Aluminium Tube Packaging: The Complete FAQ Guide In 2025

What is the first choice for packing semi-solid formulation? Every company select aluminium tube packaging as an ideal agent to pack their products. This can be due to the various fascinating reasons which ultimately offer you the safety and security of dosage.

It plays a critical role and yet promising too. In this article, you’re going to explore important details related to aluminium tube packaging. We promise, that if you are from the healthcare industry or associated, by the end of the topic, you will be able to make the right decision about packaging and equipment utilized in attaining the perfect solution. So have a look at the below discussion.

1.What is aluminium tube packaging?

Pharmaceutical tube packaging- Picture courtesy: Pharmaceutical tube

This is the ultimate solution where various semi solid preparations related to the pharmaceutical industry are taken place.

However, this route of packaging is known as the most conventional way and still used. Quite amazing to described that there is various new mode of packaging are introduced but none- of them are able to beat the aluminium tube packaging. The prime reason behind it is that easy to store, carrying, and apply.

They are present in various sizes, diameters, and lengths and all are depending on the different purposes and materials to be stored. Not only in pharma, but there are various sectors that frequently uses aluminium tubes for its product storing and packing tasks. You are just needed to squeeze a little and it gives the desirable product’s quantity.

2.Why businesses pay attention to aluminium tube packaging?

Pharmaceutical tubes

A great solution against tampering

Original product packaging- Picture courtesy: toptube

One of the prime objectives behind aluminium tube packaging is that it gives you a high level of security. In many cases, pharma products can be counterfeited. You can keep the integrity of your product by applying this mode of packaging and your customers pick and use the product with excellent satisfaction.

Your product safety from physical factors

Extra protective barrier- Picture courtesy: HD barrier

You must know that aluminium tubes have featured with an impermeable layer. This means that it resists the entry of external physical or environmental factors to penetrate inside. So it is simply performing the function of a barrier. Therefore, various formulations are now saved whether it is normal, medicated or non-medicated preparation.

No progression of microbes

No microbes- Picture courtesy: Pharmaceutical tube

The aluminium tube manufacturing takes place to keep contaminants or microbial factors away from your product. Moreover, it is pretty common that if you alter the physical and chemical properties of the packaging it results in either oxidation which results in rancidity of the formulation or direct progression of microorganisms. The aluminium tubes act as a shielding layer that stops the air or oxygen molecules and airtight packaging blocks bacterial progression. It directly allows your product to stay longer and fresh.

Easy dispensing and carry on product

Easy to carry

Aluminium tube manufacturing is not just meant for clinical or hospital-side applications. But it is required to you for daily time and life usages. It ensures easy management and offers flexible carry on from one place to another by simply keeping it in your bags, purse, or whatever pouches you use for medicine storage. This is simple, light in weight, and made up by considering all your needs making it the most demanding item.

Accurate and perfect dose dispensing

Accurate dispensing- Picture courtesy: Justkraft

Your formulation drawing is now so accurate and easy with an aluminium tube. It makes you to not worry about spilling or splashing of the formulation. All in all, your product during manufacturing and application is based on control releasing and associated with no risk or wastage. Even an inexperienced person can withdraw the required concentration of the tube formulation without need for any support or tool.

3.What are the types of aluminium tube packaging?

These tubes are not confined to a single category, but it is composed of two major types. For example:

Rigid aluminium tube packaging

Rigid aluminium tube- Picture courtesy: Linhardt

These are also known as a hard tube. They are quite rigid in the structure and not able to press or squeeze. It is mainly used for those products that are solid, stable, and firm in presentation. For example, various tablets such as effervescent tablets are commonly packed in rigid or hard aluminium tubes. These tubes are mainly known for its high durability and protection. It gives physical excellent barrier properties between product and external conditions.

Collapsible aluminium tube packaging

Collapsible aluminium tube packaging- Picture courtesy: Trend hunter

These are flexible and squeezable types of aluminium tube packaging where most often semi-solid products are packed. You can pick the tiny or required amount of squeezing the bottom of the tube. It is mainly known for anti-wastage properties as you can get whatever you want to draw without leakage or over spill.

