Industrial Leading Gummy Making Machine Manufacturer

Allpack Gummy Making Machine

Allpack could offer you with all kinds of gummy making machines of small, medium, large scale to meet your various production requirements. It is the ideal equipment for food & beverage factories, shops, and other industries requiring large quantities of gummy candy. All Allpack gummy making machines are designed with multi-function feature, allowing for the production of various types of gummy candies with different raw materials, including gelatin, pectin, and carrageenan.The machine features high-quality core components, including Siemens-ABB motors, PLC, engine, bearing, and gearbox, ensuring a long lifespan and minimal maintenance requirements.

Gummy Making Machine

APK-GM80Q Small Scale Gummy Making Machine Vitamin Gummy Jelly Candy Making Machine

Allpack APK-GM80Q small scale gummy making machine is an Ideal equipment for continuous production of high-grade soft candy and functional vitamin gummy candy. The gummy bear machine can produce high-quality single-color, double-color fondant, gel fondant, carrageenan fondant, pectin fondant, etc.; It can also produce high-quality, multi-shape, multi-color curds by changing molds or pouring heads. gummy candy. The gummy manufacturing equipment can realize the quantitative filling and mixing of flavor, pigment and acid solution. It has good stability, can ensure the quality and output of candy in a long-term production process, and can save manpower and reduce production costs.

Stable and reliable automatic rod insertion device

Hygienic design, compact structure and reliable performance

PLC to control the vacuum sugar transfer and pouring program

APK-GM150Q Medium Scale Gummy Making Machine High Quality Jelly Candy Depositing Line

Allpack APK-GM150Q medium scale gummy making machine is simple structure in linear type ,easy in installation and maintain. Adopting advanced world famous brand components in pneumatic parts ,electric parts and operation parts, can make pure candy, double color candy, center filling candy and gummy bear candy. This gummy manufacturing manufacturing line mainly consists of Jacket cooker, storage tank,weighing and mixing system,depositor and cooling machine and adopt the advanced servo system to control. It is is not only an ideal equipment which can produce products of good quality ,but also an advantage for the candy manufacturer to pass the GMP,HACCP,QS authentication easily.

Simple structure in linear type ,easy in installation and maintain.

Adopting advanced world famous brand components in pneumatic,electric, operation parts

High pressure double crank to control the die opening and closing

APK-GM300Q Large Scale Gummy Making Machine Pectin Gelatin Gummy Production Line

Allpack APK-GM300Q large scale gummy making machine is Suitable for gummy/vitamin C functional gummy/gummy with special powder ingredient, can replace molds on same machine to produce different shapes, sizes, colors, or center filling gummy. It is the best production line for production of gelatin, pectin, agar, carrageenan based gummy. The depositing machine is made of 304 stainless steel, which is healthy and safe. The operation is simple and convenient. When using the device, be careful not to touch the hopper to prevent burns. The equipment has functions such as oil spray, brush, and air blowing, which helps to better release the candy from the mold.

High-degree automation

Stable production and saves time and labor force

Driven by servo motors and controlled by motion controller

APK-GM600Q Large Scale Gummy Making Machine Jelly Gummy Candy Bean Depositing Line

Allpack APK-GM600Q large scale gummy making machine can be used to produce various styles of candy and a variety of formulas and shapes of candy, including soft candy, hard candy, toffee sugar, jelly gummy candy, chocolate and so on. It is widely used in small output candy production line, laboratory candy forming processing equipment. Features Multi-purpose, suitable for pouring hard candy, soft candy, toffee and all kinds of pouring shaped candies. Compact shape, compact structure, stable performance, easy control. The depositing quantity can be selected, the running speed can be adjusted according to the need. The working power of this machine is compressed air, and the whole working environment is clean and hygienic, which meets the production requirements of food hygiene.

PLC automatic control

High accuracy fabrication technology for deposit piston and copper

Stable running with low noise and long life

The Buyer's Guide

Gummy Making Machine: The Complete Buying Guide In 2025

The allures of gummies are irresistible due to their enticing colors, flavors, and attractive shapes. This is the reason why gummy manufacturers are trying to expand their sphere of production which is only possible with the use of advanced equipment. In this way, Gummy Making Machine is a notable equipment that can efficiently produce large number of gummies.

In this guide, we will introduce you to this sophisticated machine by exploring its specifications, working principles, components, and applications etc. In addition to it, how the machine can be maintained, and the common problems can be solved, everything will be discussed. So, stay tuned and keep reading!

1.What Is A Gummy Making Machine?

APK-GM150Q Medium Scale Gummy Making Machine

Gummy making machine can be defined as an equipment designed to produce gummies of various sizes, shapes, and texture. The machine is made up of quality material and is qualified to efficiently make large number of gummies while reducing waste and time spent.

It undertakes the gummy making task in a very gentle way where ingredients are mixed and heated to prepare slurry which is turned into gummies after depositing and cooling. Although, the automation of gummy making machine vary from one type of machine to another, however, the quality and performance remain the same. That's why, it can be used in multiple sectors such as pharmaceutical, confectionery, and nutraceutical industry etc.

2.Explain Some Of The Prominent Benefits Of A Gummy Making Machine?

Well, gummy making machine features various specifications through which eclectic advantages can be achieved. These are highlighted below:

Enhanced Production

Production of large number of gummies- Picture Courtesy: gummymakingmachine.com

Efficiency is one of the key benefits of a gummy making machine through which it can produce thousands of gummies in a very short time. This exceptional efficiency ultimately leads to high production growth which is the first prerequisite for your business success.

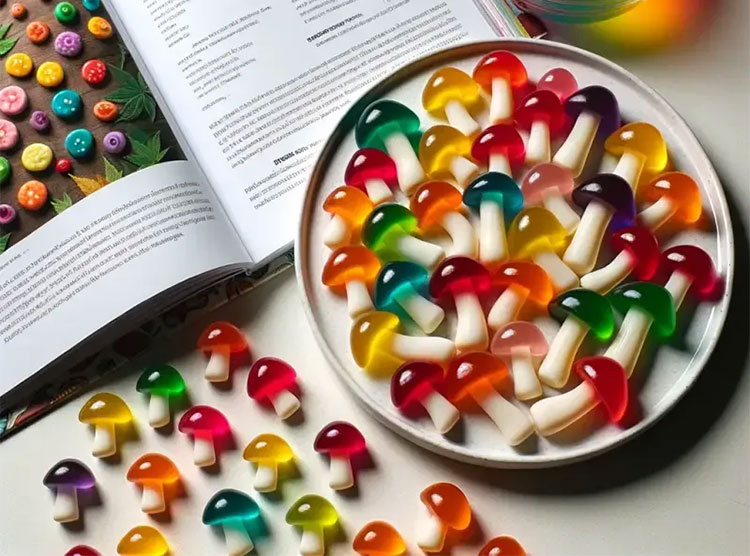

Customization

Mushroom gummies- Picture Courtesy: mushroom-corner.com

Another crucial advantage of the machine is quality of customization which enable you to make adjustments according to your needs such as using different molds, and making multiple shape gummies by using the same machine.

High Precision

Gummies with mold tray- Picture Courtesy: tgmachine.com

The machine is perfectly qualified for producing precise shape gummies with no bubbles and tails. Moreover, the stainless steel body provide hygienic environment for the production of safe and quality gummies.

Reduce Labor

Gummy making machine is made with high level of automation where each step is carried out by the machine. This feature greatly reduce the need for manual labor as well as the errors caused by it.

Multifunctional

Multifunctional gummy making machine depositor- Picture Courtesy: huadapharma.com

Manufacturers of large scale industries often look for equipment which can perform multiple tasks in a synchronous way. With fully automatic gummy making machine this is easily possible. In fact, it just requires you to load material and set parameters and it will carry out ingredients mixing, heating, depositing and cooling in a single run.

3.What Type Of Gummies Are Produced By Gummy Making Machine?

When it comes to discuss the types of gummies a gummy making machine can produce, a long-lasting list will be there. However, we will cover them under the following headings:

Gummies According to Shape

| No | Gummy Shape | Description |

| 1 | Gummy bear

Various gummy bears- Picture Courtesy: Getty Images |

Gummy bear is the most popular gummy type being made by a gummy making machine. Its shape resembles bear and the flavor is also tasty which is why people love to consume gummy bears. |

| 2 | Gummy egg

Gummy fried eggs- Picture Courtesy: bulkcandystore.com |

Gummy egg is another delicious gummy candy which looks like fried egg. These gummies have peachy flavor which makes it fun for kids to have gummy eggs as snacks. |

| 3 | Gummy shark

Various gummy sharks- Picture Courtesy: albanesecandy.com |

Gummy sharks are demersal species representing life inside ocean and rivers. These gummies can be easily made with the help of a gummy making machine by using shark shape molds. |

| 4 | Gummy rings

Gummy rings- Picture Courtesy: albanesecandy.com |

Gummy rings are go-to candies which are made in multiple flavors encompassing cherry, watermelon, apple, and peach etc., to enjoy different flavors. |

| 5 | Gummy hearts

Gummy hearts bicolor- Picture Courtesy: mtcmexicocarepackage.com |

Gummy hearts are beautiful candy with assorted colors and flavors which you can present to your loved once for reminding them your compassion. |

| 6 | Gummy soda pop bottles

Various gummy soda pop bottles- Picture Courtesy: stagestopcandy.com |

Gummy soda pop bottles represent cola, orange, and other colors soft drinks. These are small gummies which are beautifully made by a gummy making machine. |

| 7 | Gummy body parts

Gummy body parts |

Gummy body parts include brain, teeth, fingers, and eyeballs etc. These are among other famous gummy types which are produced by using this machine. |

Gummies According to Color

| No | Gummy Color | Description |

| 1 | Uni color gummy

Uni color gummy bears- Picture Courtesy: albanesecandy.com |

Single color gummy is the most common type of gummies being made by this machine. Such gummies are holding one flavor like peach, mango, and orange etc. |

| 2 | Bicolor gummy

Bicolor gummy frogs- Picture Courtesy: bulknbits.ca |

The machine is capable of making bicolor gummies like egg gummies with white and yellow color holding two flavors. Gummy frogs are also bicolor. |

| 3 | Multicolor color gummy

Multicolor gummy worms- Picture Courtesy: nutstoyou.com |

Gummy making machine can also make gummies with three or more colors. Similarly, their taste also varies. The common examples include gummy worms and gummy pizza. |

Gummies According to Size

| No | Gummy Size | Description |

| 1 | Regular gummy

Regular size gummy bears- Picture Courtesy: nuts.com |

Regular size gummies are commonly produced and delivered as gummy snacks, gummy vitamins, and gummy supplements. Their size is about 0.13 OZ. |

| 2 | Big gummy

Big gummy bears- Picture Courtesy: raisingthecandybar.com |

Big gummies have size of 2.3 OZ which are larger than regular gummies. They are easily made by a gummy making machine. |

| 3 | Giant gummy

Giant gummy bears- Picture Courtesy: crazycandies.co.nz |

The size of giant gummy is 0.5 LBS. The common example is gummy bear which is consumed as gummy snacks in parties. So, this size of gummy is also supported by a gummy making machine. |

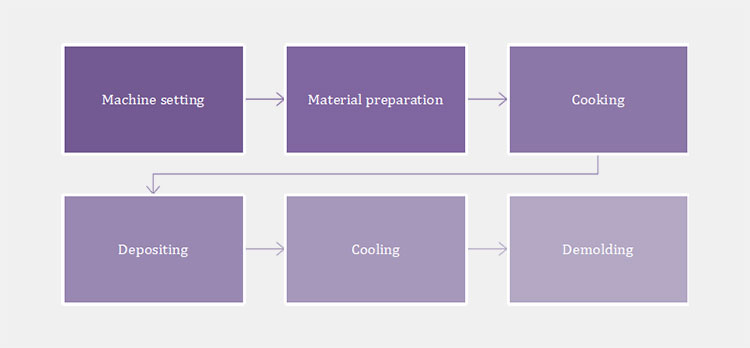

4.How Does A Gummy Making Machine Works?

Gummy making machine follow simple working procedure to done with gummy making. It is necessary to understand these principles in order to operate the machine in a right way. It can be understood by looking into the following steps:

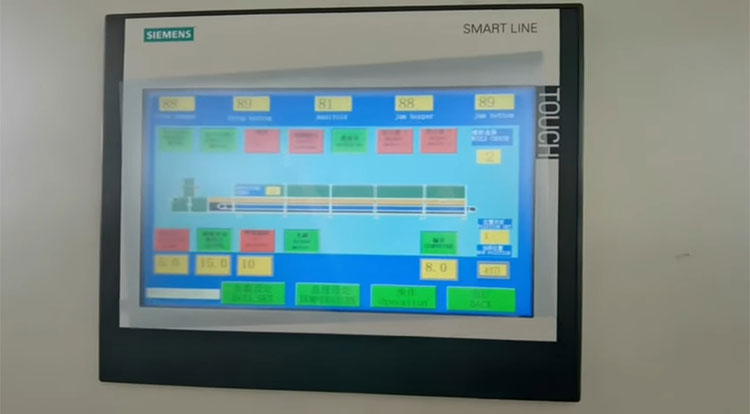

Machine Setting

Machine setting in touch screen interface- Picture Courtesy: yinrich.com

The first step you need to follow is to set the machine. For this, you have to adjust the structural components by fitting different parts in their exact locations and setting the parameters of machine such as the temperature, volume of gummy slurry to be filled in molds, and cooling etc.

Material Preparation

Now, when you are done with a gummy making machine setting, it is the time for next step. This phase involves preparing and measuring the various ingredients which are required for gummy recipe.

Cooking

Gummy slurry in hopper- Picture Courtesy: gummygenix.com

The prepared ingredients are now poured in cooking tank for making slurry. The constant heat along with mixing lead to the cooking of a slurry in about 15 minutes. This gummy mixture is then transferred to buffer tanks for adding flavors, acids, and colorants. The final mixture is moved towards depositor.

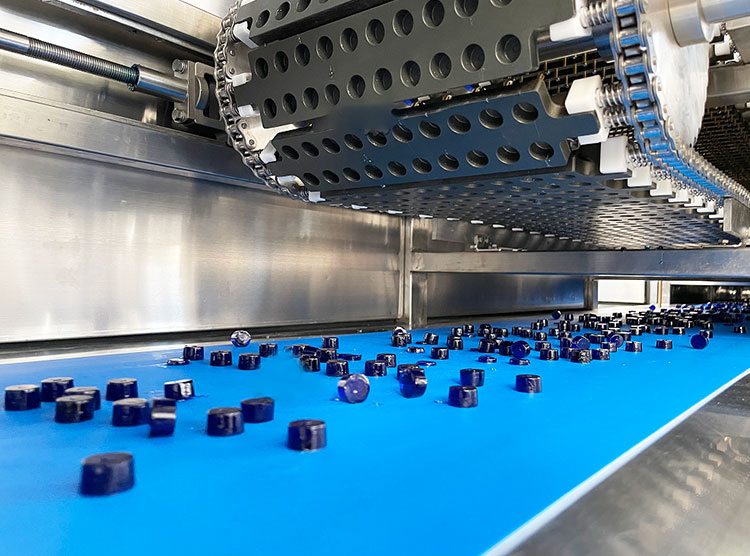

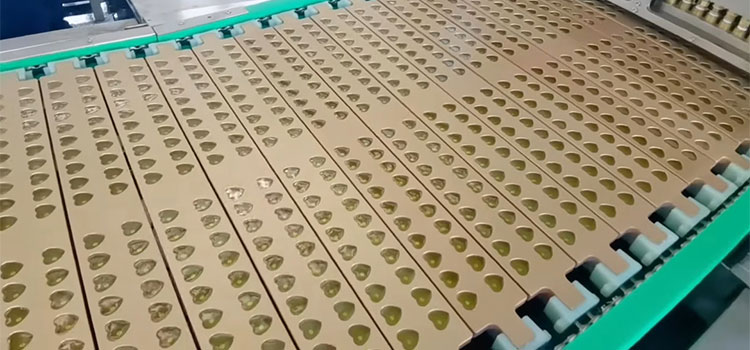

Depositing

Gummy depositing into molds- Picture Courtesy: yinrich.com

It is one of the crucial steps carried out during gummy making machine process. It takes the gummy slurry from hopper and precisely deposit into gummy molds through narrow nozzles. During depositing, the volume of mixture is measured to ensure consistency.

Cooling

In this step, the filled gummy mold trays are mobilized towards cooling. Here, they pass under the cooling tunnel where extreme low temperature turns the liquid gummy solution into solid and they take the form of molds.

Demolding

Gummy demolding- Picture Courtesy: yinrich.com

After cooling, the gummies are removed from mold trays through demolding where needles enter into the back side of molds causing gummies to fall over conveyor.

Discharging

Gummy discharging from machine- Picture Courtesy: yinrich.com

The finished gummies are discharged out of the machine via conveyor belt. After discharging, these gummies are dried, coated, and packed for final delivery.

5.Describe The Structure And Components Of A Gummy Making Machine?

Gummy making machine is a complicated machine which is made up of several components. Each part is important for enabling the machine to carry out gummy making process. Let's know what these are along with their functions!

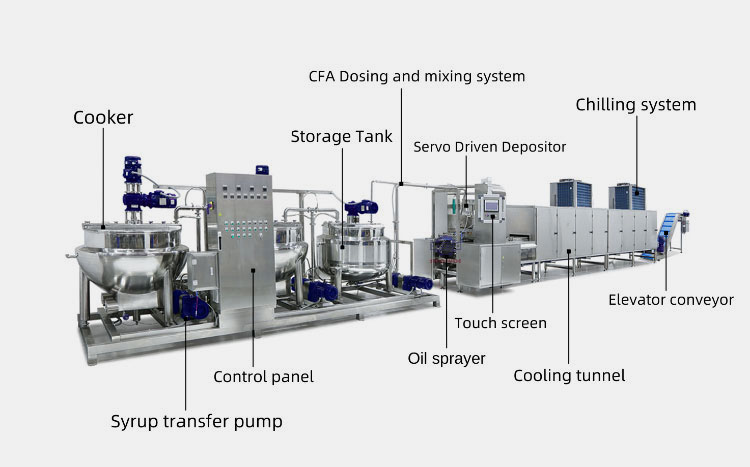

Components of Fully Automatic Gummy Machine- Picture Courtesy: globalsources.com

Cooker

The cooker is first unit of a gummy making machine which is also called cooking pot or tank. It is multi-layer cooker where raw materials for gummy are poured for making slurry. It has fitted system of temperature and agitator both of which are considered the key systems.

Syrup Transfer Pump

It refers to the pump that connect cooker with storage tank. It undertakes the task of transporting prepared gummy mixture to storage tank for further processing.

Control Panel

The cooking section of a gummy making machine has independent control cabinet through which its working is regulated such as the temperature for cooking and speed of agitator etc.

Storage Tank

Storage tank is a large size container made up of stainless steel where gummy slurry is stored. It has proper heat system to keep the gummy solution at suitable temperature in order to avoid lumps creation and jamming.

Dosing & Mixing System

Dosing and mixing system can be integrated with cooker or depositor. Its function is to mix the colors, flavors, and minerals etc., with prepared gummy formula.

Oil Sprayer

It is a device located in gummy depositor with the primary purpose of spraying oil over the passing trays. It thus eradicates the chances of stickiness and help in quick demolded of gummies.

Servo Driven Depositor

This part of gummy making machine is of paramount importance. It consists of a hopper, narrow filling nozzles, and main frame. Its function is to take the liquid gummy slurry from hopper and precisely deposit into mold trays through nozzles.

Touch Screen

It refers to the multi-language touch screen interface through which user operate the machine.

Cooling Tunnel

Cooling tunnel is a large size tunnel inside which controlled temperature is provided to the gummies. When filled gummy mold trays are passed through this tunnel, heat is extracted from them, and hard gummies are formed. Mostly, gummy demolding occurred in this part.

Chilling System

Chilling system is another important part which is attached to the cooling tunnel. It dries the formed gummies by reducing the heat level.

Elevator Conveyor

Elevator conveyor is used alongside a gummy making machine. Through this, formed gummies are discharged from the machine towards other machines such as coating machine and packaging machine etc.

6.What Are Types Of Gummy Making Machine?

Gummy making machine can be divided into three types on the basis of their automation. These types are explained below:

Fully Automatic Gummy Making Machine

Allpack APK-GM300Q Large Scale Gummy Making Machine

Fully automatic gummy making machine is the latest technology evolved for making large number of gummies. It is made up of quality stainless steel making it safe and hygienic to process different types of gummies. The machine is multifunctional with cooking, mixing, depositing, cooling, and demolding capabilities. Its production capacity is up to 80,150,300kgs per hour.

Structure

The machine has large body covering more space. The main sections include cooking tank, mixing tank, transfer pump, gummy depositor, and cooling tunnel.

Working Principles

It has simple working procedure where every step is carried out automatically once machine is loaded and set by the user. Thus, no manual intervention is required here.

Semi-Automatic Gummy Making Machine

Semi-automatic gummy making machine- Picture Courtesy: tgmachine.com

Semi-automatic gummy making machine is a compact size equipment with good efficiency level that can produce gummies of various sizes, shapes, and special forms such as center filled gummies. It is cost-effective and is best solution for small to medium scale industries with production output of about 6,000-10,000 gummies per hour.

Structure

The machine has precise body with small footprint that is easy to mobilize and handle. The major components include a hopper, PLC control panel, filling nozzles, main frame, and electric cabinet etc.

Working Principles

The machine require operator to load the hopper, set parameters, and place mold trays. Afterwards, it works by depositing gummy mixture into molds through narrow heads. Once the precise volume is poured, it automatically stops depositing and the user manually remove filled mold trays for cooling and demolding.

Manual Gummy Making Machine

Manual gummy making machine

As the name indicates, this type of gummy making machine is manually operated. It is a single machine with precise body that can be placed anywhere you want. The machine is good for small scale businesses which are associated with the production of gummies and jellies. However, it has low output and time consuming due to manual operation.

Structure

Manual gummy making machine is extremely small in size with few components including a hopper, handle, filling heads, and conveyor.

Working Principles

It can be brought into operation by loading the hopper and placing mold trays. Similarly, for mold tray filling, the handle of machine is supposed to be manually pressed by the user until desired level is reached.

7.What Are The Uses Of A Gummy Making Machine?

The production of gummies is not only confined to confectionery industry but now it can be seen areas far beyond food such as medicine and herbal industry. It shows the machine relevance and importance demonstrating its multiple applications. Some of the common uses are as follows:

Confectionery Industry

Gummy snacks- Picture Courtesy: sinofudegroup.com

Confectioneries are not only rich in sugar but also carry essential vitamins and minerals. Similarly, gummies are also made by using sugar, flavors and colorants in confectionery industry to prepare it as snacks. This production is often on large scale which require sophisticated machine like gummy making machine.

Pharmaceutical Industry

Medicated gummies bottle- Picture Courtesy: yourdiscountchemist.com.au

The ever-rapid advancements has also taken pharmaceutical industry into its umbrella and now range of medicated gummies like CBD gummies and THC gummies can be seen in stores. These along with other gummies are beneficial for health such as boosting immunity and help body in detoxification against diseases.

Nutraceutical Industry

Gummy supplements- Picture Courtesy: megafood.com

Probiotic gummies, prebiotic gummies, gummy vitamins and supplements are the common examples which can be termed as nutritional gummies. They are made by combining together essential ingredients from natural foods like fruits and vegetables etc. Thus, a gummy making machine is also applicable to this industry.

Herbal Industry

Herbal gummy bottles- Picture Courtesy: gaiaherbs.com

Herbal products are still considered effective among masses and this belief has led to the expansion of herbal industry which is why gummies production can be seen here. Now, different types of herbal gummies are available in market. Thus, a gummy making machine can be used for

Beauty Care Industry

Beauty gummy presentation idea- Picture Courtesy: vitalproteins.com

In addition to nutraceutical and herbal industry, beauty care industry has also revolutionized the mode of products delivery. In this way, beauty gummies are the common example which are used for beautiful skin, strong nails, and hair. These gummies help in providing collagen and keratin production. Hence, this machine is also used in this sector.

8.How To Check The Quality Of A Gummy Making Machine?

The quality of a gummy making machine can be checked by looking into its structure, technology, and electrical connections for safety and efficiency. However, it is not possible to do so as a layman or a business person because not everyone has expertise in machines manufacturing. Thus, the simple way there is to check its compliance with quality standards covering all aspects. These include:

Quality certification logo of CE, ISO, & ISO- Picture Courtesy: sapheneia.com

International Organization for Standardization (ISO):This quality standards demonstrates the machine's high level of quality control in terms of environmental safety and quality management.

Good Manufacturing Practices (GMP):GMP deals with the structural integrity of machine by fixing 304 stainless steel as a construction material for machine which is corrosion resistant.

Food And Drug Administration (FDA):It is USA based agency established to regulate rules regarding public health and safety. Therefore, a gummy making machine adhering FDA principles is of high quality.

Conformate European (CE):It represents the safety concerns of European Union countries. So, a machine must be certified with CE if produced or sold inside in these states.

9.What Are The Future Prospects For Gummy Making Machine?

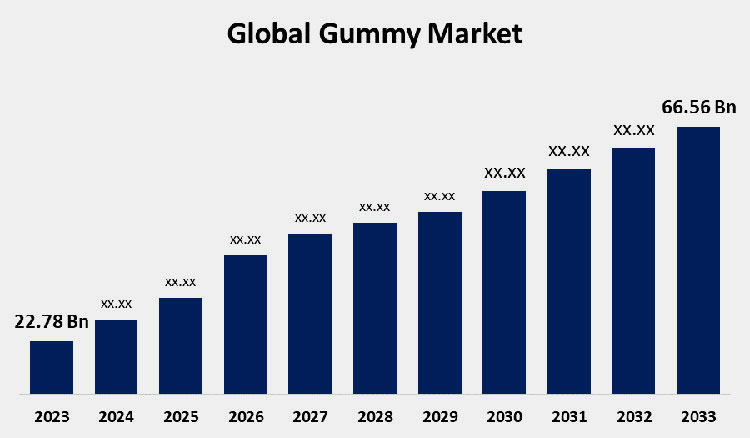

Global gummy market index- Picture Courtesy: sphericalinsights.com

Gummy market can be seen as rapidly growing in fields beyond confectionery due to the demand for gummy supplements and vitamins. Similarly, various forms of gummies with different flavors and texture are also expected to emerge. However, all these things require efficient, safe, and quality machines.

Thus, the future prospects on part of a gummy making machine are the advancements in machine safety level and capabilities to produce eclectic gummies. The inclusion of AI along with other specifications will enhance the machine value.

10.How To Clean And Maintain A Gummy Making Machine?

Regular cleaning and maintenance ensure optimal performance and longevity of a gummy making machine. Therefore, make sure to conduct it on regular basis for which underlying principles can be helpful:

Operator cleaning a gummy making machine- Picture Courtesy: gummygenix.com

Cleaning

Turn off and unplug the machine for safety.

Disassemble removable parts such as molds and trays etc., and soak in warm soapy water. Scrub with a soft brush, rinse, and dry.

Clean external surfaces with a damp cloth and mild soap.

Clean internal components like pumps and pipes with warm water and recommended detergent.

Wipe sticky areas with a cloth or use vinegar-water solution for the removal of residues.

Maintenance

Lubricate movable parts by adding oil as per manufacturer's instructions.

Inspect for wear and tear on seals and parts and replace damaged components.

Run a test cycle during operation to ensure everything works smoothly.

Keep the machine in a dry environment when not in use.

Update the software to enhance the efficiency and performance of machine.

11.List Down The Machines Which Can Be Used Alongside A Gummy Making Machine?

There are certain machines which can be used alongside a gummy making machine to make its working more efficient and effective. These are enlisted below:

Gummy Drying Trays & Dollies

Gummy trays & trolley- Picture Courtesy: tgmachine.com

Gummy drying trays and dollies are made from quality material with high resistance to heat. The plastic perforated trays are perfect for drying gummies, while as, the dollies make it very easy to mobilize the trays from one place to another covering less space.

Sugar/ Oil/ Wax Coating Machine

Gummy Making Machine Oil Coating Machine

This is another machine which can be used along with a gummy making machine for coating gummy with oil, sugar, or wax. It is made from quality stainless steel and the body of the machine is durable. It can perfectly coat the gummies by applying uniform layer in a rotating drum.

Gummy Packaging Machine

APKRL200-G Multihead Weigher Premade Pouch Filling Machine

Gummy packaging machine is a significant equipment which is needed for securing the quality and shelf life of produced gummies. Hence, it provides a safer and convenient way to pack gummies into flexible pouches and bags. It weighs the gummies and pack them into containers by creating strong sealing.

Elevating Conveyor

Feeding Machine / Mesh belt elevator

Elevating conveyor is a type of lifting conveyor which is useful for moving gummies from one unit to another. It can be integrated with a gummy making machine. The conveyor has simple design with beautiful compartment conveyor which restrict the falling of gummies.

12.How To Choose The Best Gummy Making Machine For Your Business?

In order to choose the best gummy making machine for your business, consider the underlying key points. It will help you to find a gummy making machine that fits your needs, budget, and production goals.

Production Volume

Large number of filled gummy mold trays- Picture Courtesy: yinrich.com

What production volume you are working on? Answering this question will let you know the machine which you need. For instance, small to medium level output can be achieved by using a semi-automatic gummy making machine. While as, large scale production needs fully automatic machine. So, consider the machine with desired efficiency and throughput.

Adaptability

Allpack- gummy molds with different shapes

Choose a machine that supports different gummy shapes and sizes if you need variety. This is only possible if the machine support adjustable settings to ensure consistent size, shape, and texture.

Quality & Compliance

Compliance aspects- Picture Courtesy: consortiumlegal.com

Look for food-grade, stainless steel construction for easy cleaning and durability. It gets easy by checking the machine's compliance with necessary standards such as FDA, GMP, and ISO etc.

Supplier Reputation

The reputation of supplier is very important for establishing long term connection as you may need their help for troubleshooting and maintenance etc. Therefore, check reviews and manufacturer support for customer support and after-sale service.

Conclusion

To summarize, this buying guide about a Gummy Making Machine underscores the equipment growing worth in manufacturing market. Its use is becoming more prevalent in industries like confectionery, nutraceutical, and beauty care industry. However, mere knowing its benefits will not be enough rather its structure, working process and maintenance is also very important which are discussed in the above explained guide. Apart from this, gummy making machine also need other equipment to work along with it. So, if you are interested in purchasing a gummy making machine or related equipment then do consider Allpack which has latest inventory to explore. For further information, please contact us!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp:+86 18171018586