Tablet Counting and Filling Machine: The Complete Buying Guide In 2025

Tablet Counting and Filling Machine: The Complete Buying Guide In 2025

Today, in the fast era, counting and filling medications and timely adhering to dispensing limits has become a tough challenge across the globe. In the corporate world, tablet counting and filling machine has changed the perception of packaging significantly. With the abundance of versatility, this equipment is considered as a tool of profitability in every production processes. Due to overwhelming performance and promising business revenue; a tablet counting and filling machine is now an indicator of competitive market success.

‘Tablet Counting and Filling Machine: The complete buying Guide in 2023’ is a comprehensive informative guide article that will help you in understanding all essential parameters one must know when thinking about investment on this machine. This article is composed of basic exploration about working principles, parts, types, troubleshooting, and other important key attributes about the machine.

1.What Is a Tablet Counting and Filling Machine?

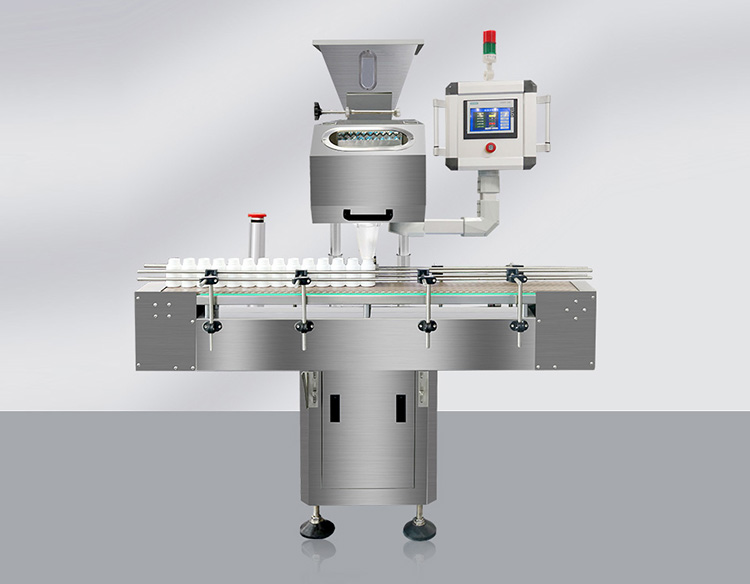

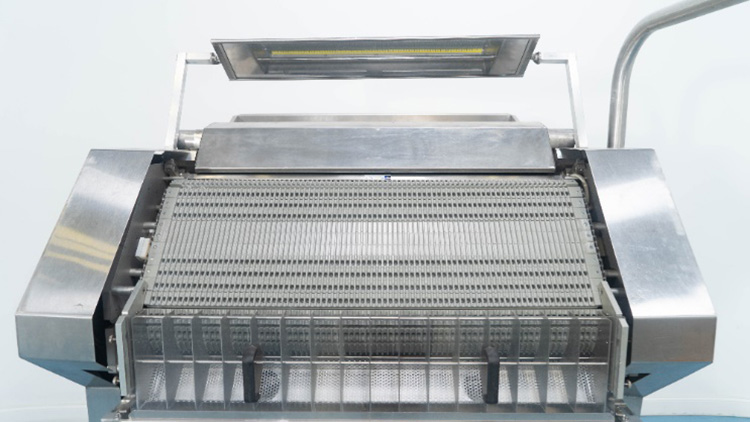

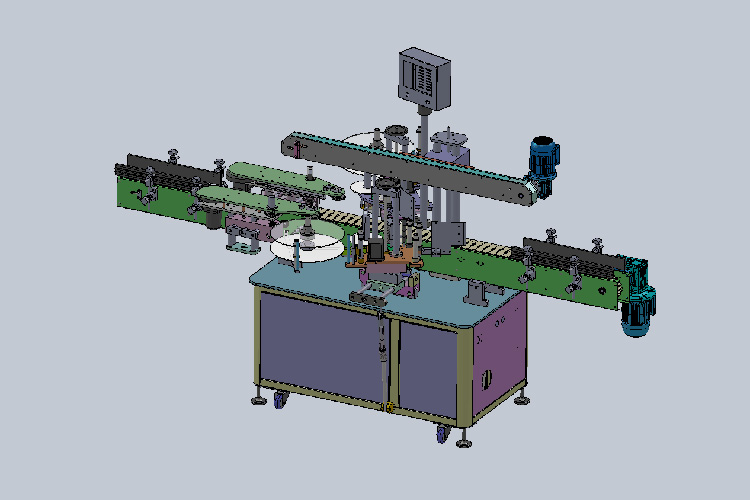

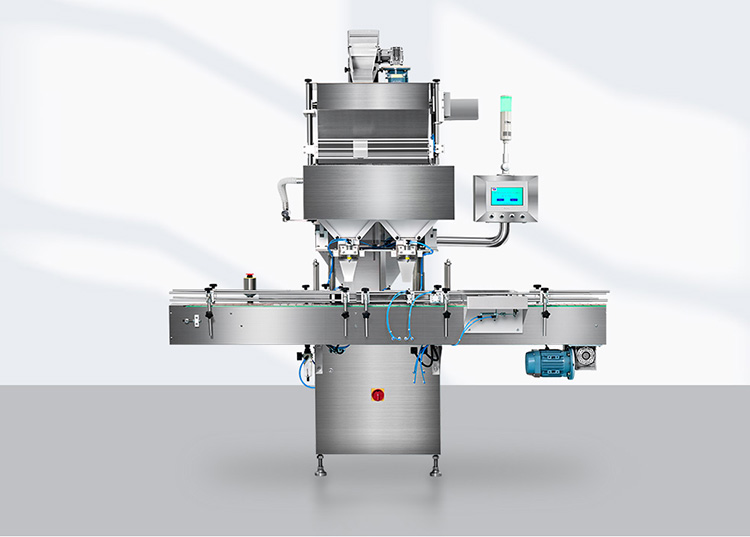

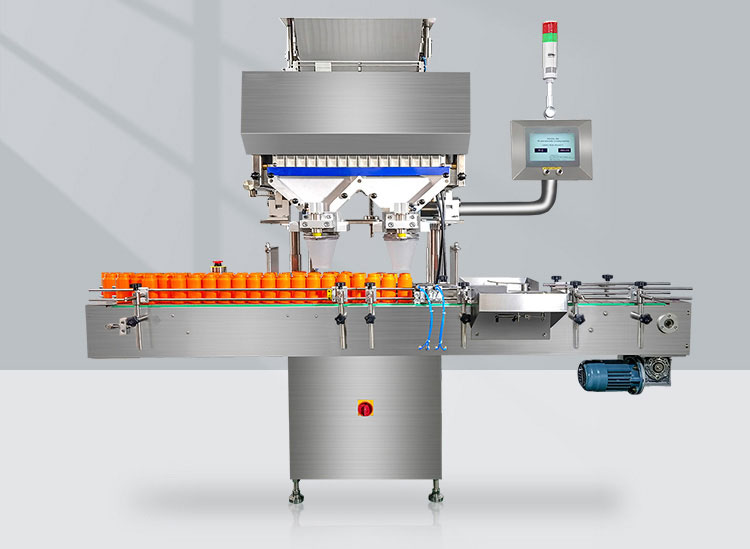

Tablet Counting and Filling Machine

A tablet counting and filling machine is advanced solution that is used for accurate counting and filling of tablets, capsules, pills, and related items into their packaging materials.

The machine is compact in structure available in various sizes, designs, automation, and with different working principles. Due to tremendous significance and offering sustained productivity; this is adopted by practices in many small to large industries for accurate and precise counting and filling outcomes.

2.Where Do You Use the Tablet Counting and Filling Machine?

Not only confined to the huge pharmaceutical sector of industry, but this tablet counting machine is perfect to be used by other industries. Let’s read their industrial applications now.

Food and Confectionery Industry

Gummy Candies- Picture Courtesy:Kopper’s Choco

The food industry is an important production area that produces delicacies like candies, chocolates, chewing gums, gummies, chocolate beans, and other food products like coffee beans, frozen items, condiments and spices, cornflakes, chips, and biscuits can be filled using a tablet counting and filling machine. These items require to be filled with accurately weighed processes so that undercounting doesn’t disappoint the consumer.

Nutraceutical Industry

Multivitamins- Picture Courtesy:Nutragean Healthcare

The Nutraceutical industry is another important sector where manufacturers of nutritional supplements use this machine for errorless counting of their products. Their products include multivitamins, dietary supplements, probiotics, probiotics, glutathione, capsules for skin, nails, and hair health, etc. These are found usually in the form of pills or capsules and so require a precise counted quantity of the product.

Chemical Industry

Deodorizing Tablets- Picture Courtesy: Blue Mountain

A chemical industry where day to day manufacturing of chemical takes place require tablet counting and filling machine to dispense right quantity of packaging chemicals such as laundry pods, detergent tablets, phenyl balls etc. Precise counting is necessary to prevent any hazard and cross-contamination.

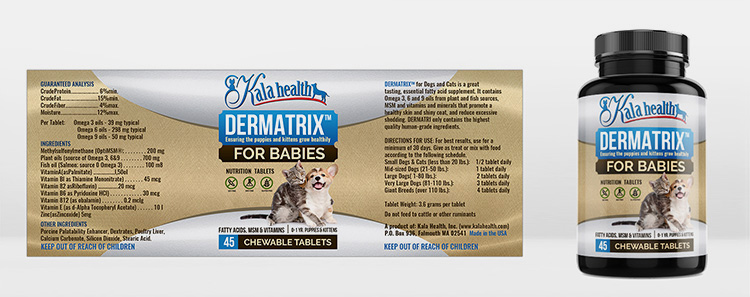

Veterinary Industry

Nutritional Pills- Picture Courtesy: Vet Practise Magazine

This industry deals with preparing and packaging of nutritional food for animals. For the purpose of veterinarian health and food, their products like cat and dog food, fish food, medicines for different animals are packaged using a tablet counting machine.

Agricultural Industry

Fertilizer Booster

The agricultural industry uses this machine to count seeds, beans, lentils, pulses, peas, fertilizer, etc. These products are present in circular, oblong, and even irregular shapes that can be otherwise difficult to count manually.

Herbal Industry

Organic Tablets- Picture Courtesy: Banyan Botanic

Now a days, the herbal industry is generating profitable revenue as people around the globe are more interested in using organic herbal products. For instance, all types of perennials, herbs such as such as, Medical Cannabis, Basil, Catnip, Jasmine, Lavender, Lemon verdena, Lemon balm, Mint, Peppermint, Rosemary, Thyme and others are easily counted using tablet counting and filling machine.

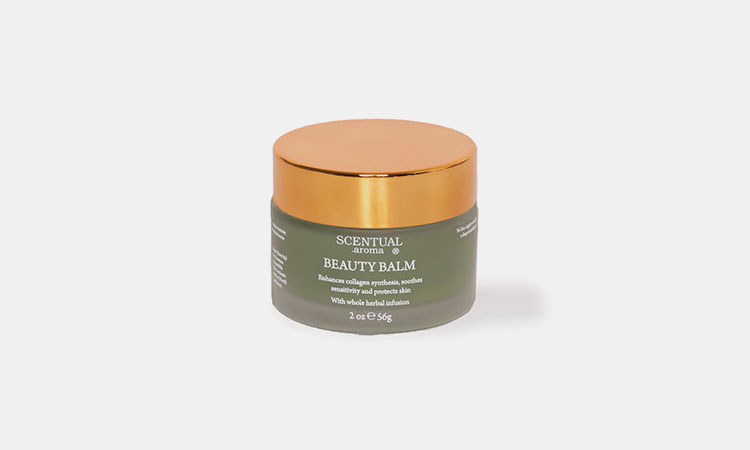

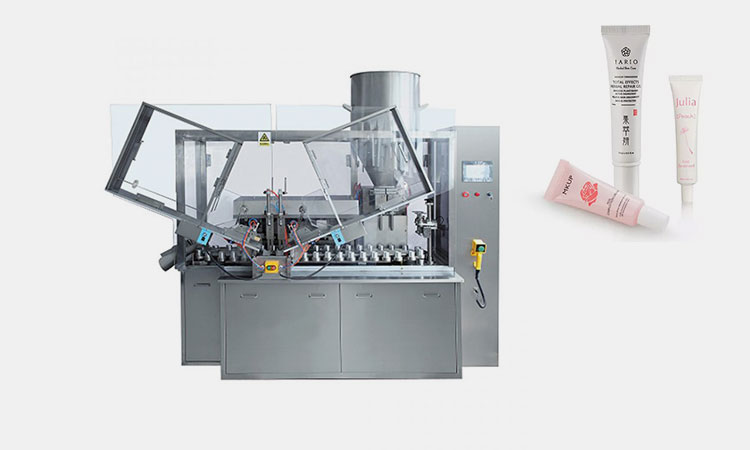

Cosmetics Industry

Waxing Beans Cosmetic Products

The cosmetics industry deals with the manufacturing of cosmetic products where accuracy and aesthetics can boost the products. This industry uses tablet counting and filling machine as well for products like wax beans, whitening beads, wax strips, nose strips, face masks , artificial nails, and some accessories like hair clips, rubber bands etc.

Electronics Industry

Screw, Nuts, Bolts

This industry produces hardware items that are required for engineering, construction, automobile, and other construction industries. For example: nails, screws, screw bolts, buttons, electronic chips, and other mechanical small parts are also countable using tablet filling and counting machine.

