Find Your Efficient Gummy Packaging Machine Here

- Fast And Accurate Counting

- Easy Use And Change-over

- No Gummy Blockage At The Funnel

Allpack Gummy Packaging Machine

Allpack gummy packaging machine is mainly composed of a bag-feeding fully-automatic packaging machine and a screw scale. It has a wide range of packaging and can package liquids, powders, granules, and solid materials. It only needs to choose different metering and filling according to different materials. Through multiple stations, a series of actions such as opening, printing, filling and sealing of the packaging bag are completed. The gummy packaging machine can check there is no packing article or wrapping bag not to open, make sure the filling device and hot sealing device no work(option), this avoid wasting packing materials and raw materials.

Gummy Packaging Machine

Automatic Multi-head Weigher Gummy Jelly Candy Premade Pouch Packaging Machine

Allpack automatic multi-head weigher gummy packaging machine adopts precision indexing device and PLC to control each action and working station to make sure the machine operates easily and does accurately. The speed of this machine is adjusted by frequency conversion with the range, and the actual speed depends on type of products and pouch. Automatic checking system can check bag situation, filling and sealing situation. The system shows 1.no bag feeding, no filling and no sealing. 2.no bag opening/opening error, no filling and no sealing 3.no filling, no sealing.

Wide application : various shapes, state and nature of products

Easy to operate: PLC controller

HMI system, fault indication on the touch screen

High Speed Automatic Zipper Bag Premade Doypack Rotary Gummy Packaging Machine

Allpack high-speed zipper bag premade doypack gummy packaging machine can be used for premade bag, stand-up bag with or without zipper. It is suitable for weighing grain, stick, slice, globose, irregular shape products such as candy, chocolate, jelly, pasta, melon seeds, roasted seeds, peanuts, pistachios, almonds, cashews, nuts, coffee bean, chips ,raisins,plum, cereals and other leisure foods, pet food, puffed food, vegetable, dehydrated vegetables ,fruits, sea food, frozen food, small hardware, etc. The gummy packaging machine adopts Z Shape bucket elevator / incline conveyor to raise material to multi weigher which controls the start and stop of the hoister.

No pouch/ incorrect pouch opening-no fill-no seal, machine alarm.

Machine will show alarm and stop when inadequate air pressure.

Safety guards with safety-switches, machine alarm and stop

The Buyer's Guide

Gummy Packaging Machine: The Complete Buying Guide In 2025

While gummies are consumed as delectable confectionery and gummy supplements, packaging is also very important to enhance their security against environmental elements and retain their original quality. However, the packaging must be done keeping in mind their sensitivity and texture. Do you agree? If yes! Then what about a Gummy Packaging Machine? Isn't it a perfect solution to carry out this task? Of course it is!

Gummy packaging machine is a flexible solution that come up with diverse features to pack gummies into beautiful packages. With user-friendly operation method and simple maintenance, it provides ease throughout packaging. You can make best use of it after understanding its importance, structure, and uses. So, let's begin reading it!

1.Define A Gummy Packaging Machine?

Allpack- Automatic Multi-head Weigher Gummy Jelly Candy Premade Pouch Packaging Machine

Gummy packaging machine can be defined as a durable and automated machine that efficiently pack various types of gummies into beautiful packages. These packages encompass pouches, bags, and containers like jars and bottles.

The machine has hygienic body which is made up of stainless steel. Together with precision and intelligence, it packs the exact number of gummies into packages, retaining their quality and shelf life. It uses different techniques such as weighing and counting to deal with the number of gummies and reduce errors. Moreover, it can also be customized to make packaging more appealing through sealing and cutting etc.

2.What Are The Advantages Of A Gummy Packaging Machine?

Gummy packaging machine is such an important equipment that if not used can ruin the taste, texture, and color of produced gummies. However, no manufacturer would ever want to dare this horrible challenge! So, it is clear that packaging is obligatory for gummies but what are the advantages of gummies packaging machine? You will find them in below explanation:

Enhanced Protection

Enhanced safety of gummy packaging machine- Aipak

The foremost advantage of a gummy packaging machine is that it is made up of GMP's recommended 304 stainless steel body which is antibacterial and corrosion resistant. Due to this reason, the quality of gummies is retained throughout packaging step.

Strong Sealing

Tightly sealed transparent gummy pouch- Picture Courtesy: freepik.com

Another significance of the machine is its capability to create strong and tamper proof sealing during gummy packaging. It thus protects the gummies from bacteria, humidity, and contamination. The result is increased shelf life with same aroma upon first opening of the package.

Uniformity & Consistency

Gummy uniform weighing- Picture Courtesy: paxiom.com

Gummy manufacturers often struggle with inconsistency in volume of gummies as under or overweight during packaging. It leads to customer dissatisfaction as well as profit minimization. Thus, to end this fluctuation, a gummy packaging machine is best suitable to maintain uniformity in gummy volume.

High Automation

Automation is among other major concerns for large scale producers because of the time waste and errors caused by manual work. Now, it is only possible with an advanced and latest technology equipment like gummy packaging machine which can pack thousands of gummies just in an hour.

Improved Customization

Various sizes of gummies- Picture Courtesy: Freepik

Well, packaging is the first thing that attract consumers and indeed it must be as attractive and appealing as possible. With gummy packaging machine, you can modify the shape, size, and design of packaging as you want. Thus, it highlights the machine's feature of being highly flexible.

3.What Type Of Gummies Can Be Packed By A Gummy Packaging Machine?

When it comes to discuss the types of gummies which can be packed by using a gummy packaging machine, so, almost all kinds are eligible. Below you will know about some of the prominent ones:

Gummy Snacks

Allpack- Gummy snacks packaging in pouches

The term gummy snacks denotes gummy confectionery which we consume for fun like after meal, in parties, and outdoor gathering etc. These gummies are made with normal ingredients, thus, can go with any packaging. That's why flexible pouches and doypack are often used. The common examples include gummy bears, gummy teeth, and gummy worms etc.

Gummy Vitamins

Gummies for hair vitamin- Picture Courtesy: eu.womensbest.com

Gummy vitamins refer to nutritional gummies which contain essential vitamins, minerals, and nutrients. They are used to fill nutritional gaps such as taking for calcium, collagen, and nutrients. The common examples include beauty gummies, vitamin C gummies, and gummy multivitamin.

Medicated Gummies

Doctor smiling alongside certified medicated hemp gummies bottle- Picture Courtesy: australianews.clubeo.com

Medicated gummies are derived from plants and herbal sources. They do have therapeutic effects such as detoxifying body, stabilizing sleep routine, and managing depression and anxiety. This category include CBD gummies, THC gummies, and herbal gummies which require durable packaging like bottles and cans.

Gummy Supplements

Gummy supplement bottle

Gummy supplements is a form of gummy vitamins which are used for boosting immunity and assisting digestive health etc. Hence, they may also be packed by using a gummy packaging machine.

Various Sizes of Gummies

Small & large size gummy bears- Picture Courtesy: allcitycandy.com

It is not the case that a gummy packaging machine can only deal with single size of gummies, rather you can pack gummies of various sizes such as regular gummies (0.13 oz), big gummies (2.3 oz), and giant gummies (0.5 LBS).

4.Explain The Working Principles Of A Gummy Packaging Machine?

If you want to get benefited from a gummy packaging machine, it is necessary to operate it on right working principles. For this, we have explained the process of the machine which will surely help you in clear understanding. These are as follows:

Machine Loading

Gummy loading into hopper- Picture Courtesy: samfull.net

It is the first stage where machine is supposed to be loaded with material. It includes feeding the hopper of machine with bulk of gummies as well as supplying packaging material like film or pouches. The machine may also be attached with a feeding system for non-stop automatic loading throughout packaging process.