4.What areas require aluminium tube packaging?

With so many specialized properties, aluminium tube packaging is required in broad industrial sectors and related areas. In industrial settings, promising quality is always maintained with these packaging options. Let's see where this leading choice is preferably opted.

Pharmaceutical and medical industry

Pharmaceutical industry- Picture courtesy: pharmaceuticaltubes

The aluminium tube packaging provides you with excellent protective effects. It is prioritized in pharmaceutical sectors because it gives you greater hygiene and formulation safety. Today, various ointments, balms, topical creams, lotions, gels, and pastes are dispensed in them.

Cosmetics industry

Cosmetic industry- Picture courtesy: blueskysolutionuk

It was always found challenging for cosmetic industry to get an ideal solution for their products' packaging. Therefore, delicate and way more sensitive formulation is always acquired with aluminium tube packaging. This is because it is known as a golden standard storing offer for cosmetics products. So cosmetic and personal care items have mostly come in these packaging materials.

Food Industry

Food industry- Picture courtesy: perfektup

Food preservation and packaging are always significantly concerned with freshness, aroma, durability and sustaining their flavors. The aluminium tube packaging is therefore known as good way to ensure food products are stored in a high shielding layer of barriers and it does not affect the properties of your perishable item.

Personal hygiene industry

Personal hygiene- Picture courtesy: Three bamboos

Whether it is your haircare, skincare, oral hygiene, etc. the personal hygiene manufacturing selects aluminium tube packaging for its high-quality solutions and rates. It is well well-recognized mode of packaging with a tremendous safety record across the globe. In this industry, mainly collapsible or soft aluminium tube packaging are chosen for products to squeeze and get the formulation you have prepared.

Chemical Industry

Chemical industry- Picture courtesy: Jarsking

Chemicals are hard to touch, they are corrosive in nature. The aluminium tube packaging gives a high level of security to you. It is anti-leak and anti-wastage in characteristic. You can get small or exact amount of chemicals packed in it. There are various organic, inorganic, neutral salts, or various semi-solid substances packed in them such as hydrogen peroxide bases, bleaches, paints, watercolors, oil paints, etc.

Construction industry

Construction industry- Picture courtesy: montebellopkg

Almost every industry related to construction or manufacturing household items uses aluminium tube packaging for filling and packing products. This is because it gives high strength and safety and is present in various diverse sizes. So, it is not impossible to get tubes with various capacities storage options. For example, adhesives, shining pastes, cleaners, lubricants etc.

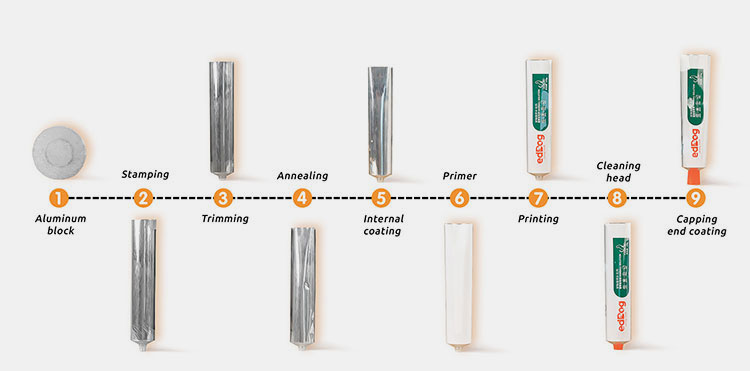

5.How aluminium tube packaging is made?

Making of aluminium tube packaging

| STEP 1: Aluminium Slug

|

You can start the process of aluminium tube packaging with aluminium blocks or slugs. These slugs are about a size of a coin. They are damp into slugging container with the incorporation of lubricating powder known as a zinc stearate. You can now close the container which keeps spinning constantly to mix the lubricant all over the slug, followed by another spinning machine that helps in the orientation of the blocks to move for the stamping process. |

| STEP 2: Stamping

|

This step is also known as a ‘forming press’ where some extent of temperature and greater force is applied over the slug to extrude the layer. This is followed by its setting into a die to mold in the form of a tube. The machine is capable of exerting the pressure up to 200 tons and the amount of slug passed through it as noticed approximately 150 per minute. Now the aligned number of tubes for the next step. |

| STEP 3: Annealing & Trimming

|

The trimming machine is meant to cut and sharpen the tube when it passes through sync rollers.

The top of the neck is trimmed with the help of stationery blades of the machine. It ultimately makes the neck of tube safe till you use. Moreover, small and thin layer of the seal is left that you can pierce before application. During the stamping some parts of the tube is indeed not in an ideal and suitable shape. Therefore, further corrections are achieved from this process. It is mainly providing heat to some extent, and it ensures that the tubes are entirely smooth and finished. After achieving the final shape, the tubes are cooled down and simultaneously sent to the next step. |

| STEP 5: Internal Coating & Primer

|

To create a barrier between aluminium and the product contact, the coating spray is applied inside the surface. It is done by using protective lacquer or primer and ensuring a promising interior. So, when you fill the tubes with a product, you will be pretty assured that your ingredients or product is stable and safe by inert nature of the inside surface. |

| STEP 6: Printing

|

Now the tubes go for cleaning, by this step, if any sticky or unwanted particle is present over the tube’s surface is removed. With the help of a printing machine. The prepared tubes are printed and improved with the application of attractive graphics and critical details along with brand name etc. |

| STEP 7: Cleaning and Capping

|

The tube surface is cleaned and secured by application of closures. All tubes are oriented and checked. The faulty tubes are sent to the rejection unit, and non-damaged tubes are now ready for filling with desirable products. |

6.What are the machines used for aluminium tube packaging?

The machine used in the aluminium tube packaging production line is detailed below:

Semi-automatic aluminium tube packaging machine

AIPAK semi automatic aluminium tube packaging machine

This is an ideal machine for you if you’re associated with small or limited batches production. The machine gives you an affordable solution to offer professional packaging. This unit is designed with hi-tech features that give you accurate filling along with sealing of the formulation without requiring so much time and energy.

You just need to position the empty tubes in the holder, remaining the task will be performed by the machine itself.

Automatic aluminium tube packaging machine

AIPAK automatic aluminium tube packaging machine

This machine is preferably selected by various large industries related to medicine, cosmetic, chemical, etc. where day to day production demands is controlled by it. The unit gives you three amazing working options including filling the formulation along with sealing, and batch embossing.

The surprising thing is that it doesn’t involve human intervention except loading of empty tubes. The machine acts as a leader to control the entire operating tasks itself. Now you can enjoy carefree working if automatic option is installed at your facility.

Cartoning machine

AIPAK aluminium tube cartoning machine

This is an automatic option without which the aluminium tube packaging process is incomplete. You can load the flat bunch of cartons or cards in the feeding magazine of the machine.

The machine is capable of picking the flat cards and folding them to form a carton of loaded specifications in. By utilizing a photoelectric eye detector, the presence of an empty carton is identified and filled aluminium tubes are position in it followed by the folding and closing of the carton.

Due to the high-tech mechanism, the machine forms the carton by utilizing the hot melt glue or can by using other ways such as spraying glue methodology. The overall, aluminium tube packaging by the end of the production line would be the same as you find on the store’s shelves.

7.What are the common aluminium tube packaging head styles?

Based on your product, its requirements to be dispensed and flowability, you can select the options for its packaging styles. We have enlisted the diverse range of head styles present in aluminium tube packaging.

| Style | Description | Image |

| Flip top | This is the commonly used and best-known standard style used for head security. It allows you to flip up and pick the formulation and flip down. So easy! You can see this style in regular uses of tubes of toothpaste, balms, lip gloss, etc. |  |

| Twisted Top | Another conventional and very popular head style for aluminium tube packaging is the twisted top. You can dispense the product on the go once you twist the cap and tear the sealing. |  |

| Dome | Most often, the aluminium tube packaging offers this style where small and smooth dome heads present a beautiful and aesthetic appearance to your product. Various cosmetic and personal care products are today facilitated with dome head styles. |  |

| Lotion pump style | This is a very handy and user-friendly style where you can flip off the cap and press the pump to get your product. For example, various topical creams, lotions, gels, etc. are acquired with this head style. |  |

| Spray style | They are also known as an atomizer head, which produces aerosol molecules upon pressing the head. This is a luxury style allowing you to enjoy formulation in a greater pressure from its nozzle best fit in aluminium tube packaging. |  |

| Pinpoint | Various tubes used for dispensing of ophthalmic preparation available in gels, pastes, ointment form are packed in pinpoint heads that ensure precise and accurate quantity of product when you need. |  |

8.What are products filled with aluminium tube packaging?

There are unlimited products that are packed by using these options. However, we can’t discuss all of them. Nonetheless, we have highlighted some very important and popular formulation that use regularly implemented aluminium tube packaging.

Toothpastes

Toothpaste- Picture courtesy: Colgate

This is the product that starts your day. You just squeeze a little and freshness releases in the form of paste. They are packed with high confidence in aluminium tube packaging that ensures toothpaste are preserved longer and offers you potent properties. This is included with herbal toothpastes, ayurvedic toothpastes, etc. where herbal and potent extracts are combined to produce therapeutic effects.

Pain relief tubes

Pain relieving tubes- Picture courtesy: montebellopkg

The pain or body aches are mainly deal with painkiller topical formulation. This is mainly used to relieve your discomfort. The aluminium tube packaging in this case not only acts as your bodyguard but ensures simple and easy application.

Ointments

Aluminium ointment tube packaging

Whether medicated or non-medicated, the basic category of the ointment products is mainly filled in aluminium tube packaging. This is included with products related to skin related ailments such as dermatitis, burns, infections, and wounds. This packaging acts as a solution to give a stable and potent medicine.

Hair dye tubes

Hair colors

You can’t ignore aluminium tube packaging when it comes to getting accurate concentration of hair dyes. The high barrier properties let it allow you to store sensitive and delicate hair dyes in an airtight packaging seal.

Creams

Cream

When it comes to talk about medicated creams, they are mainly designed to treat problems like eczema, and fungal problems, producing soothing effects to your skin. These are often present in aluminium tube packaging. Similarly in this way, various creams used for beauty purposes are formulated in a way that must be packed in an air-tight packaging are also maintained in them till the end user.

Gels

Gel- Picture courtesy: NSI Australia

There are many types of gel formulations are significantly packed in aluminium tube packaging to produce rapid application wherever it is required. It is also included with skincare gels such as retinol gel, dark circle removing gels, etc. However, various ophthalmic gels are also packed in using the same mode and materials of packaging across the globe.

Condiments and sauces

Condiments and sauces- Picture courtesy: Tubettificio Perfektüp

This is one of the advanced ways of meeting your demand by packaging food products like tomato ketchups, mayonnaise, butter, creams, mustard paste, etc. in the form of aluminium tube packaging. It is considered a highly concerning mode of packaging as it practically benefits sectors like air travel, hotels, hospitals, and homes.

9.What is the expiry of aluminium tube packaging?

The expiry date of aluminium tube packaging- Picture courtesy: EPL Packaging

The aluminium tube, itself does not have any shelf life. It has high durability and long-lasting effects. Therefore, nothing can break or melt its surface. Yes, the materials packed in it are considered as so safe and it offers a high shelf life which is based on type to type and properties of the formulation.

For instance, if you store food products in them, its shelf life would be different. Many food products range with a shelf life of 1 to 2 years. This means, that if you store your food items in aluminium tubes packaging, it promises you to offer shelf life and preservation of food till 24 months.

However, in the case of cosmetics, the scenario would be changed. If you store creams, gels, masks, etc. They are mainly stable for 2 to 3 years or more. It is all depending upon your storing conditions. However, the packaging itself gives you anti-moisture, anti-UV, and anti-microbial protection that is absolutely safe for your products.

In the case of chemicals or products related to oral or personal hygiene, the aluminium tube packaging shelf life is observed even more. It is noticed that your product under a controlled or favorable environment is stable for 3 to 4 years.

