Primary VS Secondary Packaging:What Are Their Difference?

Any product comes with packaging, which can protect the product and also have an aesthetic effect. If the product has exquisite packaging, it will bring bonus points to the product.

Do you know that packaging is divided into primary packaging and secondary packaging? What are their difference between primary vs secondary packaging?

Next, I will introduce you to the basic information of primary packaging vs secondary packaging, as well as the differences between them.

1.What is Primary VS Secondary Packaging?

Primary Packaging - Sourced: OPC Direct

Based on this name, maybe you should know its definition, right. Primary packaging refers to the first packaging of a product when it is taken off the production line. This form of packaging will ultimately be marketed to consumers, so it must meet their aesthetic preferences. It comes into direct contact with the product, thus protecting it from the effects of air and temperature.

Secondary Packaging - Sourced: Contract Pharma

Secondary packaging refers to the packaging of one or more primary packaging. It is convenient for product transportation and storage. Therefore, it ensures that the products are not damaged or stolen during logistics, warehousing, and retail processes. Besides, some secondary packaging also can be designed to enhance the appearance of the product.

2.What is the Benefits of Primary VS Secondary Packaging?

Primary vs secondary packaging is inevitable for every product, and the forms of packaging are becoming increasingly diverse.

(1)Benefits of primary packaging

Extending product shelf life

Extending Product Shelf Life - Sourced: Campden BRI

The product will become damp and deteriorate after prolonged exposure to air and water vapor. Primary packaging can protect products from the effects of air, light, and humidity can extend the shelf life of products.

Ensuring product hygiene

If the product is exposed to the outside for a long time, it will be affected by dust, microorganisms, etc. Primary packaging can block the product from being affected by external bacteria or other harmful substances.

(2)The benefits of secondary packaging

Addingvalue to the product

Adding Value to the Product - Sourced: Elite Custom Boxes

Secondary packaging has more space than primary packaging, and design elements such as product logos, images, etc. can be added to it. Various packaging designs can add value to products, attract customers’ purchases, and improve customer satisfaction.

Providingadditional protection

Some primary packaging may be damaged during transportation, such as glass bottles that are prone to breakage, which seriously affects the customer’s purchasing experience. Therefore, secondary packaging is needed to provide additional protection and improve customer satisfaction.

Simplifyinghandling and transportation

Simplifying Handling and Transportation - Sourced: DFreight

The handling and transportation of a single product can be chaotic and time-consuming. Secondary packaging combines multiple primary packaging to facilitate handling.

3.What are the Types of Primary VS Secondary Packaging?

Our lives are inseparable from packaging. Can you distinguish between primary packaging vs secondary packaging?

(1)Primary packaging example:

Can

Can - Sourced: GrocerApp

Can is mainly used for canned beverages, beer, and other products. Usually made of metal, plastic, or other hard materials, it has good sealing and protective effects, and can prevent moisture, shock, and pollution.

Blister packaging

Blister Packaging - Sourced: Plastics Today

This packaging form is commonly used in drugs, mainly for packaging single dose tablet products, making it easy for consumers to remove a certain amount of the product for use. Products packaged in blister packaging have a tight seal, which can prevent air transmission and environmental pollution.

Stick packaging

Food Stick Packing - Sourced: globalsources

This packaging form is common in the food industry, such as the coffee we often drink. Usually made of materials such as cardboard, plastic, or metal, it has a beautiful appearance, is easy to carry, and has a certain display effect.

Tube packaging

Tube Packaging - Sourced: Free Mockup World

This packaging form is commonly used in the cosmetics and personal care industries, such as facial cleansers, hand creams, toothpaste, etc. Flexible tube packaging is convenient and practical, and can also protect products.

Bottle

Plastic Bottle - Sourced: Nunzio’s Pizza

Bottles are mainly used for liquid products such as beverages, alcoholic beverages, etc. Usually made of glass or plastic, it has good sealing and transparency, making it easy to observe the product’s condition.

(1)Secondary packaging example:

Carton packaging

Carton packaging

Due to the minimal environmental pollution caused by carton packaging during production and processing, this packaging form is widely used.

Shrinkingpackaging

Shrinking Packaging - Sourced: Codico Distributors

It is commonly used for packaging bottled, canned, boxed foods and electronic products. This packaging method has the characteristics of good sealing, high transparency, and has the advantages of waterproof, moisture-proof, and dustproof.

4.What are the Applied Industries of Primary VS Secondary Packaging?

To tell the truth, packaging is required in any industry. Let’s take a look at which industries primary vs secondary packaging are specifically applied to!

(1)Personal care industry

Personal Care Industry - Sourced: Environmental Factor

The products in the personal care industry are daily necessities with high sales volume, and most of them require packaging. For example, the facial cleansers, shampoos, shower gels, etc. that we usually use need to be packaged.

(2)Food industry

Food Industry - Sourced: ProAmpac

Both beverages and snacks require packaging. For example, beverages generally require plastic bottles and other primary packaging, followed by secondary packaging using shrink wrap to facilitate the handling and transportation of beverages. These packaging materials not only need to ensure the freshness and hygiene safety of the food, but also need to be aesthetically pleasing and leave a good first impression on consumers.

(3)Pharmaceutical industry

Pharmaceutical Industry - Sourced: OpenSecrets

Liquid drugs need to be packaged once in glass or plastic bottles, and there should be a certain choice of color and material for the bottles. In addition, secondary packaging such as paper boxes will be used for liquid drugs.

The medicine has higher requirements for packaging materials. Drug packaging materials need to have characteristics such as moisture resistance, light resistance, and oxidation resistance to ensure the safety.

5.Primary VS Secondary Packaging: What Are Their Difference?

Believe it or not, there are several differences between primary vs secondary packaging? Let’s take a look together.

Primary VS Secondary Packaging - Sourced: Designertable

(1)Contact with the product

Both packaging forms serve to protect the product. The primary packaging comes into direct contact with the product, while the secondary packaging does not need to come into direct contact with the product.

(2)Capacity

Generally speaking, the capacity of secondary packaging is greater than that of primary one. Secondary packaging can accommodate one or more primary packaging.

(3)Function

Function - Habefast

These two packaging forms are devised in function. Primary packaging can directly protect the product. In addition, to attract customers’ eyes, direct interaction with customers is also possible. While, secondary packaging focuses on grouping. It provides additional protection for the product and facilitates marketing efforts.

(4)Cost

Due to the need for direct contact with the product, the primary packaging requires the use of special materials, resulting in higher costs. The use of secondary packaging in large quantities results in relatively low costs.

(5)Material

Material - Sourced: Tangent Materials

The two packaging forms are different in materials. Due to features of primary packaging, the materials need to be compatible with the product, including materials such as plastic and glass. And the materials for secondary packaging often include cardboard, plastic, wood, etc.

(6)Use cases

They are used in different cases. Primary packaging is mainly used to display products on cargo racks to attract customers’ attention, while secondary packaging is mainly used during transportation and handling processes.

(7)Overlap

To be honest, there is a overlap of the two packaging forms at some level. For example, the beverages we purchase from product shelves come with both primary and secondary packaging.

6.What Quality Control and Testing for Primary VS Secondary Packaging?

To protect the product and maintain its shelf life. Primary vs secondary packaging needs to be inspected before it can be used normally.

Quality Control and Testing - Sourced: Extended Web AppTech

(1)Quality control and testing for primary packaging

Compatibility testing

Whether the product is compatible with packaging materials is a question that needs to be considered. Once incompatible, some chemical reactions may occur, affecting the quality of the product.

Sealing integrity test

The product may deteriorate if exposed to air and sunlight for a long time. Therefore, it is very important to check the sealing integrity of the packaging. For example, it is necessary to check whether the bottle cap is tightened and whether the packaging of the bag is sealed tightly.

(2)Quality control and testing for secondary packaging

Checking label and printing quality

The product label includes model, production date, brand, barcode, etc., which facilitates product identification and tracking. Therefore, you need to check whether the product label is accurate, the quality of printing, and whether it is easy to fall off.

Transportation testing

Secondary packaging is mainly used for transportation, storage, etc. Expose the packaging to various environments to test its stability. Simulate the impact and vibration of the packaging during transportation to test whether the packaging can protect the product.

7.What Are the Common Machines for Producing Primary VS Secondary Packaging?

For different types of packaging, there will be different machines. Do you know which ones are used for primary packaging and which ones are used for secondary packaging?

(1)Common machines for producing primary packaging

Stick packaging machine

Allpack Stick Packaging Machine

Stick packaging machines are primarily utilized for filling substances like powders, liquids, and granules. This machine has multiple lines such as 4 lanes, 6 lanes or more lanes for simultaneous production, with high production efficiency. It is commonly used in the food industry, such as coffee powder, coffee liquid, gummies, etc.

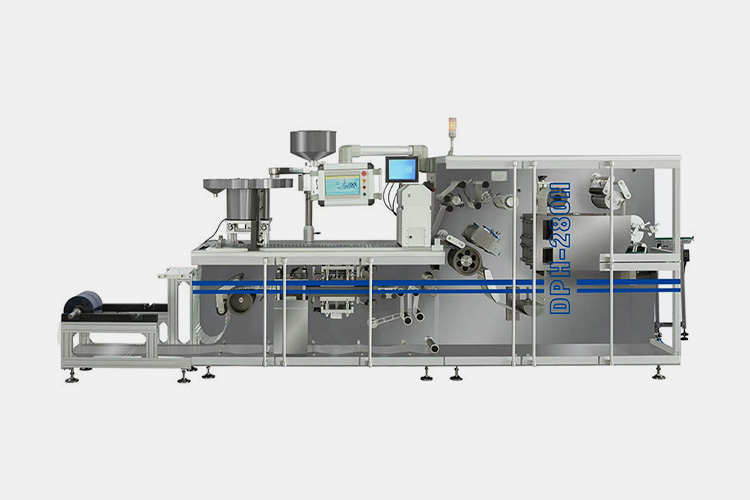

Blister packaging machine

Allapck Blistering Packaging Machine

Blister packaging machine is utilized to package capsules, tablets and other products to form blisters. The machine packages products using materials such as PVC and aluminum film through heat sealing and shearing. It is mainly used for packaging drugs and has efficient functions.

(2)Common machines for producing secondary packaging

Cartoning machine

Allpack Cartoning Machine

Cartoning machine can package a variety of things, including bottles, blister packs, cosmetics, and more. This machine has achieved a high degree of automation and can automatically fold, unpack, and pack boxes.

Shrinking packaging machine

Allpack Shrinking Packaging Machine

The shrinking packaging machine is capable of packaging products such as beverage cans and bottles. This machine wraps the product with heat shrinkable film and then heats it up to shrink the film before wrapping the product. During the shrinkage process, it does not affect the quality of the packaging and can shrink quickly and perfectly. The packaged product can be sealed, moisture-proof, and impact resistant.

8.How to Determine Primary VS Secondary Packaging for Products?

When choosing primary vs secondary packaging for a product, it is not a blind selection, but rather a comprehensive consideration of some factors.

(1)Product type

Why do some drugs need to be packaged in glass bottles while others need to be packaged in plastic bottles? The product type will determine the type of packaging. For example, some drugs can decompose and spoil when exposed to light, so brown glass bottles are needed for packaging.

(2)Cost

Some products can be packaged in multiple ways, such as laundry detergent which can be packaged in bags or bottles. If you produce a large quantity of products that require bulk transportation, you need to consider transportation costs.

(3)Sustainability

Sustainability - Sourced: SKP

Primary vs secondary packaging should pay attention to environmental protection and sustainable development, choose biodegradable and recyclable packaging materials, and reflect the social responsibility of the enterprise. At the same time, it is necessary to increase interactivity and fun, and enhance consumers’ interest and participation in the product.

(4)Hazardous material

Once hazardous substances are not handled properly, they can cause harm. So, it requires special packaging. The packaging should strictly follow the prescribed guidelines to ensure no leakage and airtightness.

(5)Transportation and storage

Transportation and Storage - Sourced: Victory Packaging

When choosing packaging, the transportation and storage of the product should also be considered. Some products require refrigeration, such as seafood and meat products, which require specialized packaging materials to control the temperature of the products and prevent them from spoiling during transportation.

Conclusion

Primary vs secondary packaging are crucial for us, as they affect everything we come into contact with. Have you gained a new understanding of primary vs secondary packaging after reading this article? If you have any further questions about packaging, please feel free to contact ALLPACK at any time

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide