Chamber Vacuum Sealer VS Suction

Chamber Vacuum Sealer VS Suction

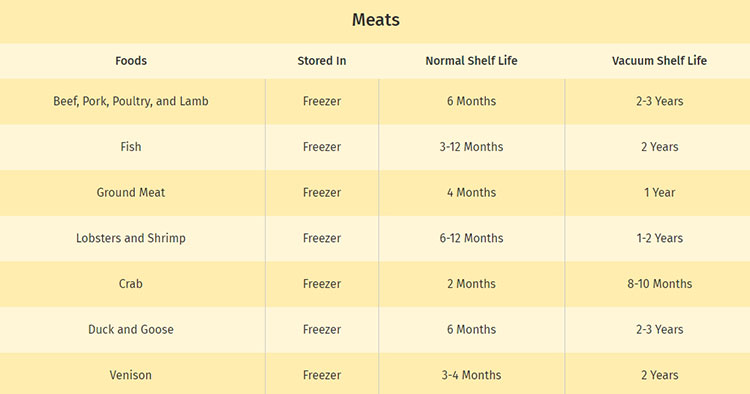

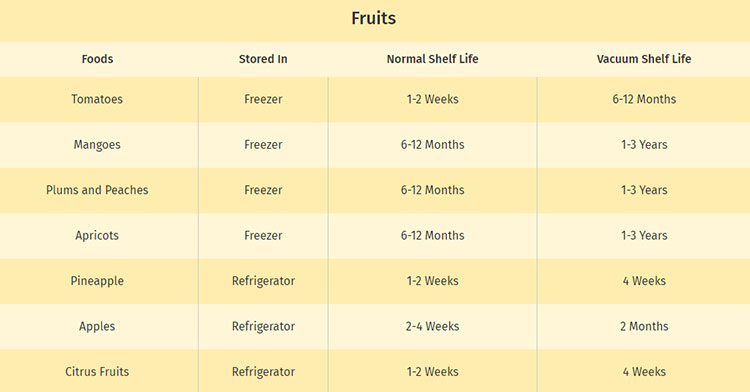

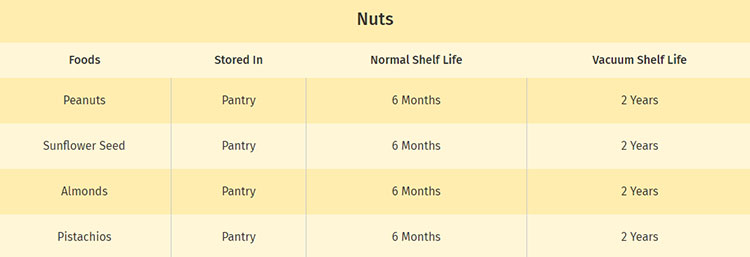

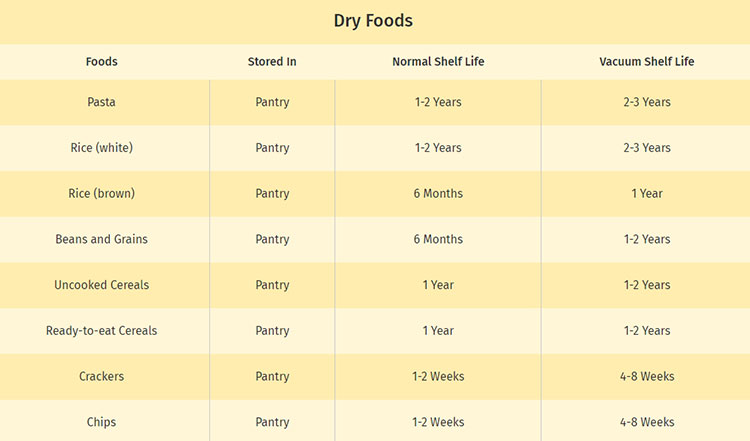

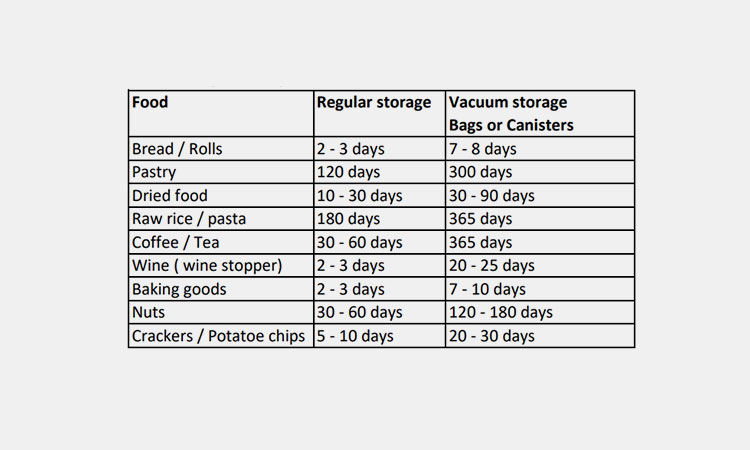

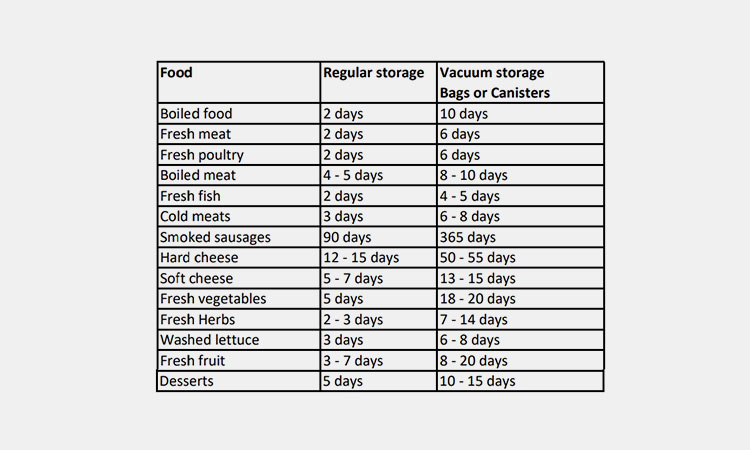

Food products can not be preserved forever, but you can try some methods to extent their shelf life, one of the most effective methods is vacuum sealing. There are many different kinds of vacuum sealers, but the most common ones are chamber vacuum sealer and suction vacuum sealer. The two different types of vacuum sealer have different appearances and they are suitable for different demands.

Are you curious about the differences between chamber vacuum sealer and suction vacuum sealer? Do you want to know which one of them can meet you food storage demand? You can find what you want in this blog which compares chamber vacuum sealer and suction vacuum sealer in different aspects, let you have a deeper understanding of them.

1.What is chamber vacuum sealer vs suction?

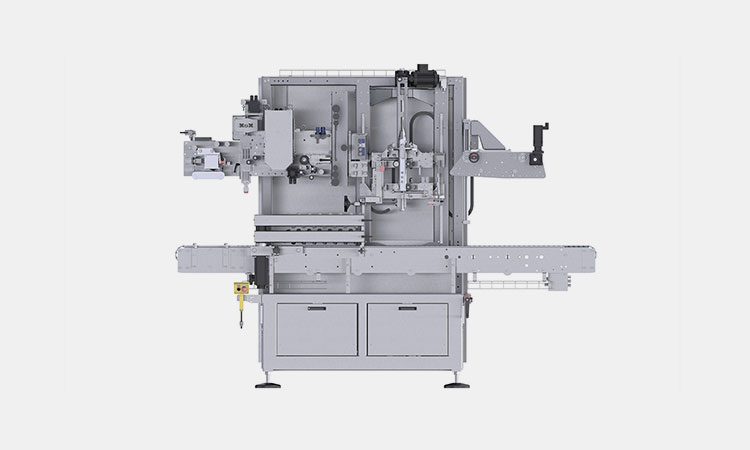

Chamber Vacuum Sealer

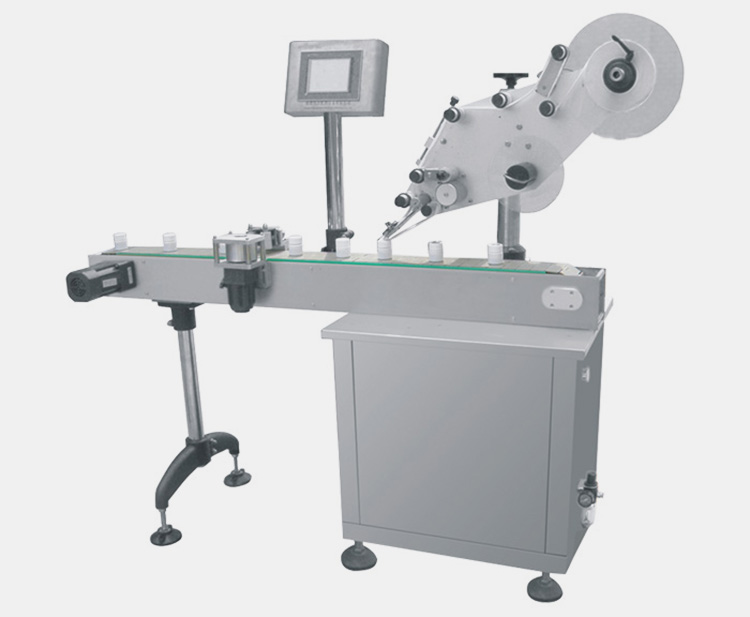

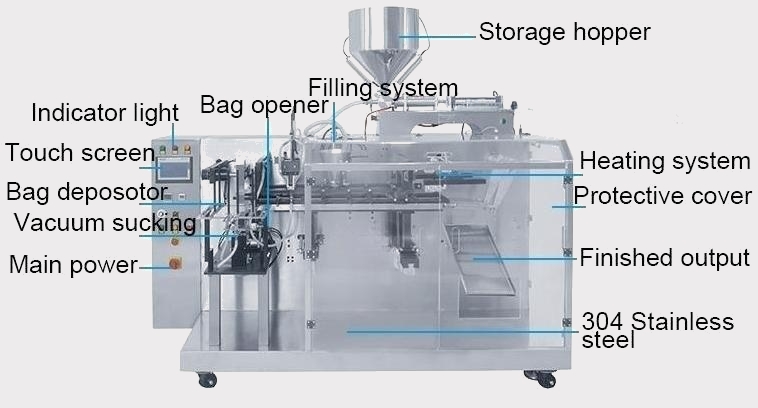

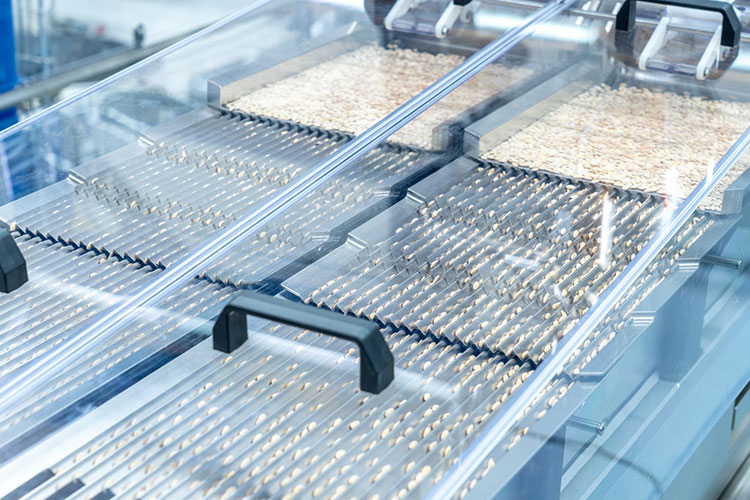

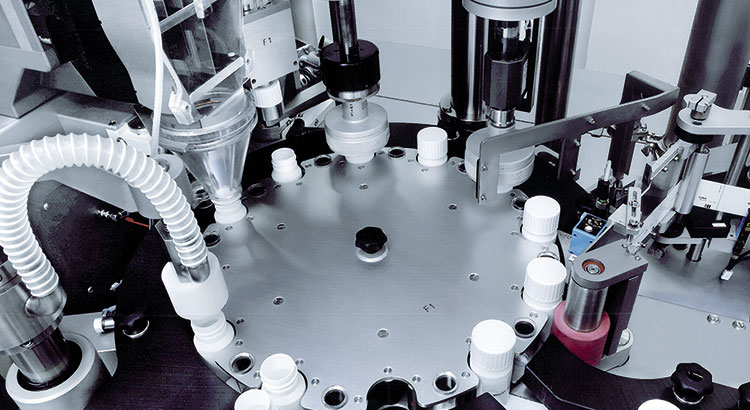

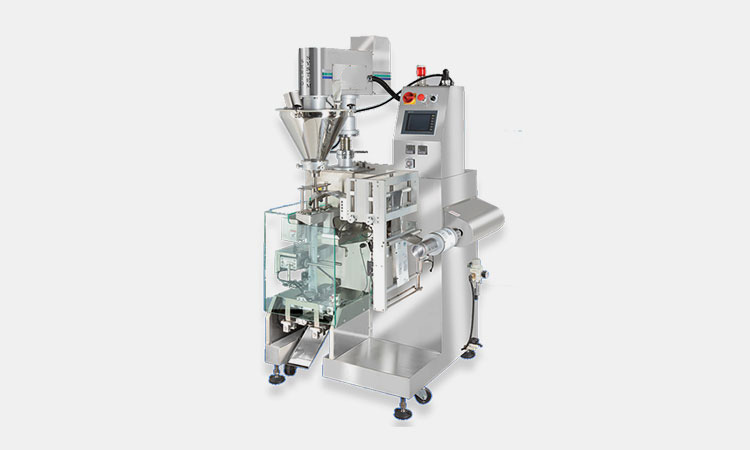

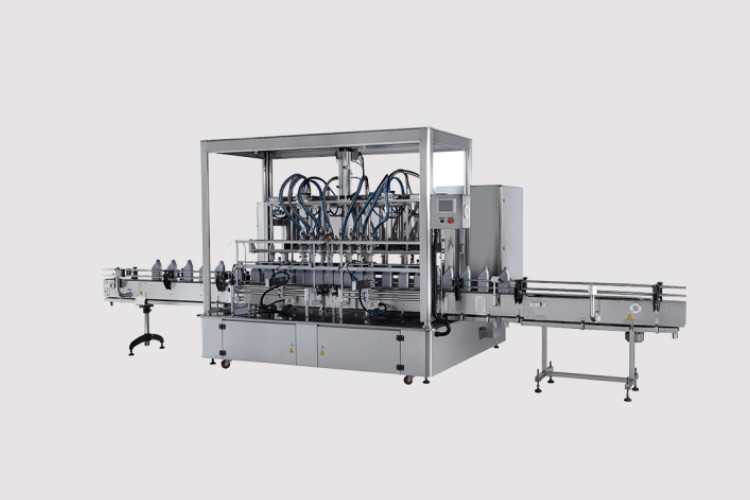

Chamber vacuum sealer is an packaging equipment which can provide vacuum sealing operation to all kinds of items, such as food products, medicines, hardware, chemicals, grains, etc. It can extract the air inside a bag and then seal it quickly so that the product in the bag can be stored for a longer time.

This machine has a chamber, during its working process, the product which is going to be vacuumed is put in the chamber. Chamber vacuum sealer has a wide range of application, it can be used for both family and commercial use.

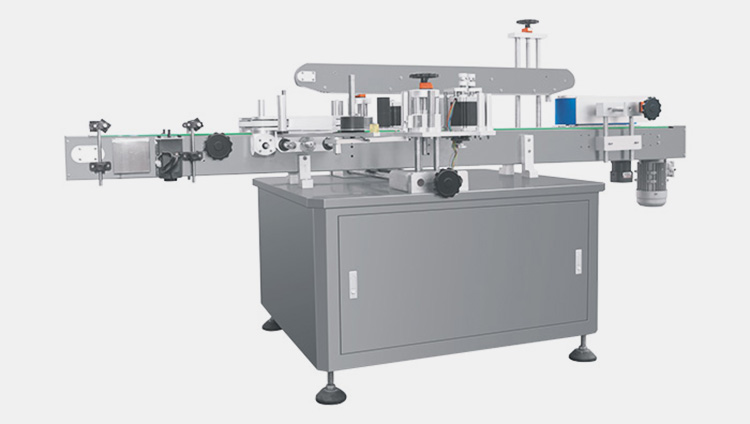

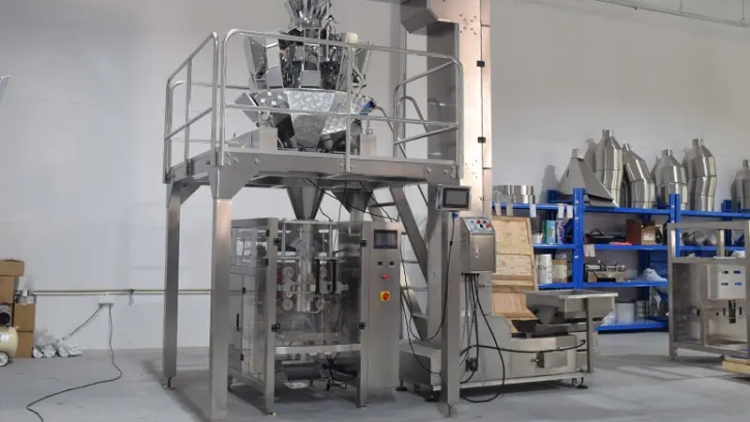

Suction Vacuum Sealer

Suction vacuum sealer is also used to vacuum packed products, it provides tight sealing to products, especially food, different from chamber vacuum sealer, suction vacuum sealer doesn’t have a large chamber, therefore, the vacuum process occurs outside the machine. As you can see, suction vacuum sealer is small in size so that it can be operated anywhere, it is generally used for household.

2.How can chamber vacuum sealer vs suction benefit you?

When talking about the benefits of using chamber vacuum sealer and suction sealer, maybe most of you will say that they can help you extend the shelf life of food, or they can keep the original taste of food. However, these are the basic role of them, are your curious about other benefits of the two machines? They are as follows:

- Benefits of Chamber Vacuum Sealer

(1). Wide Range of Application

One benefit of chamber vacuum sealer is that it has a wide range of application, this machine can seal almost all kinds of food products such as fruits, vegetables, snacks, seafood, fresh meat, tea leaves, etc. And besides food products, chamber vacuum sealer can also pack electric components, hardware, medical products, agriculture products, herbs and so on.

(2). Wet & Dry Dual Use

Chamber vacuum sealer can be used for both solid products and liquid products, you can use this machine to seal fluid products such as soup, sauce, chemical liquids and so on, the sealing effect will be perfect, without leakage.

(3). Long Service Life

On the one side, chamber vacuum sealer adopts high quality electrical components which let it has stable performance; on the other side, chamber vacuum sealer is made of durable stainless steel and it has hard construction, as a result, this machine has long service life, can serve for you for long-term.

- Benefits of Suction Vacuum Sealer

(1). Increase Space Efficiency

Why it is said that suction vacuum sealer can increase space efficiency? On the one hand, this machine itself has a small size so that it doesn’t occupy too much space when you using it; on the other hand, the food products are vacuum sealed by suction vacuum sealer and their sizes are largely reduced, which save more space for storage.

(2).Cost Effective

Generally speaking, the price of suction vacuum sealer isn’t too expensive, you don’t need to use high cost to get such a machine, and the vacuum seal bags are very easy to buy. You only need to use less cost to save food for a long time and prevent waste, it is cost-effective in the long run.

(3).Prevent Freezer Burn

If you need to store food products in the freezer of your fridge, using a suction vacuum sealer is necessary. This machine seals the food in vacuum seal bag so that there will be crystals against frostbite and the food can be fresh for a longer time. In a word, suction vacuum sealer can bring great benefit to you.

3.In which industries can chamber vacuum sealer vs suction play their roles?

Both chamber vacuum sealer and suction vacuum sealer can be applied in food industry, besides this industry, are there any other industries can these two machines play their roles? Let’s explore together.

- Application of Chamber Vacuum Sealer

(1). Chemical Industry

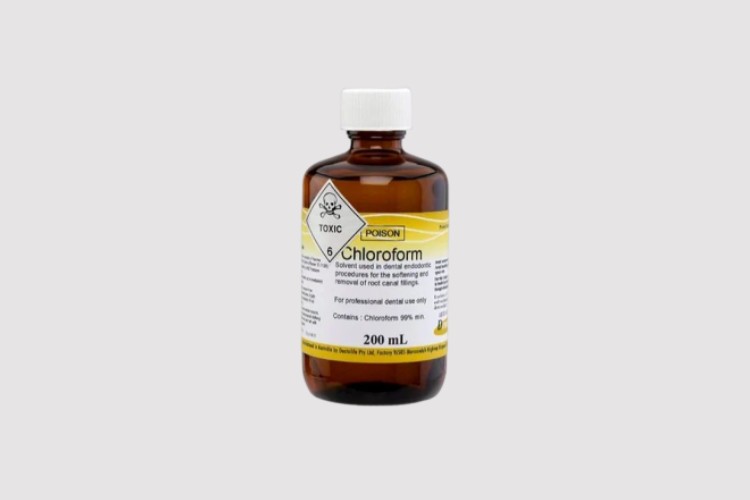

In chemical industry, there are some chemical products don’t have stable properties, they often be affected by some external factors such as air, light, moisture and so on. Therefore, using a chamber vacuum sealer to vacuum and seal these products is a good solution, which let the industry store important chemical products well.

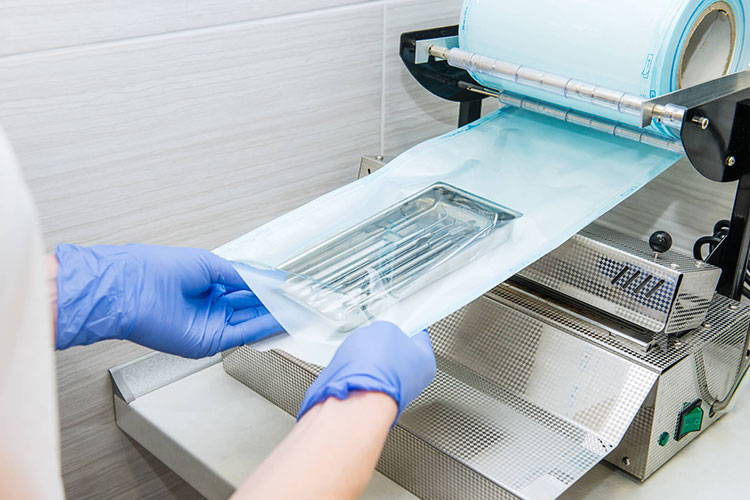

(2). Pharmaceutical Industry

In fact, chamber vacuum sealer also plays a vital role in pharmaceutical industry, it is applied to seal capsules, tablets, drugs, medical tools, etc. Why can chamber vacuum sealer do this? It is because of the particularity of this industry, medicines and medical tools need to be clean and sterile, therefore, chamber vacuum sealer is used to prevent these products from the air.

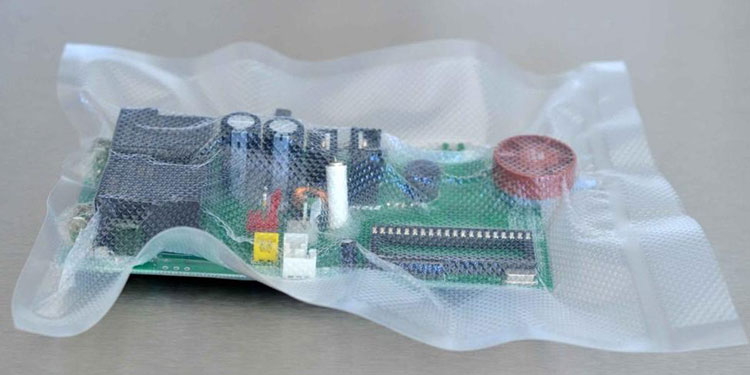

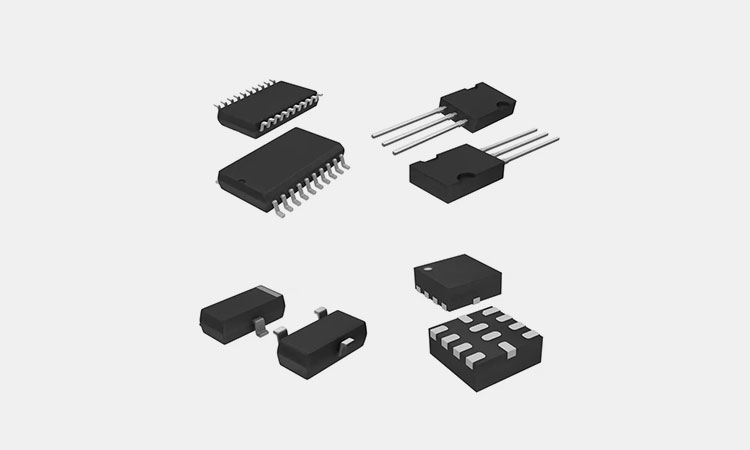

(3). Electronic Industry

What is the role of chamber vacuum sealer in the electronic industry? This machine is used to pack all kinds of electronic products such as batteries, PCB circuit boards, chips, semiconductors, ICs, metal processing parts and so on, to prevent them from oxidation, discoloration and moisture.

- Application of Suction Vacuum Sealer

(1) Hardware Industry

Suction vacuum sealer can be applied in hardware industry to prevent products oxidation and discoloration, it can be used to pack all kinds of metal products, hardware tools, hardware parts, daily hardware, construction hardware and so on.

