Detergent Packaging: The Complete FAQ Guide In 2025

Detergent Packaging: The Complete FAQ Guide In 2025

Detergents are types of goods used for regular chores. The type of requirements includes cleaning cloths, maintaining, and wiping equipment, automobiles, general house cleaning, warehouses, and so on.

As much as you use and require detergent; this can directly increase the demand for calling the product from industries. The production of detergent is a long process that is finalized by an aesthetic packaging method.

There is a broad market size of various detergent packaging machines around you. What is your choice? Which detergent packaging machine is offering good features? What is best fit for your production goals? We’re here to discuss this important topic today with amazing machines options. Please check out!

1.What is Detergent Packaging?

This is an old practise to clean your cloths using detergent; whether liquid detergent or powdery, you must pick the one that has beautiful packaging.

The detergent packaging is the mode of securing detergent in an intact form. This includes protection against chemical and physical hazards, moisture, dusts, temperature, leakage and other.

The finish form of detergent packaging allows an easy transportation and make your product capable of withstanding against harsh handling and wear & tear during shipments across the globe.

So, you need to carefully monitor the packaging types and packaging machines that helps to bring this job perfect awesome.

2.What are Types of Detergent?

Indeed, you cannot think only about dry or powdery detergent, there are various available options for detergent packaging based on types of detergents.

There are basically three major types of detergents:

Powder Detergent

An old way of detergents available in various pouches, sachets and other packaging materials where you can pour a scoop of powder into either a bucket or washing machine to clean you cloths or other tasks such as cleaning floors, equipment, etc.,

Liquid Detergent

These are new and modern way detergents that is mostly used to eliminate heavy and hard stains. The advanced washing machines are commonly friendly with using liquid detergents in a small amount which is considered as very effective in treating your cloths mildly.

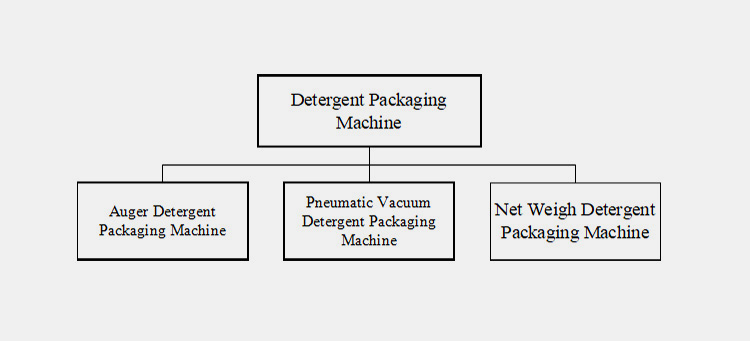

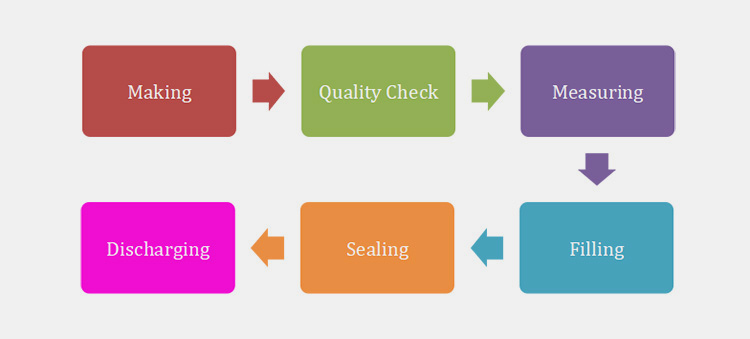

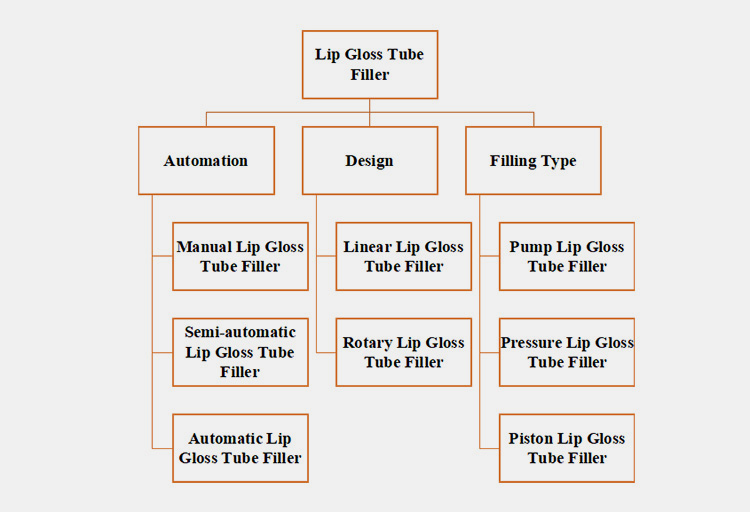

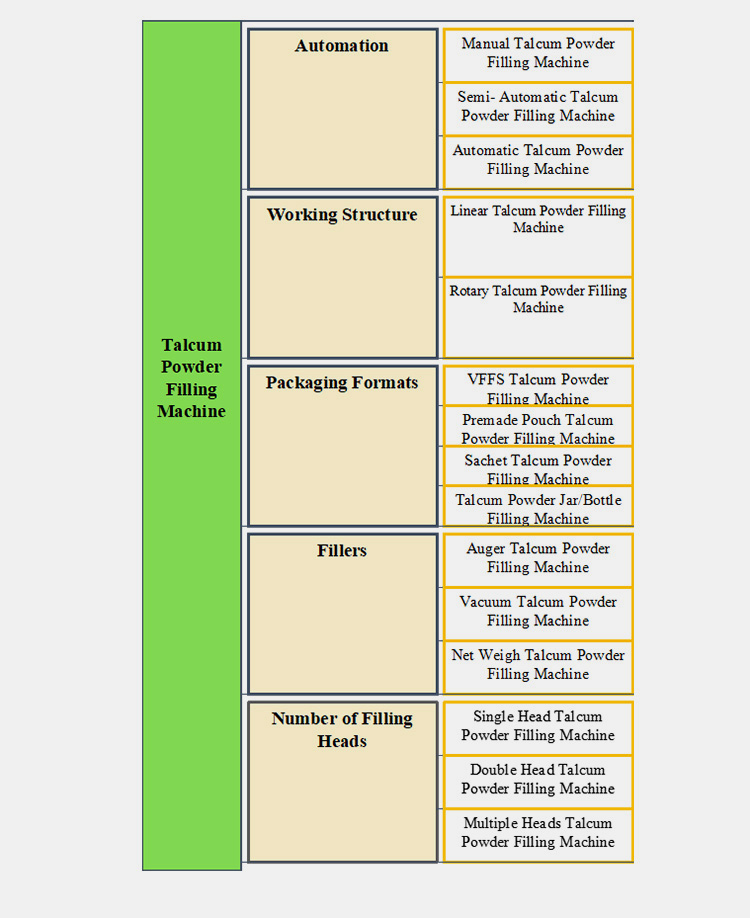

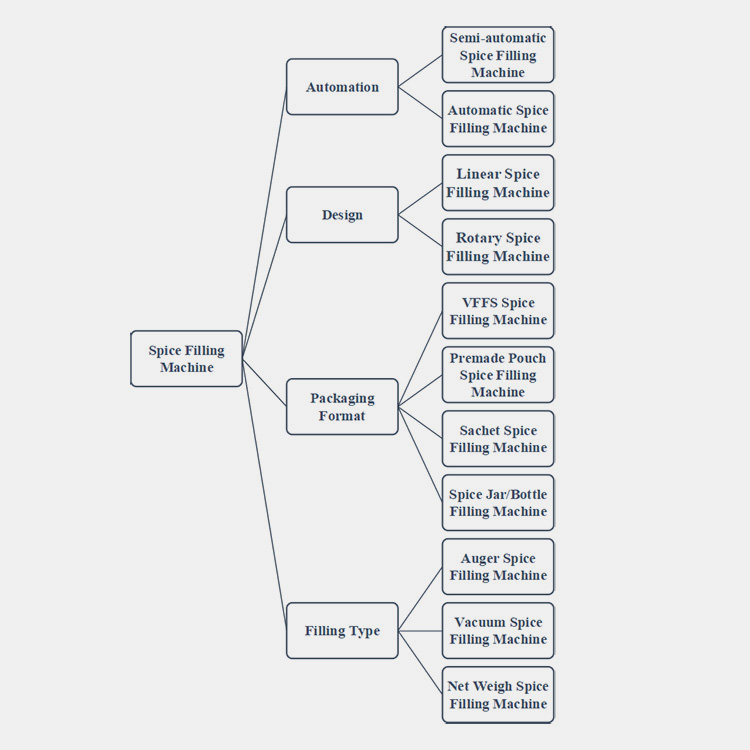

3.What Is Various Machine’s List of Detergent Packaging and Working?