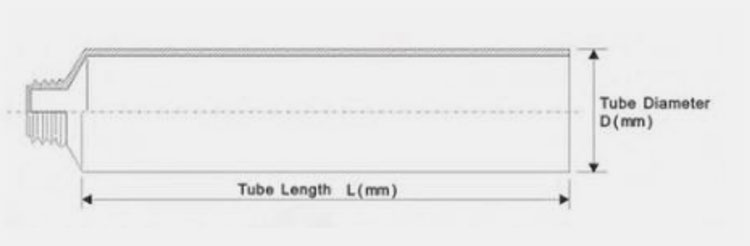

10.What are the sizes used for aluminium tube packaging?

Aluminium tube packaging sizes- Picture courtesy: perfeckup

| Diameter(mm)

Length (mm) Capacity (ml) |

Size of round tube | |||||||||||

| 13 Ø | 16 Ø | 19 Ø | 22 Ø | 25 Ø | 30 Ø | 35 Ø | 38

Ø |

40 Ø | 45 Ø | 50 Ø | 60 Ø | |

| 3 ml | 45 | |||||||||||

| 5 ml | 61 | 45 | 40 | |||||||||

| 10 ml | 73 | 55 | 48 | |||||||||

| 15 ml | 101 | 75 | 65 | 55 | ||||||||

| 20 ml | 95 | 81 | 67 | |||||||||

| 25 ml | 115 | 95 | 78 | 65 | ||||||||

| 30 ml | 108 | 89 | 74 | |||||||||

| 35 ml | 122 | 100 | 81 | |||||||||

| 40 ml | 110 | 88 | 71 | |||||||||

| 45 ml | 120 | 96 | 77 | |||||||||

| 50 ml | 130 | 105 | 82 | 78 | ||||||||

| 60 ml | 120 | 95 | 88 | 85 | ||||||||

| 70 ml | 110 | 98 | 93 | |||||||||

| 80 ml | 120 | 109 | 103 | 86 | ||||||||

| 90 ml | 130 | 117 | 112 | 94 | ||||||||

| 100 ml | 142 | 127 | 120 | 105 | ||||||||

| 120 ml | 147 | 140 | 124 | 101 | ||||||||

| 150 ml | 166 | 140 | 121 | |||||||||

| 180 ml | 166 | 159 | 138 | 111 | ||||||||

| 200 ml | 173 | 148 | 120 | |||||||||

| 220 ml | 160 | 131 | ||||||||||

| 240 ml | 170 | 141 | ||||||||||

| 250 ml | 175 | 146 | ||||||||||

| 300 ml | 165 | |||||||||||

| 350 ml | 185 | |||||||||||

| 400 ml | 210 | |||||||||||

The aluminium tube packaging size chart courtesy: Auber cosmetic tube solution

The above chart illustrates the size of aluminium tubes including their sealing width. This is the most used size chart that is depending on the size and number of materials can be packed. The larger the diameter, more would be ideal space to accommodate your formulation.

The small size aluminium tubes are mainly used for storing small and concentrated products such as adhesives, serums etc. The larger diameters are mainly considered with a range of 25 mm to 35 mm and are mainly used in food, pharma, and cosmetic applications.

11.Is aluminium tube packaging contributing to sustainability? How are they recycled?

Sustainability- Picture courtesy: somewang

Indeed yes, the aluminium tube packaging is significantly known as an ecofriendly substance. Therefore, it is mostly known that the primary and first choice of many manufacturers. See below how they contribute to sustainability.

| Collection | In various regions of the world, aluminium tubes are gathered or collected in specified location, and this can be achieved by a recycling campaign. Once collected the unwanted materials are removed. |

| Cleaning | The aluminium tubes are ground and turned to small pieces that will help and eases the melting process. |

| Melting | The small particles of aluminium are now heated and melted by utilization of high temperatures. In this phase, the molten materials are cleaned again by passing through molds and dies to eliminate unwanted residues or particles present and turned back to old shape. For instance, aluminium block, slug, etc. |

| Ready to form a new product | Now aluminium is ready to reuse and in this way to not only conserves energy, and materials, but also promotes sustainability. |

12.What are the issues that affect the formation of aluminium tube packaging?

The aluminium tube packaging is a beautiful and interesting thing! It is all about the game of your mind and machines to craft your thoughts into reality. But there are some commonly happening issues that can suddenly drip the flow of the production line. We know, this can be so annoying. Let’s discuss the commonly happening problems with solutions.

Spillage and Leakage

Aluminium tube packaging testing- picture courtesy: packtest

This problem is like anyone can expect. Your packaging can face this issue anytime and anywhere. The real goal is to deal with it to avoid and fix the issue by identifying the main culprit.

Solution

There might be an overflow of the formulation in the tubes. Therefore, the filling nozzles start leaking the product. Moreover, it is suggested that the product must be filled optimizing the setting of tube size with your machine. Moreover, we would recommend passing your tubes for quality check where certain tests such as the leak test which is known as the ‘tube burst test’ will ensure that your aluminium tube packaging is great and will resist to pressure for a long time.

Inaccurate packaging

Inaccurate packaging

For every manufacturer, the inaccuracy, or inconsistency is nothing but a nightmare. Your tubes are filled with inaccurate levels of the product that could directly lead to the withdrawal of entire batches.

Solution

There could be three reasons, and these reasons are easy to tackle. First of all, you can assess the viscosity of the materials to be filled in the tubes. By knowing the option, you can pick the right type of filler machine. For example, piston filler, pressure filler, gravity filler, etc. all are based on your product needs and its flowability.

Secondly, check and calibrate the machine setting. This could be the main reason most of the time which causes inconsistencies. Thirdly, checking the obstruction in the filling nozzle, or associated parts of the unit, side by side with daily maintenance can be helpful in eliminating these issues and ensuring smooth operation.

Poor Sealing

Aluminium tube sealing- picture courtesy: the whole packaging

The aluminium tube packaging sealing can be weakened sometimes, and it not only causes the product loss but also affects your brand image.

Solution

Just don’t worry in this case, it mostly happens if the machine settings are not properly adjusted. That’s why we mostly suggest that to run a test before going for final production. Check the sealers or sealing bars' temperature.

Sometimes, too much high temperatures can get you in trouble by weakening the sealing bond between the layer of aluminium tubes. The most common suggested sealing temperature lies approximately 160 °C which melts the layer and is folded and crimped by using the machine that ensures that sealing is promisingly done.

13.How to get an ideal aluminium tube packaging?

When it comes to getting an ideal aluminium tube packaging, you should look for certain factors that directly impacts on the production.

Understand your formulation

Formulation

The aluminium tube packaging comes in a variety of styles, and each of them offers you certain specifications and packaging benefits. It is all dependent on your formulation types. For example, flip-up top of the aluminium tube packaging is highly ideal if your product is regularly used and needs fast application, and so on. Therefore, understanding your formulation texture and types would be the first and foremost step to getting an ideal option.

Embrace your packaging with vibrant prints

Innovative prints- Picture courtesy: Three bamboo

We all love to get products with beautiful prints and packaging. Why not choose this option to improve and boost your product? Today, digital graphics and prints are quite revolutionized and give you tremendous and fast results. So go for it when it comes to labelling your aluminium tube packaging. This technology indeed gives an appearance without extra expenditure.

Size selection of packaging

Aluminium tube sizes- Picture courtesy: Montebello packaging

Determine the volume, production size, and dimensions you need that fulfil the packaging requirements of our formulation. This may be does not count in aesthetics but yes it gives great quality value to your brand. For small and delicate formulations, mostly smaller tubes are used for large formulations such as masks, and adhesives, comparatively larger sizes are recommended. See above our most commonly used sizes in aluminium tube packaging.

Conclusion

After reading the article on ‘aluminium tube packaging’, now you will be able to distinguish the primary factors related to aluminium tube packaging. It includes with types, styles, manufacturing, filling, and so on. Remember, choosing the right machine and determining your needs can all together bring an ideal result. This mode of packaging not only offers formulation integrity but also ensuring anti-tampering properties. Looking for a solution that gives you efficient and packaging meant for boosting your business? Do contact our team now! You will be served with friendly and fruitful guidance related to your project and supporting a series of machines in an affordable price range.

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide