Pharmacy Pill Counter Machine: The Complete Buying Guide In 2025

Pharmacy Pill Counter Machine: The Complete Buying Guide In 2025

Pharmacy is the area continuously engaged in discovering new drugs, their production, and safe packaging. In this long run, the most critical part is indeed precise packaging of drugs where accurate counting is the key. Here, most of the manufacturers do struggle with manual counting, which lead them to false results.

However, the pharmacy pill counter machine has resolved this issue. Now, you can employ the type of pharmacy pill counter machine which suits you the most. But how will you do so? It's easy! You simply need to read this buying guide thoroughly which will undoubtedly unveil the distinctive aspects of a pharmacy pill counter machine. So, let's get started!

1.What Is A Pharmacy Pill Counter Machine?

Allpack APC-8 Automatic Tablet Counting Machine

A pharmacy pill counter machine is the equipment tailored with cutting-edge technology and different features to cope up with the growing demand of pills by aiding its counting. The machine does so by observing the pills' counting through sensors and vibratory channel.

As the processing of tablets and capsules require high safety and prescription alertness, the machine provide full scale protection against corrosion, bacteria, and dirt due to its body. Hence, no matter the type, shape, or size of your pills a pharmacy pill counter machine is the right tool to be used for.

2.Why Pharmacy Pill Counter Machine Is Inevitable In Pharmaceutical Industry?

Pharmaceutical industry- Picture Courtesy: ey.com

Pharmacy pill counter machine is the most crucial equipment utilized in pharmaceutical industry for counting purpose. Its role in the sector is commendable due to its quality material which entirely protect the sterility and susceptibility of pills and tablets.

In this way, international concerns of FDA, ISO, and GMP regarding drugs' safety is one of the major reasons why the use of pharmacy pill counter machine is prioritized in this field. Moreover, the abundant production of tablets, pills, and capsules demand precise and efficient counting for which only pharmacy pill counter machine can be used.

3.Explain The Features Of A Pharmacy Pill Counter Machine?

Pharmacy pill counter machine is designed in such a way that each of its aspect will provide you substantial benefits. Some of these advantages are explained below:

Error-Proof

Pharmacy pill counter machine detecting damaged capsule- Picture Courtesy: cremer.com

No doubt, the most crucial characteristic for which a pharmacy pill counter machine is well-known is its precision level. The machine has fitted system of detection which greatly helps in the accurate counting of pills. Along with that, in case of inconsistencies, the alarm will alert you to eliminate the fault.

High Protection

Tablets counting undergoing under transparent window- Picture Courtesy: cremer.com

The machine is highly protected against environmental elements due to its enclosed body which provide you the room to administer the entire processing without touching it. Not only that, but it also have safety features to keep the operation smooth.

Efficient

We are familiar with the fact that manual counting of pills is a tiresome and time-consuming task, but here it is done within minutes. This surprising counting results of a pharmacy pill counter machine will amaze you and help you in exceeding your output ratio.

Flexible

Different types of capsules and tablets- Picture Courtesy: medicspharmacy.com

Most of us want to have multiple benefits being taken by the single source. This theory can be simply applied here where you can count different kinds of tablets pills, candies, and gummies etc., by using this machine.

Easy-to-use

Easy-to-use icon- Picture Courtesy: freepik.com

Pharmacy pill counter machine is extremely easy-to-use with a touch screen control panel through which you simply put in the necessary data. Even in some cases, you just need to switch the setting because the machine can save multiple settings in it.

4.What Sizes And Shapes Of Pills Can Be Counted By A Pharmacy Pill Counter Machine?

Pills of different sizes and shapes- Picture Courtesy: sunlightrecovery.com

Pills come in so many sizes and shapes due to varying reasons encompassing the convenience of swallowing to the quantity of each dosage and patients' demography like children, adults, and pets etc. Similarly, by keeping these factors tablets and capsules are made in different shapes and sizes.

These include the common sizes of tablets pills which start from 1mm to 22mm and capsules sizes from 14mm to 23mm. Apart from this the standard size of tablet pills is 5mm in diameter, 0 size for hardgel capsules and 00 size for softgels.

When it comes to discuss the shapes of pills, so, multiple shapes including circular, oval, square, triangle, pentagon, heart, diamond, and many others are available. Hence, all of these sizes and shapes of pills can be easily counted by a pill counter machine.

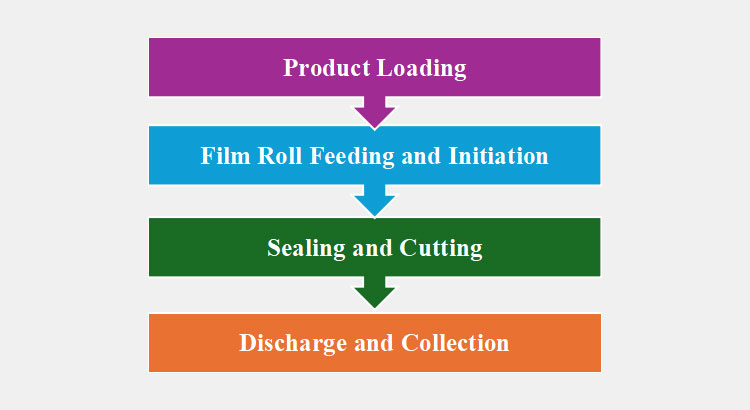

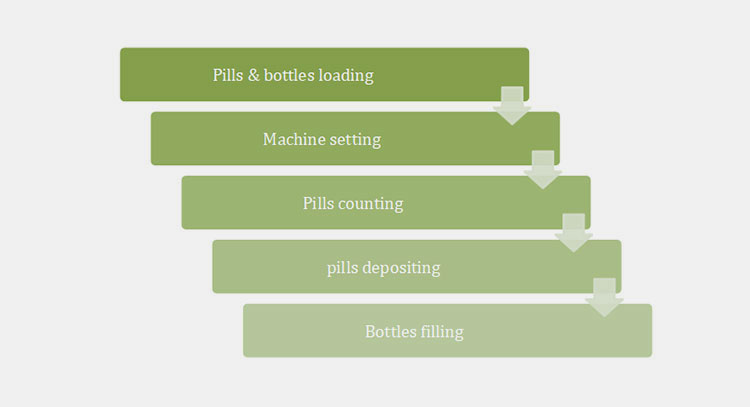

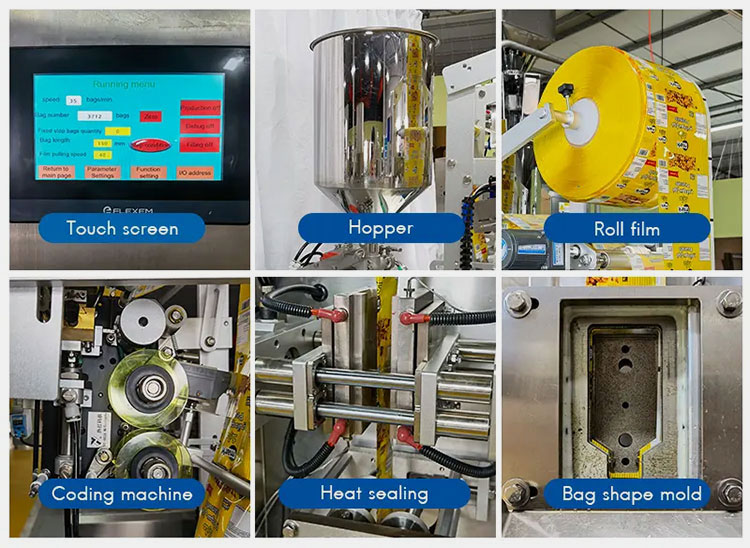

5.How Does A Pharmacy Pill Counter Machine Work?

The working process of a pharmacy pill counter machine entirely depends upon its type, automation, as well as structure. Therefore, in order to operate the machine on a right track you need to understand the relevant procedure. Similarly, in this question we will be going to show you the working principles of an automatic pharmacy pill counter machine. Just explore these!

Pills & Bottles Loading

When you intend to operate your pharmacy pill counter machine you need to pour the bulk volume of pills into the machine's hopper which will be then processed by the machine. At the same time, you need to load the required number of bottles onto the conveyor or on a bottle unscrambler attached with the machine.

Machine Setting

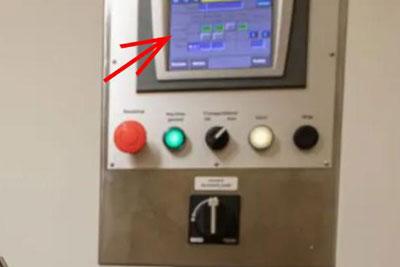

Operator adjusting parameters in control panel- Picture Courtesy: cremer.com

Once loading Phase has been carried out the next step will be to set the machine's parameters. For this, a pharmacy pill counter machine has a touch screen display on its front which once powered on will show you multiple options regarding pills processing. With the help of control panel, you will fix the number of pills to be counted and adjust the speed of conveyor. Now, just push the power button on to initiate the process.

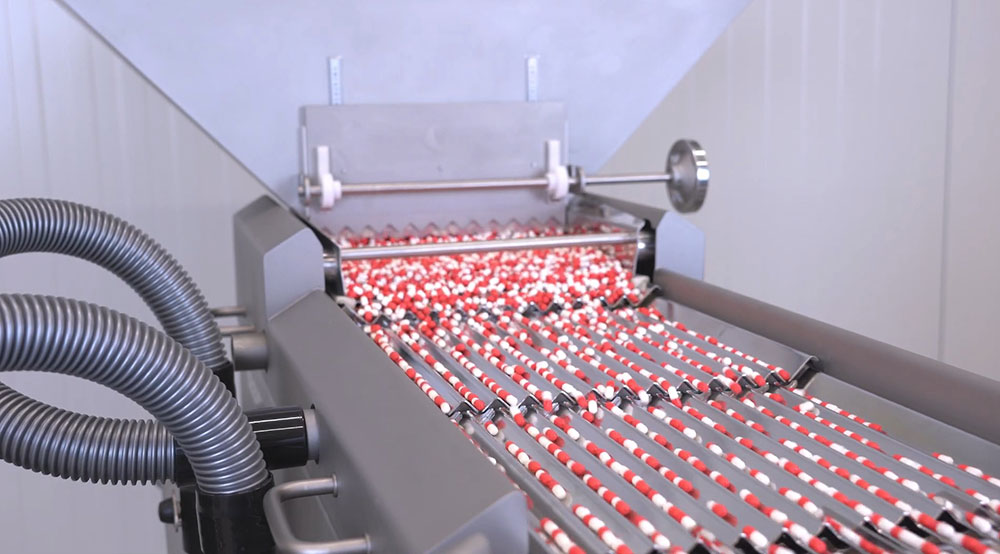

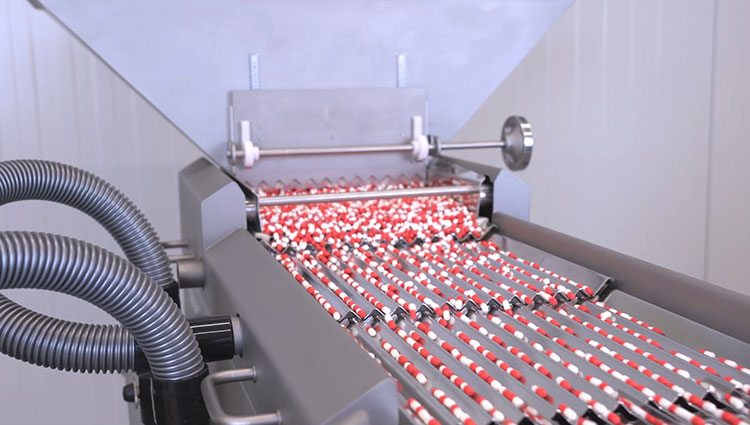

Pills Counting

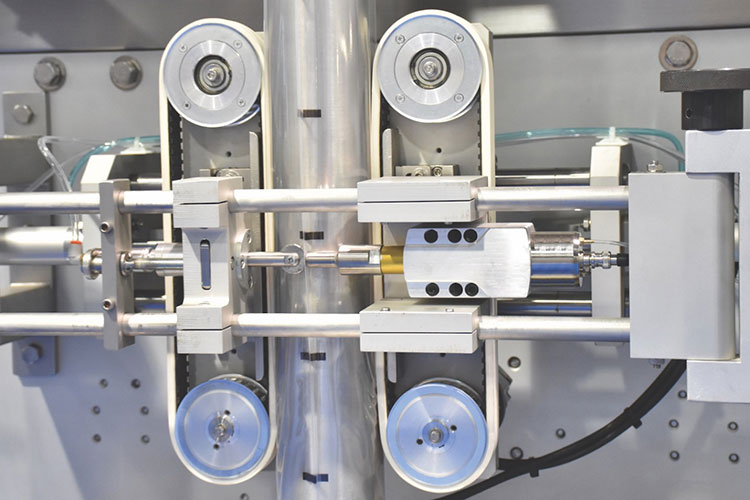

Capsules counting on vibratory channel- Picture Courtesy: cremer.com

In this step, DC motor will energize the vibratory trays and pills will start dropping from hopper onto vibratory trays. The continuous motion of trays will align the pills in relevant columns and their tilted position will make the pills move forward. Hence, the pills will be counted through automatic detection system and moved ahead.

Pills Depositing

Capsules depositing in compartments- Picture Courtesy: cremer.com

At this stage, each collection of counted pills will be deposited into separate sections. These pills remain there until dropped from the machine.

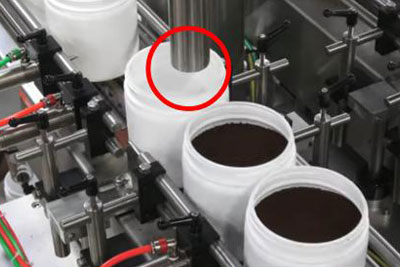

Bottles Filling

Capsules filling into bottles- Picture Courtesy: cremer.com

Finally, when the sensor detect the presence of bottles under the filling heads, the message will be transmitted to machine's control system after which each collection of counted tablets will be dropped out of the compartment and filled into bottle. The process will be continued for other bottles.

Discharging

Bottles' discharging- Picture Courtesy: cremer.com

At last, when all the bottles are get filled with pills their discharging from machine takes place for further packaging.

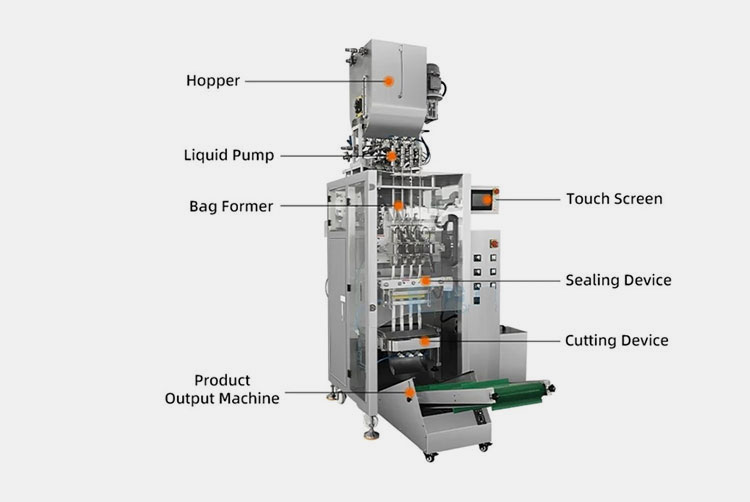

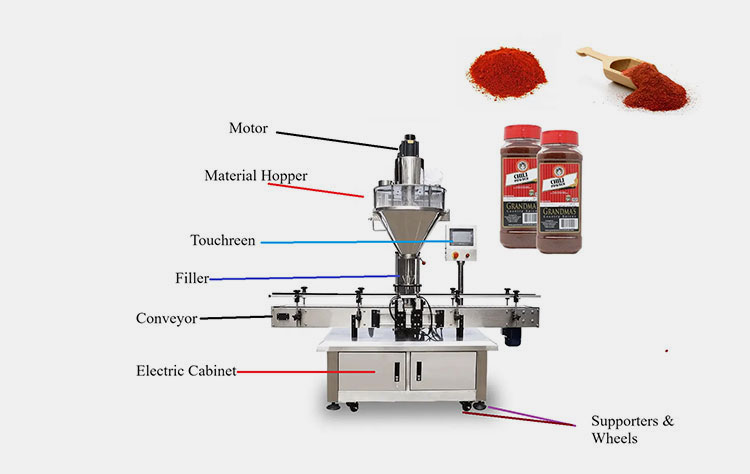

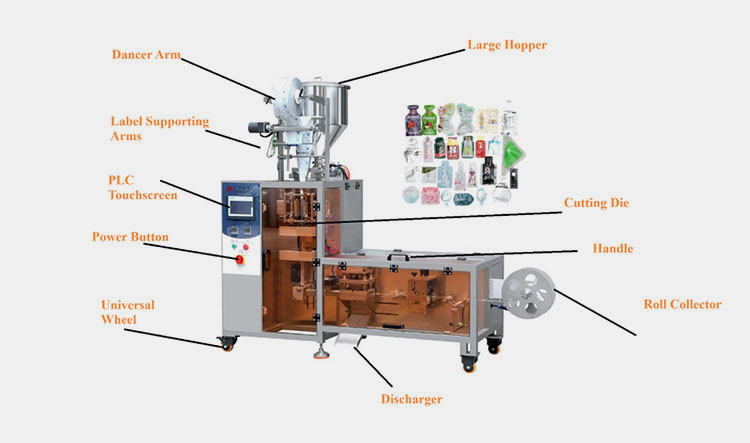

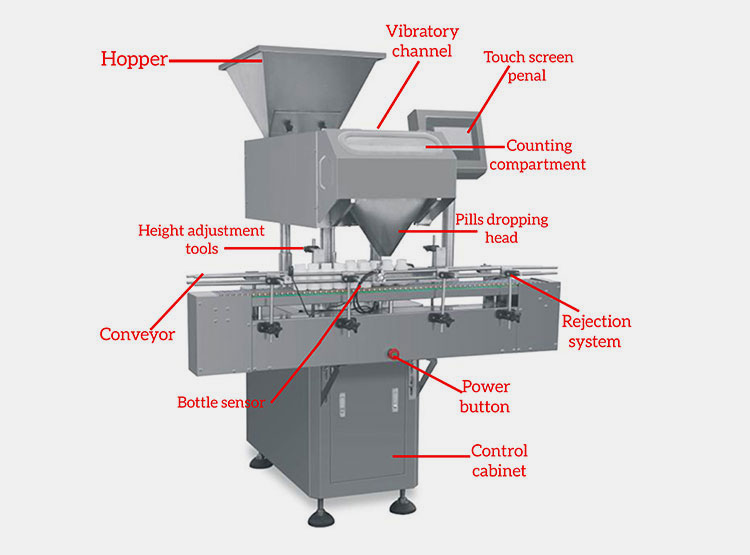

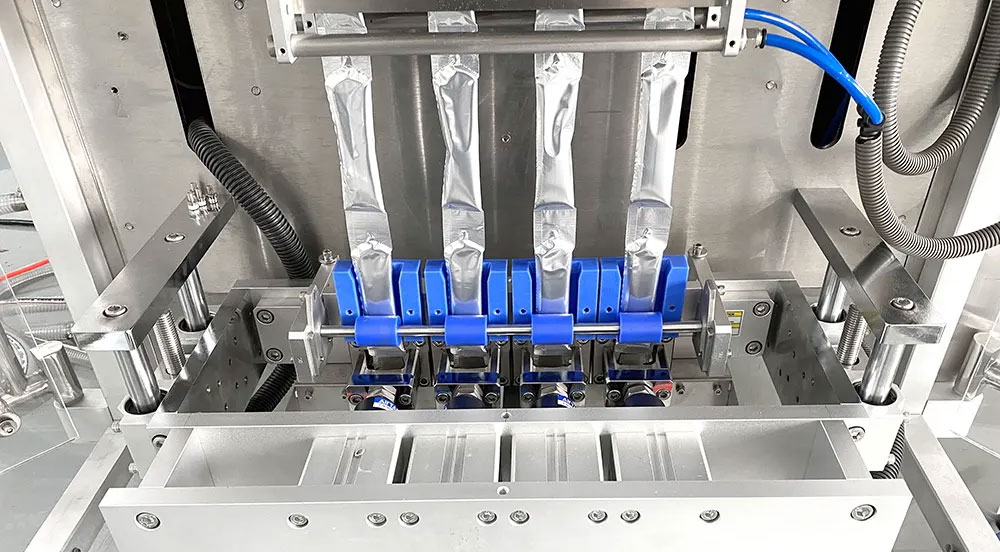

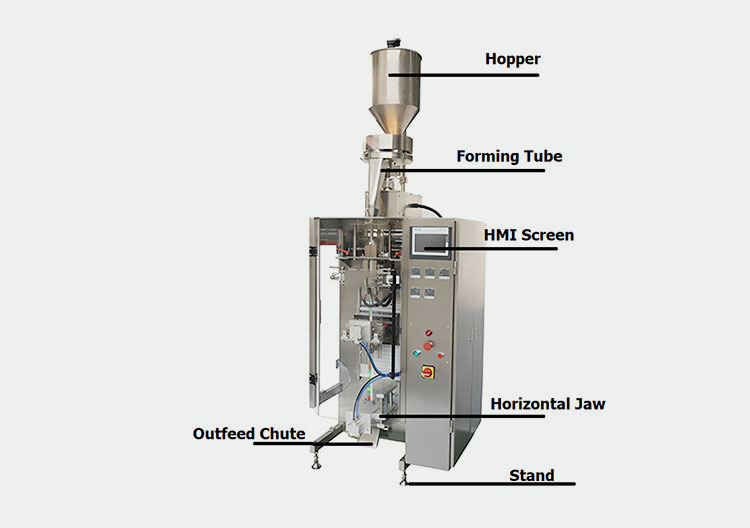

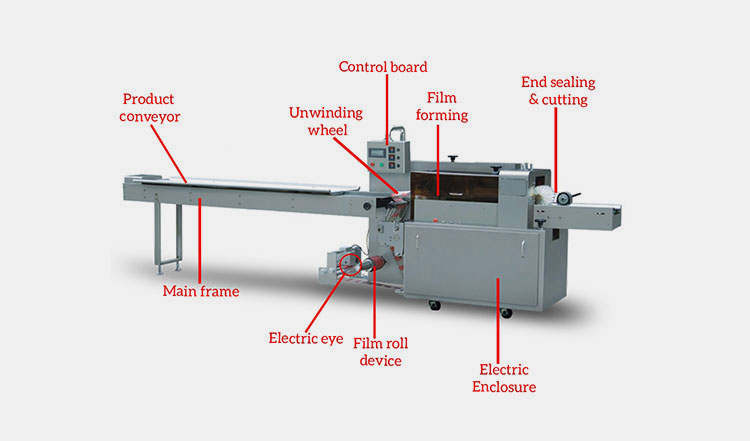

6.Describe The Components Of A Pharmacy Pill Counter Machine?

A pharmacy pill counter machine is composed of following components:

Components of Allpack's APC-12 Automatic Tablet Counting Machine

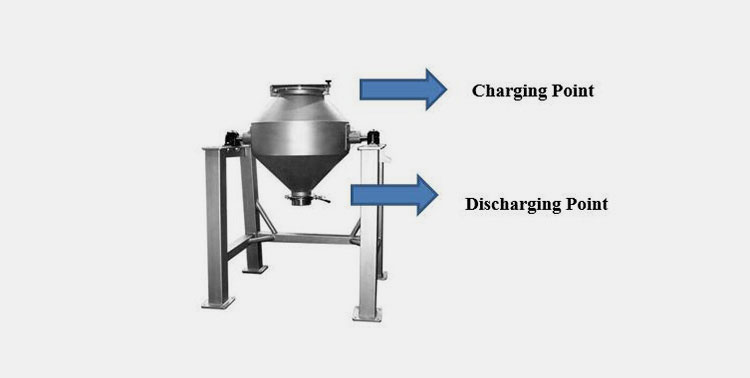

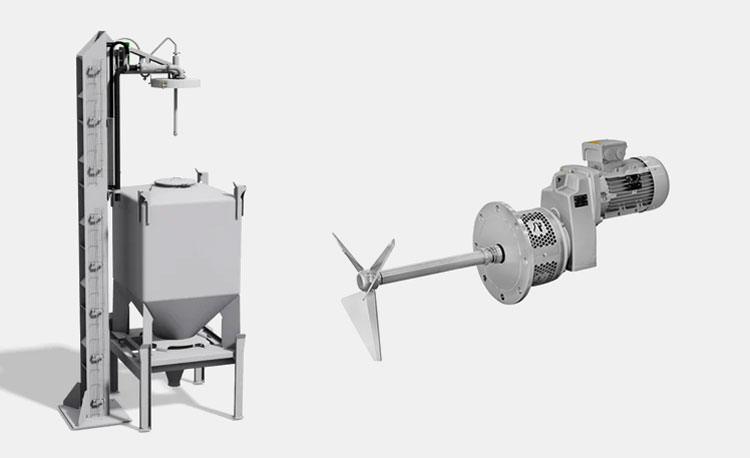

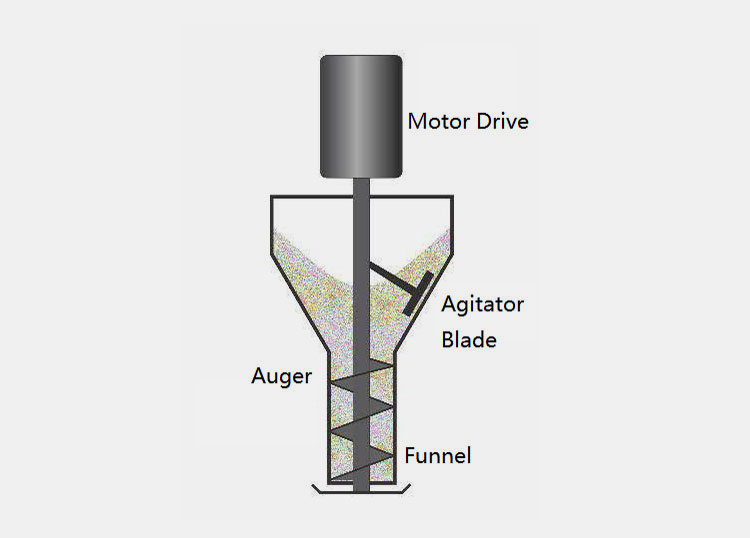

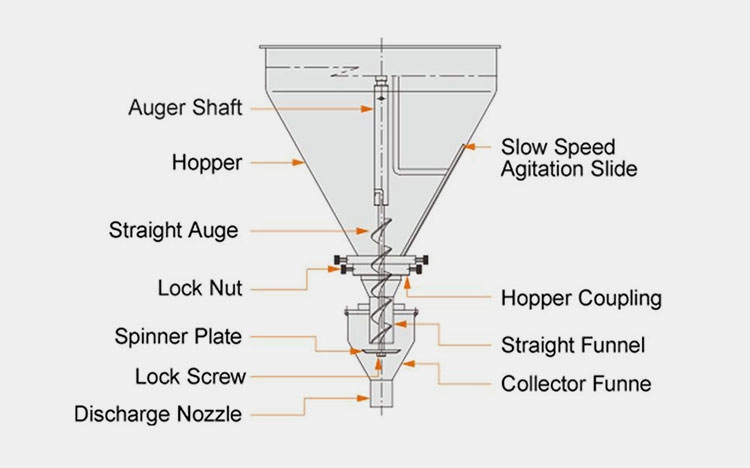

Hopper

Hopper is the feeder of a pharmacy pill counter machine located at its top. Its function is to hold the large amount of unprocessed pills. It has a broad opening on upper side while as narrow end attached to the vibratory trough through which pills are gradually released.

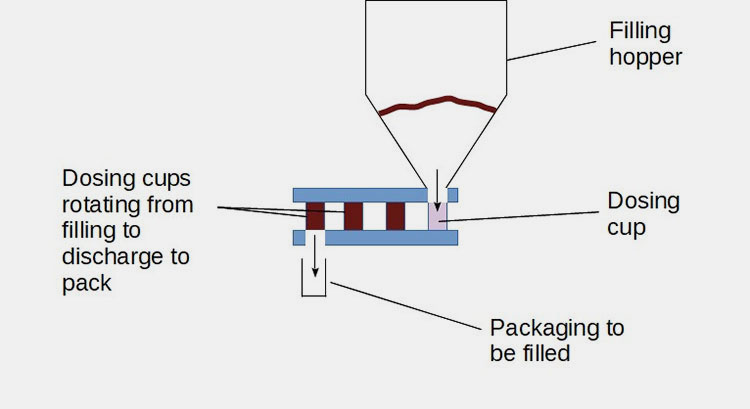

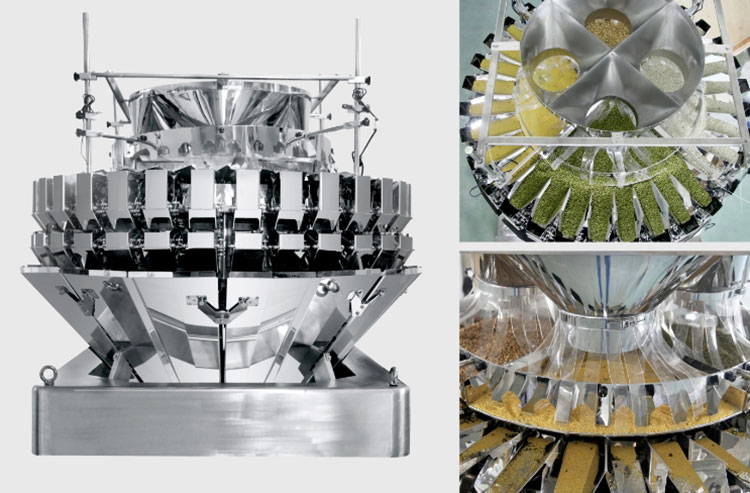

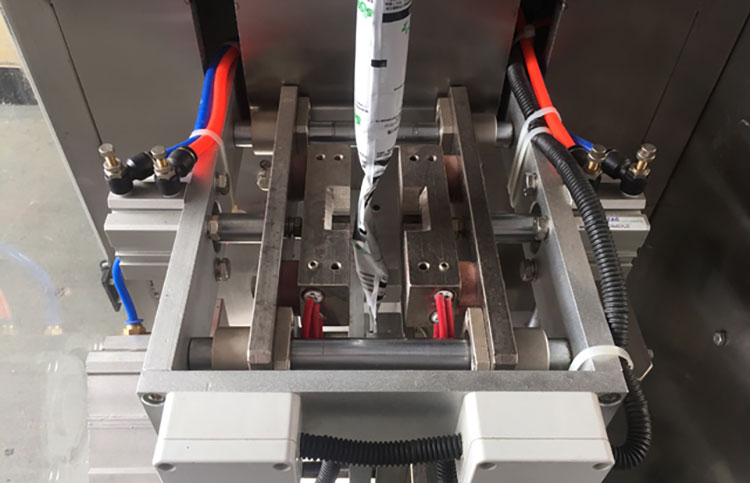

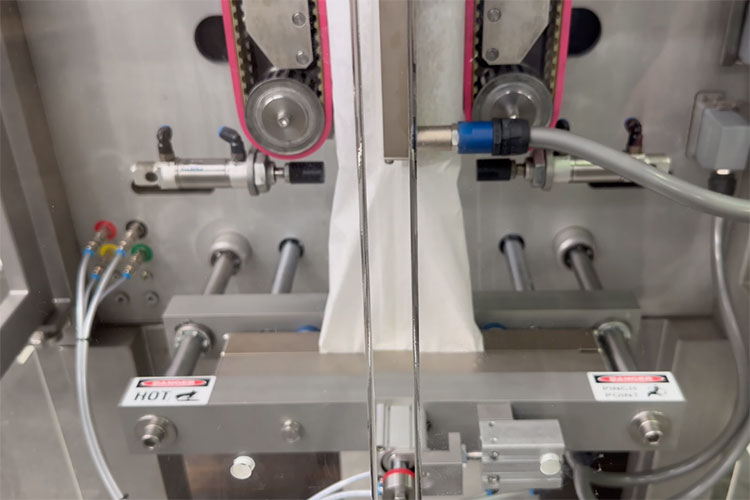

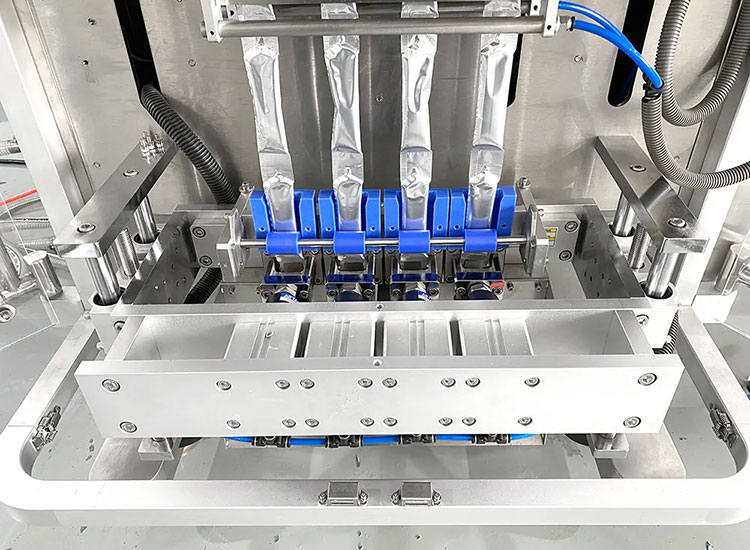

Vibratory Channel

Vibratory channel is one of the most crucial part of this machine. It has a collection of stainless steel trays placed in a synchronized way where one tray is positioned right below the end of upper tray. It has attached motor which is responsible to create vibratory effects in this channel.

Counting Compartment

Counting compartments are multiple small sections where pills are counted through photoelectric sensors. These compartments keep the accurately counted pills and defective pills are sucked by the dust collection system.

Touch Screen Panel

Touch screen penal is a human machine interface that has a user-friendly system to enable users for adjusting the machine setting.

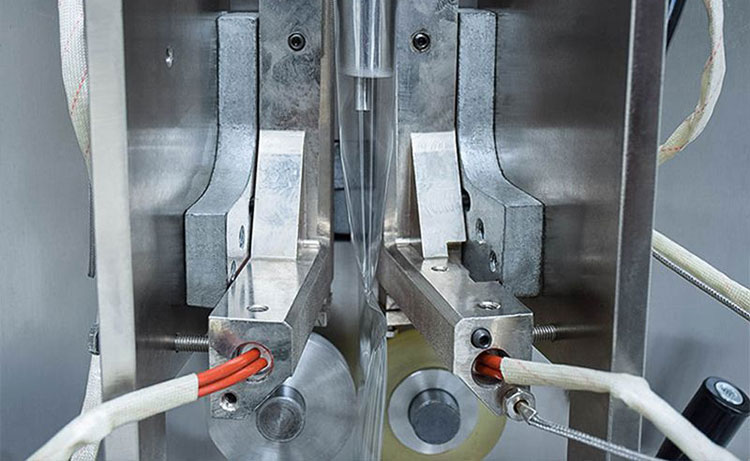

Pills Dropping Head

It is a large stainless-steel tool having a broader upper side that is connected to the counting compartments and having a small head through which pills are dispensed into bottles.

Height Adjustment Tools

As automatic pharmacy pill counter machine can handle small to large bottles, height adjustment tools are responsible for this adaptability.

Conveyor

Conveyor is the significant part of an automatic pharmacy pill counter machine that perform the duty of mobilizing bottles from one end to the other.

Bottle Sensor

Bottle sensor is located on the side of conveyor. It helps in detecting the presence of bottles, so, that machine will dispense pills accordingly.

Power Button

Power button is a big red color button situated in the center front of machine. Its function is to start the machine or stop it.

Control Cabinet

Control cabinet is the electric box of a pharmacy pill counter machine holding in it all the sensitive electric wires and fuses.

Rejection System

Rejection system is integrated on the conveyor at the place through which bottles are discharged. It detects whether the bottle passing is loaded with pills or is empty. In case, bottle is empty then it will be rejected and collected in a separate section.

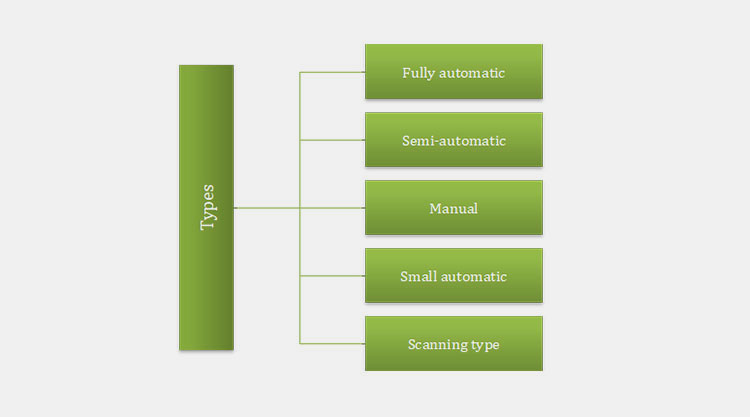

7.What Are The Types Of A Pharmacy Pill Counter Machine?

Pharmacy pill counter machine is available in small to large size with varying pills counting capacity and automation. The underlying classification will be enough to show these types and mark distinction between them:

Automatic Capsule/ Tablet Counting Machine

Allpack APC-16 Automatic High Speed Pharmaceutical Capsule Tablet Counting Machine

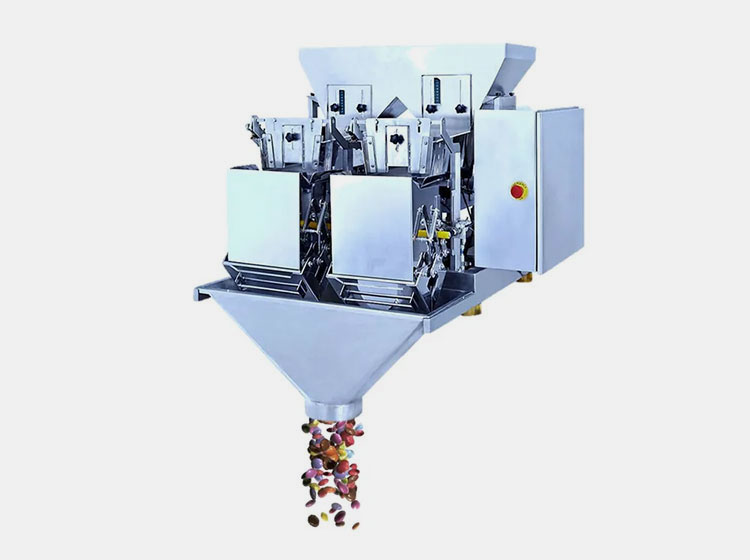

It is a fully automatic machine designed with ultrafast technology to meet the excessive demands on part of pills counting. Although, it is a bit expensive, but this pharmacy pill counter machine can fill up to 150 bottles in just a minute and is applicable to multitude of small pallets, seeds, candies and different sizes of pills.

Structure

The structure of machine is complex with heavy-duty machinery. Its robust body is made up of a control panel, a hopper, vibratory trays, counting section, conveying mechanism, detection system, and filling heads etc.

Process

The machine perform function automatically when the operator initiates it. The pills are automatically released from hopper onto trays, then get counted and deposited to the bottles precisely.

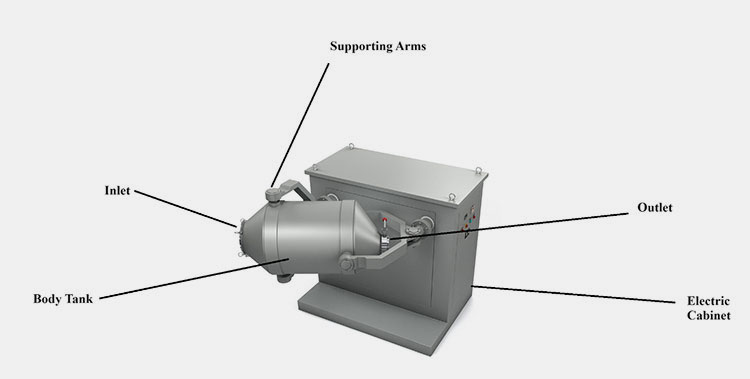

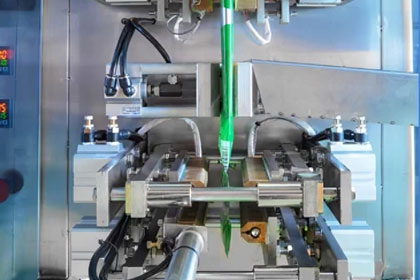

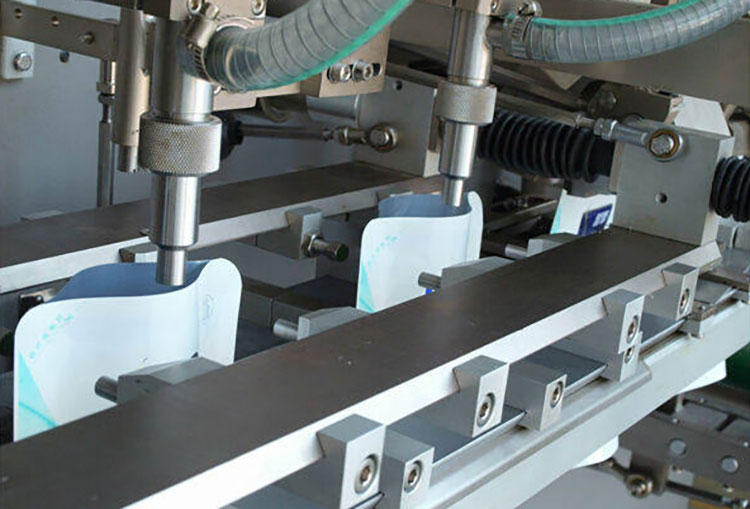

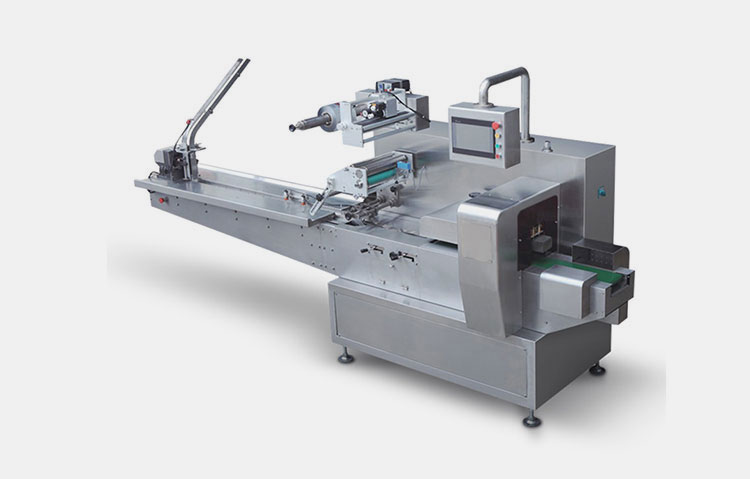

Semi-Automatic Capsule/ Tablet Counting Machine

Allpack SLJ-100B semi-automatic pharmaceutical desktop rotary capsule tablet counting machine

Semi-automatic capsule tablet counting machine is another type of pharmacy pill counter machine employed to deal with medium size production. It is cost-effective with product flexibility and best counting range with counting 100 pills per minute.

Structure

The machine has a compact and stable structure that is easily movable. The major parts include a stainless-steel hopper, rotary channel, moulds disc, power button, speed regulator, and pills discharging chute.

Process

The working of machine is extremely easy with requiring one operator who will load the hopper with the pills. Afterwards, the machine will automatically count pills through continuous rotation in such a way that empty moulds will be filled with pills. When the rotary disc reaches at a place where below area is hollow, the pills will be dropped and filled into bottles through filling head.

Manual Tablet Counter

Manual Tablet Counter MTC-30

Manual tablet counter is another tool you can utilize for making your manual pill counting more handy and safe. This manual tablet counter by Allpack provide safe means to count drugs and avoid direct contact with them to ensure their hygiene.

Structure

This manual tablet counter is made from food safe plastic with having 30 moulds and a handle for holding it.

Process

Its operation is simple where you are required to fill all the empty moulds of tablet counter with pills. Hence, filling one tray means having 30 pills. So, just pour these counted pills into bottle without recounting.

Small Automatic Tablet & Capsule Counter

Rx-4 Automatic Tablet & Capsule Counter- Picture Courtesy: rxcount.com

This small size automatic tablet and capsule counter is most handy and prestigious pharmacy pill counter machine due to its small body, high accuracy, and automatic processing. The machine is widely used in small pharmacies and research laboratories to make the process of pills counting safe and healthy.

Structure

With extremely small footprint the body of machine is made up of a 100% FDA approved materials, easy-to-use LED digital display, counting sensor, rotary disc, sorting wheel, and pills discharge chute.

Process

It simply works when pills are loaded onto the rotary disc and operator set the configuration of machine through 16 keypad. After turning it on, the disc will start revolving around the sorting wheel and pills will be triggered. This ultimately leads to the accurate counting of pills and each counted pill is pushed ahead towards discharge chute and filled into an attached bottle.

Pharmacy Pill Counter

Vivid pharmacy pill counter- Picture Courtesy: pillcounters.com

This type of a pharmacy pill counter machine is a sort of semi-automatic and digital. The advance system of photoelectric detection system greatly helps in the precise counting of tablets and pills.

Structure

The overall structure of machine is compact and consists of a digital interface, scanning tray, pills collection devices, and main frame etc.

Process

To operate the machine you need to disperse tablets or capsules over the scanning tray. The scanner will take image of these tablets and capsules and will display it on the interface. Similarly, you will get to know the amount of pills. Now, just move the tray upward from one end and pills will be collected in side tool. So, you can easily drop these counted pills into may bottle or container.

8.Enlist The Uses Of A Pharmacy Pill Counter Machine On Broader Level?

A pharmacy pill counter machine is the most notable machine used not only in pharmaceutical industry but other sectors as well. These sectors are enlisted below:

Healthcare Industry

Lady doctor smiling- Picture Courtesy: t-systems.com

Whether it is a pharmaceutical industry, veterinary industry, herbal industry, or nutraceutical industry everywhere there is a common goal to provide tablets and capsules for humans’ and animals’ care. Hence, healthcare industry is on the top of the list where a pharmacy pill counter machine can be used.

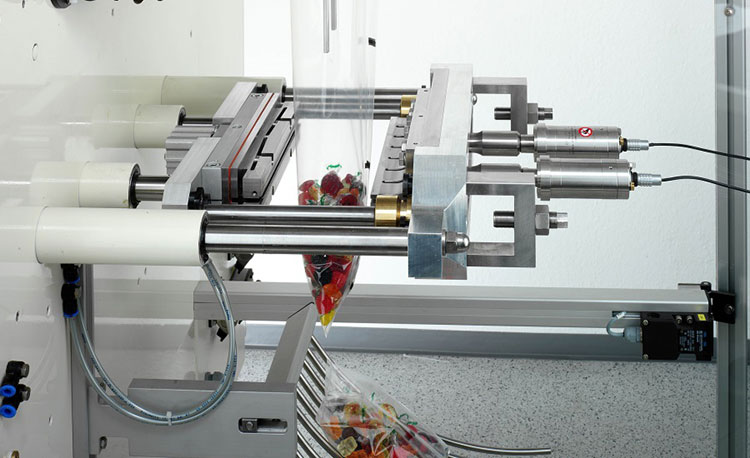

Confectionery Industry

Various confectioneries jars on shelves- Picture Courtesy: thehiveblog.com

Most of the confectioneries like bubble gum, candies, gummies, and chocolate balls are properly counted and then packed into bottles and jars. Therefore, a pharmacy pill counter machine is always preferred in confectionery industry to make sure the accuracy of counting during packaging.

Agricultural Industry

Agricultural seeds- Picture Courtesy: farmkey.in

Grains, seeds, and pesticides pellets are some of the popular objects which are being processed in agricultural industry. That's why, a high check on their counting and packaging is carried out for which a pharmacy pill counter machine is the perfect choice.

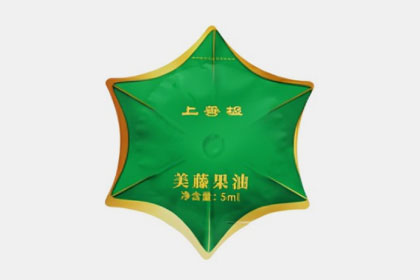

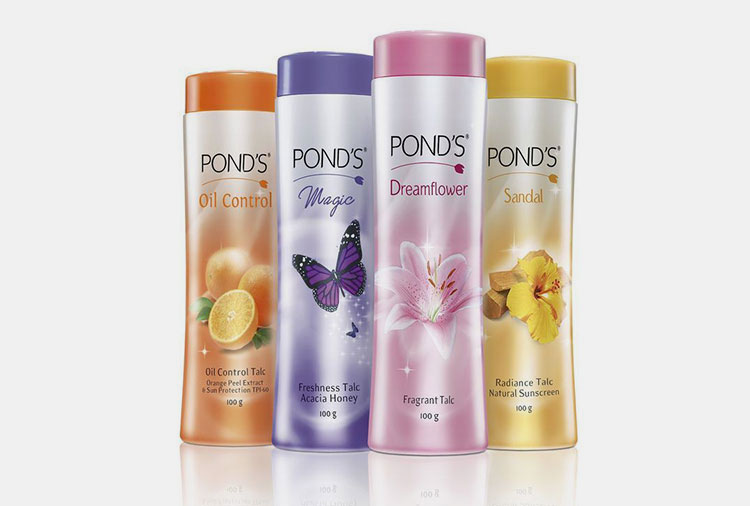

Beauty Care Industry

Beauty Omega-3 softgels

The time has gone when beauty was only dependent upon external things like makeup tools. Now, people are more concerned about working on inner glow for which they use capsules of vitamins, proteins, and fish oil. This is where the need of a pharmacy pill counter is realized to aid the step of pills counting.

Chemical Industry

Chemical processing in funnel- Picture Courtesy: pcimag.com

Chemical industry is among other areas where a pharmacy pill counter machine can be utilized to accurately count the tablets with greater protection under enclosed environment.

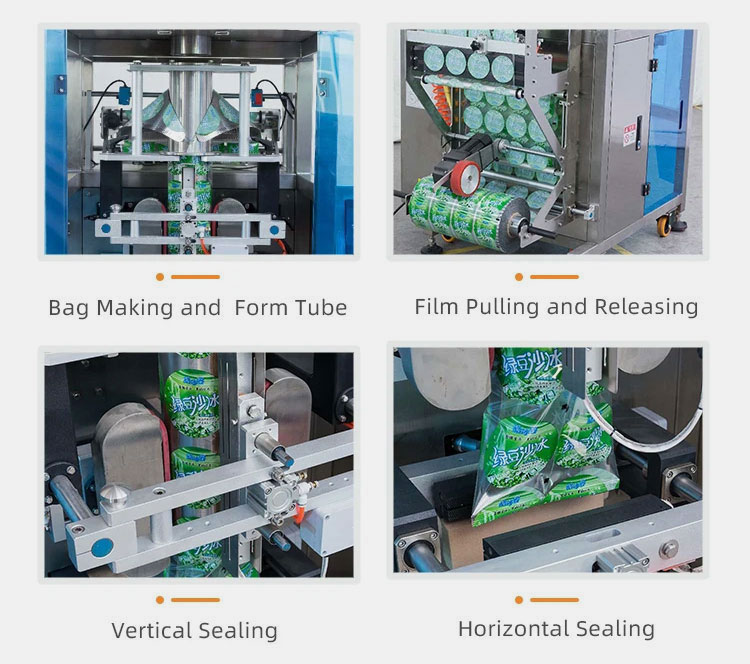

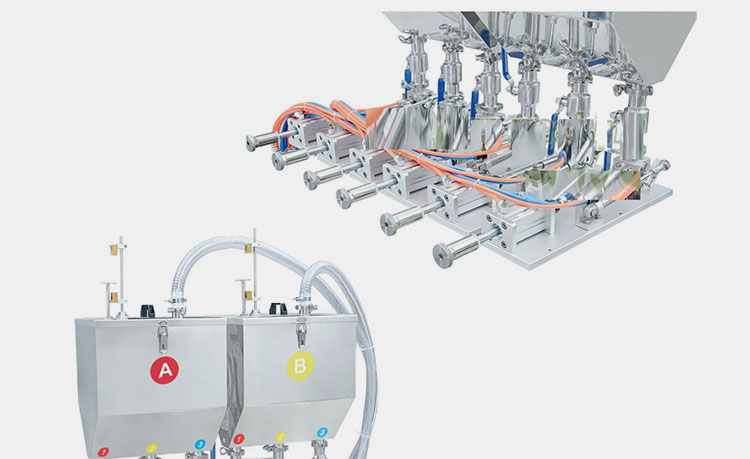

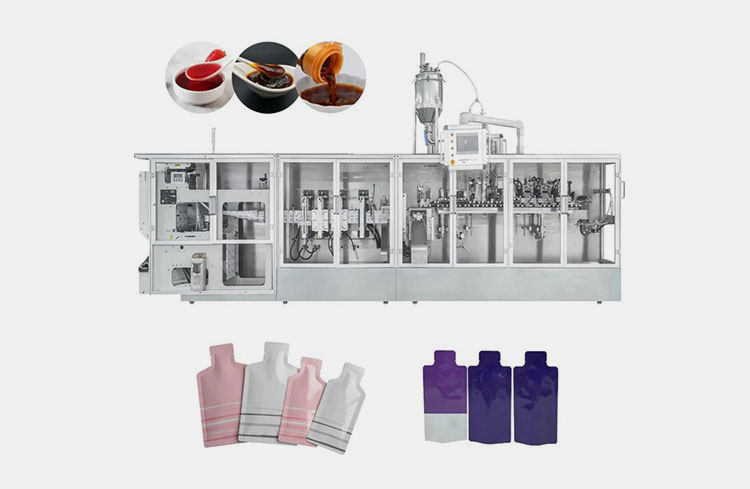

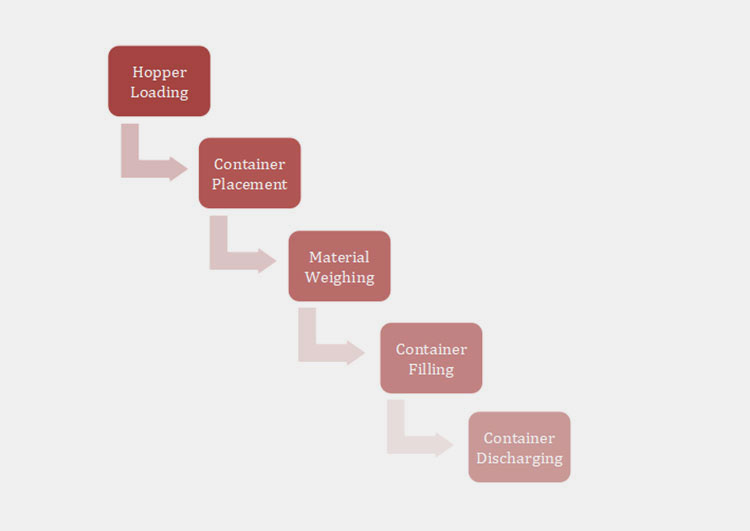

9.What Is The Counting Line For Pharmacy Pill Counter Machine?

To resolve the issues of high production facilities regarding tablets counting and their packaging, counting line has been introduced into the field. This counting line is becoming popular with every passing day due to its comprehensive performance. Let's look deep into its structure, function, and process!

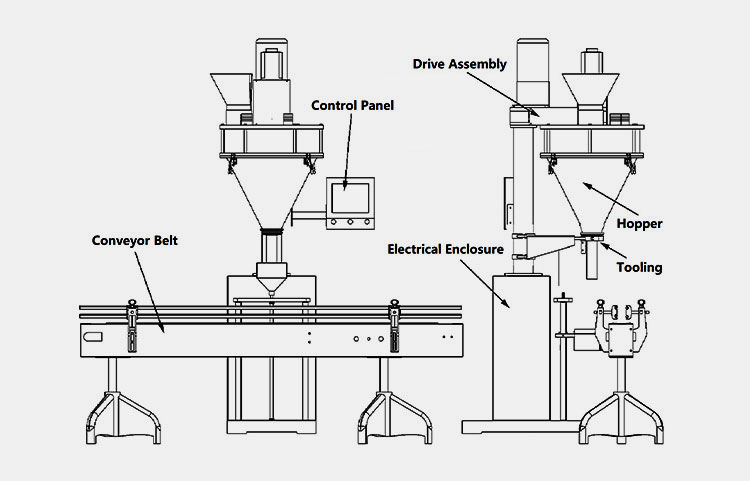

Allpack Medium Speed Automatic Multifunction Capsule & Tablet and Pill Counting Line

Bottle Unscrambler

Bottle unscrambler is an automatic machine designed to place the bottles into an upright position. It is the very first unit of pills counting line that mainly consists of a robust stainless-steel body, a transparent window for clear observation, bottles processing unit, control system, and aligning channel. Initially, the bottles are fed into the machine after which it sorts these bottles and align them sequentially towards the filling machine.

Automatic Tablets Counting Machine

Automatic tablets counting machine is the second machine in number which has been assigned with the task of accurately counting pills. It has comparably complex body with multiple components encompassing a hopper, vibratory channel, counting compartment, filling heads, sensors, conveyor belt, and control panel etc. It simply starts dropping tablets from hopper which falls onto vibratory channel. Similarly, the tablets are counted, filled into bottles and discharged.

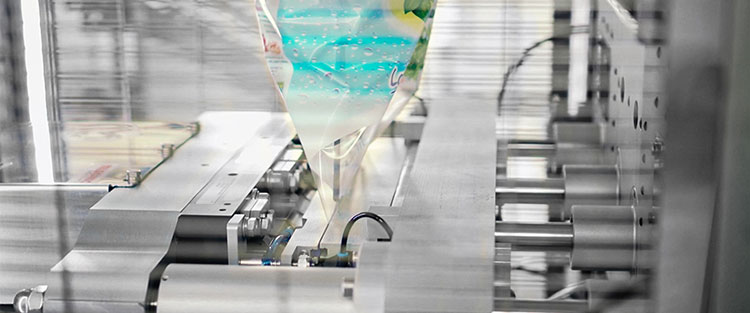

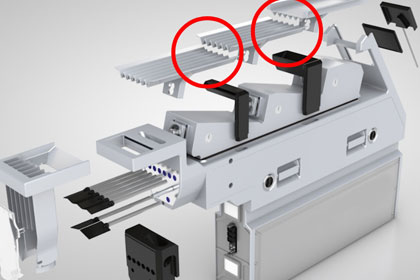

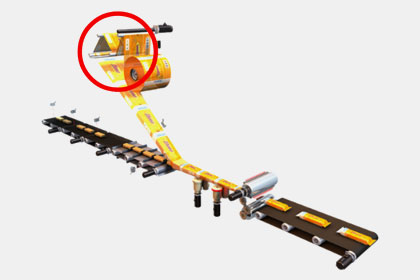

Desiccant Inserting Machine

Desiccant inserting machine is an innovative machine that is integrated into the main line for inserting desiccants or oxygen absorbents into tablets filled bottles. It offers an easy and reliable operation with machine unwinding the strip, filling it with silica gel, sealing it and loading one desiccant bag into one bottle. The overall components which account for the machine include film roll, support roller, bottle rejection system, strip sealing, and cutting.

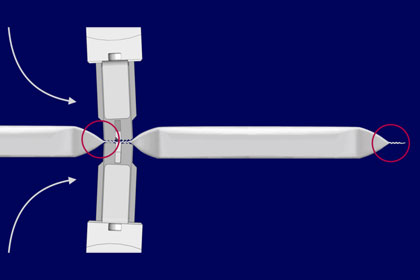

Automatic Capping Machine

Automatic capping machine is a vital equipment in tablets counting automation. Its primary function is to take the caps of bottles and apply them over bottles' opening. Similarly, the caps are tightly screwed to achieve airtight capping. This function is performed by various components such as cap orienter unit, cap chute, control panel, capping station, and conveyor belt etc.

Induction Sealer

Another machine necessary for pills counting line is the induction sealer which is employed to create a stringent seal of the thermoplastic foil attached to bottles' caps through electromagnetic radiation. It is composed of a durable stainless steel main frame, conveyor, sealing head, alarm, water cooler, induction coil, control unit, and time regulator.

Labeling Machine

The last and essential unit of pills counting line is the labeling machine. Several components constitute the body of a labeling machine including reel, touch screen penal, labeling wheel, bottle stop wheel, pulleys, label applicator, and label cylinder. It performs the labeling by pulling label from reel, separating the label from back paper and applying it around the passing bottles.

10.What Are The Daily Cleaning And Maintenance Requirements Of A Pharmacy Pill Counter Machine?

Operator maintaining a pharmacy pill counter machine- Picture Courtesy: cremer.com

Cleaning and maintenance are the prerequisites for long lasting smooth performance of a pharmacy pill counter machine. Therefore, you are obliged to fulfill these requirements regularly and properly. The upcoming guidelines will be helpful in this way.

Cleaning

It is recommended that cleaning of a pharmacy pill counter machine must be done every weak and if the product processed is dusty then daily cleaning is necessary for removing residues. For this, you can take few steps including:

- Disassemble the hopper of machine, the protected window glass, and vibratory trays.

- Wash these parts with chemical free detergent mixed in water.

- After washing, use a clean dry cloth to remove the streaks from all these parts by continuously wiping in a back and front position.

- Place these parts in their relevant positions and screw them tightly.

- For cleaning sensors and control panel you need to use a wet computer screen cleaning cloth and then use a dry soft cloth to completely remove the marks.

Maintenance

Maintenance of a pharmacy pill counter machine include both the structural adjustment and internal parameters such as:

- Maintain the height of pills filling head in accordance with the height of bottles.

- Adjust the conveyor width to that of the size of bottles.

- Lubricate the movable parts of machine every month.

- Keep the screws and nuts of machine tight.

- Make sure to have fixed the speed of conveyor, number of pills, and the speed of DC motor.

11.Troubleshoot The Major Pitfalls Of A Pharmacy Pill Counter Machine?

There are times when your pharmacy pill counter machine might show malfunctions during operation. However, it does not mean that the machine is not good, but the reasons can be technical and can be easily solved by properly understanding the table below:

| No | Pitfall | Causes | Solution | Picture |

| 1 | Sensor creating trouble in detection | This happen when the sensor has dusty particulates which cause difficulty in detecting pills | It can be resolved by properly cleaning the sensor window with soft, clean cloth |

Displaying sensor detecting incorrect product- Picture Courtesy: cremer.com |

| 2 | Under counting of pills | The reason is badly placed counting channel and the speed of vibratory motor | You need to make sure the accurate positioning of counting trays and the suitable speed of motor to ensure accurate counting |

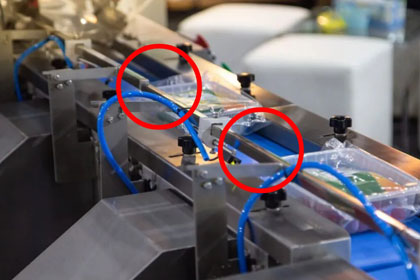

Encircled vibratory trays- Picture Courtesy: cremer.com |

| 3 | Over counting of pills | Mostly, the polluted detector glass window led the machine to drop pills collectively from compartments | To solve this problem, you have to clean the sensor, so, that each compartment will deposit pills separately |

Overfilled capsules bottl- Picture Courtesy: cremer.com |

| 4 | Pills segregation during deposition to bottles | The filling head of machine is higher than the mouth of bottle | It can be corrected by adjusting the height of filling head near to bottle opening |

Scattered softgel capsules- Picture Courtesy: freepik.com |

12.Factors To Look For When Buying A Pharmacy Pill Counter Machine?

Whenever you intend to incorporate a pharmacy pill counter machine into your production make sure to be vigilant enough to avoid taking unsuitable decision in hurry. Some of the significant considerations are given below for your guidance:

Production Capacity

High production capacity pharmacy pill counter machine- Picture Courtesy: cremer.com

The very first question to ask for arises from you. It is the current production volume of your manufacturing. Knowing this will ultimately help you to determine which type of pharmacy pill counter machine is suitable for you.

Budget

Budget presentation idea- Picture Courtesy: livemint.com

No doubt budget is one of the essential factors to have in your mind all the time. It is because your economic position play an instrumental role that whether you can afford a sophisticated but expensive machine or precise machine with cost-effective price.

Auxiliary Machines

It is for sure that every machine has a demand for spare parts and auxiliary machines who if not fulfilled can obstruct the existing performance. Hence, it is important to consider the availability of such tools.

Quality Compliance

Quality complying puzzle

How it can be possible that you are looking for a pharmacy pill counter machine and neglect its quality compliance? Of course, it can't be! So, make sure that the machine you purchase is fully adhering the national and international quality standards. Moreover, warranty policy and after-sale service are other crucial factors to look for.

Conclusion

To wrap up this comprehensive buying guide about a Pharmacy Pill Counter Machine, we are glad to have been successful in communicating you the significance, resilience, and applicability of the machine. Not only that, but we are now sure that you can even operate your pharmacy pill counter machine. If you are new or an old manufacturer looking for an excellent machine, then Allpack is offering an extensive line of pharmacy pill counter machines. Make sure to check our inventory for pills counting. Don't hesitate to ask for further information!

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide

Pharmacy Pill Counter Machine: The Complete Buying Guide In 2025 Read More »

Tell us your material or budget, we'll reply you ASAP within 24 hours

Tell us your material or budget, we'll reply you ASAP within 24 hours