Detergent packaging can be achieved by using the following enlisted machines.

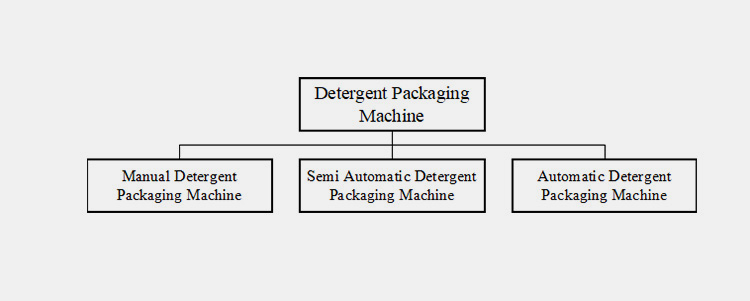

According to Automation

Manual Detergent Packaging Machine

Manual Detergent Packaging Machine

This is a handy and very cost-effective solution for those entrepreneurs who are handling small detergent packaging businesses.

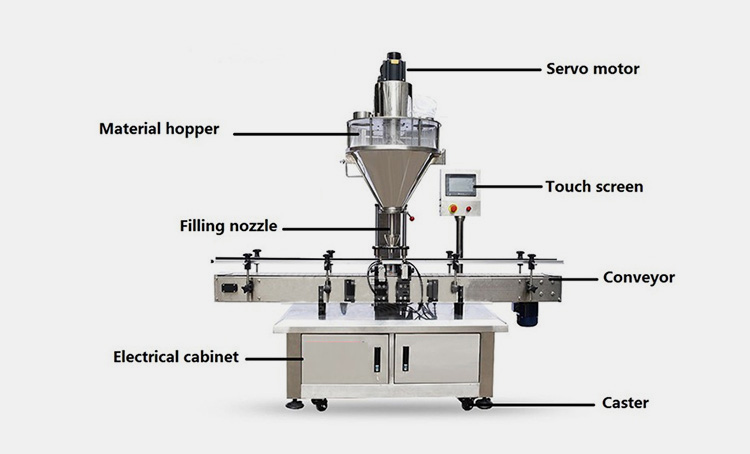

This machine is designed to pack detergent by manual working where you can load detergent (liquid or powder) into the hopper of the machine and place the filling material or pouch just below the nozzle (auger or filling nozzle) followed by twisting the handle which allows the material directly to the detergent packaging.

Once the material is placed inside, you can remove the pack and place the cap or seal them via manual sealer and label them carefully.

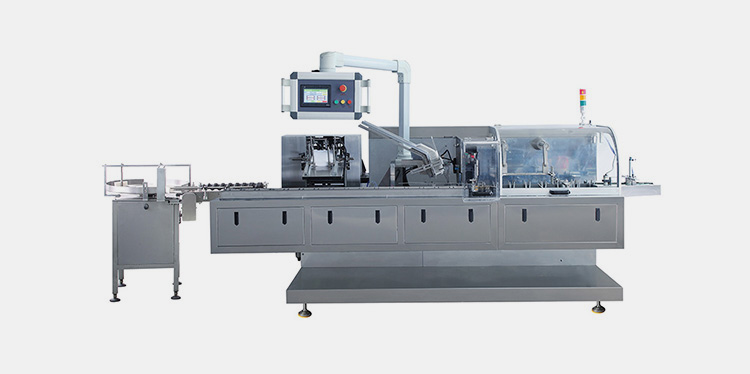

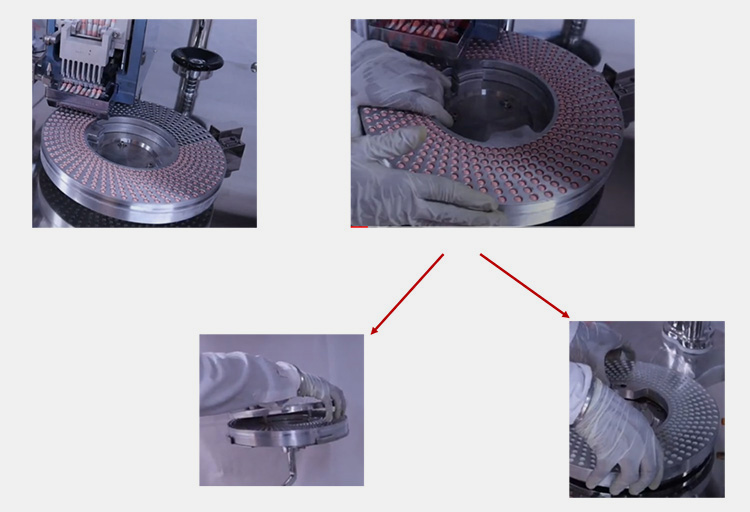

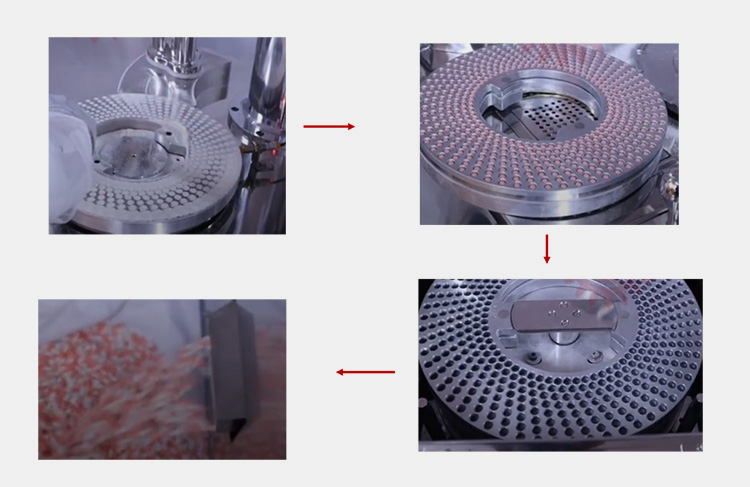

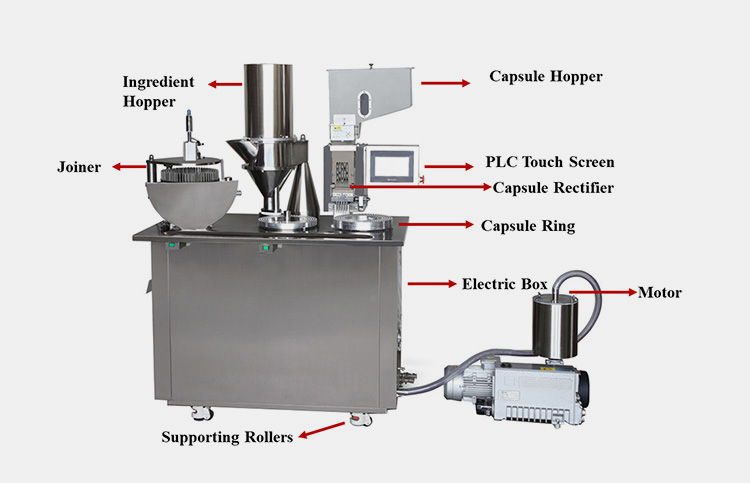

Semi-Automatic Detergent Packaging Machine

Semi-Automatic Detergent Packaging Machine

This is an advanced machine as compared to manual equipment.

Here, you need to place and remove the packaging material manually, whereas the filling, and sealing process is taken place automatically. You can enter the required details on PLC featured by semi-automatic machines.

This machine partially operates needing manual or human interventions and partially works automatically. That’s why this is a suitable solution if you’re running moderate to large batches for detergent packaging.

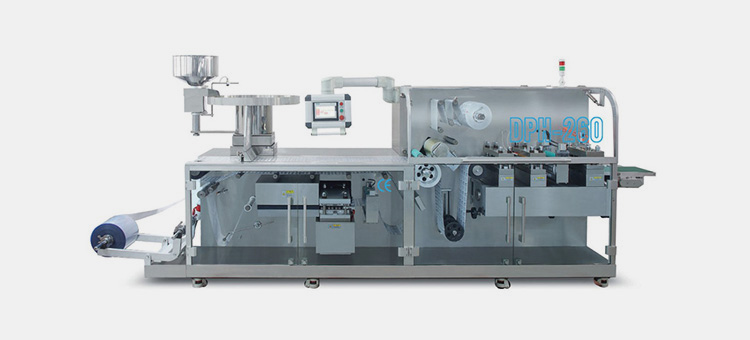

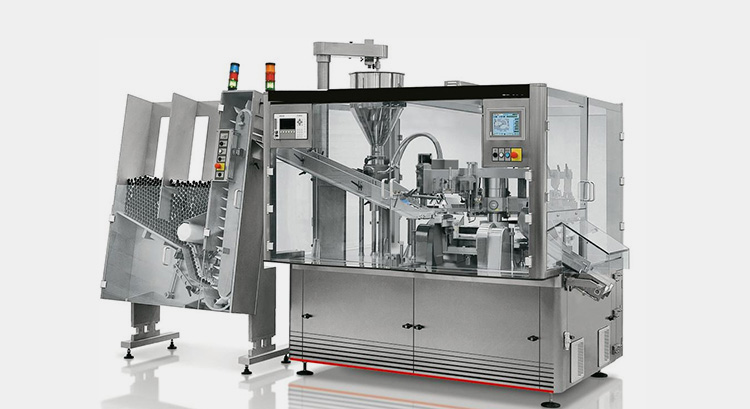

Automatic Detergent Packaging Machine

Automatic Detergent Packaging Machine

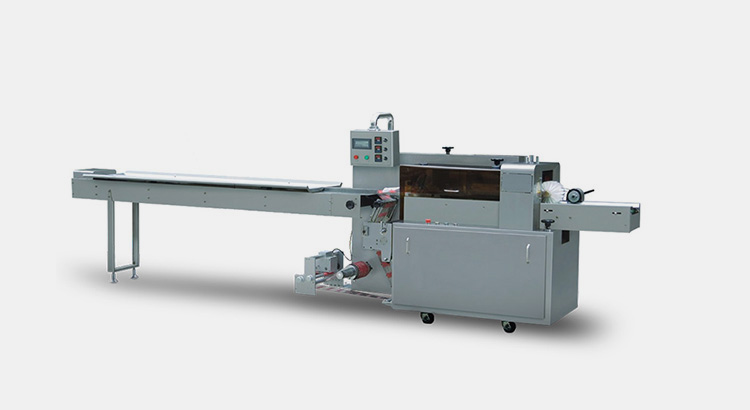

This is an excellent and fastest detergent packaging machine which is entirely operating based on high automation including starting, placement filling, and discharging to another machine.

An automatic detergent packaging machine offers rapid as well as an accurate filling and packaging solutions without exclusive monitoring and a lethargic work process. Therefore, this machine is an ideal solution to add in large production setups.

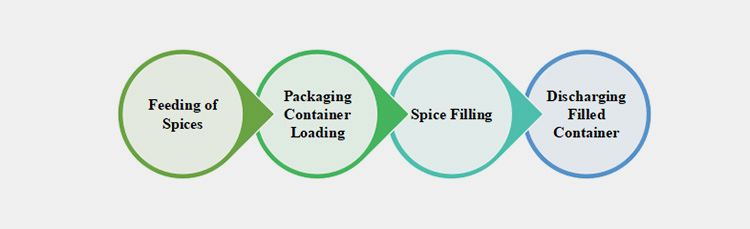

Here, an integrated machine allows the packaging material to come towards filling stations where high detectors sense the presence and ensure precise filling followed by subsequent discharging toward the next process.

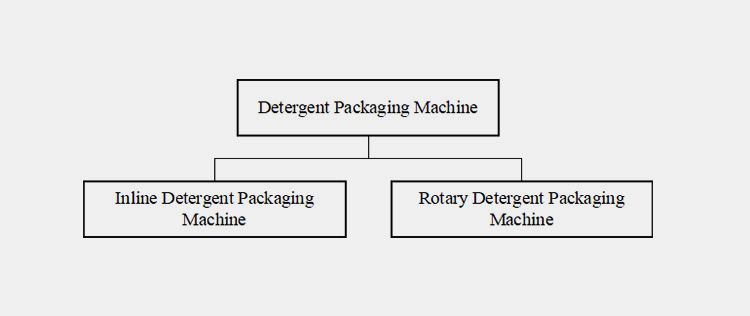

According to Design

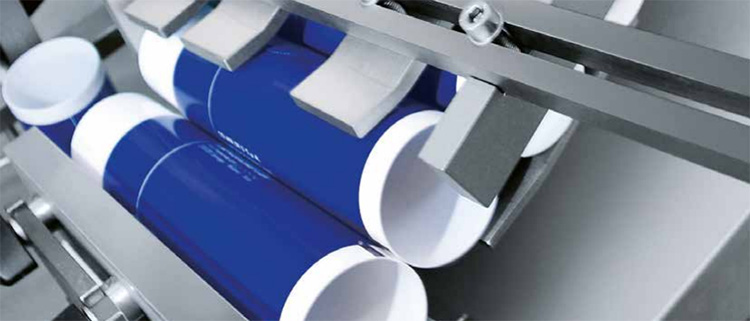

Inline Detergent Packaging Machine

Inline Detergent Packaging Machine

This is very simple in structure detergent packaging unit that basically follows a linear working order where packaging process is taken place via incoming of packaging material in a straight direction towards the filling stations,

The process of entrance, filling, capping, and discharging process follows a linear fashion. This machine is considered as a straightforward functionality and available in a cost-effective budget across the globe.

Rotary Detergent Packaging Machine

Rotary Detergent Packaging Machine

This is a new and compact solution for detergent packaging that works by incoming, filling, and outgoing packaging material following a circular or rotational way.

The machine is offering you a compact packaging solution which is capable of adjusting in a small workstation that requires large packaging outcomes in a short time.

That’s why the machine is allowing their users to bring a high production capacity.

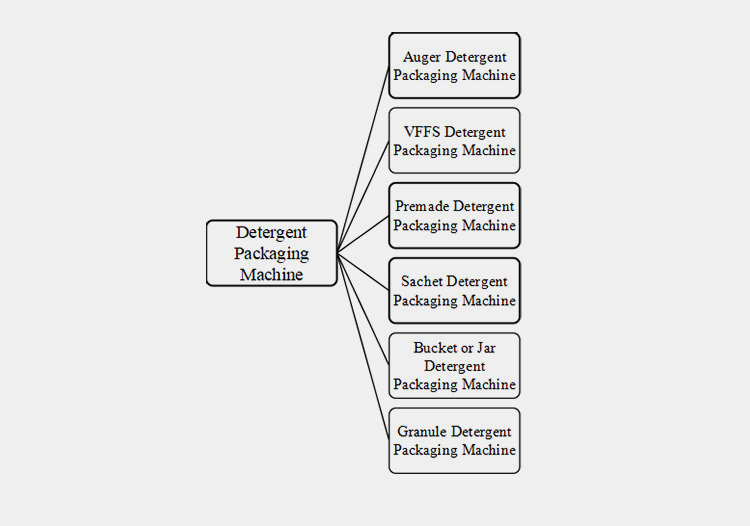

According to Filling Working Format

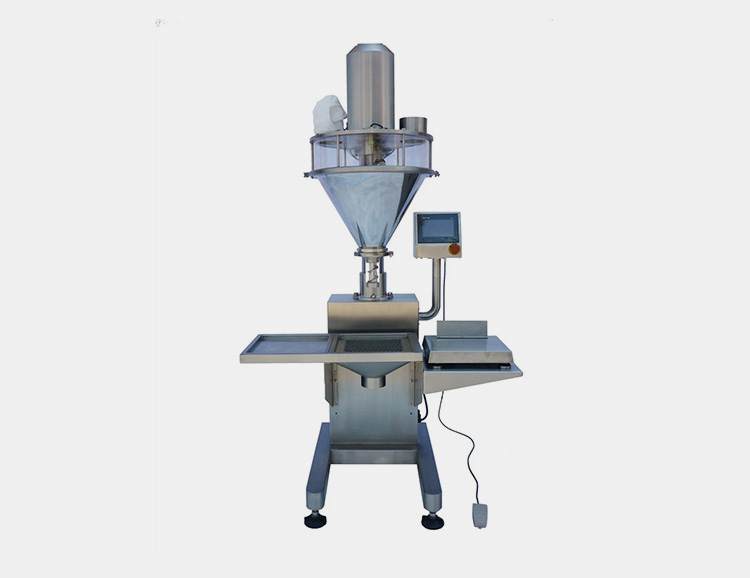

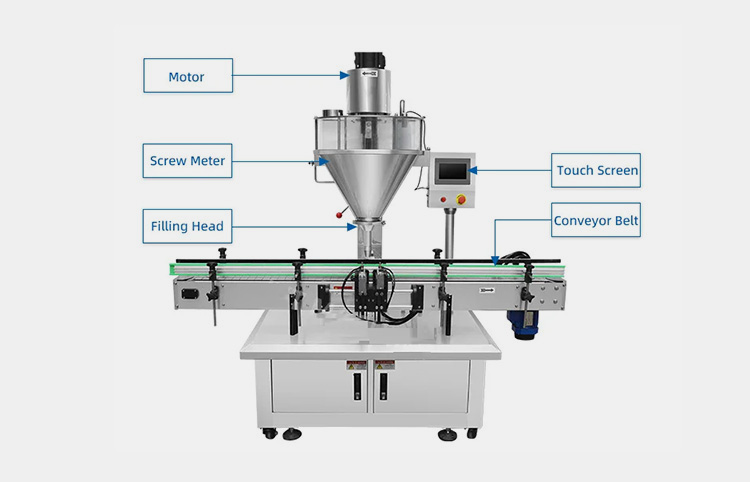

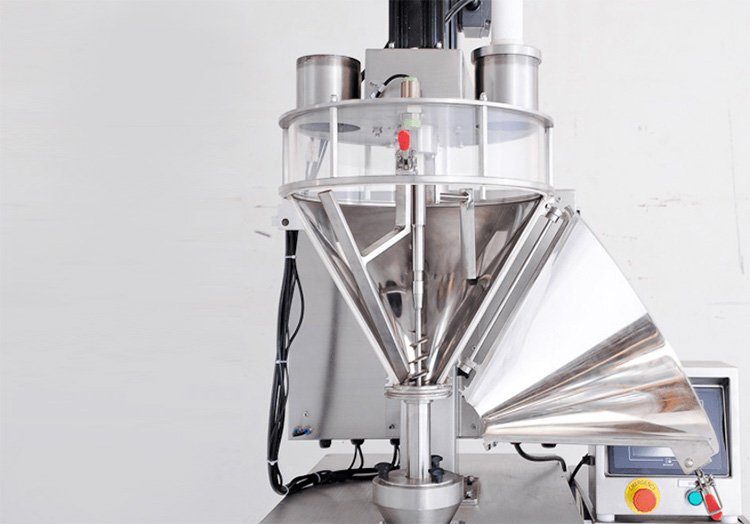

Auger Detergent Packaging Machine

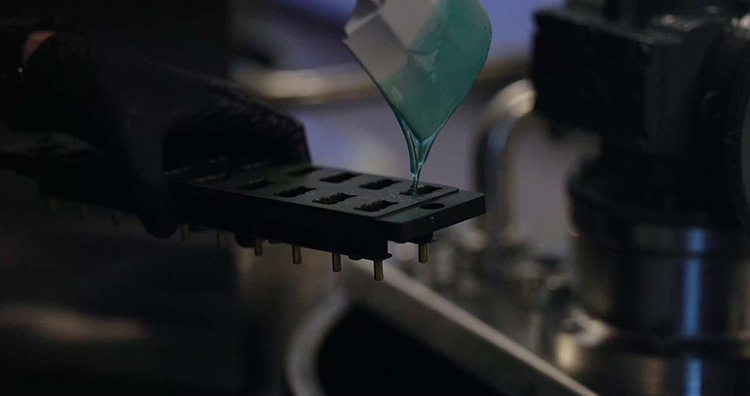

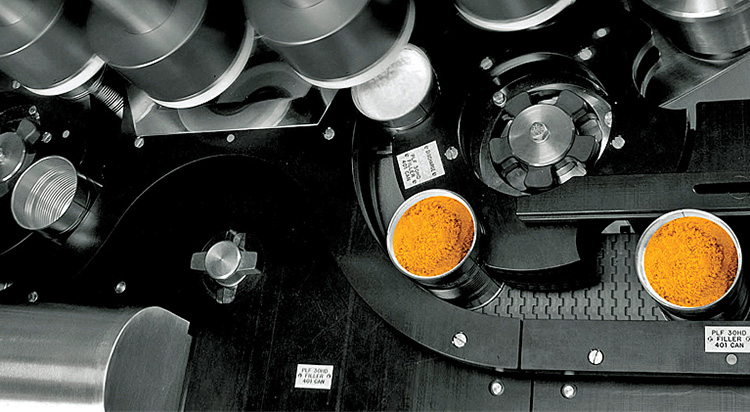

Auger Detergent Packaging Machine- Picture Courtesy: Shanghai Dahe Packaging

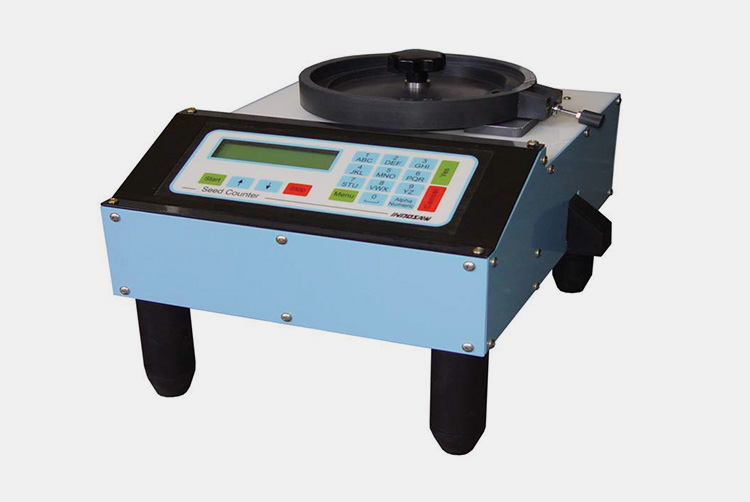

An auger detergent packaging machine utilizes methodology of auger for filling or packaging task which assists you in the dispensing of an accurate concentration of powder into the material.

This machine is available in various designs and automation to bring detergent packaging job perfectly.

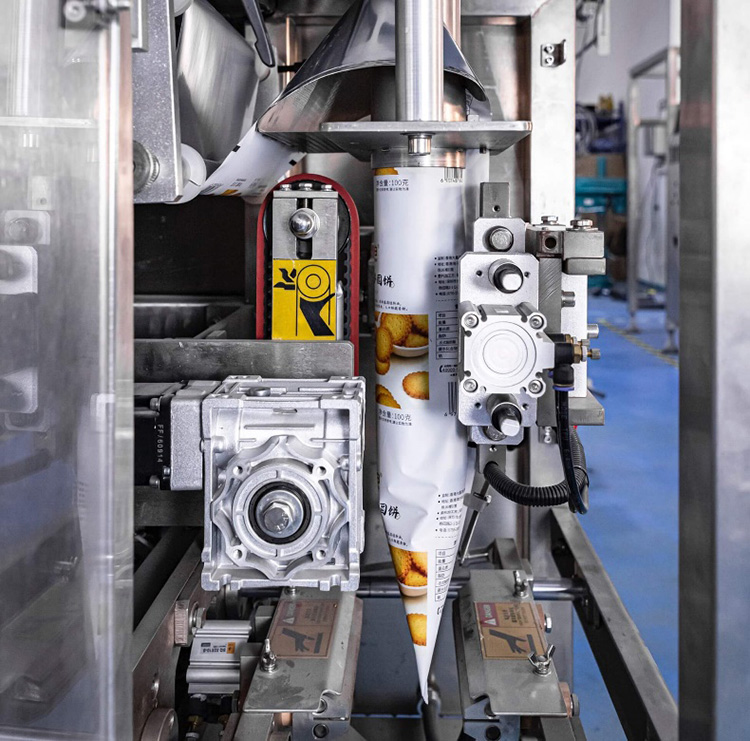

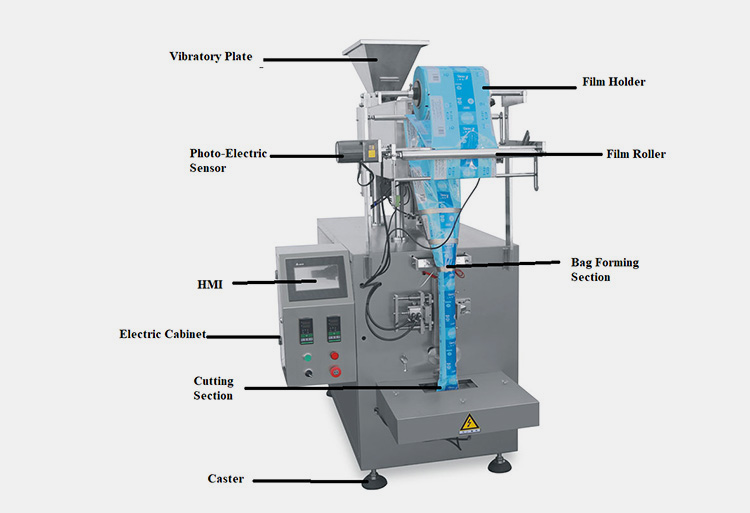

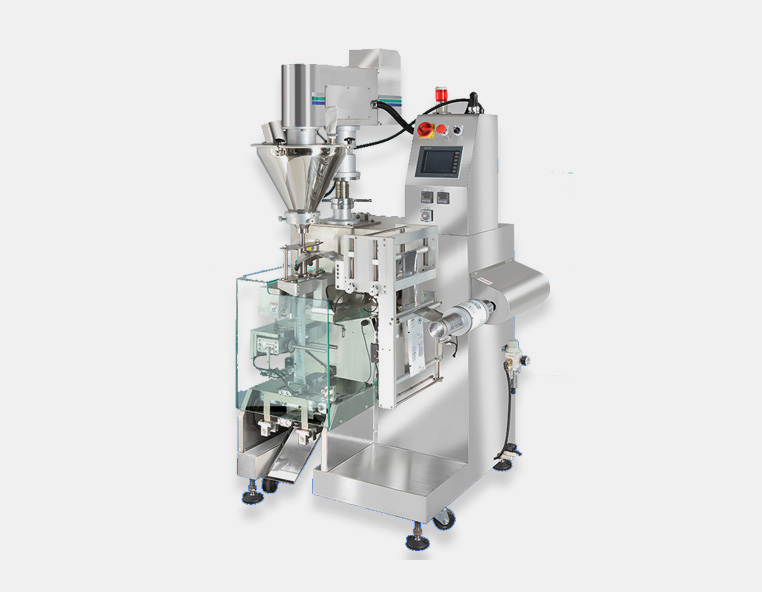

VFFS Detergent Packaging Machine

VFFS Detergent Packaging Machine

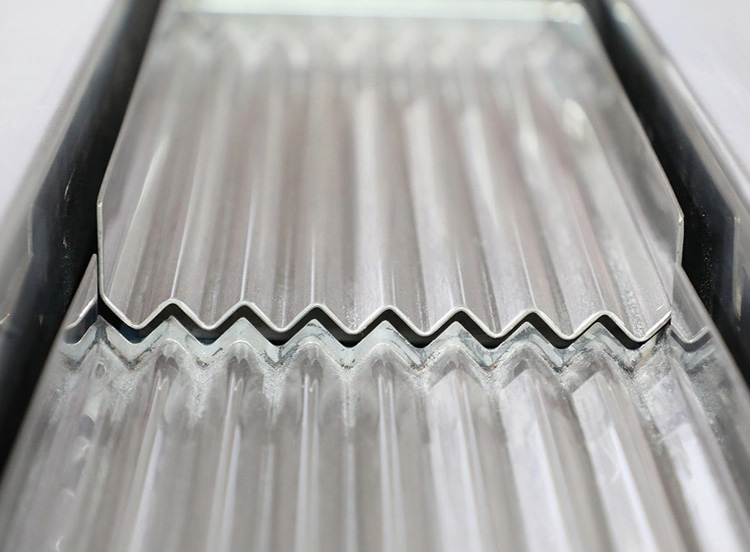

This is the commonly used machine for detergent packaging that basically works based on the creation bag or pouch followed by filling as well as sealing of the pack. The final process of detergent packaging in VFFS machine is accompanied by the cutting of each prepared pack.

The entire work process in VFFS machine is taken place in a vertical fashion. For example, submission adjustment, and expansion of film roll and its bag formation with a help of forming tube. Once it is sealed around 3 corners the filling of detergent is done and the joining of packet is achieved by using hot sealers and a sharp cutter for separation.

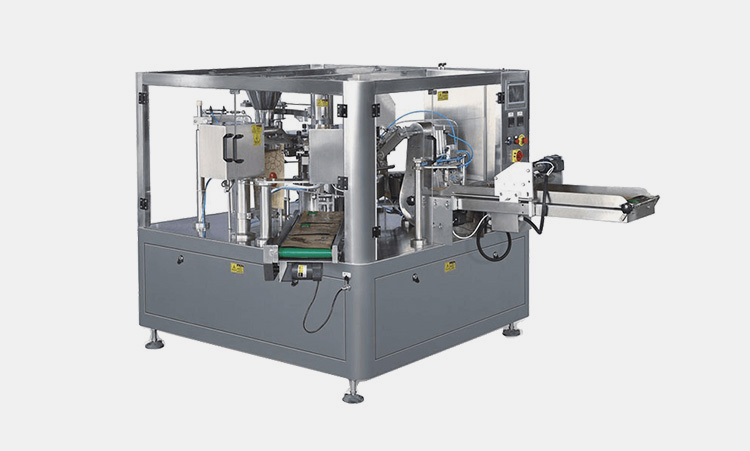

Premade Pouches Detergent Packaging Machine

Premade Pouches Detergent Packaging Machine

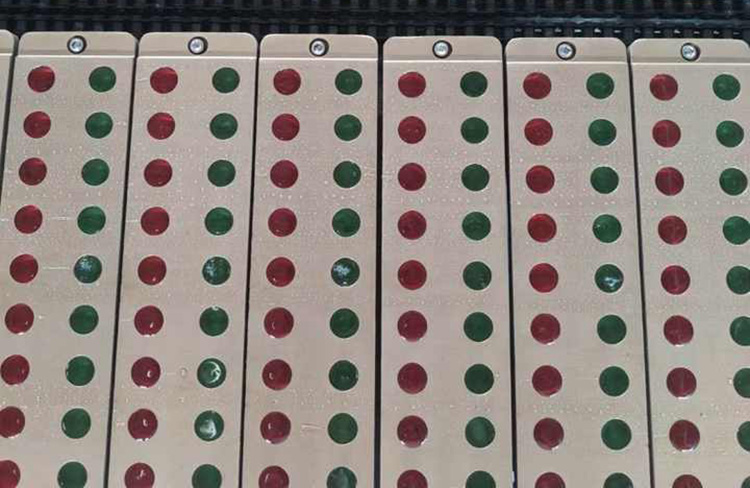

This is the fastest way of detergent packaging where already formed pouches are kept in a magazine of the machine. The gripers of the unit pick the bag one by one. The inflators are used to open the bag by high blowing system. Once the bags are opens, they are subjected toward the filling nozzle of the machine.

The machine load detergent into the bag; upon filling the machine detects and discharge the pack toward the next station.

Sachet Detergent Packaging Machine

Sachet Detergent Packaging Machine

The sachet detergent packaging machine is used when it is required to make an individual and small packets of the detergent. This machine works by including a linear series which including formation of small sachet from a flat film.

The formation of sachet takes place by unwinding of the film roll followed by respective sealing, once the sachets are created their corners are joined by sealers. The predetermined concentration of substance is entered inside the pack. This can be done mostly auger (powders) or volumetric fillers (liquid).

The sharp knives of the machines make a porous punch to separate the sachets wherever you required.

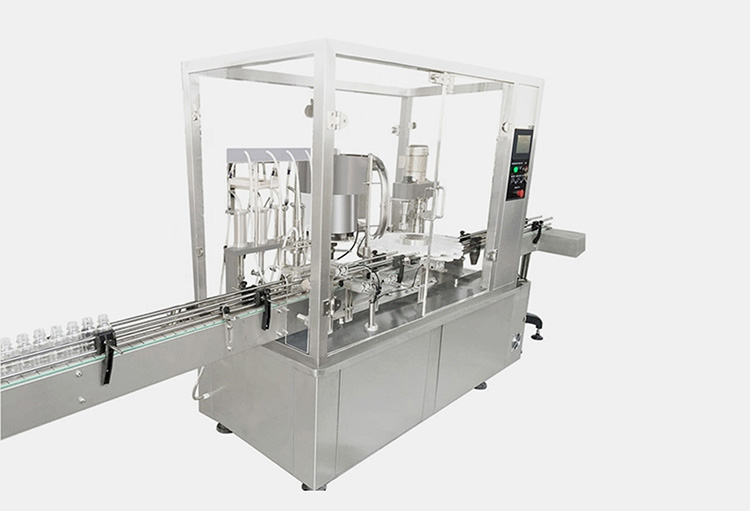

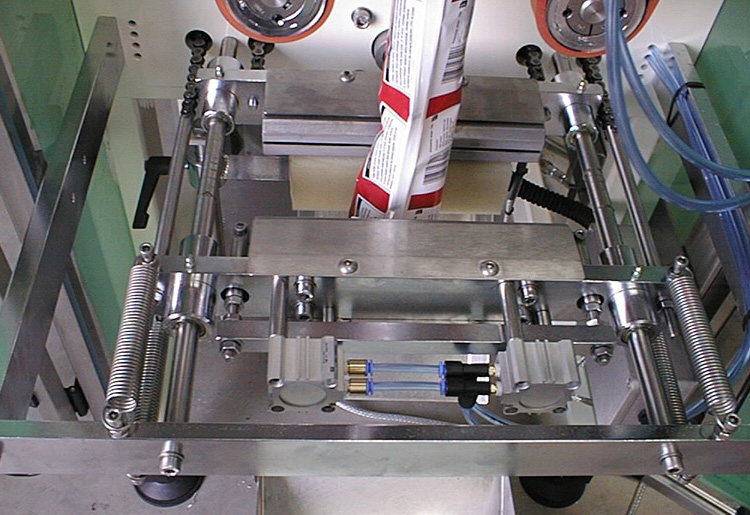

Bucket/Bottle/Jar Detergent Packaging Machine

Bucket/Bottle/Jar Detergent Packaging Machine

This machine is mostly used in large industries where conventional preparation method is used for detergent packaging. Todays, jars or bucket packaging machine are employed when there is dispensing of high capacity of detergent is required.

The machine is working smoothly by integration of unscrambler which allow smooth flow of corrected position bottles or jars toward the machine for filling; once the detergent is filled the machine transports the number of containers toward the next station such as capping machine to secure the content.

Granule Detergent Packaging Machine

Granule Detergent Packaging Machine

The granule detergent packaging machine allows volumetric filling of detergent that is present in granular or powdery texture. The machine is able to form a bag and offers you excellent operability without any chances of error or dust formation. This machine is ideal for small or compact installation spaces with a highly economical budget ensuring precise and accurate packaging.

According to the Filling Type

Auger Detergent Packaging Machine

Auger Detergent Packaging Machine

Firstly, you should understand the term auger which generates a narrow and helical screw function to improve the right flow of detergent toward packaging material. There are various sizes of auger available in the packaging market that you can select depending upon the type of your production line. This machine works by circulation or rotation of the auger to induce smooth filling of the detergent with controlled and accurate packaging.

Pneumatic Vacuum Detergent Packaging Machine

Pneumatic Vacuum Detergent Packaging Machine

This is another modern and commonly used type of detergent packaging machine that utilizes vacuum technology to remove the presence of air particles inside the packaging material. side by side, your product fills and seals offering an airtight sealing. This packaging is very important and offers you promising outcomes by retaining the shelf life, quality, and efficiency of the detergents.

Net Weigh Detergent Packaging Machine

Net Weigh Detergent Packaging Machine

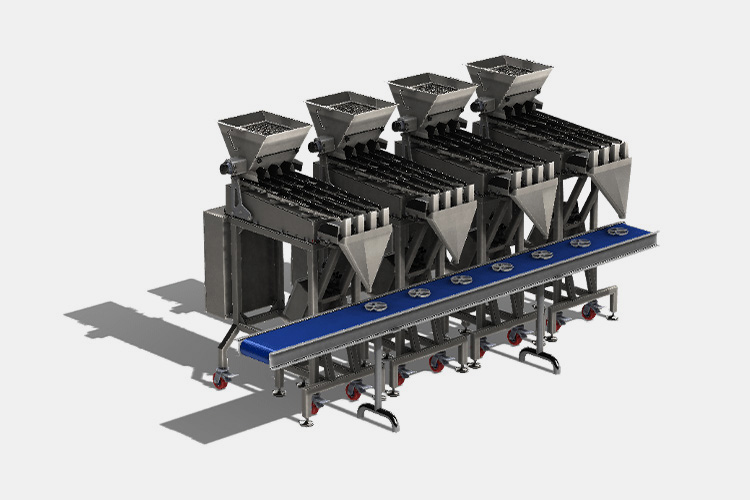

This machine works at a fast pace by measuring the net weight of the detergent. Once the required weight of the detergent is achieved it will help you notify and ensure you precise and correct packaging with high accuracy. This machine is mostly used on a larger industrial scale where a bulk quantity of detergent packaging is dealt with.

According to Filling Heads

Single Head Detergent Packaging Machine

Single Head Detergent Packaging Machine

This machine is composed of a single head for detergent packaging that is presented in semi-automatic as well as automatic features. This is an ideal solution to deal with small to moderate production batches because a single head is responsible for dispensing of item.

Dual Head Detergent Packaging

Dual Head Detergent Packaging- Picture Courtesy: inpak

Comparatively, a dual head detergent packaging machine is the more efficient and fast answer to fill and pack detergent packaging material as it can carry the task by handling subjects with double filling heads. The machine can run two packaging containers or pouches simultaneously.

4.Why Detergent Packaging Should be Done in Plastic?

Plastic Detergent Packaging

To answer this question, you need to understand the basic concept of detergent makeup. It is composed of a surfactant that carries a strong bleaching property to react with clothes, floors, or anything else.

If the detergent packaging material is weak then it can react and form a reaction and ultimately lowers the potency and efficiency of detergent.

We don’t want this! That’s why you must prefer plastic detergent packaging over any other form to keep your material safe and anti-leakage.

There are various arguments behind this problem; but simply, a strong and heavy-duty plastic such as high density polyethylene (HDPE) offers you hard and inert barrier properties that seldom can react with detergent, therefore zero chances of their interaction and keep detergent fresh as well as with preserved their fragrance for longer.

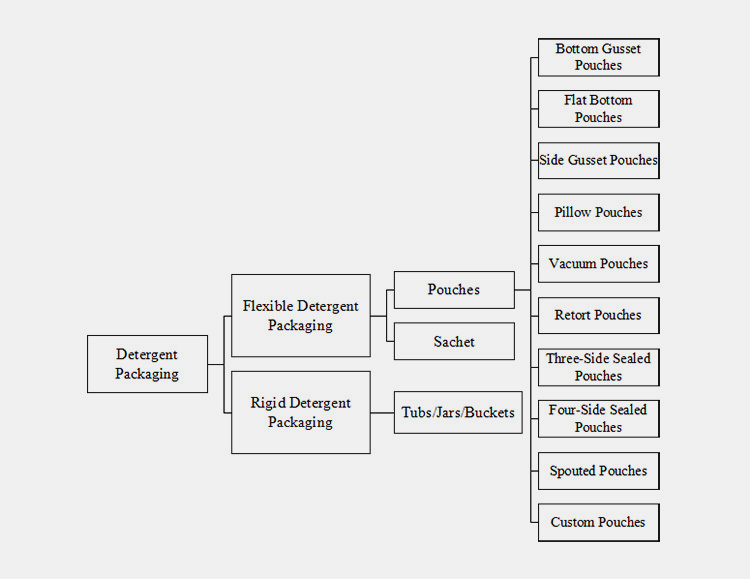

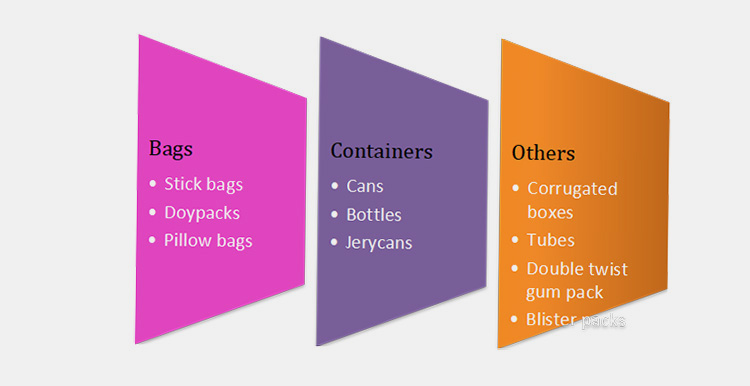

5.What are the Available Packaging Formats of Detergent Packaging?

Detergent Packaging- Picture Courtesy: I wash u wash

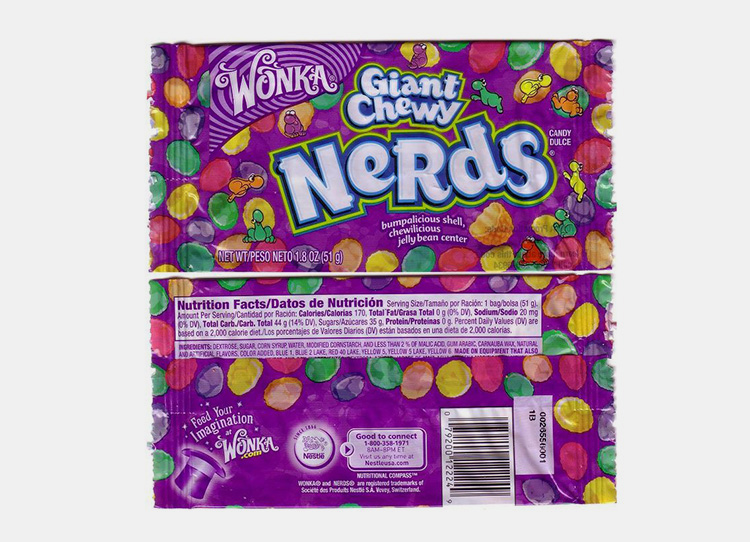

The detergent packaging can come in flexible packaging and rigid packaging.

An informative illustration about types of detergent packaging

Flexible Detergent Packaging

A flexible detergent packaging

The new attraction with high popularity; flexible detergent packaging offers you several benefits as they’re easily customizable way with lightweight features with ample applications.

Bottom Gusset Pouches Detergent Packaging

Bottom Gusset Pouches Detergent Packaging

This is the most common and preferable form of detergent packaging which is ideal for detergent as it can be placed and stands on its own on respective shelves offering an attractive presentation.

Flat Bottom Pouches Detergent Packaging

Flat Bottom Pouches Detergent Packaging

You can call it box pouches where the under or bottom surface of the pouch is completely flat offering an easy standing. You can put more weight in these style pouches as compared to gusseted pouches as it has side as well as bottom gusseted edges.

Side Gusset Pouches Detergent Packaging

Side Gusset Pouches Detergent Packaging

This type of flexible detergent packaging has two sides gussets that offer you high space for storage of detergent. The upper and lower parts of the pouches are sealed horizontally with an opened top for placement and dispensing of the material.

Pillow Pouches Detergent Packaging

Pillow Pouches Detergent Packaging

As it name shows it has a signature pillow shape for detergent packaging. It has central back sealing with top to bottom. This is an economical detergent packaging type used commonly for small number of detergents.

Vacuum Pouches Detergent Packaging

Vacuum Pouches Detergent Packaging

This is a highly moisture-resistant form of detergent packaging which is formed with various plastic layers to resist external factors to affect the detergent. Before final seal, the pouches are subjected to a vacuum to eliminate air in order to keep the product fresh and effective.

Retort Pouches Detergent Packaging

Retort Pouches Detergent Packaging- Picture Courtesy: ouma

The pouches are made up of a multi-layer combination of plastic with aluminum foil and are commonly used for detergent packaging. This packaging offering you to store the detergent with extended shelf life and temperature resistant.

Three-Side Sealed Pouches Detergent Packaging

Three-Side Sealed Pouches Detergent Packaging

This is accompanied by one central continuous sealing with two folds leaving an upper opened edge for filling and sealing in the last. This is an economical pouch with high volume storing as compared to four-side sealing pouches.

Four-Side Sealed Pouches Detergent Packaging

Four-Side Sealed Pouches Detergent Packaging

This sealing is featured with two sides identical layers with top and bottom equal with overall 4 side sealing with zero gussets. These are also known as flat pouches with high vacuum and strength for stored detergent.

Spouted Pouches Detergent Packaging

Spouted Pouches Detergent Packaging

These are beautiful pouches where one end of the sealing is featured with a re-closable cap which allows you to re-use the packet again and again. These are easy to transport and incredibly easy to use.

Rigid Detergent Packaging

Rigid Detergent Packaging

This is a conventional way used in ancient days till now for detergent packaging. This packaging material that are tough and hard in nature with difficult in moving or customization once it forms.

6.Is Powder Detergent Packaging Use Same Equipment as Liquid Detergent Packaging?

Yes, if you see above mentioned categories of machines, they’re suitable for various states of detergent packaging. For example, liquid as well as solid, granular, or powdery.

The technical point in this case is that you will need to inform your manufacturer what type of detergent packaging you need to dispense.

There are various filler types that are best suited to texture and type of detergent. Such as:

For Powder Detergent Packaging- Auger Filler

Auger Filler

The auger filler is the best fit for to pack powder texture of the detergent. The type of device is featured in the detergent packaging machine which is suitable for filling of dry content.

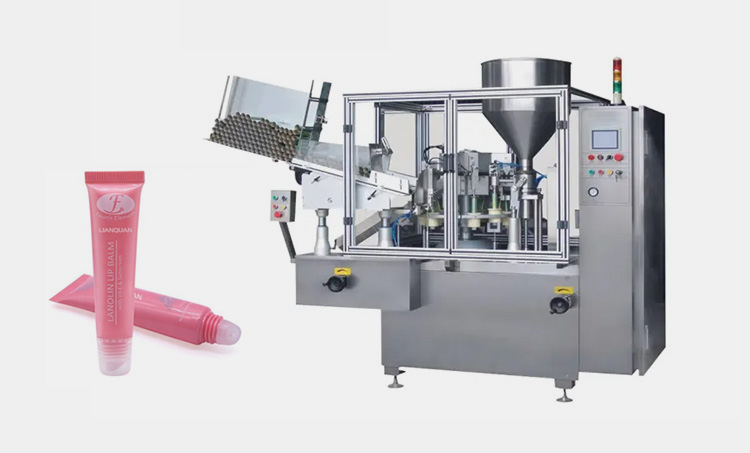

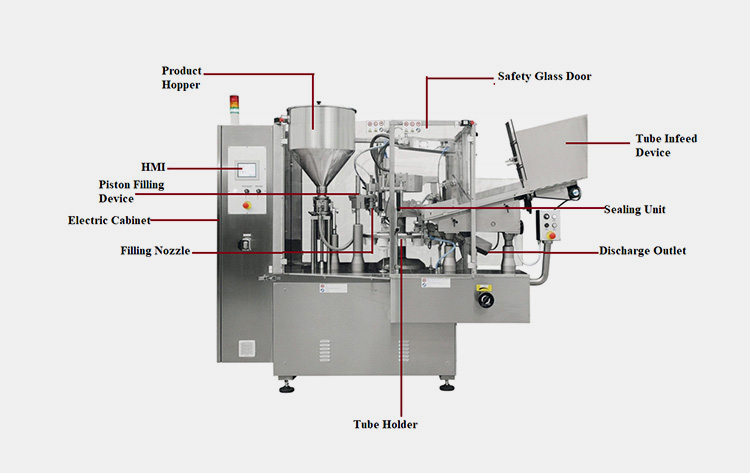

For Liquid Detergent Packaging- Piston Filler

Piston Filler

The machine is useful in the filling and packaging of detergent by considering the determined volume of the content using a piston to drop a fine layer of liquid detergent in a safe and accurate manner.

This machine is suitable for light, mild, or highly viscous solutions as well as oil, water, and other products with promising results.

7.What are the Effects of Detergent Packaging on Potency & Shelf life?

The shelf life of the detergent is based on the correct and stable packaging. This is true that detergents are cleaning agents containing strong or mild bleaching agents, surfactants, alkali and neutralized salts, and other elements but the combination of the mentioned substances can affect its potency and efficiency once stored perfectly.

If detergent packaging is effectively created and maintained at the correct temperature, then it will help to maximize the shelf life of the product. Such as keeping it dry and at room temperature with no humidity to retain its enzymatic activity.

An unopened detergent packaging will sustain the shelf life of the product till eight to nine months; soon after that your product won’t expire but it will start losing the efficacy to eliminate and fight against stains and dirt. Also, you can feel the mildness or loss in its fragrance, caky texture as well and difficult dissolution.

8.What are Detergent Packaging Leakage Tests?

Leakage of detergent packaging is the worst nightmare of every manufacturer who wants to sell their products with high market value and reviews. But this could be a great problem for you if you can find the exact leakage portion before it reaches the end user.

To control such problems, there are various assessments available in the market that help you in testing the detergent packaging and presenting a promising outcome.

Does that sound like a good idea?

The number of tests are discussed below:

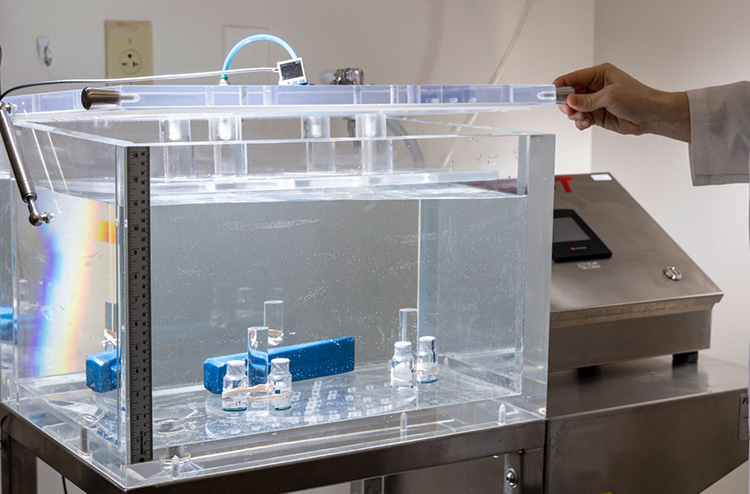

Underwater Leak Testing

Underwater Leak Testing- Picture Courtesy: Packaging Compliance Labs

In this testing, detergent packaging is submerged into an enclosed and transparent tank which is filled with water, and the procedure is controlled by putting a vacuum. If there is any minute leakage present, it will subsequently produce bubbles from that area to alert you about the presence of leakage.

This method is very precise and accurate to let you know about the number of leaks and their locations.

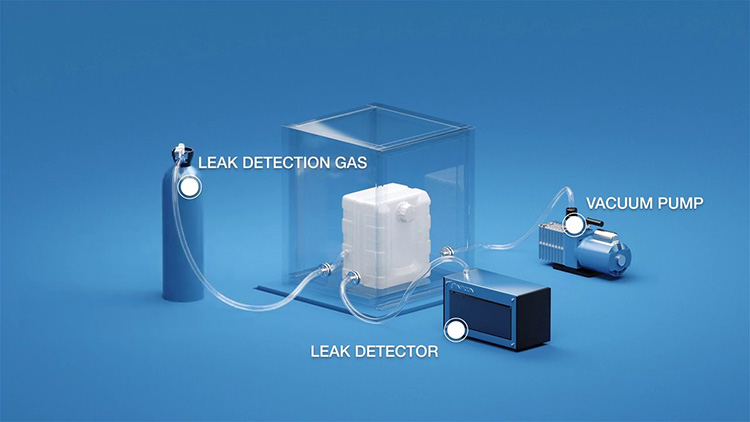

Pressure Decay Testing

Pressure decay testing

This testing takes place in an identified chamber where you need to put the packaging under a controlled vacuum. The tester is helpful in assessing the level of vacuum, if more time taken to reach the value of vacuum, then it will help you in determining the presence of leakage even fine-sized leaks which demonstrated by the quick pressure decay towards atmospheric pressure; even after the vacuum stabilization is off.

Optical Laser-Based detection system

Optical Laser-Based detection system

This is a modern and very accurate leakage testing technique that allows you to determine the leakage by MAP-based unit to achieve 99.99% accurate results.

The test using CO2 as a testing gas where a laser beam with a narrow wavelength in an IR or infrared beam can help you in measuring the absorption of wavelength by c02 gas. If CO2 gas gives a signal on display the leakage is presented in a detergent packaging.

9.What Are the Major Problems And Solution While Detergent Packaging?

There are arrays of challenges that exist in the packaging industry production that require complex research and serious intervention when addressing detergent packaging. This is because it protects your valued product against wastage and keeps you economically safe. Please have a look below mentioned detergent packaging problems with their solutions:

Problem: Formation of Dust During Detergent Packaging

Solution

If your detergent is granular and powdery in texture we bet you, this problem can bother you anytime. Dust formation during the filling of detergent can not only waste your product but can damage the user physically as well as affect the healthy ecosystem.

Dust resistance enclosures: Picture Courtesy:Spack

To prevent this problem, currently advanced machines are designed with anti-dust or dustproof features that make the dispensing task safe. By addition of glidants such as talc, magnesium stearate, and silicon dioxide (colloidal/fumed silica), can improve the flowability of detergent with lower chances of dust formation.

Problem: Wrong Film Sealing

Solution

Calibration of sealers can control leakage of detergent packaging- Picture Courtesy: Spack

During the formation or creation of a bag, pouch, or sachet, sometimes you may observe the wrong sealing at the edges of the bag which affects the proper integrity of the detergent packaging.

This problem can occur due to ultra-high temperatures of the sealing jaws or due to the wrong placement of the sealer instead of the desirable position.

To solve this problem, we would recommend correcting or resetting the temperature and calibrating the machine to achieve ideal sealing at the right position.

Problem: Leakage of Detergent Packaging

Solution

Select the right packaging material can improve packaging needs- Picture Courtesy: Design Stuff

This problem can arise due to various factors including wrong selection of packaging materials, improper packaging machines, trouble in detecting or sensing the filling of materials, wrong formation of the bag, problems with heat sealers, temperatures., and others.

To solve it is recommended to scrutinize prior to selecting the packaging material such as flexible or rigid packaging concerning transportation.

Moreover, by calibration, you can correct temperature, sealing, detection, PLC, or system refreshing issues hence the root cause can be reduced.

Problem: Over and Under Filling of Detergent Packaging

Solution

Regular maintenance of detergent packaging machine can offer promising outcomes

If your machine works regularly non-stop; the following problem is likely to result in over or under-filling of detergent packaging.

To solve this problem, we would recommend regularly checking and cleaning the machine to determine unwanted factors such as dust, breakage, loss, and problems in feed data. Check the quality and assess the points to avoid minor issues.

10.Powder VS Liquid- Which Detergent Packaging is Suitable for You?

Detergent Packaging- Picture Courtesy:Klien Brand

Whether powder or liquid detergent packaging, both states have their own important, aesthetic and market value. But if you’re new and confused to decide then please check the mentioned below points.

According to our expertise, powder detergent or solid detergent packaging is easy to form, fill, and dispense across the globe with more space and lighter in weight. Similarly, in terms of equipment, you will find easy and economical detergent packaging machines that work in a simple way.

Also, powdery detergent packaging is seldom prone to leak and if leakage occurs it won’t affect your budget as compared to liquid.

On the other side, liquid detergent packaging requires more attention if it needs to be dispensed in a bulk quantity and may affect the budget in terms of leakage.

Moreover, machines for liquids in the market works are like solid so it is easy to acquire but you need to be more careful during production procedures to avoid product waste.

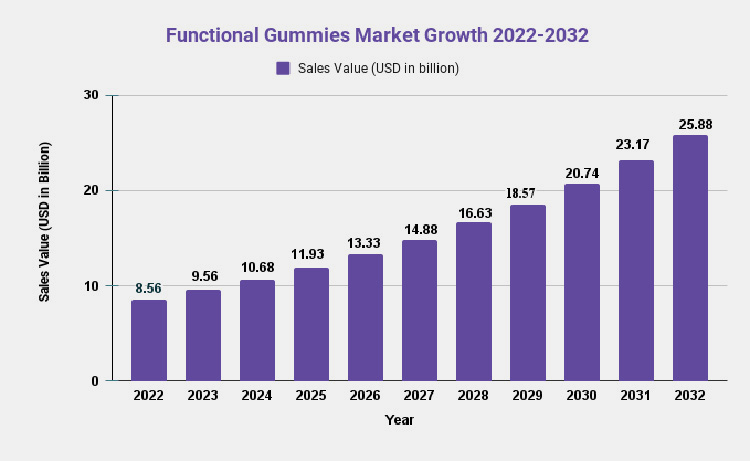

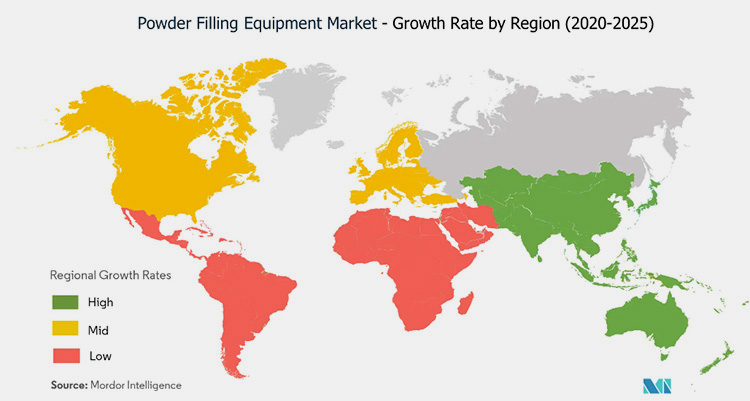

11.What is the Future Scope for Detergent Packaging?

Future prospect for Detergent Packaging – Picture Courtesy:American Home Shield

The detergent packaging is showing a significant market value in today’s world. This rise in popularity can directly improve its high demand in the packaging industry. That is why it is expected to raise its global market which was 420 billion USD in 2022 and expected to up approx. 759.3 billion USD in 2032.

The future scope of detergent packaging is increasing with high implementation in its packaging by introducing new methodologies such as small or unit detergent packaging, pods, and single-dose detergents, also with smaller prices and more dynamic innovations.

Conclusion

The detergent packaging plays a vital role in the dispensing, distribution, preserving efficacy, fragrance, and quality of detergent across the globe. As a manufacturer, you must know the right packaging types, and machines to present your product intact and stable to your customers. When it comes to purchasing the right detergent packaging machine, Allpack is the name that offers promising detergent packaging solutions. Whether you are confused about selecting packaging Types or Packaging Machines, we are here to help! Please contact us now to explore various amazing detergent packaging machines according to your budget.

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide

Detergent Packaging: The Complete FAQ Guide In 2025 Read More »