Stationery Industry

Fancy Pen, Pencil’s Toper

The stationery industry is also significant zone for producing items like pencils, erasers, sharpeners, staple pins, thumb pins, clips etc also find its application with this tablet counting and filling machine.

3.What is the Significance of utilizing Tablet Counting and Filling Machine and why is it worthwhile?

Tablet Counting and Filling Machine

Many industries rely on tablet counting and filling machine because it offers key benefits to every consumer who opts for this in production processes, including:

Dosage Accuracy: A sophisticated technology ensuring tablet counting and filling method with accuracy.

No Cross-Contamination: The machine allows the filling of prescriptions and packaging of medication with lesser physical contact. Furthermore, it is made up of finest stainless steel and complies with safety features, it offers products safety and no chances of cross-contamination.

Simplified Detectors: The machine is equipped with electronic and digital features that are equipped with scanners and detectors that pick up the errors or malfunctioning either in the machine or tablet and sort the problem by simply notifications.

Improved Efficiency: The tablet counting and filling machine has eliminated manual sorting, counting, and filling of pills, tablets, and capsules. This machine has streamlined the hectic process with flexible automation which is a good indicator for improving production efficiency.

Cost-Saving: Many industries, pharmacies, and other sectors save money when they don’t have to pay for technicians to stand all day long watching, counting, and packaging tablets in bottles, and containers. Plus, this machine saves your time, and energy, resulting in more productivity with high throughput.

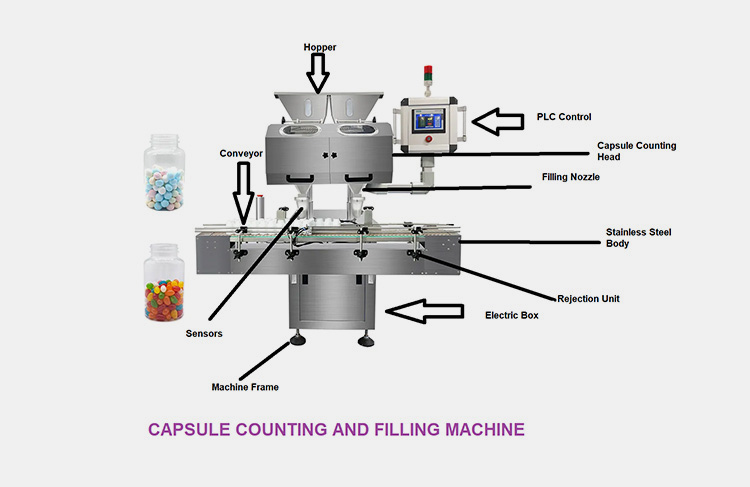

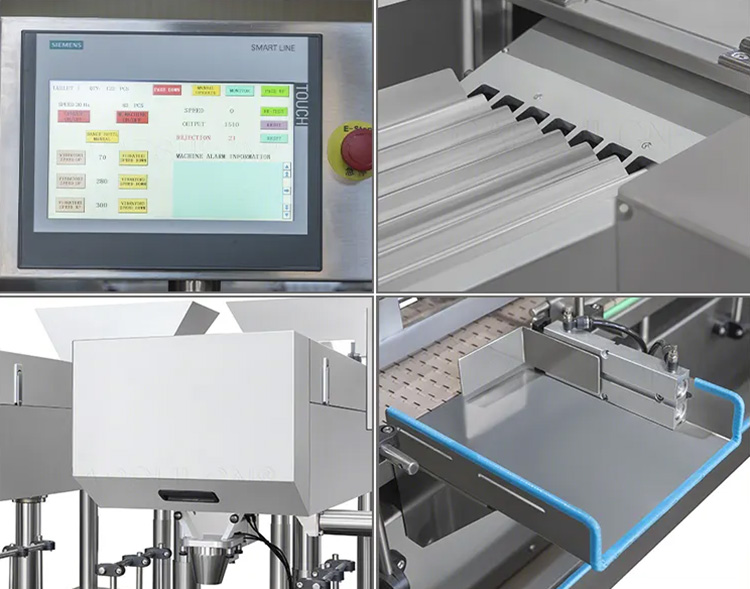

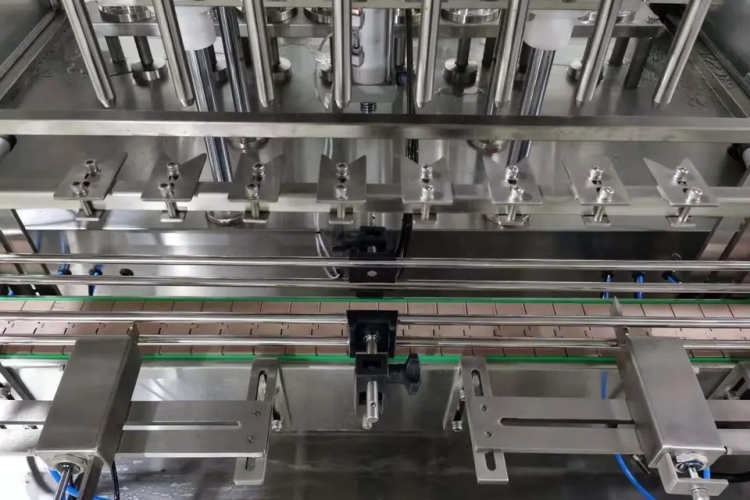

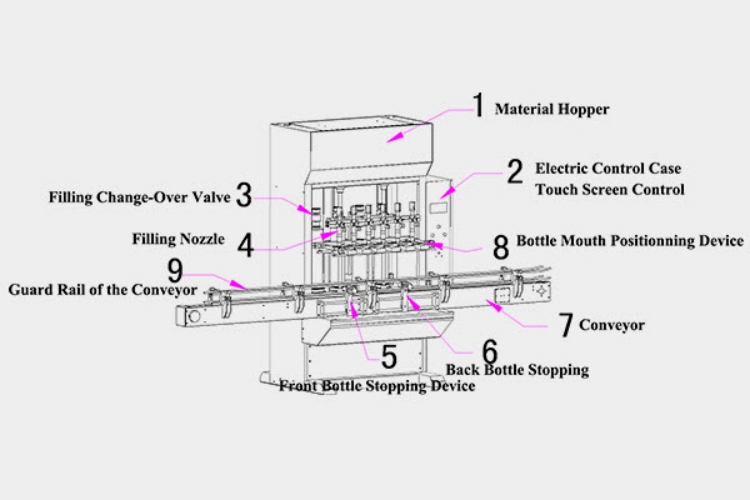

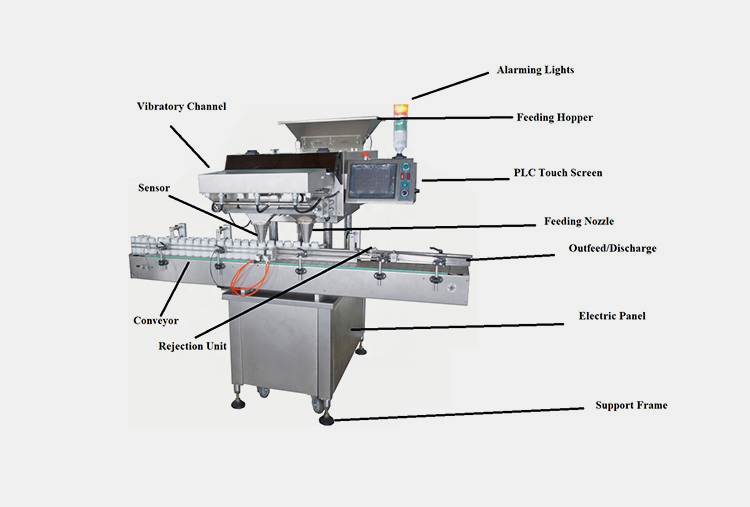

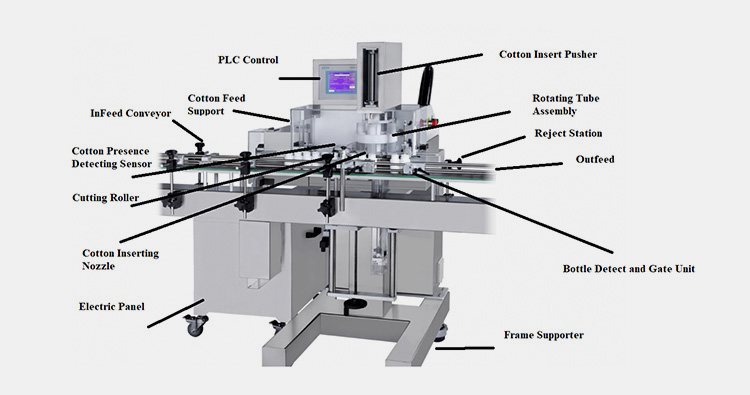

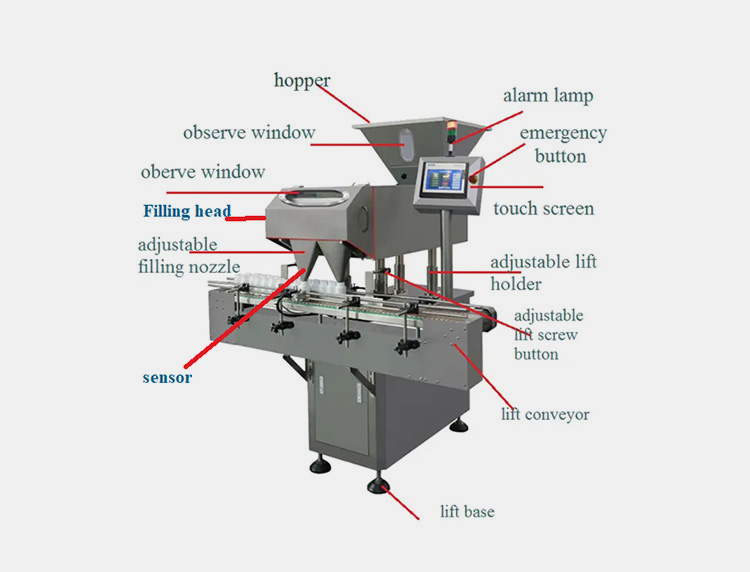

4.What are Tablet Counting and Filling Machine Components?

| PART | DESCRIPTION |

| Feeding Hopper | This is a storage tank that holds tablets or pill in the bulk quantity for further packaging and filling stage. A feeding hopper is located at top of the machine where it ensures the supply of tablets are steady and smooth for counting. |

| Alarming Light | The tablet counting and filling machine is designed with alarming light that features the certain situation such as power on, working mode, emergency mode, and other related condition. For e.g., once hopper is empty or tablets supply is stopped machine indicate it by indicating an alarm. |

| Vibratory Channel | A tablet counting and filling machine prevent clumping or jamming of tablets flow. This is due to vibratory channel that provide a confined pathway where uniform movement of tablets take place. Moreover, the vibratory channel promotes the transporting tablets toward filling nozzle via shaky or vibratory movement. |

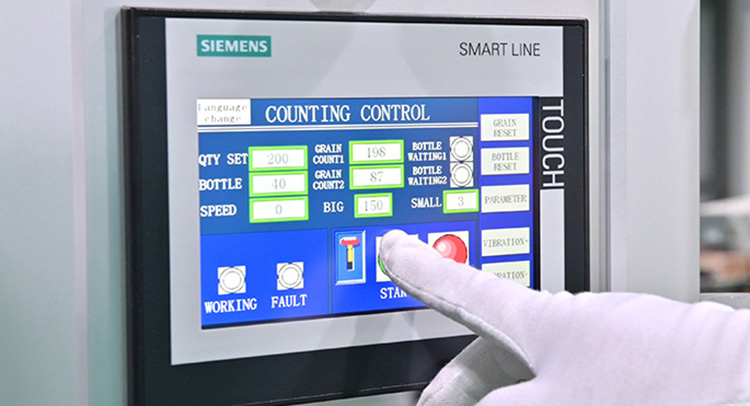

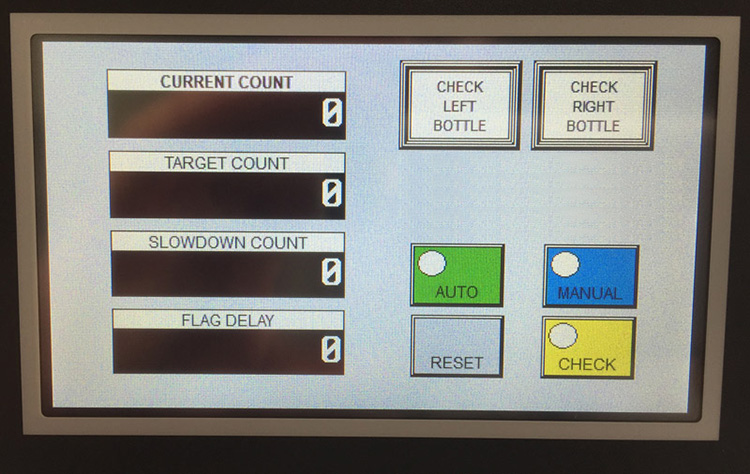

| PLC Touch Screen | This is a Programmable Logic Controller which is controlled by touchscreen keys present on the monitor. You can consider this unit as a commander of the machine that sends and receives signals of entire procedure. When operator feed in the protocol and adjustments, machine send signals and begin working as interpreted command. |

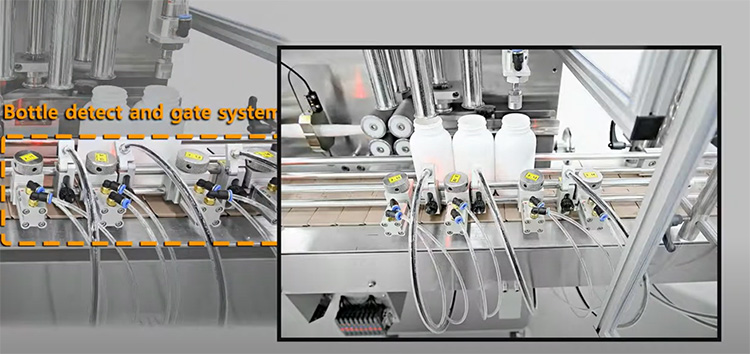

| Sensor | Sensors or detectors are featured in the tablet counting and filling machine which is responsible for various important functions. First of all, it senses the presence tablet and marking them among counted lot, monitor and notifies if any tablet missing, determining any malfunctioning and send signals to major unit (PLC) for further evaluation. |

| Feeding Nozzle | This unit is composed of a narrow passage that facilitates a cleared and uniform follow of tablets which are considered as counted and filled into respective present packaging material. This unit performs promising tasks that ensure entire operation is well-controlled. |

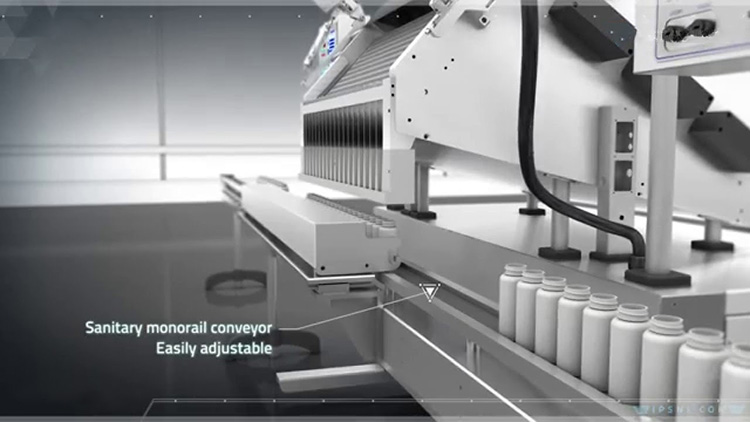

| Conveyor | This unit acts as a limb of the system that helps you transportation of packaging material such as bottles, pouches, jars, etc toward counting and filling section. Upon filling conveyor moves and discharge the packed material from the machine. A conveyor helps in continuous flow of the material in a proper aligned manner. The speed of conveyor can be regulated using PLC controller. |

| Outfeed | Once the tablets are counted and filled, they’re released to another machine via outfeed. |

| Rejection Unit | This unit works when receive negative feedback. This unit is featured with advanced detectors that identifies abnormality in packaging container, for e.g., missing tablets, might be filled with defected tablets are sent to rejected section. This section is performing promising tasks as it ensures all approved tablet packaging bottles for final process are 100% corrected. |

| Electric Panel | This section is housed with important electrical parts that are composed of wiring, switches, plugs, connections, relay, that ensure proper and safe distribution of electric current across various parts of machine that allows simultaneous electricity during processes. |

| Support Frame | The structure of the tablet counting and filling machine is supported by frame which is made up of stainless steel offer a stable holding capacity. Moreover, it supports the machine and prevent vibrations, so the counting and filling procedure take place in stable work condition. |

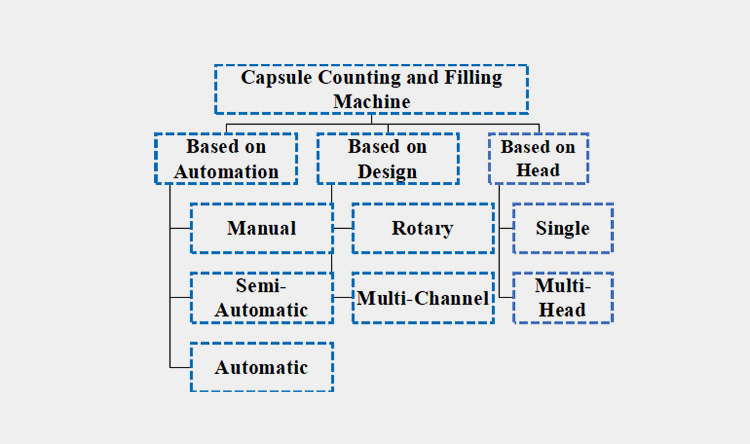

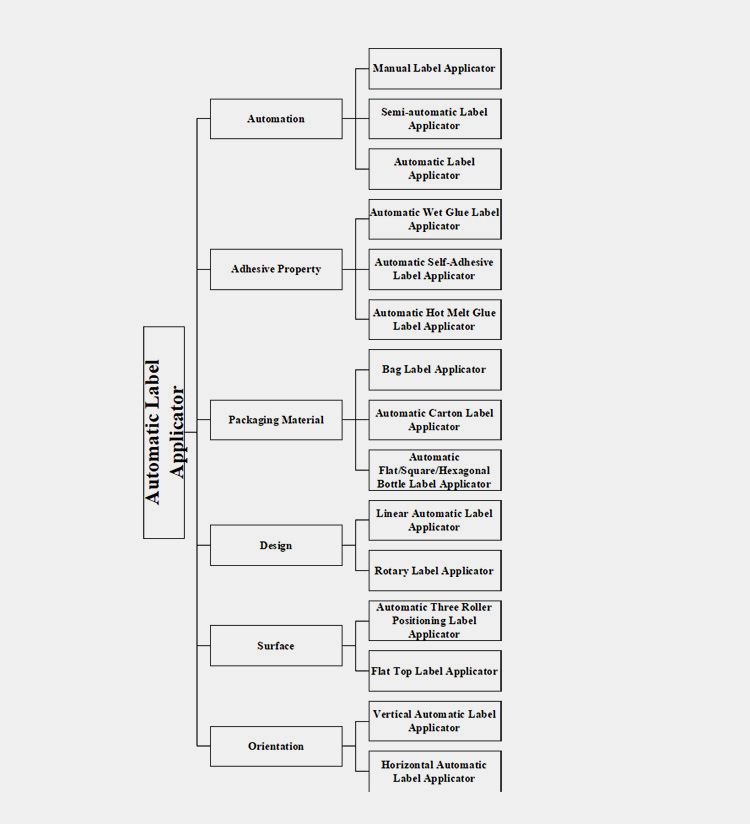

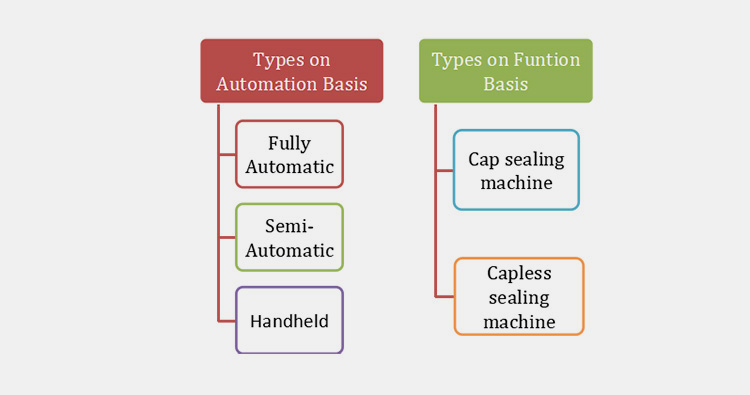

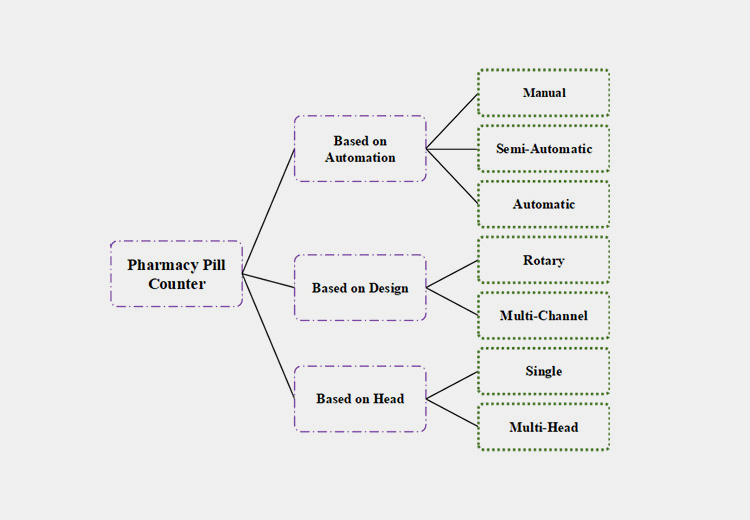

5.How to Classify a Tablet Counting and Filling Machine?

A tablet counting and filling machine is categorised into various types which is based on different technical behaviour of the equipment. The prime purpose of presenting this classification is to understand the possible available features of the machine in the market for the better selection.

TABLET COUNTING AND FILLING MACHINE WITH AUTOMATION

In this case, machine is sub-classified into three broad classes.

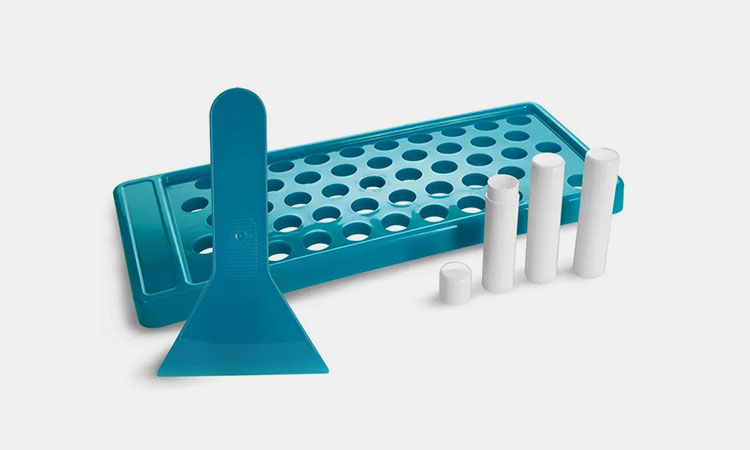

Manual Tablet Counting and Filling Machine

Manual Tablet Counting and Filling Machine

You can call it a robust method of counting and filling solid medication that entirely requires human intervention. Here, you can subject the medication on the counting tray; with the help of spatula each of the counted tablet is separated from the random category and at the same time, you can put each tablet into the filling material. For the smaller businesses or small scale operations, this is suitable method as it does not cost you higher or need a large space for installation. Side by side, this way of counting can help in accurate filling with minimum chances of error and cross-contamination.

Semi-Automatic Tablet Counting and Filling Machine

Semi-Automatic Tablet Counting and Filling Machine- Picture Courtesy: CVC Tech

By comparison to manual, a semi-automatic tablet counting and filling machine is way too advanced development in the field of packaging and branding. This machine is the fastest solution that can counts and fills hundred of tablet packs in an hour. But, as it name shows, it still expects some human involvement. The machine is absolutely automatic but when it comes to loading containers or any packaging material, you need a technician, once the tablets are counted and filled, they’re discharged manually. This machine is best fit solution for medium to large production sectors. As this machine is way too cheap that’s why it is mostly preferred one for those who’re beginning with the business.

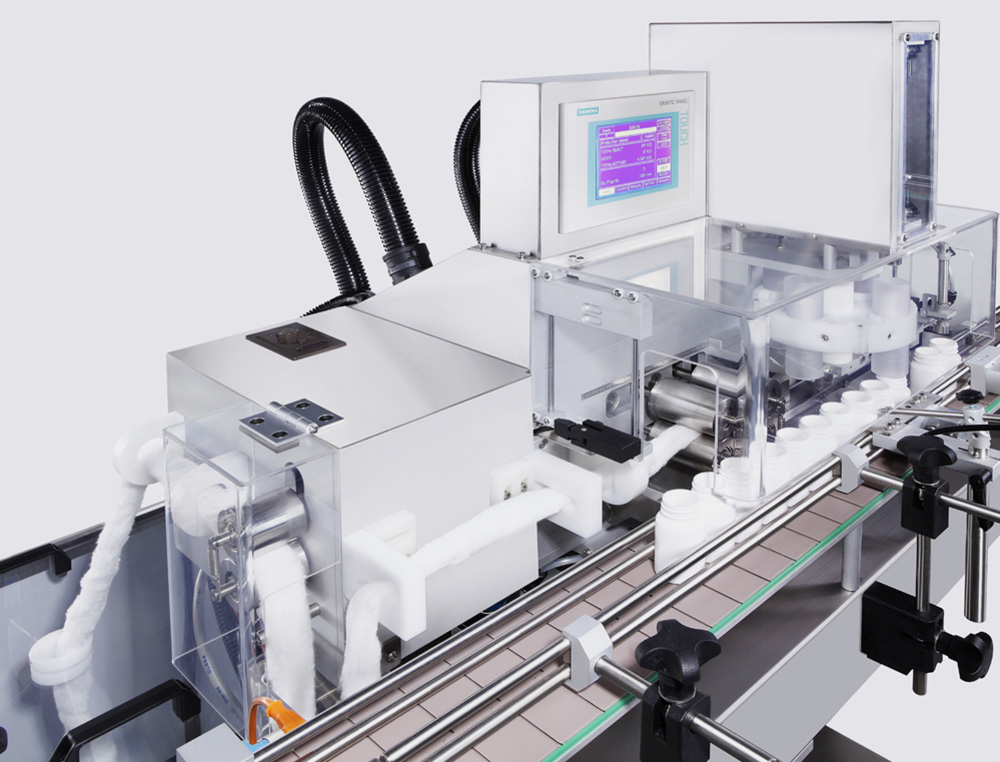

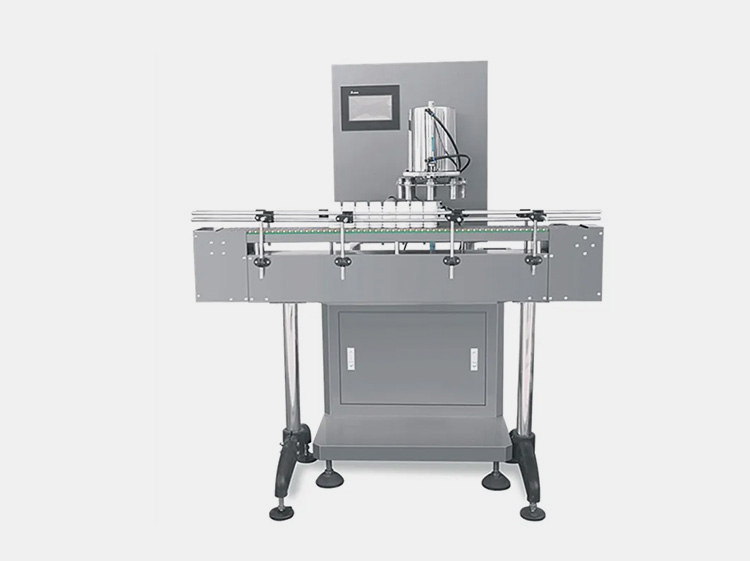

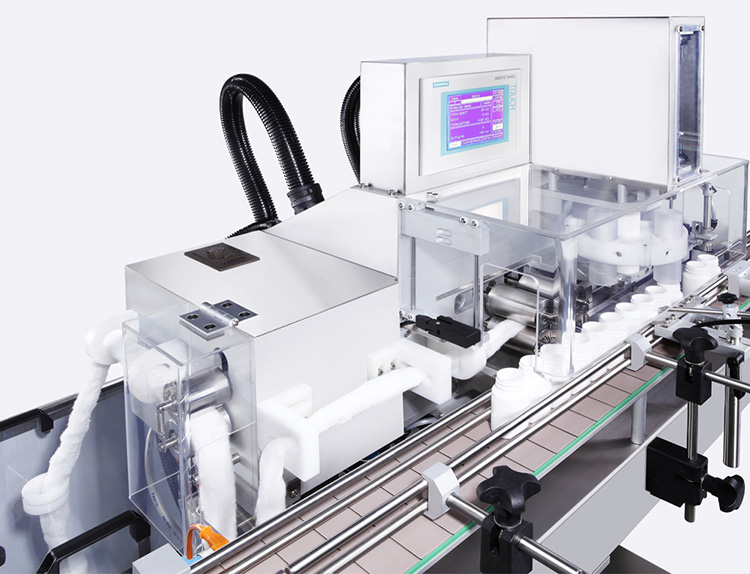

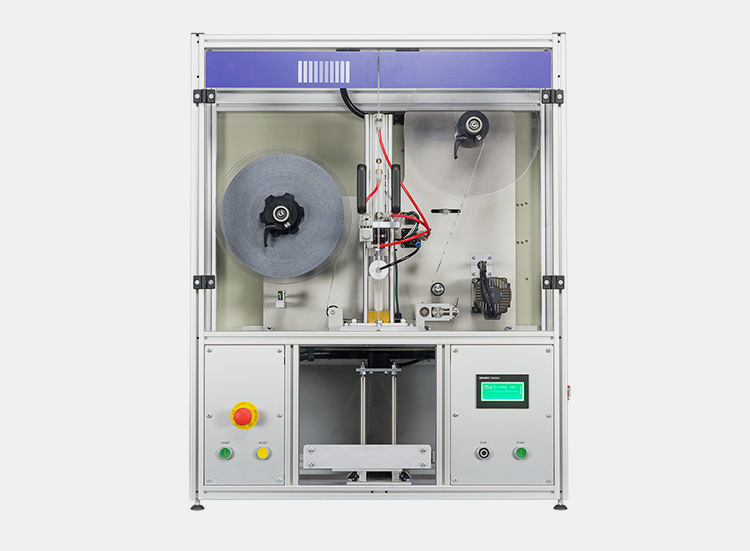

Automatic Tablet Counting and Filling Machine

Automatic Tablet Counting and Filling Machine-Picture Courtesy: Cremer

When it comes to automatic machines; No one can beat it working efficiency. This machine is mostly recommended for a larger industry where day night working batches are easily catered with no chances of errors. Machine itself is responsible for infeed, counting, filling, and discharging the containers by the help of conveyor belt. Here, you don’t need a fixed manpower throughout the process. An operator must click the data and start the process. This is an ideal solution for obtaining hundreds of accurate packaging products per minute.

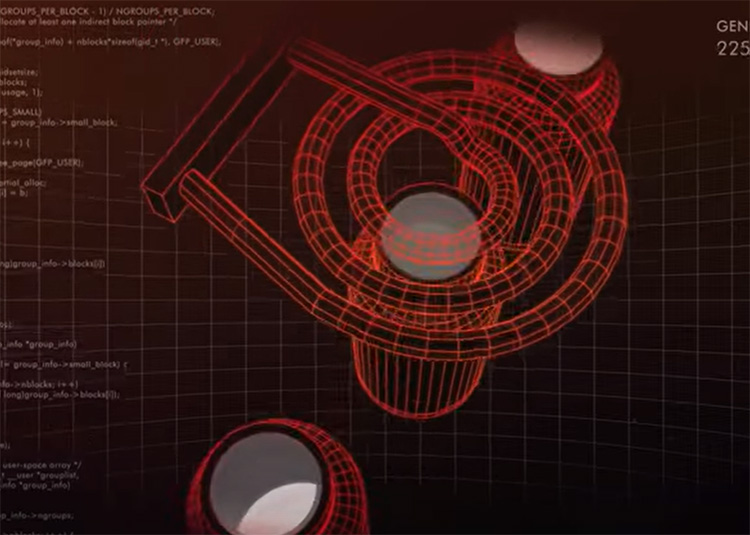

TABLET COUNTING AND FILLING MACHINE WITH COUNTING TECHNOLOGY

Based on technologies, a tablet counting and filling machine is classified into rotary wheel, vibratory and slat methods. Although the basic design and working presentation of these types are different but primary objective of counting is the same.

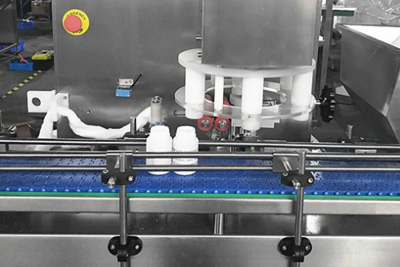

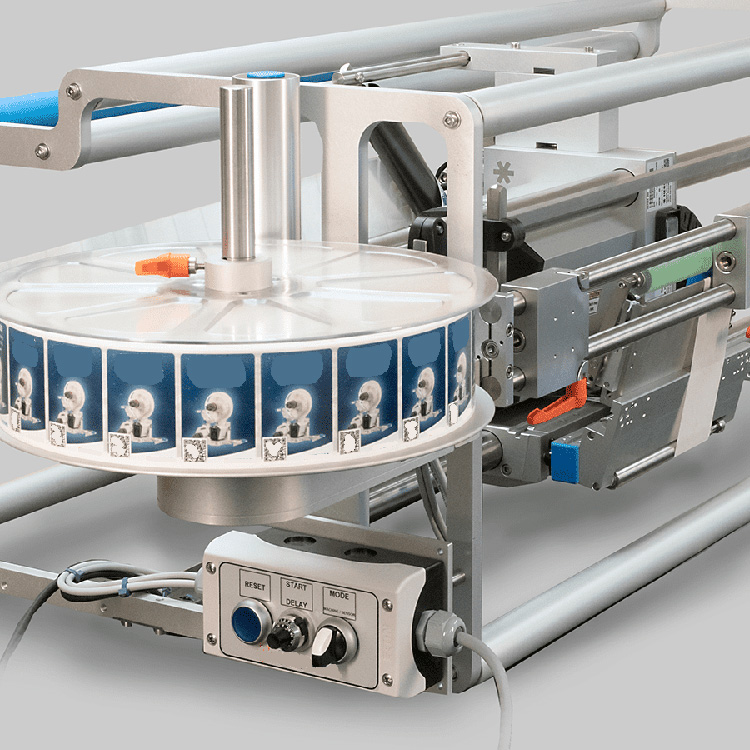

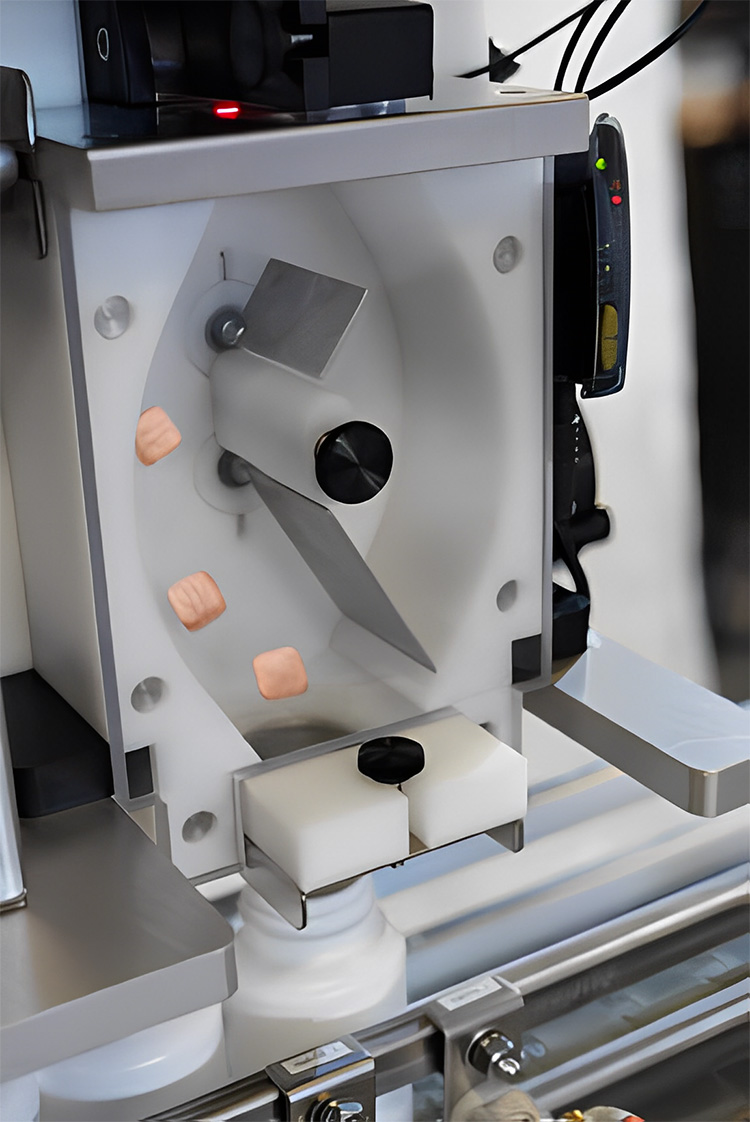

Rotary Wheels Tablet Counting and Filling Machine

Tablet counting and filling machine- Picture Courtesy: Allpack

This technology is present in semi-automatic and automatic tablet counting and filling machines. The significant benefit of this technology is easy to handle and easy to change over for various shapes and sizes of tablets, capsules or other pills. The most important feature of this machine is gentle movement of rotary wheel allows tablets to drops into filling nozzle unit where presence of detector senses the tablet and making them count and fills into respective containers. The entire work process is accurate and very easy. This machine is available in relatively low price and not suitable for high or larger production industries as it output capacity is relatively lower than other machines.

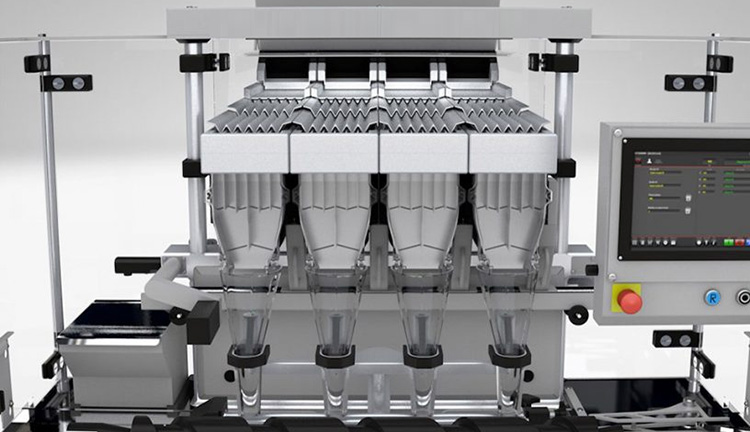

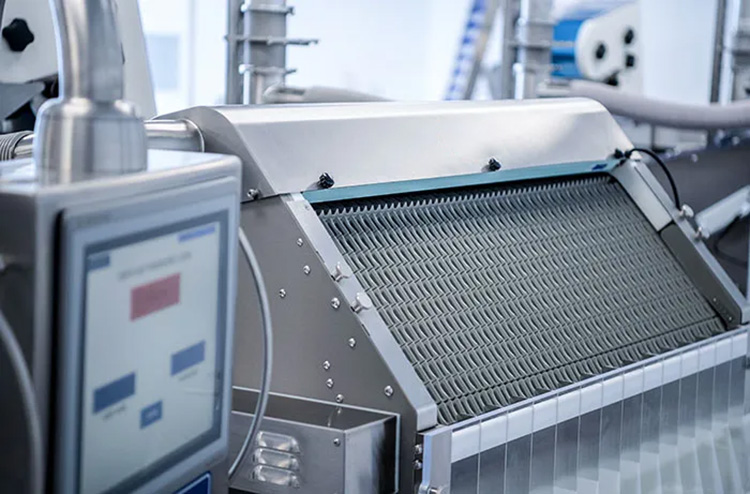

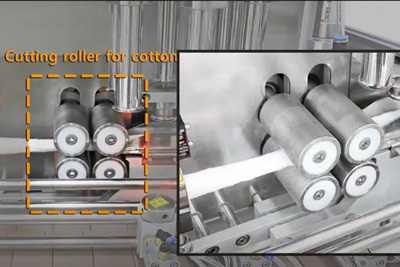

Vibratory Tablet Counting and Filling Machine

Vibratory Tablet Counting and Filling Machine- Picture Courtesy :NMJ Packaging

This machine is much fast solution than a rotary tablet counting and filling machine in which tablets utilizes feeding channels for alignment; by implementing vibrations each tablet passes through scanning area one by one and drops down toward feeding nozzle for further counting and filling process. This machine is suitable for running large production capacity zones where requirement of packaging is almost higher. Moreover, this machine is further classified in the term of available channels, this is presented as single, 8, 16, or 24 vibratory channels ensuring counting and filling task in a bulk with no chances of errors.

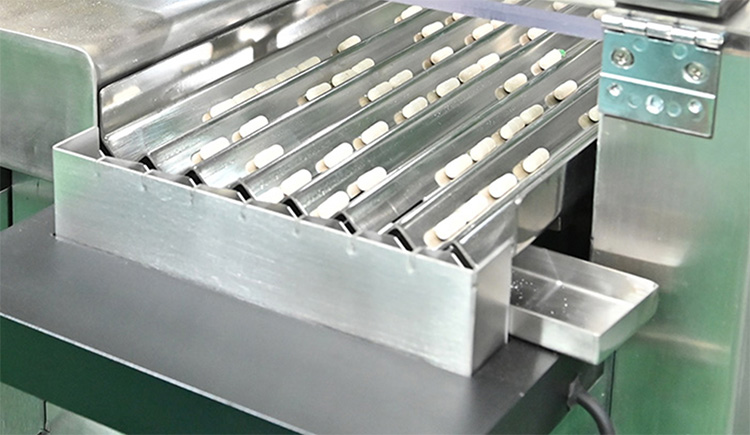

Slat Tablet Counting and Filling Machine

Slat Tablet Counting and Filling Machine- Picture Courtesy:Surplus Solution

Indeed, a fastest solution than rotary wheel and vibratory tablet counting and filling machine. The slat technology utilized special cavities for tablet counting where each tablet fixed and counted and dropped toward filling containers. in this way, thousands of containers are filled accurately each hour. The presence of cavities are meant for typically specific shape of pills that follows particular operation where each tablet is capable to fix in each cavity with no chances of leaving empty or double-filled. In this way, it offers quite accurate results. This machine has a limitation of having continuous changeover for different sizes tablets if required.

TABLET COUNTING AND FILLING MACHINE WITH DIFFERENT COUNTING HEADS

A tablet counting and filling machine is a versatile machine which are available in different counting heads. Such as:

Single Head Tablet Counting and Filling Machine

Single Head Tablet Counting and Filling Machine

A single heading machine is a simple structure and the most cost-economical solution for attaining automatic tablet counting and filling features. This machine is basically designed for those consumers who’re wished to add this robust solution but running a smaller or moderate projects. The machine is equipped with only single counting and filling feeder that are equipped with all amazing features like other machines such as sensors, PLC, visualizing camera, etc.,

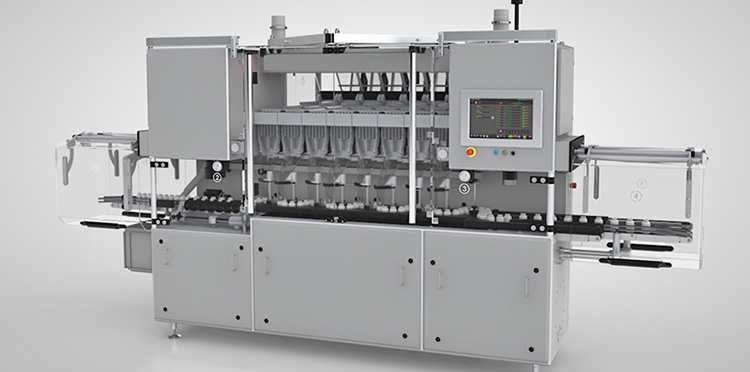

Multi- Head Tablet Counting and Filling Machine

Multi- Head Tablet Counting and Filling Machine- Picture Courtesy: COUNTEC

This is incredible machine that’s featured with multiple counting and filling heads located parallel to each other respectively. Hence, the use of machine offers significantly high counting and filling tasks with faster throughput each time. Due to this property; the machine is highly recommended for running larger production areas for catering bulk production flexibly.

TABLET COUNTING AND FILLING MACHINE WITH DIFFERENT COUNTING CHANNELS

The counting channel is an important feature of tablet counting and filling machine that orient tablets and allows their smooth movement. These channels are equipped with scanners that pick the tablet structure and evaluate it for approval or disqualify from the lot. The channels are further sub-classified into the following:

Single Channel Tablet Counting and Filling Machine

Single Channel Tablet Counting and Filling Machine

This is generally suitable option for lower capacity production lines where machine ensure accurate counting and filling method for a limited capacity. This machine is featured with only one or single pathway through which tablets or pills are easily flow toward feeding nozzle for further filling.

Multi- Channel Tablet Counting and Filling Machine

Multi- Channel Tablet Counting and Filling Machine- Picture Courtesy:COUNTEC

This machine is featured with multiple channels that allows flow of tablets for counting and filling task simultaneously. The working and movement of tablet flow takes place parallel to each other that offers high counting and filling speed. The counting channels are equipped highly advanced scanners where any fault or damage can easily be detected. This machine is highly recommended for large production industries because it can cater bulk quantity products so far.

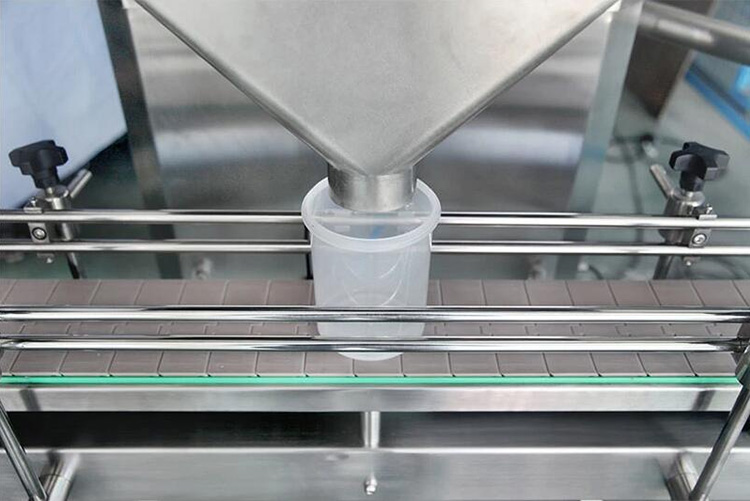

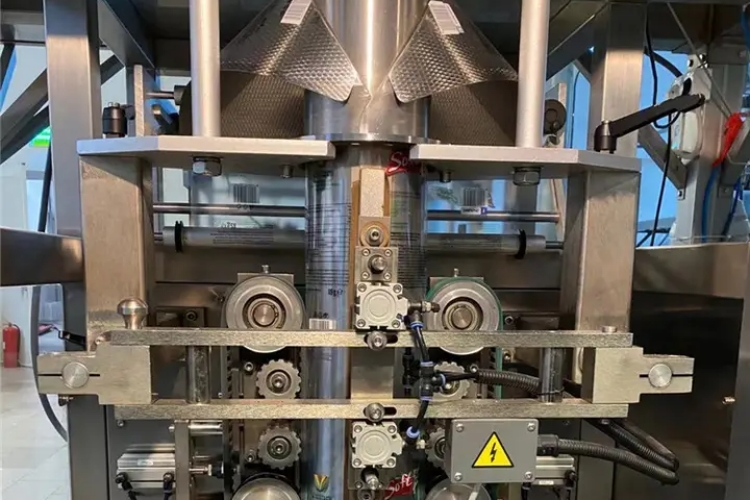

6.How Does Tablet Counting and Filling Machine Work?

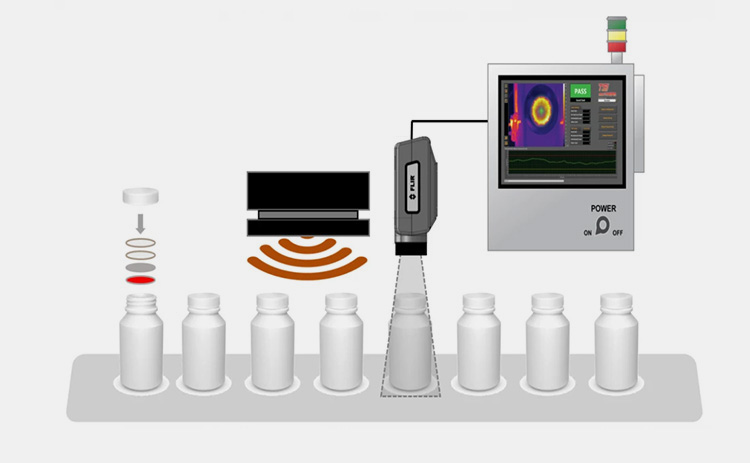

The working of the tablet counting and filling machine is pretty simple. For your understanding, we have explained it with mentioned illustrations. Keep reading!

| STEP | DESCRIPTION | ILLUSTRATION |

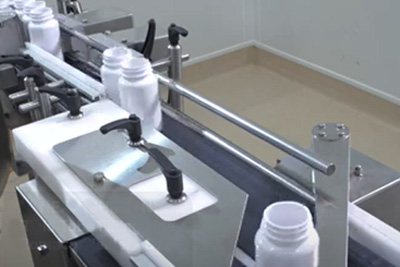

| Bottle Feeding | The tablet counting and filling process begins when bottles are come inside the system by the help of conveyor. These bottles or packaging materials are transferred in proper upright direction for easy filling. |  |

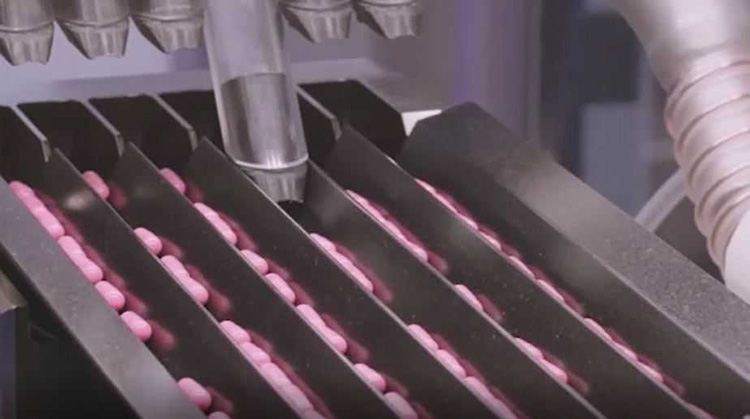

| Tablet Flow | Tablets from hopper are subjected to the vibratory channels where they move properly by gently vibratory movement that pushes them and one by one falls toward filling nozzle. These vibratory trays are equipped with scanners that determine the shapes, structure, and presence of the tablet. |  |

| Counting and Filling | The number of tablets drops down into the filling feeders that are equipped with high-degree sensors which detects and count the tablet and allow them to fill the container. The specified number of tablets are introduced into each container depends upon protocol fed by an operator. |  |

| Discharge | This is the final stage, where containers are filled and leaves the system by the help of conveyor. |  |

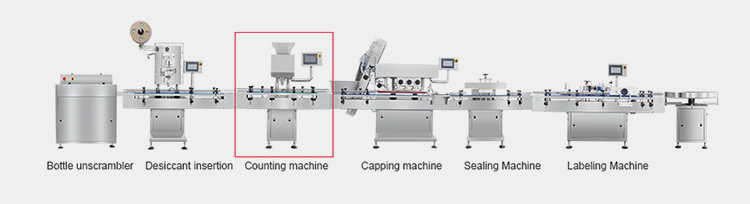

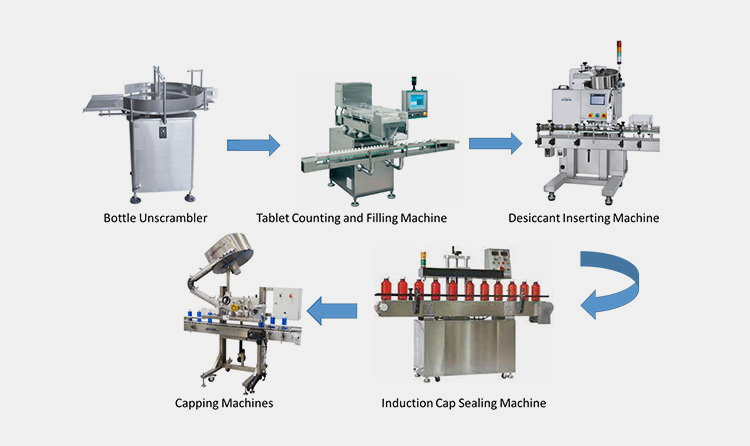

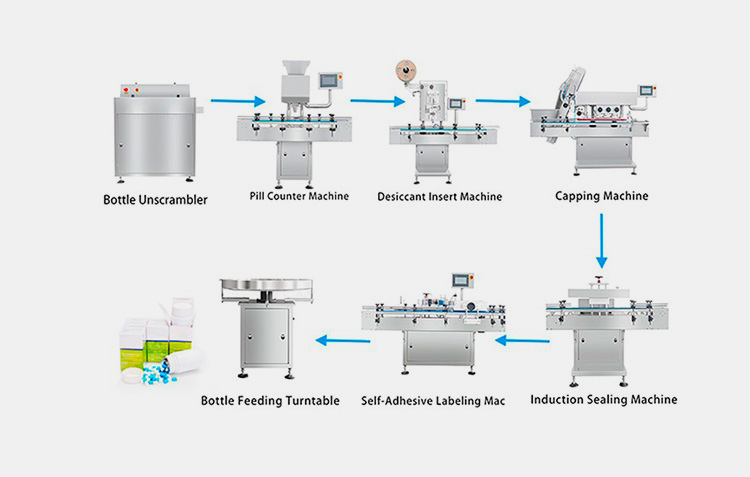

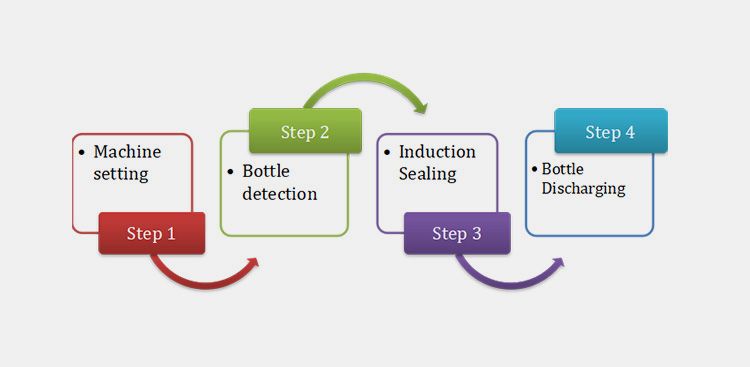

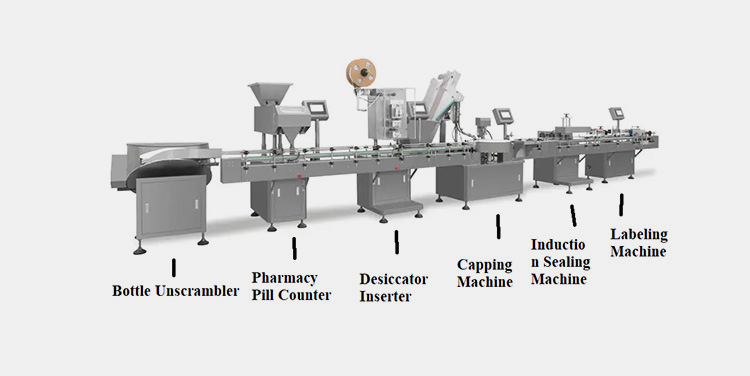

7.What Integrated Units of Tablet Counting and Filling Machine?

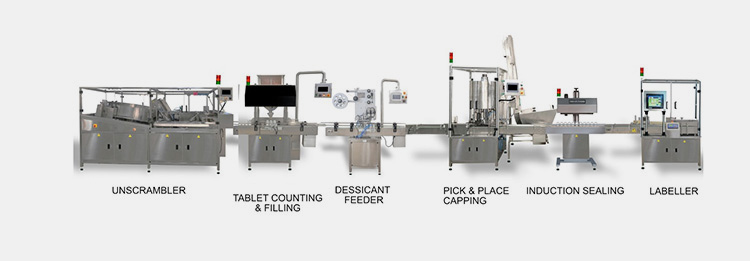

The tablet counting and filling machine is best fit machine works flexibly in a packaging production line composed of various machines. We have discussed them one by one below, have a look.

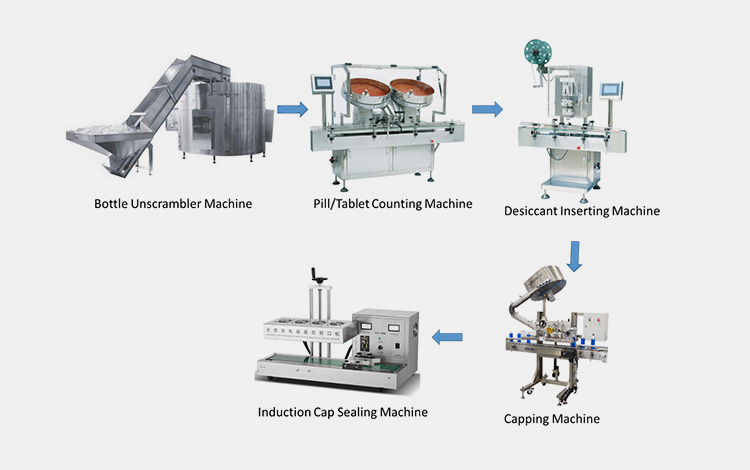

STEP 1: Bottle Unscrambler

The packaging bottles, containers, or jars are fed into the system randomly. The bottle unscrambler is responsible for making them an upright and proper position by use of air blowers, vibratory tray and sensors. If any bottle is damaged or not approved for further packaging would be rejected and added to the discard unit.

STEP 2: Tablet Counting and Filling Machine

By the help of conveyor, bottles are entered to tablet counting and filling machine where optimized numbers of filling product is introduced. The packed product is now subjected to the next machine of the system.

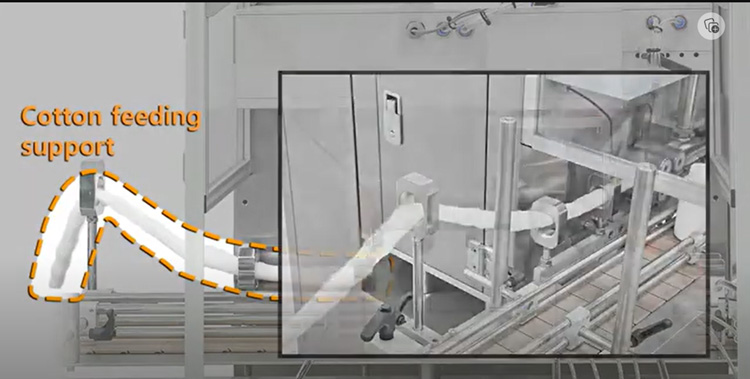

STEP 3: Desiccator Feeder

To avoid development of moisture inside the container, a desiccant is inserted that assure product is safe throughout the transportation and usage. The roll of desiccant is adjusted using supporters equipped in the machine. By the help of roller cutter each strip is separated and positioned inside the bottle. Now, bottle is ready to leave the system.

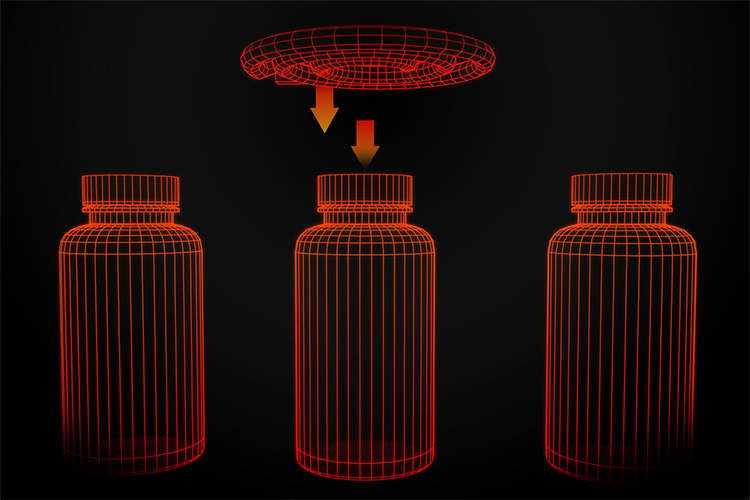

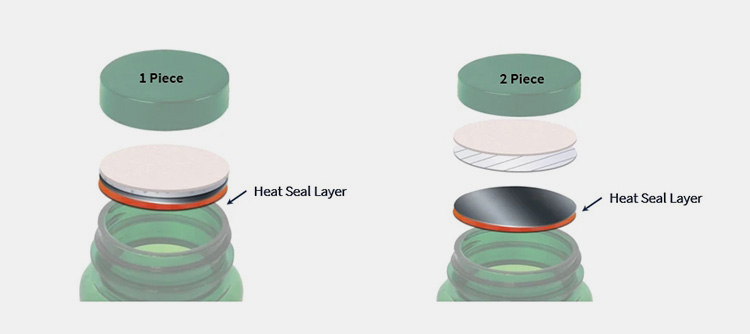

STEP 4: Capping Machine

Inside the capping machine, bottles/containers/pouches are subjected to automatic grippers that helps in holding and twisting caps over the neck of each container. The purpose of this machine is to secure product firmly.

