Attar Manufacturing Process: The Complete FAQ Guide In 2025

Have you ever been attracted by the intoxicating scent of attar? Do you want to collect all the essence of attar for your own use? The production of attar can be traced back to a long time ago. And many ancient methods of making attar are still preserved. Now, you may know how to make attar with the water distillation and steam distillation methods for your business.

This complete FAQ guide of attar may introduce you all details about how to make attar. You can apply this method to various flowers, herbs and spices to collect their precious essential oils. Collecting these essential oils and mixing them into your favorite formula can bring more fun to your life. Let's get started now!

1.What Is Attar And How It Is Made?

Attar

What Is Attar-sourced: zaoud

Attar is an aromatic essential oil with a charming aroma. It is usually made from rose petals. In addition to rose petals, you can also extract essential oils from other flowers, herbs or plant species. Attar does not contain any alcohol or other chemicals and is a pure natural product.

How is it made?

How is attar made-sourced: Dukhni

Attar mainly uses distillation to extract the essence from the petals, so it has a very high concentration and a very strong taste. The specific production method is to collect the essence through crushing, extraction, distillation and condensation to make essential oils. The most common types of attar are rose, jasmine and lavender.

2.What Are The Key Steps In Attar Manufacturing Process?

To make a successful attar, you need:

Step 1 Raw material selection

Flowers

Flowers-sourced: naturalalchemy

Flowers are one of the most important raw materials for making attar. The aromatic essence of attar comes from flowers. The most popular ones are rose, jasmine, lavender, rose, lavender, etc.

Herbs

Herbs-sourced: takeonethingoff

Functional attar can also be obtained by extracting and distilling herbs. This kind of attar can provide you with fragrance while also reducing swelling and pain. Among them, saffron, patchouli and vetiver are the most popular types.

Wood

Woods-sourced: attarbazaar

There are many types of perfumes extracted from wood on the market, and the same is true for attar. The essential oil extracted from wood has a soothing, gentle and long-lasting smell that can calm the mind.

Spices

Spices-sourced: attarayurveda

Attar can also be added and used with spices. For example, cloves or cinnamon can increase the sweetness and deep smell of attar.

Step 2 Distillation and extraction

Grinding

Flower grinding-sourced: MIUPOO

Grinding the selected raw materials. However, you can also choose not to grind, directly distill and extract, but the effect and efficiency of this is not as good as grinding in advance.

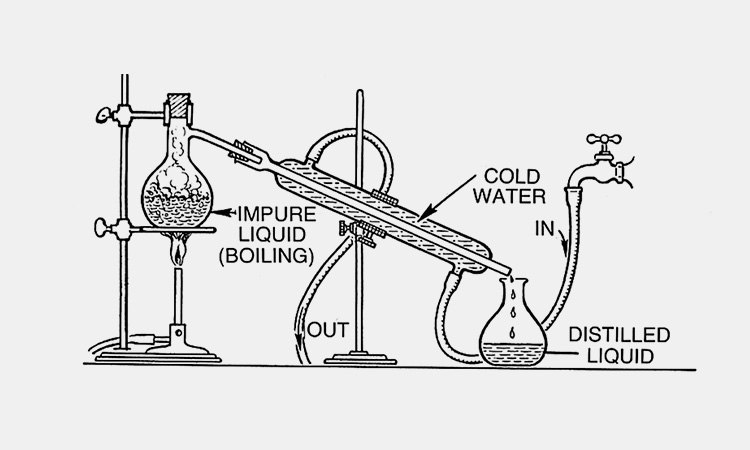

Water distillation

Water distillation-sourced: precisionwaterusa

Soak the ground raw materials in water, heat the temperature, and then boil. When the essence in the petals is separated from the raw material body in the form of water vapor, these essences are obtained by condensation.

