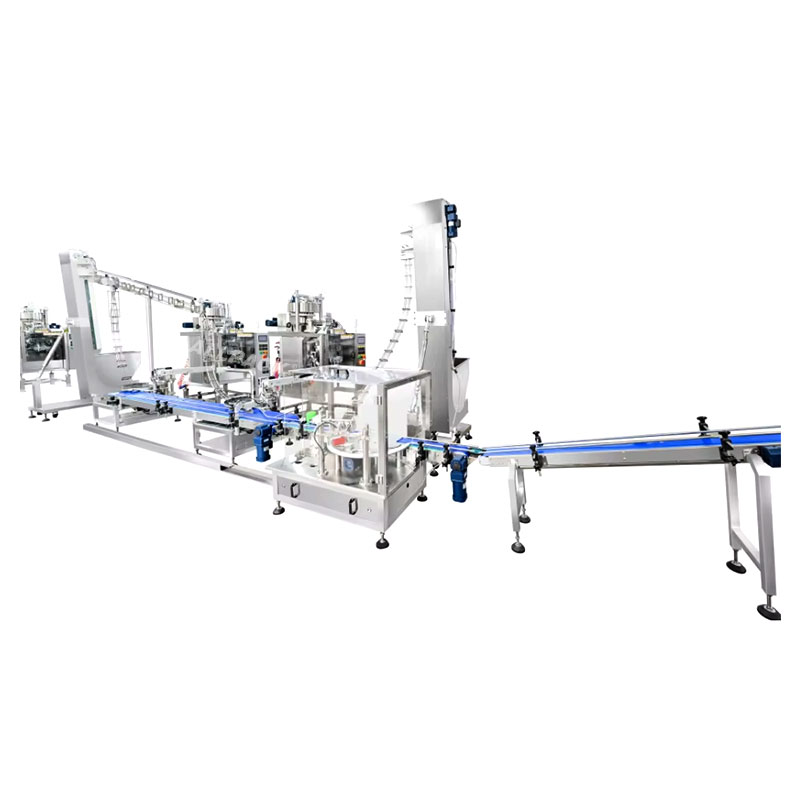

10-Lanes Feibin Mouth Tobacco Pouch Snus Packing Machine Production Line

ALLPACK 10-lanes snus packing machine automatic production line can complete the production processes of snus packaging, canning, capping, round bottle labeling,flat labeling, coding, etc., saving labor costs. The whole production line has the functions of self-diagnosis and fault prompt. With PLC intelligent control, stable operation, adjustable speed, parameter setting via touch screen, support for multiple languages, simple operation.All the parts in contact with materials are made of stainless steel and non-toxic and corrosion-resistant plastic, which meets the requirements of equipment and food packaging. ALLPACK could provide a variety of customized solutions, adapt to more supporting machines, and improve production efficiency.

10-Lanes Feibin Mouth Tobacco Pouch Snus Packing Machine Production Line Features:

1.Utilizes segmented chute feeders and dual-stage differential conveyor belt mechanisms to seamlessly integrate with10-lanes machines while optimizing bag spacing.

2.Equipped with a high-precislon light curtain counting system capable of detecting and accommodating any bag drop orientation, ensuring precise box packing regardless of bag quantity.

3.Features a box bottom vibration leveling system with adjustable amplitude for optimal box presentation.

4.Employs a fixed-point stop servo turntable mechanism, complemented by pre-pressing and arranging cylinder functions, to deliver uniformly packed boxes with exceptional consistency.

5.Includes an automatic box erector renowned for its swift box forming capabilities, offering versatile 1-to-2 box supply configurations tailored to production line requirements.

6.Adopts a large-angle ramp-type box erection system designed to automatically reject misaligned boxes, ensuring product integrity and operational efficiency.

7.Incorporates wire chute-style box delivery with integrated photoelectric no-box detection and programmable automatic box replenishment features for seamless operation.

8.Each rotary counting box packing machine can function independently and seamlessly integrate with 2 sets of box erectors), facilitating the establishment of a high-efficiency 4-to-1 production line.

9.Features a shared conveyor belt system designed to support parallel production lines, with integrated photoelectric detection and pneumatic box-stopping mechanisms to prevent production interruptions due to box jams.

10-Lanes Feibin Mouth Tobacco Pouch Snus Packing Machine Production Line Technical Specification:

| Machine Type: | Rotary Counting Box Packing Machine+Box Loading Machine(1-to-2)+Shared Conveyor Belt |

| Applicable Box Type: | Round shape(plastic material) |

| Box Size: | TBD-As per sample box(suggested size:OD-70mm) |

| Box Height: | TBD-As per sample box(suggested size:H-20mm) |

| Packaging Product: | SmallBack Seal Bags |

| Filling Method: | Light Curtain Counting and Filling |

| Packing Quantity: | 10-20 bags/box |

| Production Speed: | ≥18 boxes/min |

| Leveling Method: | Vibrating filling and station cylinder pressure bag |

| Hopper Volume for Box Loader: | ≥200 boxes |

| Box Sorting Method: | Inclined chain plate conveyor for elevation and reverse lid rejection |

| Box Conveying Method: | Guided chute for sliding onto the turntable box loading station;suitable for 1-to-2 production lines |

| Air Pressure and Consumption: | Box Packing machine:0.6Mpa,0.1m3/minute/machine、Box loading machine:0.6Mpa, 0.1m3/minute、Shared Conveyor Belt:0.6Mpa,0.1m3/minute |

| Power: | Box Packing machine:220V/50Hz,0.6Kw/machine、Box loading machine:220V/50Hz,0.2Kw、Shared Conveyor Belt:220V/50Hz,0.4Kw |

Snus Packing Machine Related Products