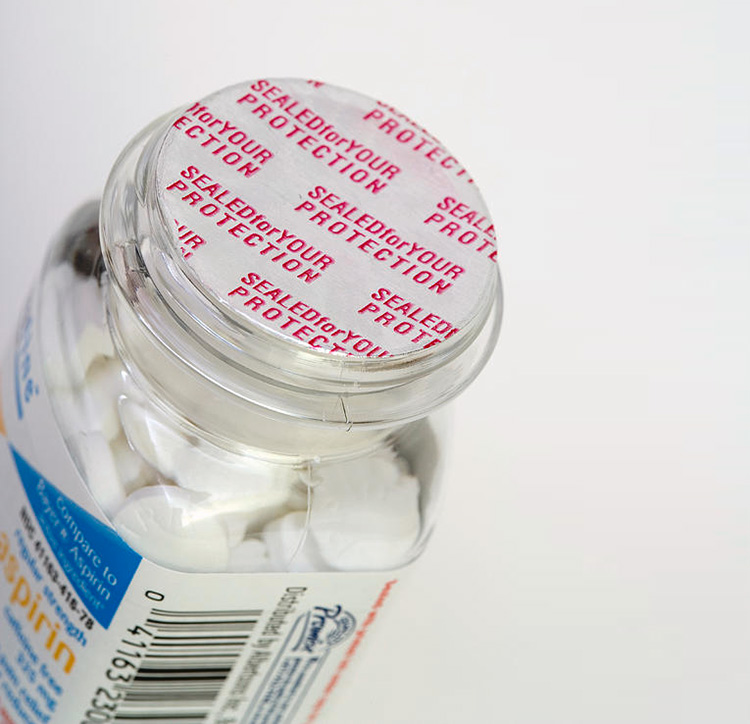

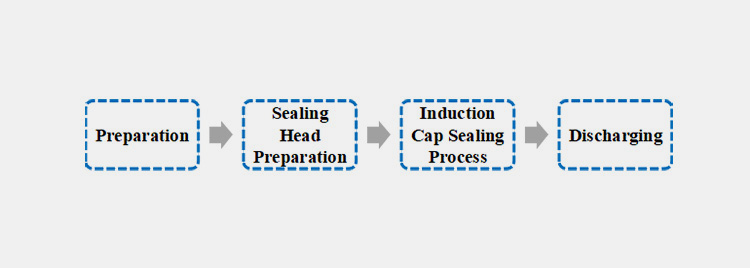

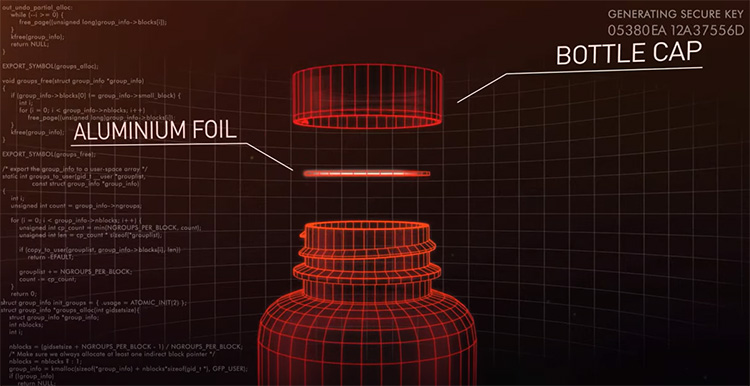

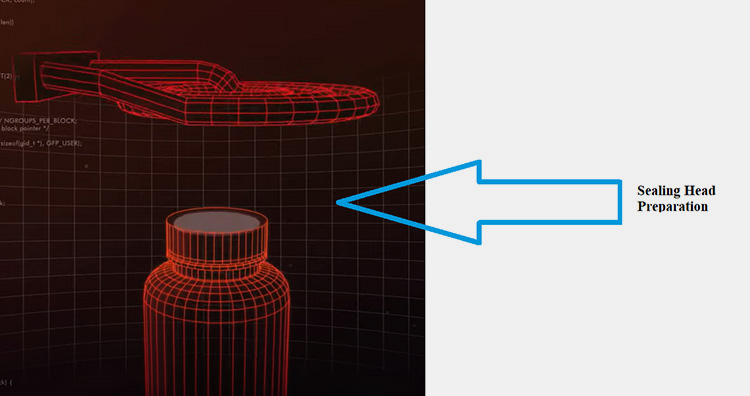

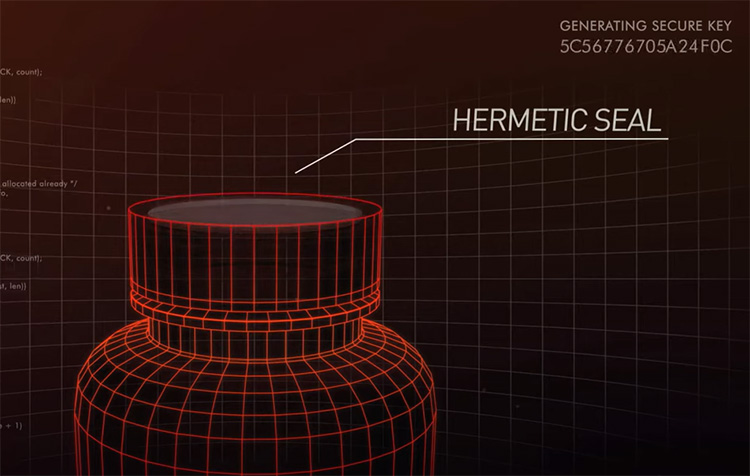

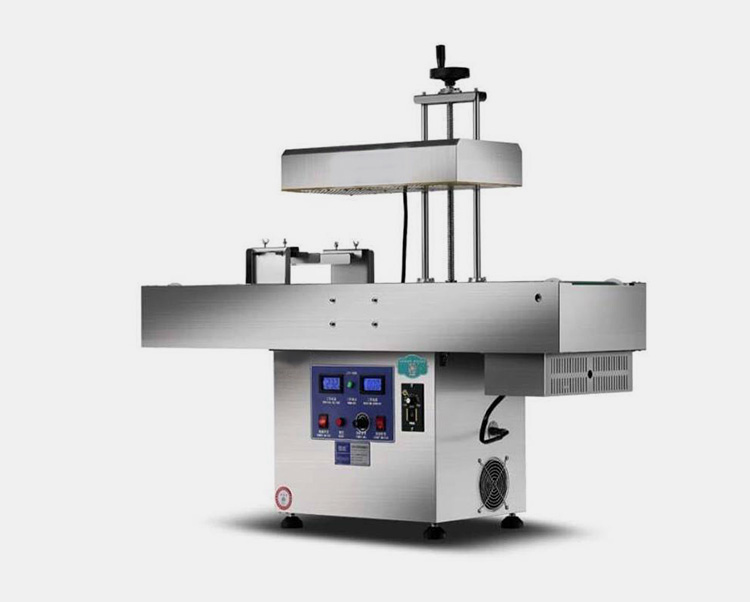

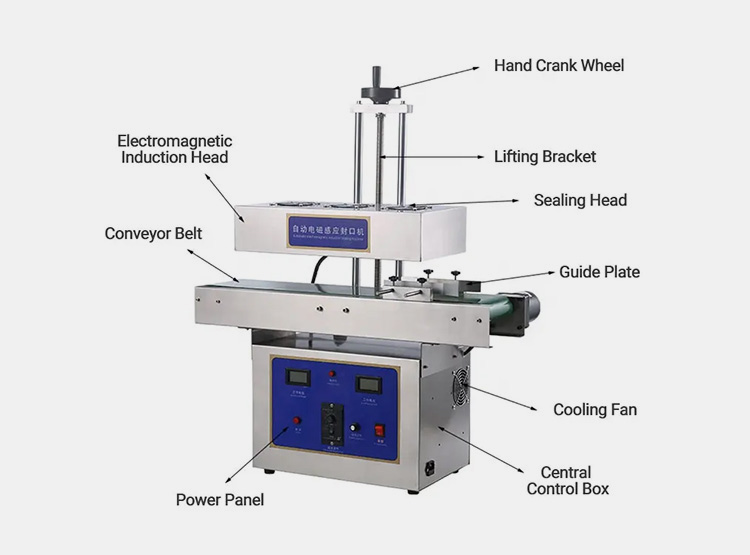

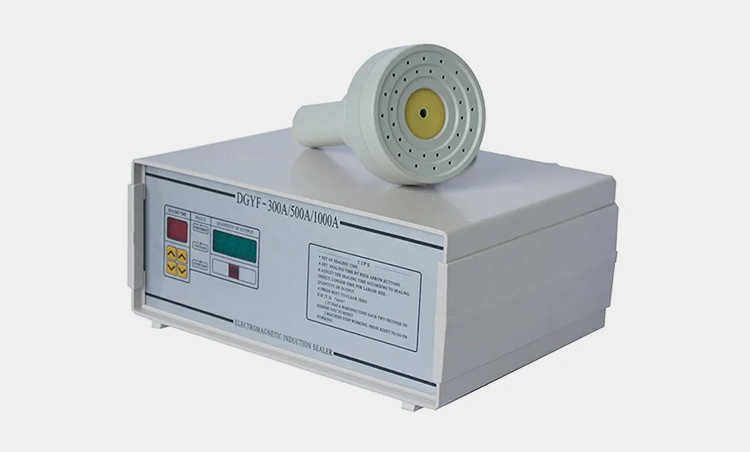

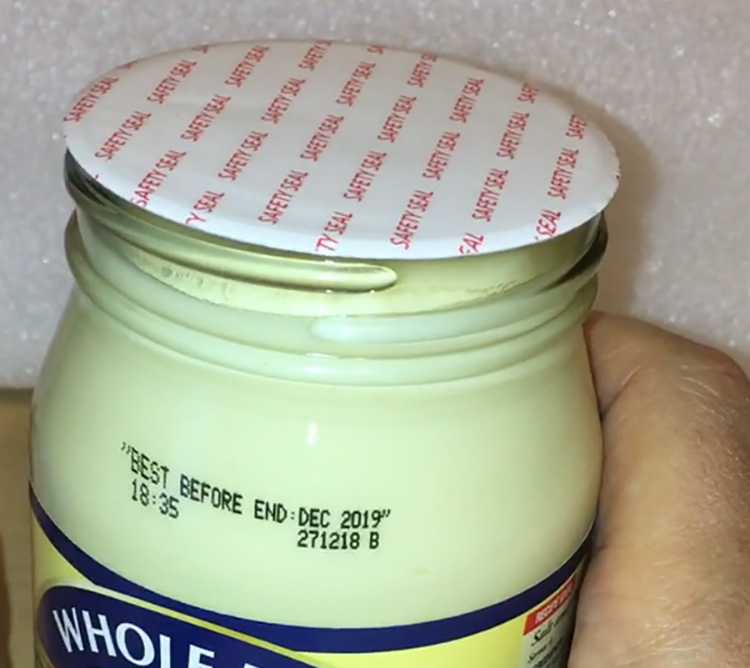

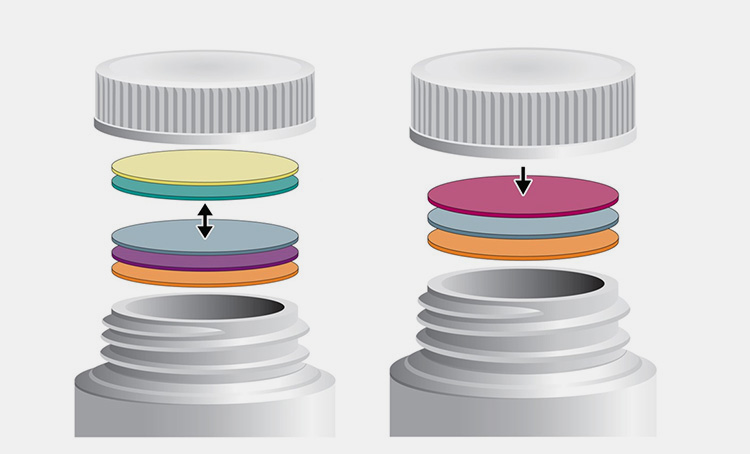

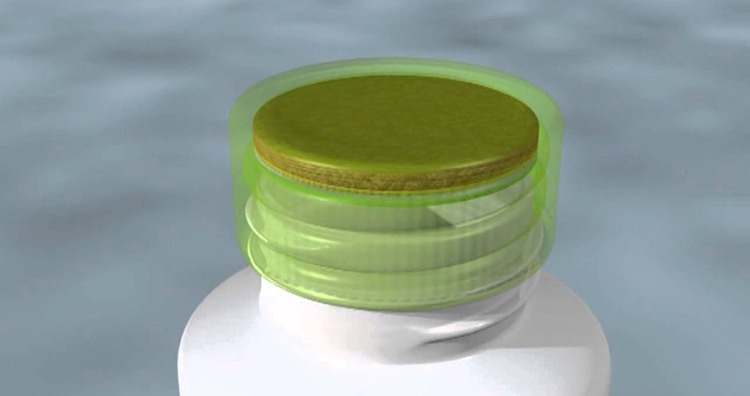

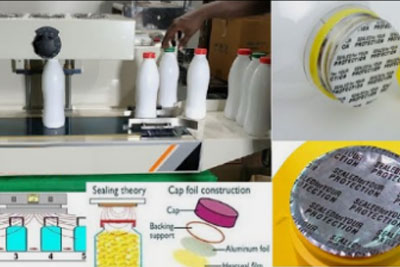

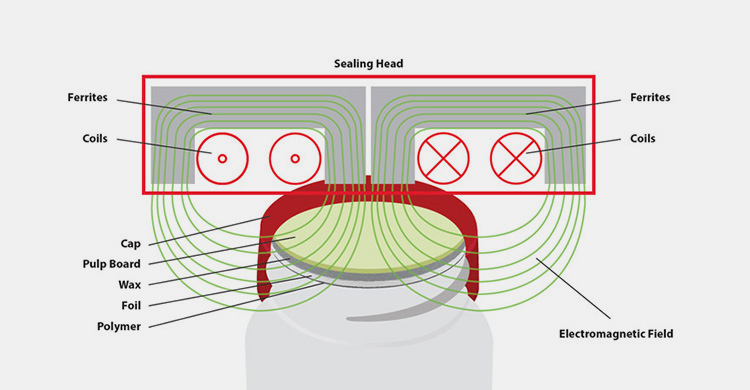

STEP 5: Induction Sealing Machine

Every healthcare, food sector and relevant field secure their packaging by inducing tamper evident sealing. An induction sealing machine works by generating electromagnetic field that melts inner lining of the cap once warmed. The lining forms a firm bond with neck edges of the bottle upon cooling that make packaging more secure against external physical factors such as light, temperature, moisture, etc.

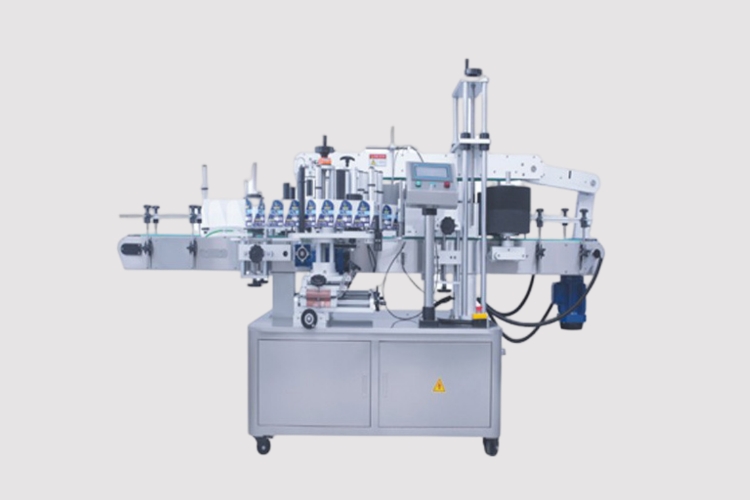

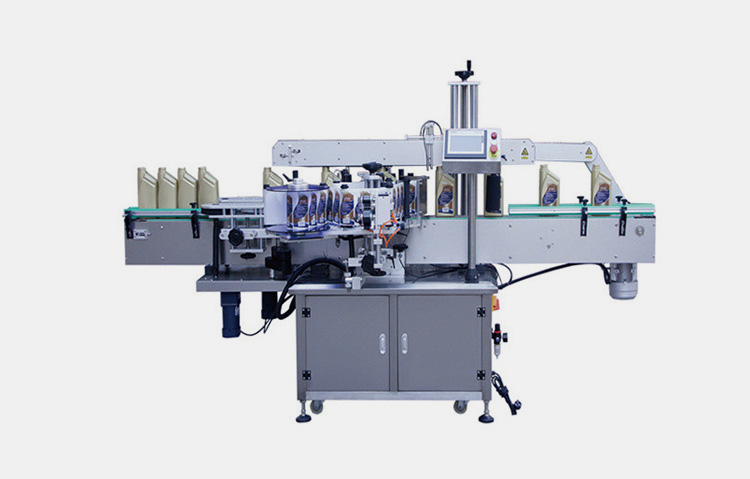

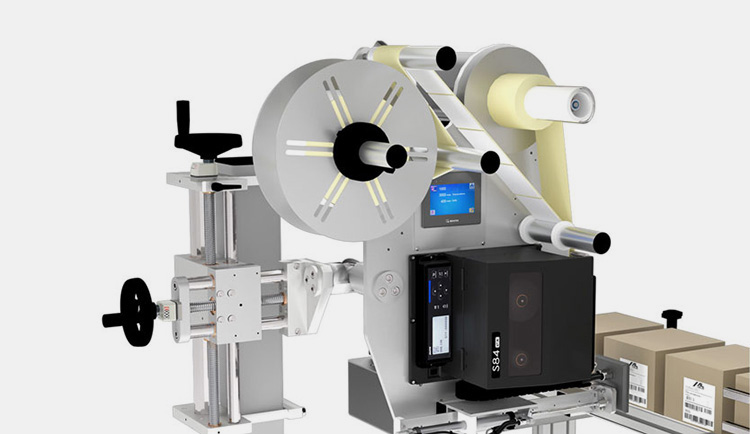

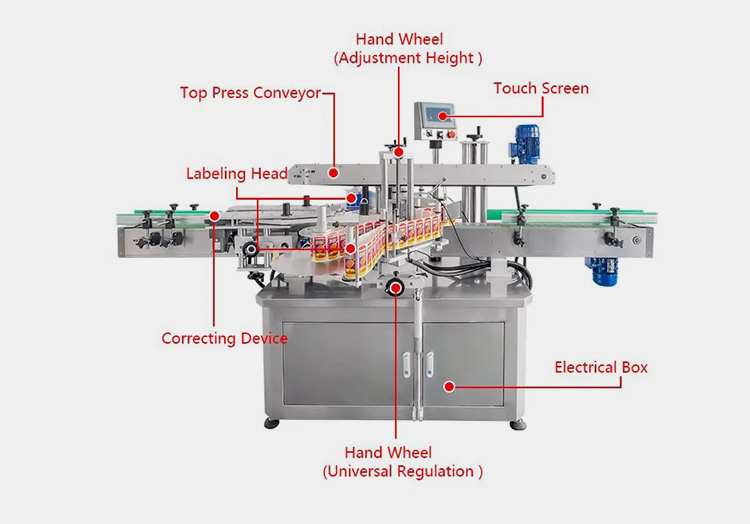

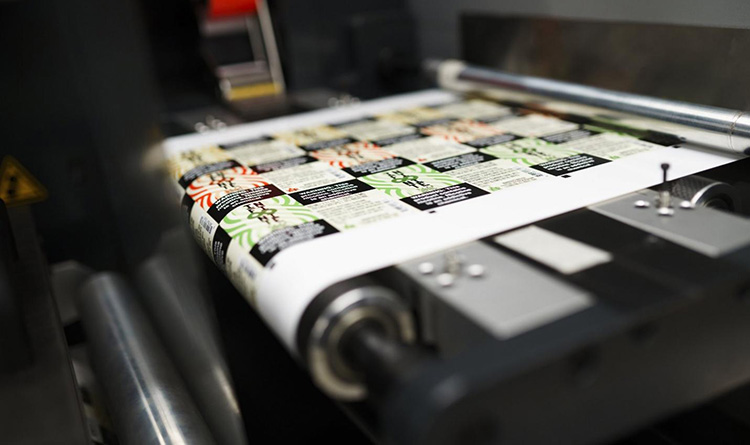

STEP 6: Labeler

This is an important piece of equipment that enhances your brand and sharing important messages, company’s slogan and information to consumers such as dosage, interaction, precaution etc., the labelling machine works by fixing roll using roller feeders which opens the label and starts applying on bottle surface. The roller pressers firmly and evenly press the label.

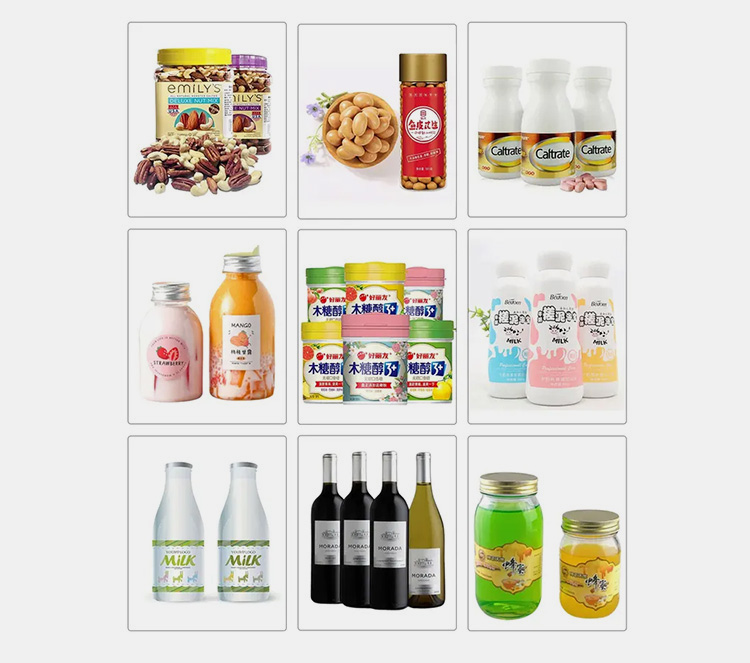

8.What Other Products Can Tablet Counting and Filling Machine Counts?

A tablet counting and filling machine can not only count your tablets, but it can also be beneficial to numerate other products used in food, confectionery, chemical and agricultural industries as well. Some of these products are as follows:

Capsules

Capsule Counted By The Tablet Filling And Counting Machine

Capsules are counted by the use of same working principle as tablets are counted. This oblong-shaped medicine is transferred to the vibration plate where sensors sense the product, count and then fill into their containers.

Pills

Pills Counted By The Tablet Filling And Counting Machine

Pills are quite similar in shape and size to tablets and capsules. So, they can also be counted and filled likewise. Hopper is filled with bulk quantity of pills, and they are further dispatched to the sensory device which counts and fills into their containers.

Gummies

Gummies Counted By The Tablet Filling And Counting Machine

Gummies belong to confectionery industry, and so transferring it in bulk amounts can be helpful using a tablet counting and filling machine. This machine is modified to handle its tangling and delivers clean and accurate count of gummies.

Coffee Beans

Coffee Beans Counted By The Tablet Filling And Counting Machine

They are small, round or oval shaped solid product which can be dumped into the hopper and further processed in a tablet counting and filling machine to be counted for bulk packaging.

Laundry Pods

Laundry Pod Counted By The Tablet Filling And Counting Machine- Picture courtesy: Best Seller

As these detergent pods or dishwashing tablets are sticky in nature, a separating vibration plate is helpful for this purpose. The tablet counting and filling machine has a bucket conveyor and multiheaded weigher specification which presents accuracy and efficiency in counting.

Candies & Chewing Gum

Candies and Chewing Gum Counted By The Tablet Filling And Counting -Picture Courtesy:Taste Tech

Candies & chewing gums as well belong to confectionery industry . Similar to gummies and laundry pods, they also present stickiness problem. For this an elevated plate and ground level hopper is present in a tablet counting machine which can count and fill, without the problem of stickiness or undercounting.

Lozenges

Lozenges Counted by Tablet counting and filling machine- Picture Courtesy :Difflam

These are commonly produced in the nutraceutical and pharmaceutical industry that are intended to dissolve in mouth once administered. Tablet counting and filling machines are worthwhile for the packaging of lozenges.

9.What is the Difference between Rotary and Slat Tablet Counting and Filling Machine?

Rotary and slat tablet counting and filling machines are intended for the same purpose (counting) but machine itself encompasses some prime distinctions.

For example:

| ROTARY | SLAT | |

| STRUCTURE | The machine is featured with circular wheel that helps in continuous movement of tablets and arrangement for counting and filling procedures. | This is an advanced machine that has equipped with unlimited number of cavities where tablets are fixed and indicated as counted and filled into the following packaging material. |

| CAPACITY | The rotary tablet counting and filling machine production capacity is relatively low. Therefore, it is suitable for small to medium production industries. | The production capacity of slat tablet counting and filling machine larger. Therefore, it is recommended for the larger industrial sector. |

| Working Principle | The working principle is based on rotation. | The working principle is based on cavity filling with linear motion. |

| Limitation | The work process is relatively slow. | The changeover rate is higher. |

| Cost | This machine is relatively cheaper. | This machine costs you higher. |

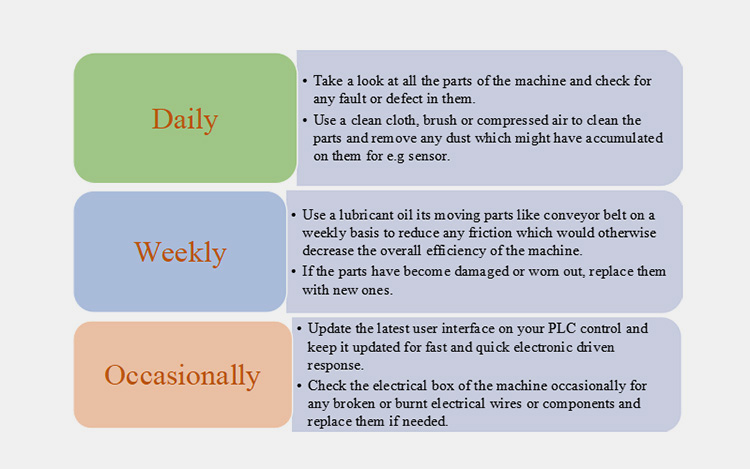

10.How to Clean and Maintain Tablet Counting and Filling Machine?

tablet counting and filling machine- Picture Courtesy:Integrated packaging

A tablet counting and filling machine is a reliable machine giving you fast and accurate counting and filling tasks; this working efficiency could be affected if you’re not properly taking care of the machine. Please check below following points to extend life of the equipment with excellent working.

| Cleaning | Maintenance |

| Always clear the hopper after work and inspect prior work to avoid cross-contamination. | Lubricate movable parts regularly to avoid abrasion, development of rust, and noise. |

| Use clean and dry fabric for cleaning important parts such as vibratory channels, sensors exterior and feeding nozzles. | The worn-out or damaged wiring must be removed and replaced with new parts to enhance the work efficiency of the machine. |

| Calibrate the equipment and ensure the correct configuration of the machine. |

11.What Type of Packaging Material Can be Supported with Tablet Counting and Filling Machine?

The tablet counting and filling machine is designed to support packaging material of various different formats such as:

Jars

These are commonly used in food and nutraceutical industry that is formatted as a wide mouth container. A tablet counting and filling machine can accurately and flexibly support jars for dispensing pills, capsules, tablets.

Bottles

You can use bottles of various shapes and sizes in tablet counting and filling machine with accurate dose dispensing.

Vials

They are commonly used for packaging pharmaceutical medicines that are usually small in structure and can easily be adjusted in tablet counting and filling machines for perfect dose storing.

Stand up pouches

Whether pre-made or film form pouches are compatible with tablet counting and filling machine for efficient and fast packaging.

12.What are the Problems and Troubleshooting of Tablet Counting and Filling Machine?

Tablet counting and filling machine

Although a tablet counting and filling machine robust and reliable machine but seldom it develops and faces some technical problems. For that, no need to worry as the machine itself is capable enough to notify and try to manage. Some of the major issues and troubleshooting are discussed below:

Machine Counts Twice

Tablet counting and filling machine- Picture Courtesy :Ropack Russia

This is an obstacle when the machine senses tablet double instead of single.

This problem occurs in multichannel tablet counting machine where the flowability of tablets is in the bulk.

Solution

We would recommend clearing the scanners and vibratory channels tray. Secondly, re-calibrate the system and run the test. Clean the machine and remove unwanted foreign particles so false readings would be avoided.

Tablets Movement are Jammed

Tablet counting and filling machine

This is another common problem where the flow of tablets is interrupted.

This condition is caused by slow or agitated movement of the vibratory channels and increased feeding of tablets from the hopper.

Solution

Regular maintenance of the machine can solve this problem. Lubricate the movable parts, clean the sensors, and feeding head, and assess the movement of the conveyor. Please check the alignment of the hopper and fix it properly so tablet movement can be controlled.

Machine Fails to Detect Tablet

Tablet counting and filling machine- Picture Courtesy :Maharshi

This is another problem where the machine can’t identify the presence of a tablet. This problem could arise due to the poor sensitivity of sensors hence machine fails to respond.

Solution

This problem can be solved by wiping out the sensor by using a dry cloth. Check and evaluate camera settings and run the test.

Conclusion

In a summary, a tablet counting and filling machine is an exceptional technology that has successfully replaced manual handling and conventional method of counting and filling products. That’s why this machine is extensively adopted in broad range industrial sectors such as pharma, nutraceuticals, food, and other businesses. Planning to purchase? Allpack is well-recognized company offering broad range tablet counting and filling machine with amazing prices. For more information, Get in Touch with Us Now.

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide

Tablet Counting and Filling Machine: The Complete Buying Guide In 2025 Read More »

Tell us your material or budget, we'll reply you ASAP within 24 hours

Tell us your material or budget, we'll reply you ASAP within 24 hours

Tell us your material or budget, we'll reply you ASAP within 24 hours

Tell us your material or budget, we'll reply you ASAP within 24 hours