These products are semi-finished products, so they are packed by suction vacuum sealer and be delivered to the destination to be processed.

(2). Agriculture Industry

In the field of agriculture, there are many grains such as soybeans, mung beans, red beans, soybeans, corn, wheat, rice, etc, and all kinds of seeds, these items all need to be stored well. To save storage space and extend the storage time of agriculture products, the industry chooses suction vacuum sealer to pack them.

(3). Catering Industry

Suction vacuum sealer is portable and convenient, isn’t it? That is why this machine is hot sale in catering industry, tourist hotels, restaurants and street vendors all need suction vacuum sealer to pack and store their ingredients and products.

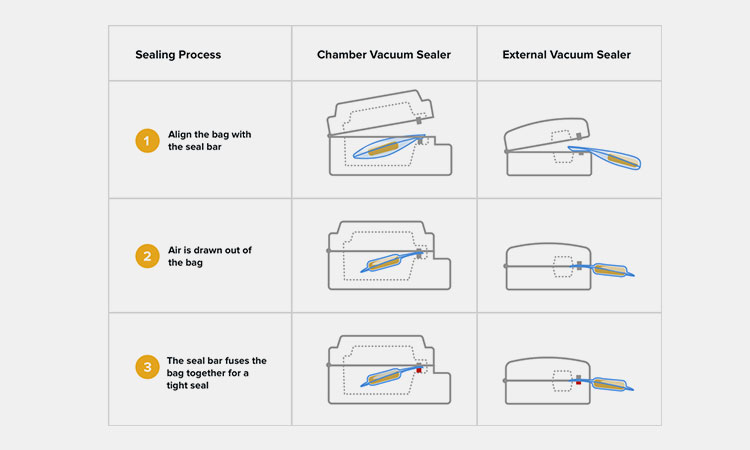

4.How does chamber vacuum sealer vs suction work?

How can chamber vacuum sealer and suction vacuum sealer pack your products and extend their shelf life? What are the principles? Are you curious about this question? It will be answered next.

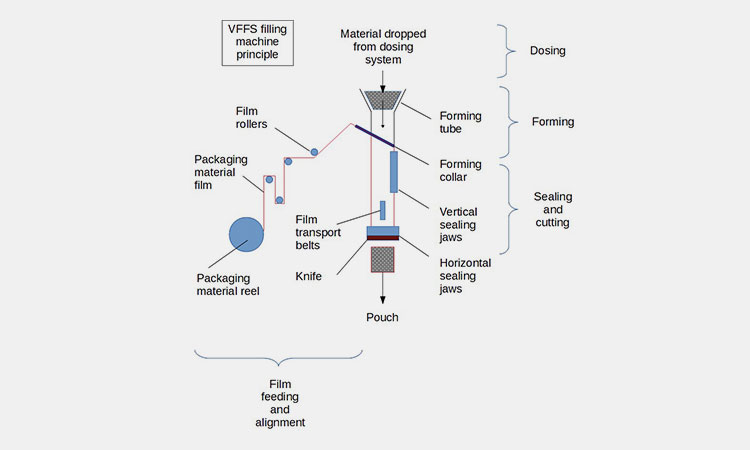

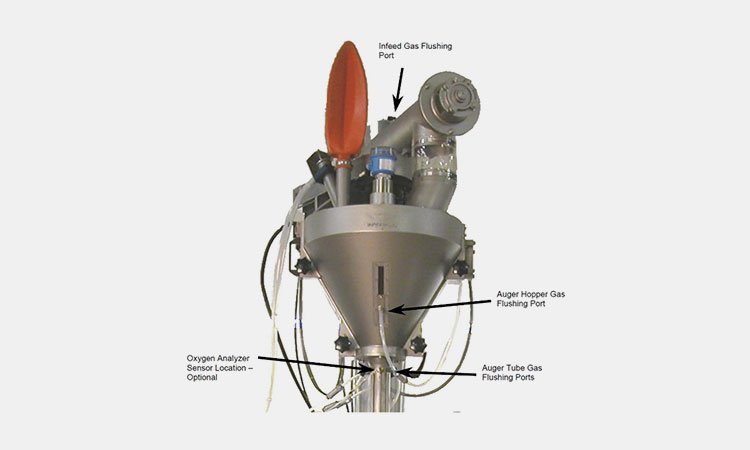

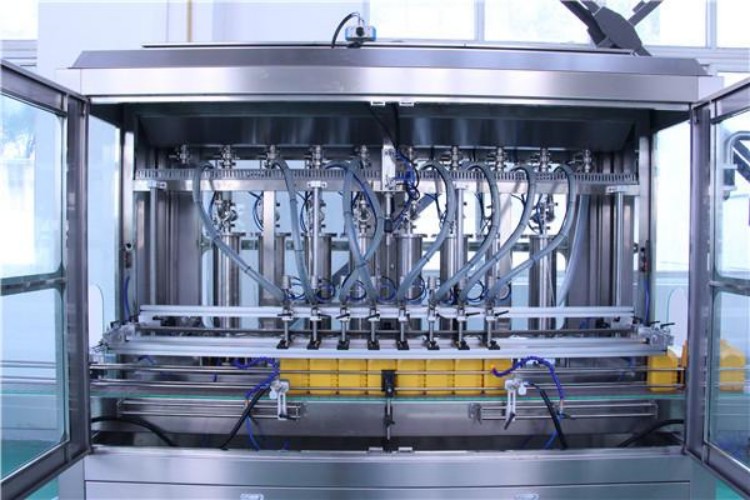

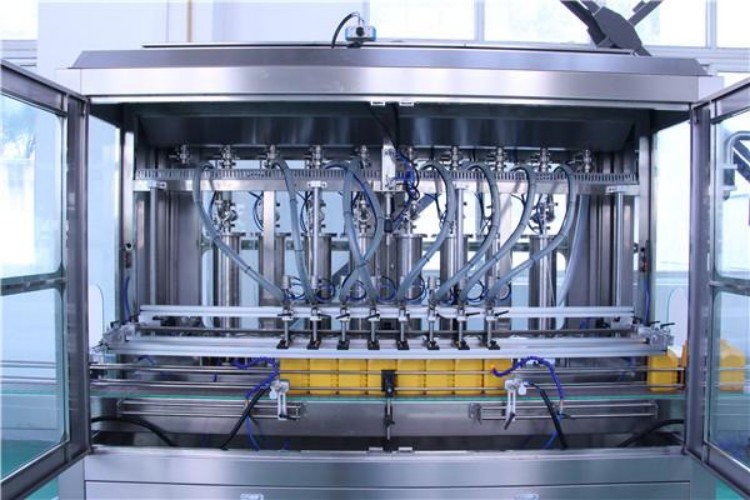

- Working Principle of Chamber Vacuum Sealer

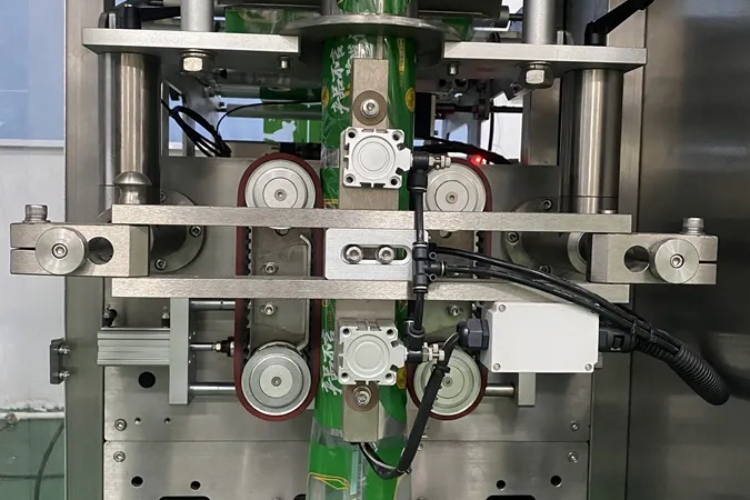

Before the vacuum process, the product is put into the vacuum chamber, and the vacuum time is set up, once the chamber vacuum sealer begins working, the vacuum pump will extract all the air inside the chamber, including the air inside the vacuum seal bag. At this moment, the pressure in the chamber is equal with that of the bag.

And then, the air is exhausted from the chamber, the machine is ready for sealing the bag, the sealing strip is heated and pressed on the mouth of the bag to seal it. When the bag is sealed, the whole packaging process is finished.

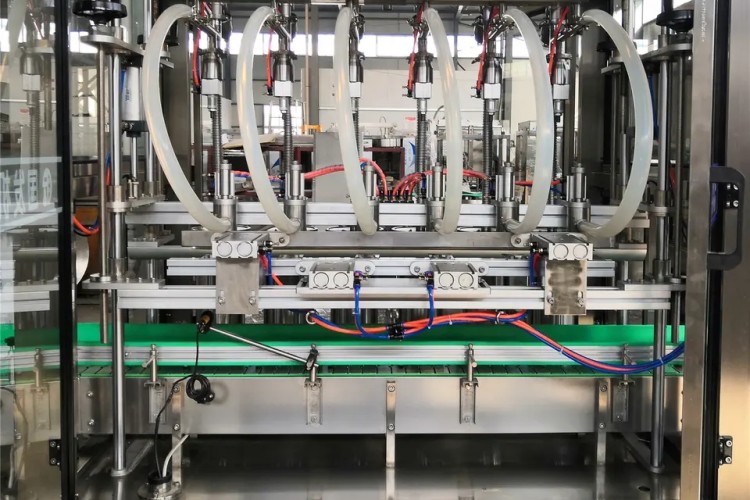

- Working Principle of Suction Vacuum Sealer

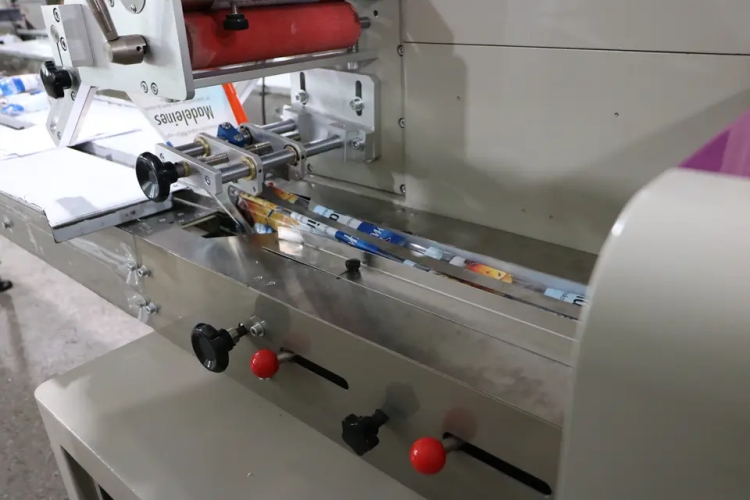

Before the suction vacuum sealer works, you need to open its lid and put vacuum seal bag on the correct place, notice that the open side of the bag should be put on the sealing strip. At the beginning, the machine adopts a suction to extract the air inside the vacuum seal bag, the vacuum process is started.

After the vacuum process, the sealing strip is heated so that it can be used to seal the open end of the vacuum seal bag tightly, after that, you can use the cutter to cut off the extra part of the bag, and the whole working process of suction vacuum sealer is finished.

5.Which parts consist of chamber vacuum sealer vs suction?

After learning how does chamber vacuum sealer and suction vacuum sealer work, you need to learn the main parts of the machine in order to better understand the working process of it. The main parts of the two machines are as follows:

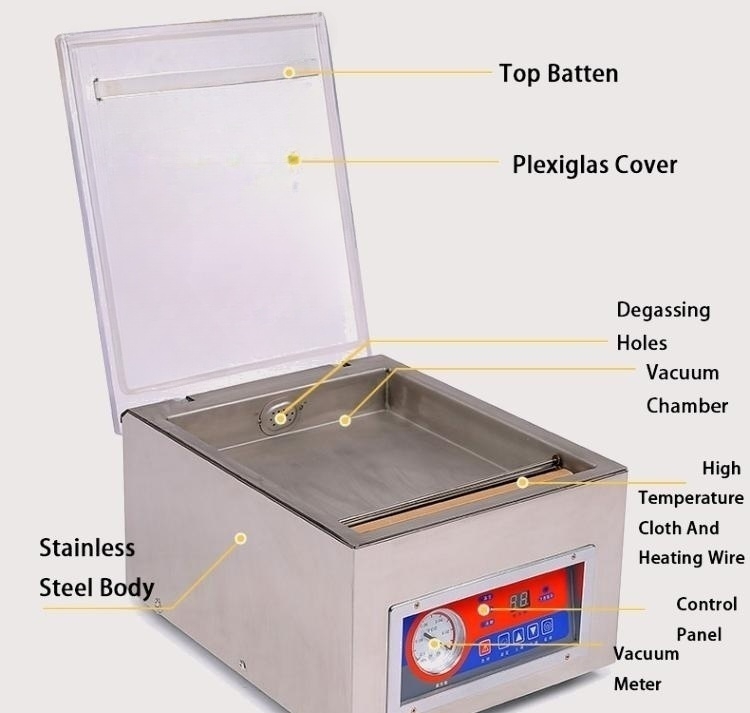

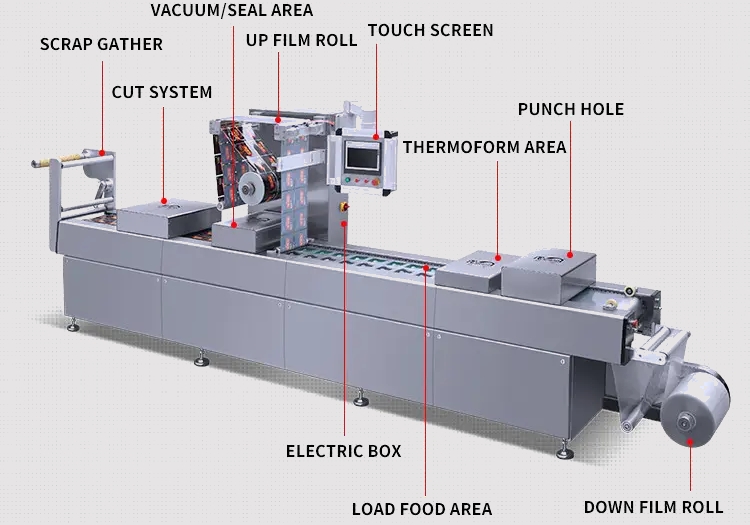

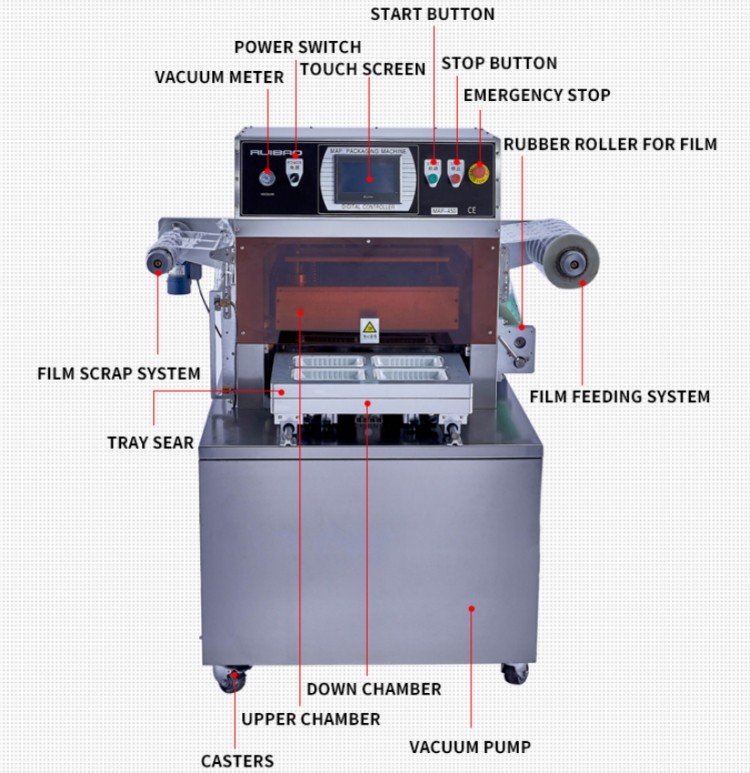

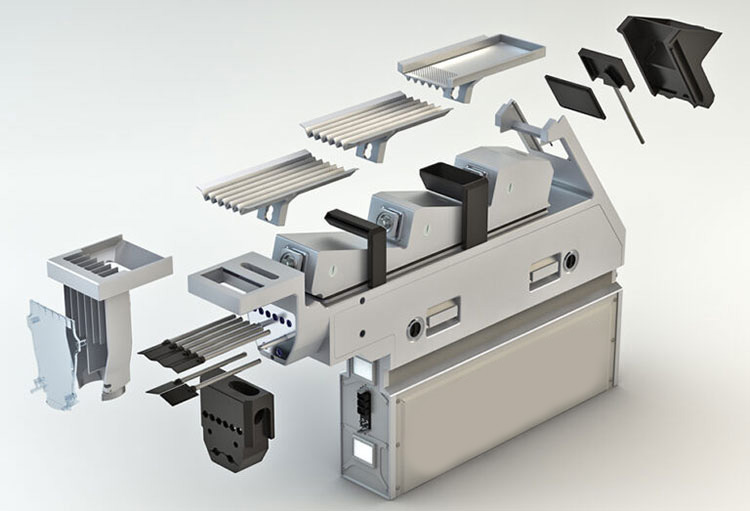

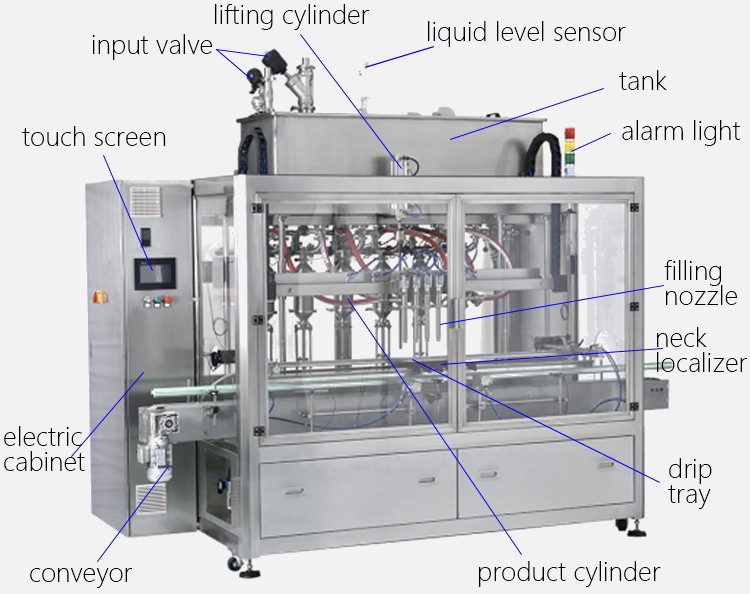

- Main Parts of Chamber Vacuum Sealer

Vacuum Chamber: You can say that this is a vital part of chamber vacuum sealer, the vacuum chamber is the work platform of the machine, the whole vacuum and sealing process are taken place at here.

Chamber Lid: When the machine is working, the chamber lid is closed, some chamber vacuum sealers are equipped with transparent chamber lids so that you can monitor the whole vacuum process.

High Temperature Cloth: This part is used to heat seal vacuum seal bags.

Control Panel: The function of control panel is to control the working of chamber vacuum sealer, there are vacuum meter, power switch, emergency stop button and other buttons on it.

Stainless Steel Body: This is the main frame of the machine, which is hard and durable.

Removable Casters: Some floor-type chamber vacuum sealers are equipped with removable casters, as a result, they are convenient to move.

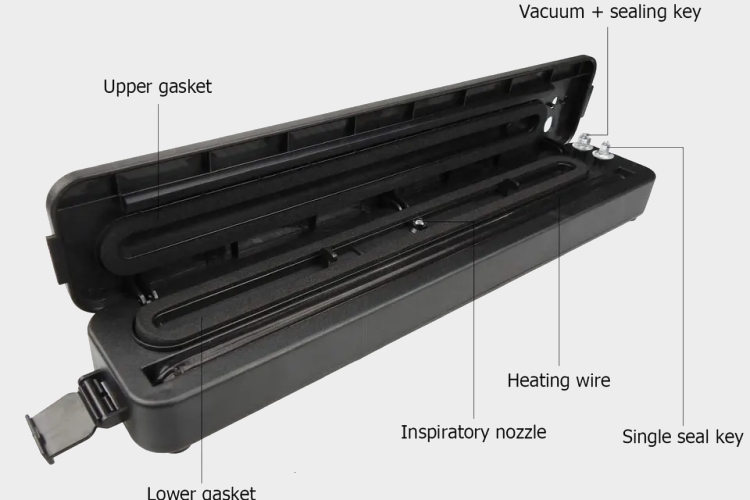

- Main Parts of Suction Vacuum Sealer

Vacuum & Sealing Key: When you click this key, the suction vacuum sealer will complete vacuum and sealing operation.

Single Sealing Key: In the same way, this key means that you only need the sealing function of the machine.

Heating Wire: The function of heating wire is to seal vacuum seal bag.

Inspiratory Nozzle: This part is used to suck the air inside the vacuum seal bag, it is an important part of suction vacuum sealer.

Upper Gasket & Lower Gasket: The upper gasket and lower gasket are used to fix the position of vacuum seal bag to ensure the smooth vacuum sealing operation.

6.What types of items can be sealed by chamber vacuum sealer vs suction?

As a matter of fact, it was briefly mentioned in the previous article which products are suitable for sealing by these two machines, and in this question, more products will be listed to the below.

Items Can Be Sealed By Chamber Vacuum Sealer-Photo Credit: Anova Culinary

Chamber vacuum sealer can be used to pack all kinds of food and non-food products, which including fruits, vegetables, meats, seafood, snacks, candies, spices, soups, milk, metal, tea leaves, medicines, electronic components, chemicals, grains, cloths, precision instruments and so on.

It is worth mentioning that this machine is suitable for both wet and dry products, which means that besides solid products, it can also deal with liquid products.

Items Can Be Sealed By Suction Vacuum Sealer-Photo Credit: Epicurious

Similar to chamber vacuum sealer, suction vacuum sealer is also suitable for sealing food products, pharmaceutical products, chemical products, agricultural products, hardware, electronics, commodities, etc. But there are also differences, suction vacuum sealer is more suitable for sealing frozen meat than chamber vacuum sealer, however, it isn’t suitable for sealing liquid products.

7.Which kinds of vacuum seal bags can be sealed by chamber vacuum sealer vs suction?

Do you know that? It is important to choose the proper vacuum seal bags for chamber vacuum sealer and suction vacuum sealer, because some vacuum bags are not compatible with them. Next, let's take a look at which vacuum seal bags are suitable for sealing by chamber vacuum sealer and suction vacuum sealer.

- Suitable Vacuum Seal Bags for Chamber Vacuum Sealer

Actually, almost all the vacuum seal bags on the market are compatible with chamber vacuum sealer, such as embossed vacuum seal bags, boilable vacuum seal bags, food storage vacuum seal bags, compostable vacuum seal bags, silicone reusable vacuum seal bags, zipper vacuum seal bags, retherm vacuum seal bags, vacuum seal rolls and so on.

In terms of thickness, the 3 mill, 4 mill and 5 mill vacuum seal bags are all suitable for chamber vacuum sealer. The machine can seal the above vacuum seal bags tightly and provide perfect sealing effect.

- Suitable Vacuum Seal Bags for Suction Vacuum Sealer

Suitable Vacuum Seal Bags for Suction Vacuum Sealer-Photo Credit: GreenPak

Relatively speaking, there are fewer types of vacuum bags that can be sealed by the suction vacuum sealer than by the chamber vacuum sealer. Suction vacuum sealer is compatible with laminated vacuum seal bags, vacuum seal bags and vacuum rolls with mesh liners. The vacuum seal bags with mesh liners can help suction vacuum sealer complete vacuum and sealing operations more smooth.

8.How should you choose between chamber vacuum sealer vs suction?

Now you have known the differences between chamber vacuum sealer and suction vacuum sealer, do you know which one is more suitable for your demand? How can you choose one of these two machines?

Firstly, you need to consider which kinds of products will you pack by a vacuum sealer, do you only need to seal solid products, or liquid products as well. Chamber vacuum sealer will be a good choice if you need to seal both solid and liquid products. But if you only need to seal solid products, both the two machines can meet your need.

Next, consider where you would use a vacuum sealer, if you want to purchase a chamber vacuum sealer, you need to prepare enough space to install it. On the contrary, if you don’t have too much space for a vacuum sealer, and you just use it for family use, you can choose the suction vacuum sealer.

Finally, ask yourself, what’s your budget? This is an important factor to think about, in general, chamber vacuum sealers are more expensive than suction vacuum sealers because they require more materials and components to manufacture.

In summary, you need to think twice when choosing a vacuum sealer, you need to comprehensively consider your real requirements, and then choose from chamber vacuum sealer and suction vacuum sealer.

Conclusion

Overall, both chamber vacuum sealer and suction vacuum sealer can help you store food for a longer time, these two machines have their own pros and cons, are suitable for different products. After reading this blog, do you think which one is better? Chamber vacuum sealer or suction vacuum sealer? Which one would you like to choose? Welcome to contact us if you have other puzzles about them.

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide

Chamber Vacuum Sealer VS Suction Read More »