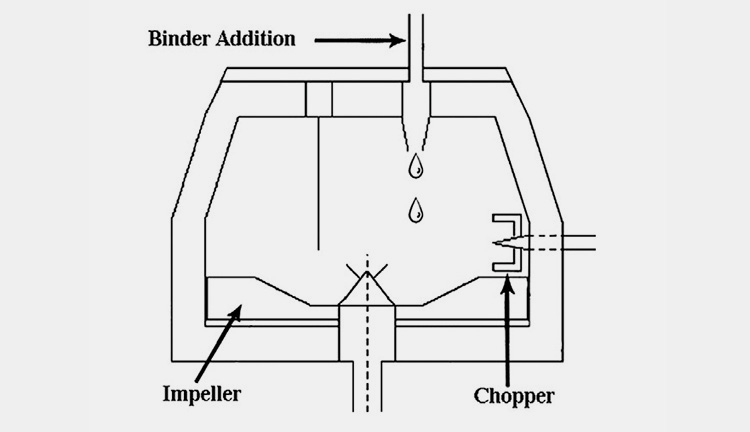

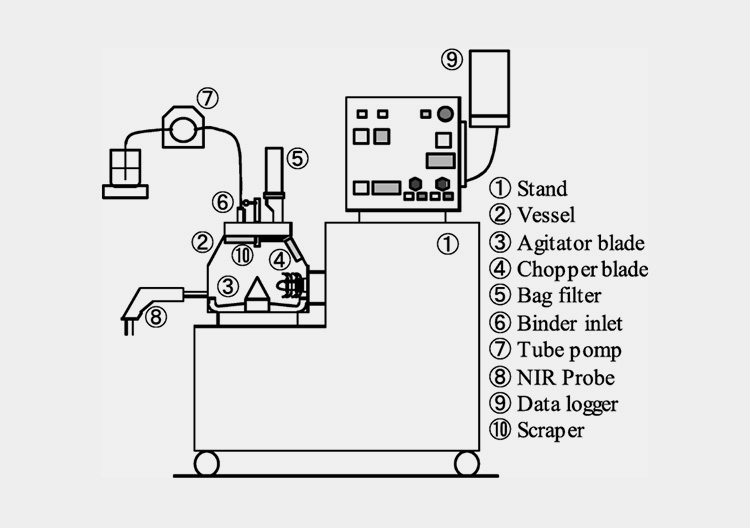

A v type blender has an ability to perform both mixing and blend in a single stainless machine. The vessel has couple of inclined agitators that includes blades in its construction. The rotation of these blades causes both mixing and blending of particles and results in homogenous mixtures.

- As A Mixer

Ideally a v type blender is used as a mixer as it can mix variety of materials together using its sharp blades and other supporting liquid content. Here the mixing of dough acts as a mixer in state.

- As A Blender

A v type blender acts as a blending machine when different types of heavy particles are tend to form micro level fine particles. Here different types of salts, mixtures and materials are blended so that they can be used as primary source in other products.

4. What Type Of Products Requires Blending By A V Type Blender?

The types of products that can be blend with a v type blender are as follows

- Dry Solids

Products produced in different industries including ceramics, cosmetic products, fertilizers, spices, and coffee and bakery use dry solids as their basic ingredients.

- Shiners

Varieties of shiners that are products in cosmetic industry are used as shiners and need to be crushed in fine particles. A v type blender assists in blending of these muscovite products into fine powder.

- Flour

Flour is also one of the most important products that are blended using a v type blender. Flour grains are mostly crushed into fine powder using sharp blades of v type blender and often mixed with other products like water, salt, milk or etc. in the same room. These fine particles of flour are then used as byproduct in many eatable, confectionary and food products.

- Food Supplement Powders

Food supplements including proteins, fibers and calcium are also blended in v type blenders to get quality powdered results. These products are then utilized by human being as a source of energy and also as a replacement of unhygienic food. Food and pharmaceutical industry product such type of food supplementary products on large scales using a v type blender.

5. What Are The Advantages Of A V Type Blender?

It is hard to find blenders with perfect mixing to blending options. Some of advantages of a v type blender are

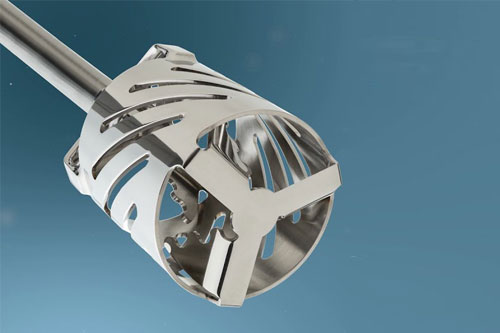

- Delicate Construction

V type blenders are famous for their unique design and have blades with agitators that blend the materials into fine particles. This process gives excessive particle size reduction which is required for many delicate substances.

- Efficient Material Flowing

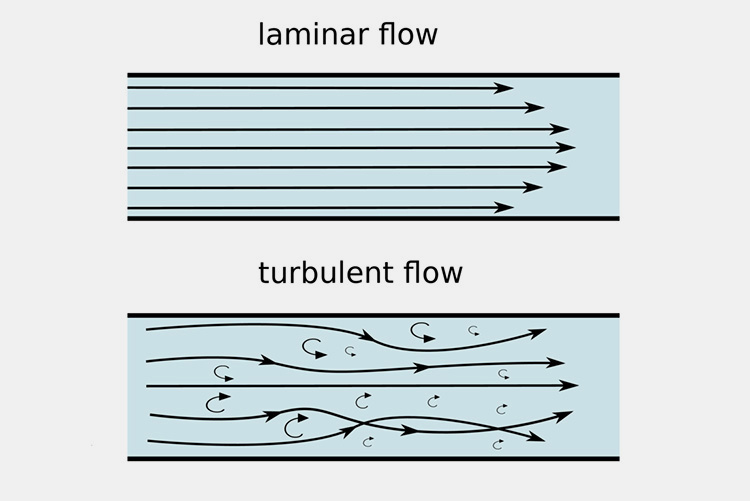

V type blenders are so perfectly designed for proper mixing of free flowing substances. The material flows smoothly within the system and is mostly preferred from pharmaceutical industry due to its diverse application.

- Preventing Distorting

One of the important benefits that can be gained using a v type blender is that the mixture remains smooth throughout the process. The particles are mixed together in a way that they certainly do not distort and also do not change the shapes. A rigorous shear mixing force widely helps in breaking large particles into desired small porous shaped particles.

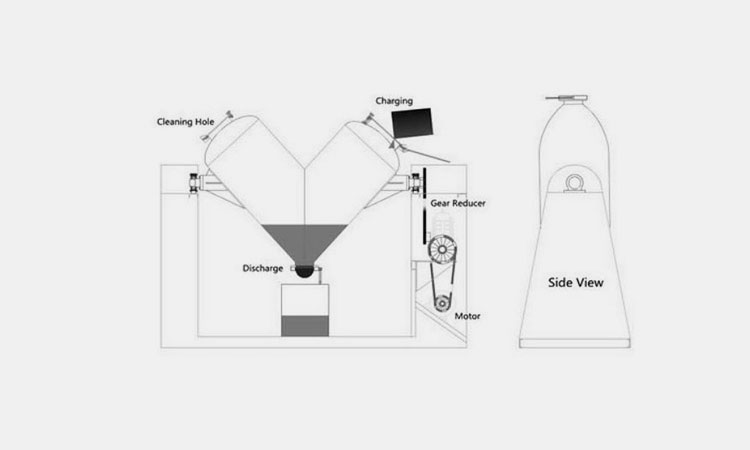

- Material Discharging

V type blenders are equipped with discharging channels that are present in the lower centered curve. The containers can also be discharged completely through these discharging channels. This discharging channel is designed in a way that all the waste can be removed and the process of cleaning may be done easily.

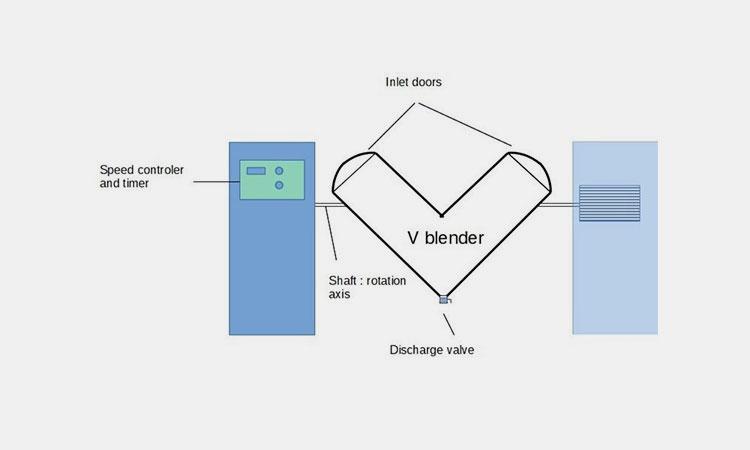

6. What Are The Working Principles Of V Type Blenders?

A v type blender follows following steps during its operation

- In a v type blender the rotary motion is generated by the difference in sizes of two barrels or inlet doors.

- Due to the difference in shaft and stand, the machine gets a greater support for other operations. Once the operation of machine gets started the materials gets decomposed and are mixed together go as horizontal movements are always difficult to assist.

- The observation is kept under ideal circumstances as the material produces radial flow and it is also important for them are radial flow remains the only discussion.

- At the end when the condition is trained you are not supported. Complete from the service males is submitted.

- The final and blended product is then removed out of the system and used in different processes.

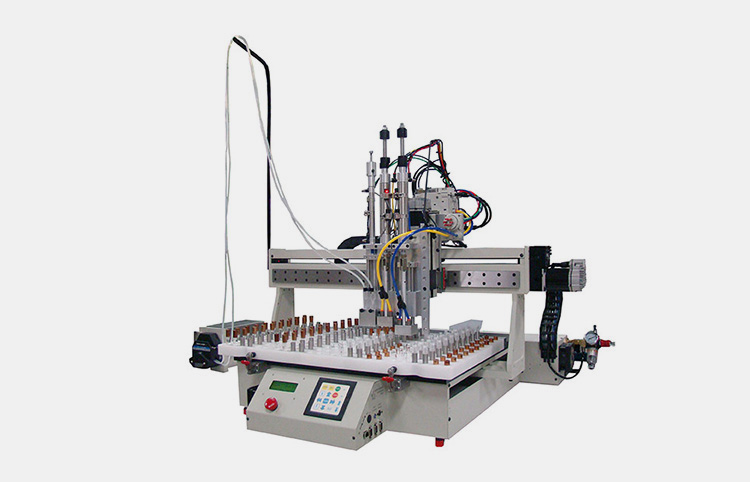

7. What Are The Main Components In V Type Blenders?

Main components of a v type blender are as follow

- Inlet Doors

Inlet doors are used for both loading and unloading of material. These doors are present at the opening sides of blender and can be opened or closed for material loading, mixing and unloading.

- Shaft

The v blender is attached to the base of a v type blender with the help of a shaft present at both sides of machine. This shaft controls the movement of a v type blender and also provides strength to its base. The rotational effect caused by motor is also directed to these shaft when then cause directly in movement of channel.

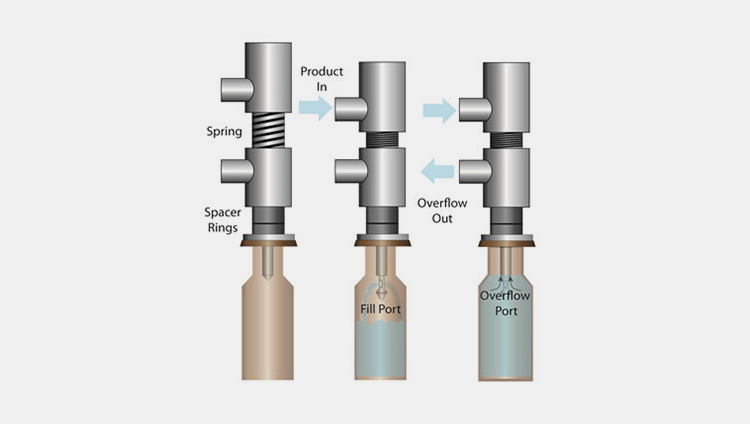

- Discharge Valve

Discharge valve is present in the bottom center of v type blender from where the mixed solution is discharged from the system. Mostly the lower end is preferred for this discharge chute as maximum product gets withdrawal and minimum wastage of material occurs.

- V Blender

The v blender or v tank is the place where all the ingredients are mixed and blended in a uniform manner. The blades and agitators are also present inside of this v blender. Here the mixing and blender of materials is done which is then removed from discharging valve after its completion.

- Speed Controller And Timer

Speed controllers and timers are responsible to control the movement cycle of v blender in a minute. This is the place from where the systems gets on and shuts off. All the mixing parameters and safety features are also controlled form this channel.

8. What Are The Types Of V Type Blenders?

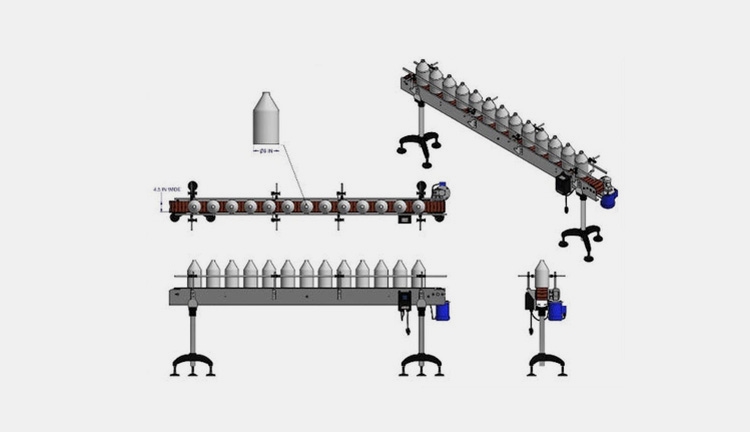

There are two main types of a v type blender are depending upon its productivity and application. Following are the types of a v type blender

- Mini V Type Blender

Mostly small scale setups are the places where mini v type blenders are used. These are such small that easily can be adjusted on platforms and also it is easy to access them. The granules are poured manually into the system and in small quantity, and then these particles are reintegrated gently. Once the process gets completed the operator removes the mixed fine powder out of the system.

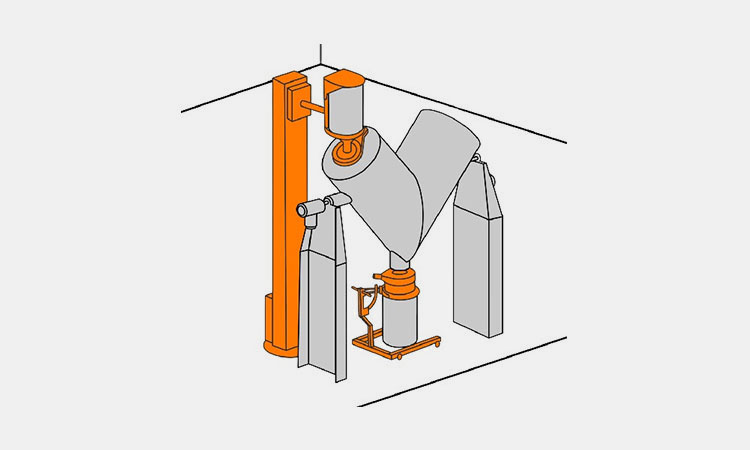

- Large V Type Blender

Large v type blenders are mostly found with complete automation and are highly precise in their operations. It has a free flowing property of materials in bulk quantity. The material is poured automatically through pre-channels where the basic steps are performed.

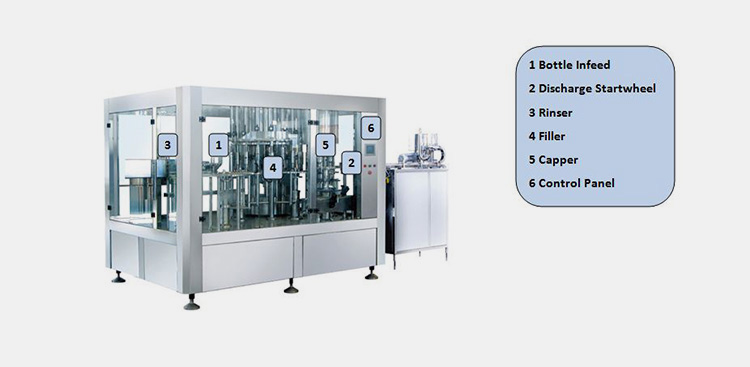

This material is then entered into the blender and then with uniform movement the particles are automatically blended into fine particles. The mixed final product gets removed from the v blender through automatic channels and is then packed into their desire packaging materials.

9. What Are The Important Controlled Parameters Of Blending In A V Type Blender?

Some of the common controlling parameters in a v type blender are

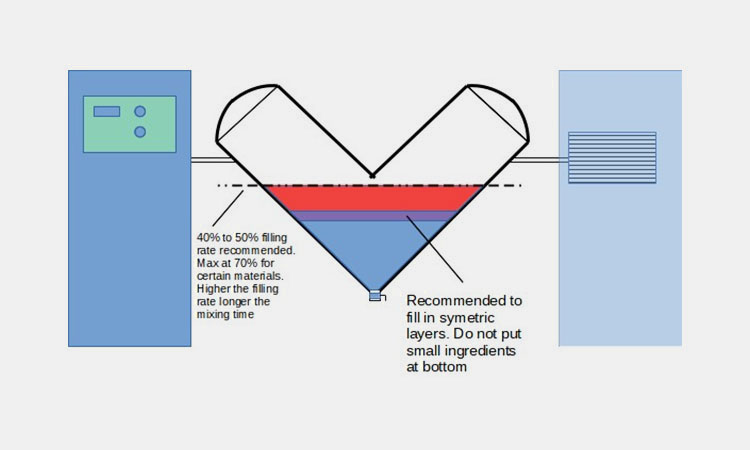

- Filling Level

The most important parameter to control is filling the appropriate level of products into the container or v blender. It is important that the ingredient and blender volume should be kept under consideration when ingredients are filled into the blending chamber. Uneven ratio can cause improper mixing of particles.

- Speed

Another critical parameter is to set the rotational speed at a standard level. As speed can directly affect the properties of mixing including excessive breakage of material, it is important to let the shear forces take their accurate time to get efficient results.

- Production Batch Size

The capacity of batch size poured into the blending chamber should be according to the standard size of it and also in a perfect ratio. This can ensure precise mixing of substances and can also prevent the system from overflow of these particles.

- Moisture

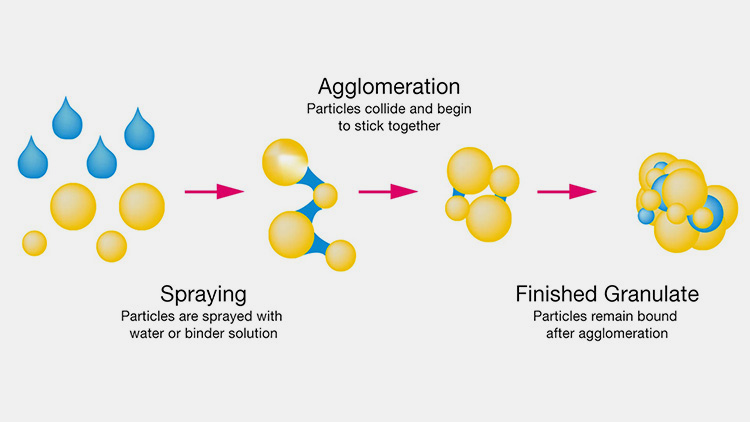

Cohesion of materials and their flow can directly be get effected by the moisture content present in it. If it is not controlled properly, the material mixing can cause agglomeration and clumping and that can cause in direct material loss.

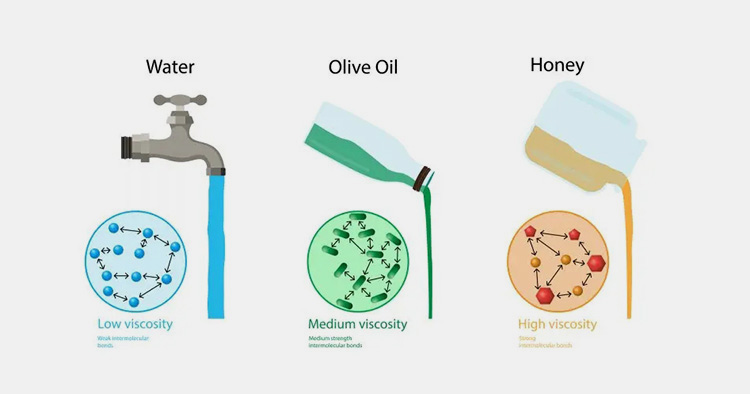

- Material Density

Density is yet another important parameter to be controlled during the mixing of particles. The density and size of particle plats a vital role as large sized particle can get segregated from the mixing process and will result in improper blending. Uniformly in blending process requires controlled particle size and density.

- Blending Duration

Pure fine particles are only obtained when the blending duration is set to a standard value according to the material used. It is necessary to blend particles for determined time so that the desired quality can be achieved. Improper blending time can cause the manufacturer both material and time wastage.

10. What Are The Differences Between A V Type Blender And A Double Cone Blender?

Differences between a v type blender and a double cone blender are

- Construction Design

A v type blender is v shaped at the center which is used for proper blending and mixing of particles. This cylinder is attached with the shaft of stand that allows its rotary movement with the help of motor.

In a double cone blender, the two common cylinders are attached in a conical shape that forms a complete blender. These containers are joined at a particular angle depending upon the rotational demand of the production.

- Range Of Mixing

A v type blender allows mixing of ten or more than ten ingredients in a single process.

Whereas a double cone blender limits its mixing capacity in between of two to five ingredients.

- Working Operation

The either side of a v shape blender is used for pouring the material into it and then moves with the help of motors associated with it. Once the blending is performed through the agitators and blade present inside the blender, fine particles are taken out of from the other side opening or from the discharge channel of a v type blender.

A double cone blender starts its working operation in a way that the material is first fed into the conical containers, it flows from top to bottom and vice versa. This movement faces blades in between that blend the material into fine particles. The blended material is then taken out of the system.

A double cone blender performs the operation in a much slower speed but gives precise solutions as a result of it. The slow process also assists the manufacturer to get long tern fine products.

- Mixing Property

Both the v type blender and a double cone blender allow the mixing of wet materials and also the blending of these ingredients. Both blenders give unique and accurate results of wet ingredients.

- Cleaning Process

V type blenders are highly versatile and have such a shape that their cleaning process can take easily. The wastage can easily be taken out of the system via discharge opening present at the bottom of it.

On the other hand, the construction of a double cone blender is not much complex. The opening and inner wide gap can make the cleaning process comfortable. Although it requires keen observations and effort as compared to a v type blender.

11. What Factors Can Affect The Efficiency Of A V Type Blender Due To Its Complex Structure?

The complex design of v-shaped container is supported with the two rotating shafts that cause its rotation. Some of the factors related to it can be

- Improper Mixing Time

The leading problem due to the complex structure of a v type blender is its improper mixing time. This is due to the reverse response from agitators once they are not maintained properly. A homogenous mixture in this regard cannot be gained once the blending time gets increased.

- Electrical Energy

Mostly importantly, the complex structure requires high energy and power. Once the motor does not get required input power, it reduces the efficiency of agitators and that result in improper blending and mixing. It is important to maintain the input power level throughout the process that is sometimes difficult to.

- Rusty Bearings

Once the bearings associated with the moving chain gets rusty, it directly effects the movement of blender and shaft both. This performs improper mixing of materials and also no uniform results are obtained.

12. How Different Type Of Products Can Easily Blend In A Single V Type Blender?

Variety of blending results can be obtained through a single v type blender. Some of them are

- Powerful Blades

The blades inside a v type blender are much sharp and powered that any type of material can be blended using this machine. These particles experience continuous blending and end up with pure fine particles.

- Pre-Processes

Some of the large v type bender that undergoes pre and post-mixing steps in automated process support in blending and mixing of a variety of materials. Pre-processed materials are blended or mixed together to form fine particles. Fine particles if left with any purity are then further crushed in another process ahead.

- Contamination Free Blender

The most viable reason for multiple types of material blending is that the machine is completely contamination and rust-free. It is easy to clean and also supports inner contamination-free blending.

13. What Should Be Considered Before Purchasing A V Type Blender?

Some of these important considerations are

- Blending Application

The task v type blender perform are different in its different types. It is always necessary to consider that what and where the selected blender can be used in. The buyer should be concerned towards the application of v type blender before buying it.

- Construction Of Blender

Before selecting a v type blender, it is also important to check the construction and appearance of it. Different sizes of v type blenders are present globally so the one compatible with production in terms of its construction should be selected.

- Blending Volume

The customer should match the right type of blender best suited according to their requirements. V blenders with low container volume cannot be suitable for high-scale productions. The blending volume in a single cycle should be closely observed and matched with the requirements.

- Cleaning Methods

V-type blenders with proper discharging channels are important to be considered as the material or residuals can be removed easily through these channels. Also, these cleaning methods can avoid any type of contamination.

Conclusion

V type blenders are globally recommended for pure and efficient blending of different sized particles. These particles are blended to fine powders and are further used in several product formations. With variety of manufactures, it has now become difficult to select the best type of v type blender. Allpack gives a wide range of v type blender to its customers with advanced technology. For more information and query contact our representatives or visit our website https://www.allpackchina.com/.

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide

Tell us your material or budget, we'll reply to you ASAP within 24 hours

V Type Blender: The Complete Buying Guide In 2025 Read More »

Tell us your material or budget, we'll reply you ASAP within 24 hours

Tell us your material or budget, we'll reply you ASAP within 24 hours