Machine Setting

The second stage involves setting machine which is important for operation. Here, the user will fix amount of gummies to be packed in each package along with sealing heat, and printing data etc. This parameters setting is carried out via touch screen interface, while as, the structural adjustment is also must in order to make the machine ready for work such as fixing sealing jaws and cutter.

Gummy Measuring

Gummy weighing- Picture Courtesy: samfull.net

Moving forward, the machine is now ready to be started for gummy packaging. At this point, packages are prepared through forming and at the same time gummies are measured either through weighing or counting. The weighed gummies are then stored in compartment for their filling into packages.

Gummy Filling

Gummy filling into pouches- Picture Courtesy: samfull.net

During this phase, the packages are opened on one hand, while as, the measured gummies are deposited from compartment into packages on the other. Similarly, one by one the packages are filled and moved ahead for sealing.

Package Sealing

Pouch sealing- Picture Courtesy: samfull.net

Now, the filled bags are tightly sealed through application of force and heat, so, the air and moisture cannot enter into packages.

Package Discharging

Package discharging- Picture Courtesy: samfull.net

At the end, sealed packages are separated from each other through cutting and discharged from the machine through conveyor.

5.Enlist The Integral Components Of A Gummy Packaging Machine?

Gummy packaging machine is made up of several components such as:

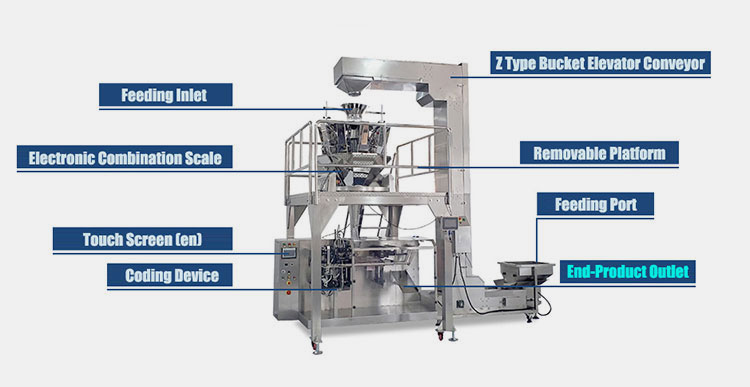

Components of gummy packaging machine- Picture Courtesy: gummymakingmachine.com

Feeding Inlet

Feeding inlet is an area which is located on the top side of machine especially in case of multi head weigher. Here, bulk gummies are poured during operation through which these gummies are further processed for measuring.

Z Type Bucket Elevator Conveyor

This special type of conveyor is highly durable and fully enclosed. It can carry large number of gummies during packaging to supply the machine throughout operation.

Electronic Combination Scale

This device works excellently to measure the exact volume and number of gummies by scaling in order to prevent error and attain precision.

Touch Screen

Gummy packaging machine has a touch screen panel which is easy to use. This operation panel has user friendly features to get done with the setting of machine for its smooth operation.

Coding Device

It is a printing device used to print data over packages which include manufacturing date, expiry date, batch no, and price etc.

Removable Platform

Removable platform is a frame that offers safety to user and stability to machine.

Feeding Port

Feeding port is another name for hopper. Here bulk of gummies are loaded at once from where they are moved towards machine for packaging through conveyor.

End Product Outlet

Gummy packaging machine also has discharge unit which is known as end product outlet. Finished packages are discharged through this section.

6.What Is The Classification Of A Gummy Packaging Machine?

Gummy packaging machines are of different types. These are explained below in detail:

Form, Fill & Seal Gummy Packaging Machine

High Speed Gummy Sachet Packaging Machine (VFFS Form Fill Seal)- Picture Courtesy: samfull.net

Form, fill, and seal gummy packaging machine is a proficient equipment tailored with amazing features to carry out the packaging of sachets. It is multifunctional as it forms the bags from rolled film, fill these bags with precisely weighed gummies, and create tight sealing. The machine has vertical structure and can be integrated with other machines for extended packaging.

Premade Pouch Gummy Packaging Machine

Allpack- Automatic Multi-head Weigher Gummy Jelly Candy Premade Pouch Packaging Machine

This is another important type of gummy packaging machine with exceptional efficiency level as the time spent on forming bags is eliminated. It can perfectly undertake the gummy packaging process by taking empty pouches from hopper and undergoing them through various stages of opening, filling, coding, and sealing etc. Moreover, it has compact body made up of stainless steel.

Bottle/ Jar Gummy Packaging Machine

Allpack- APC-16 High speed tablet capsule counting machine

Bottle or jar gummy packaging machine is a specialized machine used for packing gummies into rigid containers. It can pack various sizes and shapes of bottles with gummies. The machine has simple operation that starts with gummies counting, bottles detection, and gummies filling. This equipment can be used in production line with capping machine, induction sealer, and labeling machine. It is frequently used for gummy vitamins, supplements, and therapeutic gummies for their extra safety requirements.

7.In Which Industries A Gummy Packaging Machine Can Be Used?

As gummy packaging machine is used for packing gummies into different types of packages, it may be used in various industries with production of similar size products. These are as follows:

Snack Food Industry

Multiple snack food in bowls- Picture Courtesy: snackhousefoods.com

It refers to the industry where premade food like cake, cookies, candies, and gummies are made. So, after the production phase of such goods, packaging is considered the most critical task for which machine like gummy packaging machine is ideal solution.

Medical Industry

Various tablets & capsules- Picture Courtesy: bestinnature.com

This sector deals with the manufacturing and processing of drugs and other supplies encompassing tablets, capsules, suppositories, and oral strips etc. Not only this, but now medicated gummies are also made here. Hence, all these items needs to be hygienically packed by using a quality machine like gummy packaging machine.

Pet Food Industry

Various pets- Picture Courtesy: brunswick.ces.ncsu.edu

People like to own pets for companionship and loyalty among many reasons. So, they also take interest in feeding them with proper food which is why pet food industry can now be seen as separate industry where pet treats, pellets, and other food is made. For their durable packaging, gummy packaging machine is a perfect choice.

Cosmetic Industry

Multicolor & multipurpose beauty softgel essence in bottles

The machine may also be used in cosmetic industry for the packaging of softgel essence, beauty gummies, blusher balls, and cosmetic cotton balls. Hence, cosmetic industry is among other applications of a gummy packaging machine.

Stationary Industry

Various stationary items- Picture Courtesy: stationers.pk

Stationary items like eraser, sharpener, clips, and beats etc., are among the common stationary tools which are packed in bags and containers. Similarly, a gummy packaging machine become eligible in this industry.

8.How To Determine The Quality Of A Gummy Packaging Machine?

The quality of a gummy packaging machine can be checked by looking into its compliance with international quality standards. These include:

vietnamcleanroom.com

International Organization for Standardization (ISO)

ISO is a global organization that establishes rules for products safety. The common standards by ISO include Quality Management System ISO 9001, Environmental management ISO 1400, and Food safety ISO 22000.

Food and Drugs Administration (FDA)

FDA is USA based agency formed for regulating safety of drugs, food products, and the related machines. Thus, it is necessary for a gummy packaging machine.

Current Good Manufacturing Practices (cGMP)

Current good manufacturing practices represents special principles for machines such as their material of construction and the machine's adherence to current good manufacturing practices.

Conformate European (CE)

Gummy packaging machine made or sold in European countries must be certified by CE as it represents the region's collective security concerns for manufacturing.

9.What Is The Maintenance Requirement Of A Gummy Packaging Machine?

It is always necessary to take care of your gummy packaging machine as frequently as possible. In this way, below tips will help you know the maintenance requirements of the machine and how you can achieve them. So, let's begin!

Lubrication of movable parts- Picture Courtesy: allworldmachinery.com

Cleaning: Clean the machine everyday after daily work is done. For this, use recommended detergent for washable parts and low-pressure compressed air for the removal of debris and residues from undetachable parts. For touch screen, you may use a damp cloth.

Lubrication:lubrication is also very important to eliminate the possibility of friction that may hinder machine working. However, keep in mind to remove out old lubrication oil and use compatible one.

Upgradation:Do not forget to upgrade your gummy packaging machine as it also needs adjustment with time. The common example include parts changeover and system update.

10.How To Solve The Common Problems Of A Gummy Packaging Machine?

Despite that the gummy packaging machine is a significant component of the packaging industry that ensures you with a mass packaging of the gummies, it sometimes also encounters undesirable issues. This ultimately affects your workflow and of course productivity. To run smoothly, we have mentioned the particular and common problems with their possible solutions.

Machine Jamming

Machine jamming presentation idea- Picture Courtesy: richpacking020.com

Whether it is gummy making machine or a packaging machine, after certain periods of time, you start observing obstructions in its working.

Solution

Yes, this is a frequent issue and one of the important reasons behind is the sticky nature of gummies. With time, gummy residues build a clogging layer over the surface and cause the jamming problem. This can be cleared by regular cleaning of the machine surface and contacting gummies during packaging.

Align and calibrate the machine to ensure smooth working without interruption. Keep monitoring factors such as temperature, and lubricants to minimize the chances of blocking.

Inaccurate Packaging of Gummies

Highlighting inaccurate gummy packaging- Picture Courtesy: dribbble.com

The variation in gummy numbers inside the packaging is the main concern in the packaging section. In this problem, you observe inaccuracies in the gummies concentration and it directly affects the brand identity and market value.

Solution

Check the sensor of the machine if it is ignored for a longer time. Just calibrate the machine and observe the reading by assessing the test run. Check the speed of packaging, it should not be too high which makes gummies overlap, and the sensor can’t distinguish due to high velocity.

Machine Overheating Problem

Overheating icon- Picture Courtesy: thegarageba.com

For every machine, this is an alarming sign where excessive heat can affect the performance of the unit with more chances of impairment.

Solution

To solve these issues, check if the cooling or exhaust of the unit is working correctly. Evaluate the cause of heating, there are major possibilities of not allowing rest time to your unit, if it is used excessively for a longer time without intermittent breaks could be the reason for overheat. Keep maintaining the machine regularly and replace damaged parts with new ones to ensure a satisfactory response.

11.Factors To Look For When Buying A Gummy Packaging Machine?

If you are planning to buy a gummy packaging machine for your business, it is important to spend some time in knowing about the best machine. Interestingly, this significant aspect is associated with you to consider some factors which include:

Type of Packaging

Gummy packaging types- Picture Courtesy: theedgyveg.com

First, you need to understand the type of packaging you want to go with. For instance, whether you like to use flexible packages for gummy packaging or containers and bottles. In any case, the machine will be different as both packaging require totally different methods for handling.

Machine Specifications

Gummy counting during packaging- Picture Courtesy: bellatrx.com

Another aspect to look for is the specifications of machine such as its production capacity per hour and adaptability to support different sizes and design of packages. Once you have known your requirements, it will be easy for you to choose the best compatible machine.

Cost

Cost presented with coins- Picture Courtesy: annectolegal.co.uk

Make sure to estimate the overall cost of machine along with auxiliary equipment. It will help you know the operation charges, so, you will be able to choose the machine that suits your pocket.

Supplier Reputation

The supplier reputation is also crucial to have knowledge about such as the warranty policy, experience in the field, and after-sale service etc.

Conclusion

To sum up, this buying guide about Gummy Packaging Machine explain about the machine's importance, uses, working, and overall structure. Understanding these aspects can help you take advantage of this machine which can not only be used for gummies but range of other essentials. In addition, efficiency and hygiene are also very important for which a gummy packaging machine is best example. So, if you are interested in purchasing a new gummy packaging machine from experienced and trustable supplier then do contact us. We will response you ASAP! For further information do visit our website!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp:+86 18171018586