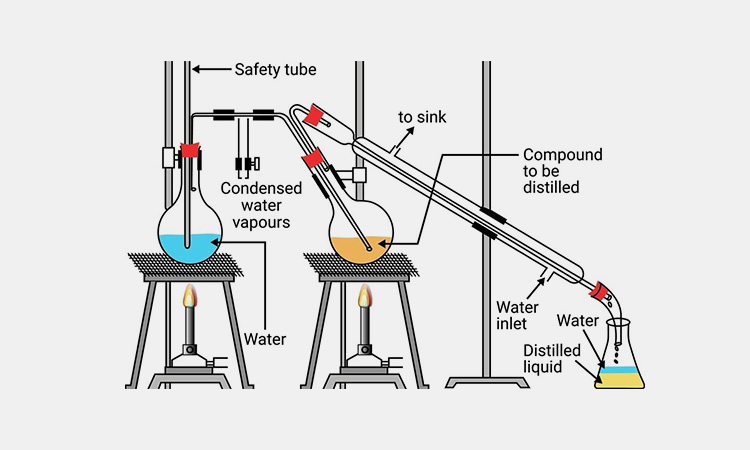

Steam distillation

Steam distillation-sourced: solnpharma

Or you can choose steam distillation. You can directly immerse the heated water vapor into the raw material. The heat generated by the steam will directly force the essence in the petals out, and then separate it from the body, and then be condensed and collected in the form of water vapor.

Step 3 Prepare base oil

Prepare base oil-sourced: infinitygalaxy

The essence extracted from the petals needs a good carrier. This carrier is the base oil. Generally, manufacturers use sandalwood or vetiver to extract as the base oil of the essential oil. Because it can well ensure the taste of the essential oil and extend the service life of the essential oil.

Step 4 Mixing and Infusion

Mixing and Infusion-sourced: medicalnewstoday

In this step, you need to mix the base oil and the extracted essence evenly. By using special equipment, you can stir and mix evenly directly in the equipment. After mixing, you need to let the mixture stand for several hours or days. During the standing process, observe the changes in the mixture at any time and check its temperature and time.

Step 5 Maturation of attar

Maturation of attar-sourced: factor

Mixed attar needs a period of maturation, that is, evaporation. Freshly made attar does not have a strong aroma because the ingredients in it have not had time to evaporate and settle. Depending on the choice of different raw materials, they may need different amounts of time to settle. Generally, it takes a few weeks to a few months.

Step 6 Dilution

Dilution-sourced: perlite

In order to ensure that the taste of attar is not too strong or pungent, it is generally diluted to ensure the final quality. You can dilute the extracted essence by adding additional base oil. At the same time, you can season it according to your preferences.

Step 7 Filtration

The final filtration of attar is essential. Since the granularity brought by the materials or base oil is inevitably not cleaned up during the production process, you can filter the attar mixture again with a fine filter. This step can ensure that the final product is smooth and pure, with higher quality. The filtered essential oil looks better and is safer to use.

Step 8 Bottling

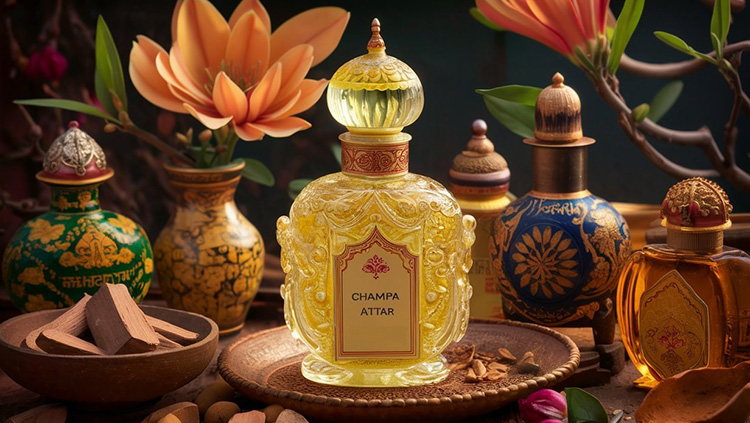

Bottling-sourced: thearomatherapyshop

Bottling is the last step of the entire attar production. To make your product last longer and look good, you can bottle attar in glass containers. Depending on the volatility of the mixture, you can choose a transparent or opaque container. Among them, a small bottle with a roller ball is a perfect choice.

3.What Are The Attar Manufacturing Equipment You Will Need?

You may need the attar manufacturing equipment like:

Hot distillation system

Hot distillation system-sourced: sinicmed

You can choose the hot distillation system that you think is suitable. It is one of the most important devices in the entire essential oil extraction process. All the essences extracted from the raw materials need to be completed by the hot distillation device. This device can intelligently control the temperature and humidity control during the hot distillation process and extract the most important essence of the plant for you.

Mixing tank

Mixing tank-sourced: gpi-degouwe

The mixing tank can be used to mix the plant essence and base oil part you extracted. It can provide the best base oil blend for your essential oil and is an indispensable component.

Filtration system

You can equip a suitable filtration system. According to your own production requirements, you can equip a manual or automatic filtration system to facilitate the impurity filtration and separation of the essential oil in the later stage.

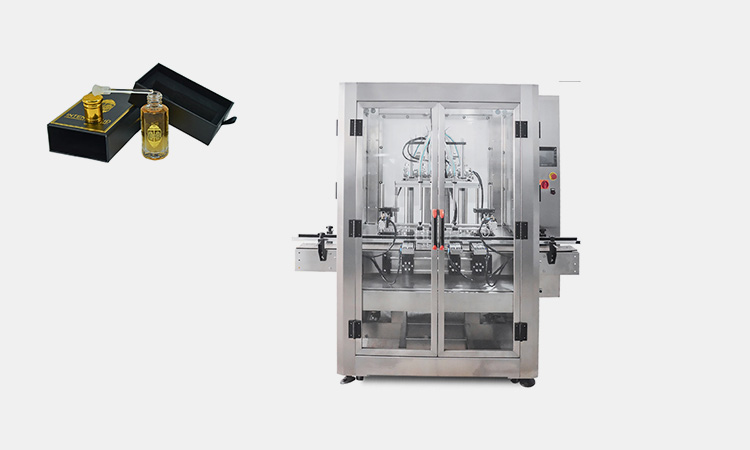

Bottling machine

ALLPACK perfume bottling machine

Bottling is the last step in the production of essential oils. A good bottling machine can provide a good protective container and beautiful display effect for your final essential oil product.

4.What Are The Regulations And Standard You Must Meet During Attar Manufacturing Process?

To obtain good attar products, you need to follow:

Quality control standards

Quality control standards-sourced: managedhealthcareresources

Attar manufacturing process requires good quality control to ensure that your finished product is of the required quality and consistent without any errors.

Good manufacturing practices

Good manufacturing practices-sourced: kfriedmanconsulting

The good manufacturing practices ensure that your attar manufacturing process is safe, clean and made with the right safety measures. This standard ensures that your products are well-made for the end user.

Labeling certification

If your products need to be exported, your labeling and imprinting are also very important. By complying with the relevant labeling and certification, you need to obtain the correct and safe labeling license.

Environmental and ethical considerations

Environmental and ethical considerations-sourced: packaging-labelling

You are better off using environmentally friendly essential oil production methods and measures and using resources wisely.

5.What Are The Top Attar Manufacturers In The Market Now?

What are the top attar manufacturers in the market now? Here are the best ones.

Kannauj Attar

Kannauj Attar

Kannauj Attar is a famous natural attar manufacturing company in India with over 5000 years of experience in extracting attar from various flowers, herbs and spices. Preserving the traditional method of hot distillation of attar, they are able to provide you with top-quality attar and fragrance products.

Al Haramain

Al Haramain

Al Haramain is a traditional attar making company. Its attar products are unique, especially wooden attar products, which are very popular in the market. By learning traditional methods, they also follow the new international production process and sell oriental attar and perfumes all over the world.

Ajmal Perfumes

Ajmal Perfumes

Ajmal Perfumes is a company with rich experience in both attar and perfume making. Their attar products are exported to more than 60 countries worldwide and they are pioneers in aromatherapy.

Amouage

Amouage

Amouage is a world-renowned attar manufacturer. Their attar products are creative and innovative and are renowned worldwide. The company has created a transparent attar production workshop for visitors to visit and tour. They are committed to leading every product in the world.

Al Rehab

Al Rehab

Established in 1975, Al Rehab is a professional attar manufacturer that produces, manufactures, packages and markets attar. They are very familiar with the market and consumer needs. Their products are wide in variety and good in quality, meeting the needs of the international market.

Conclusion:

Attar manufacturing is a combination of ancient and modern technology. Through this complete FAQ guide of the attar manufacturing process, you may know that only through this method can the best essence of plant species be obtained. This tradition and technology can bring great quality to life. If there are more you still confused, please do not feel shy to come to ALLPACK!

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide