Nicotine Pouch Packing Machine: The Complete FAQ Guide In 2025

Are you interested in nicotine pouch packing machine? And you are looking for a guidance counsellor that give you directions to choose a better or more profitable machine. This is the right place for you because here you will get all the information related to nicotine pouch packing machine.

Nicotine pouch packing industry is booming throughout the globe due to its high economic benefits. It will be a big move for you and your business if you step in this industry. Whatever queries you have about the nicotine pouch packing machine, but till the end of this guide all of your queries will be answered. So, stay here, and let’s dive deep into realm of nicotine pouch packing machine.

1.What is a nicotine pouch packing machine?

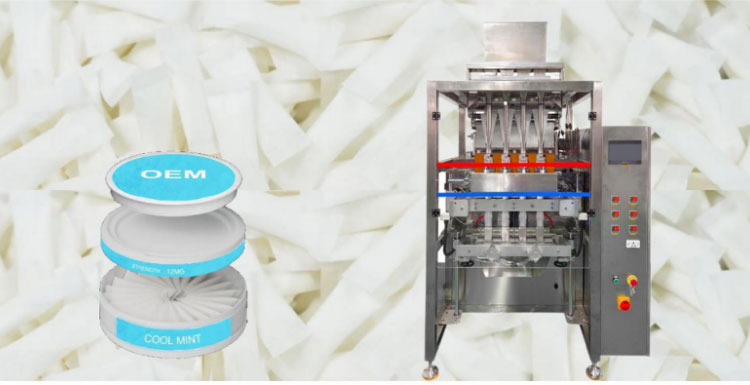

Nicotine Pouch Packing Machine

A nicotine pouch packing machine is a specialized appliance for the packaging of nicotine pouches. The nicotine pouches are usually very small in size. Nicotine pouch product manufacturing uses nicotine pouch packing machines a lot.

The most basic function that it performs is the filling of nicotine pouches with the required amount of nicotine. But it can also serve in other ways as well, like, after filling the nicotine pouches.

2.How a nicotine pouch packing machine will benefit your business?

A nicotine pouch packing machine is worthwhile, and it helps your business in many more ways. Some of these are given below:

Increasing productivity

Greater Production: Picture Courtesy: Swenico

A nicotine pouch packing machine reduces the time required for the packaging of nicotine pouches and does it in no time. Hence, it increases efficiency along with productivity and lessens the labor cost.

Consistency

Cool Mint Nicotine Pouches

This machine ensures the continuous packaging and filling of pouches with the required amount of nicotine and other ingredients. It also confirms the consistent sealing of nicotine pouches and maintains the quality of the product inside the pouches.

Better product quality

High Quality Nicotine Pouches

The quality of the nicotine products is kept high by the nicotine pouch packing machine. Because it works accurately while filling the pouches with product and then sealing, it makes sure that the product is well packed and not leaked anywhere.

Minimizes labor cost

Economical Nicotine Pouches: Picture Courtesy: Vaping Post

A nicotine pouch packing machine performs the work easily and automatically, which otherwise takes time. So, in this way, it minimizes the labor cost and helps to reduce your financial expenses.

Influences brand reputation

Nicotine Pouch Brand: Picture Courtesy: Truth Initiative

To build customers’ trust in you, your product must be fresh and highly packed, and these services are already provided by the nicotine pouch packing machine. It does not let your brand reputation fall.

3.What industries can get advantages of a nicotine pouch packing machine?

There are a number of industries that can benefit from nicotine pouch packing machines. A few of them are given below:

Pharmaceutical Industry

Nicotine Therapy Replacement: Picture Courtesy: Publichealth.jhu.edu

These companies mostly benefit from nicotine pouch packing machines for packing various pharmaceutical products. From the production process to its packaging, their first priority is the hygiene of the products. Therefore, this would be the top choice to provide safer and uncontaminated packing of pharmaceutical products such as skin patches, chewing gum, inhalators, tablets, oral strips, nasal and mouth sprays, etc.

Medical and healthcare Industry

Nicotine Pouch for Buccolabial Sulcus

The medical and healthcare industries also use this machine during the filling and packing of medications. This work is most efficiently done by the nicotine pouch packing machine. It is also useful during nicotine-based treatments.

Cosmetics and hair care industry

Cosmetic pouches

Due to its versatile nature, it is applicable in the cosmetics industry and for hair care products such as shampoo, face creams or lotions, hair colors, etc.

Food industry and beverages

Food and Beverage

The food and beverage industries use this machine for a lot of their food or drink items. Its highly automated system raises the demand and needs in this sector to give more protection to these products which increases their production and selling scale in the market.

Tobacco Industry

Tobacco Industry- Picture Courtesy: FAZ

To meet the required demand for tobacco, the tobacco industry needs a nicotine pouch packing machine to pack it in solvable form. This industry also uses this machine to produce other nicotine-containing products like snus and hookahs, etc.

Chemical Industry

Chemical Industry

The chemical industry can also use nicotine pouch packing machines for packaging chemical powders, and organic and inorganic agents for industrial purposes.

4.What is the working operation of a nicotine pouch packing machine?

Working Steps of Nicotine Pouch Packing Machine

STEP 1: Formation of the Film

The roll of laminated film (PE, PET, or aluminum foil) is drawn, and the film is fed to the machine where rollers and supporting screws ensure flexible movement. This film is shaped into pouches in a pouch former, and heat or pressure is used to seal the bottom part of the pouch. Your role is to make sure that the film feeds correctly and that the seals are tight.

STEP 2 Filling

It then fills each pouch with the appropriate amount of nicotine. The filling system, such as an auger filler or a weighing system, determines the appropriate dose and dispenses it accordingly. Verify that the filling is uniform and readjust if necessary for accuracy.

STEP 3: Cutting and Discharging

The synchronized cutting mechanism cuts these pouches from the continuous film. These pouches are then dropped individually on a conveyor belt for collection or packaging. Ensure cutting is smooth, and pouches are ready for the next step.

5.What are the different parts of a nicotine pouch packing machine?

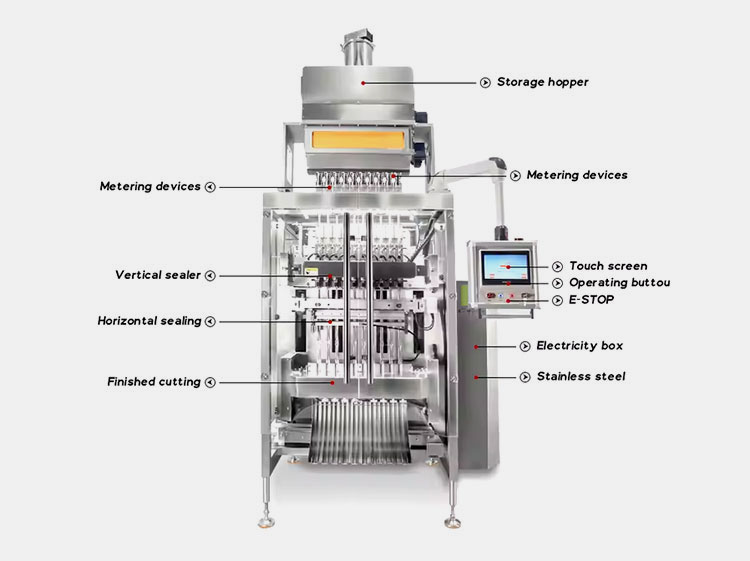

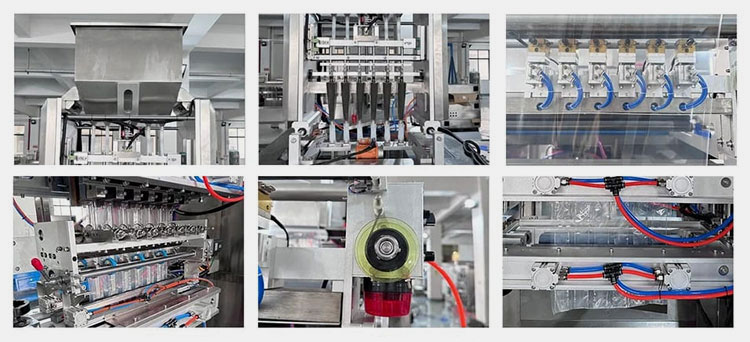

Components of nicotine pouch packaging machine

Here's the breakdown of major parts on the nicotine pouch packing machine

| Components | Description |

| Storage Hopper | Imagine loading a nicotine material into the machine without lifting a single finger. A feeder does it for you, pulling it all into the system with no attempt at all, supply constantly, and labor with no effort. |

| Metering Device | The metering device can be regarded as a cutter that senses and identifies the nicotine material correct amount to dispense. It holds a reasonable amount of product to ensure the smooth running of the machine so that consistency would be maintained. |

| Vertical Sealing | The vertical seal is responsible for sealing pouches in a vertical position. This portion controls the amount of the nicotine pouch joining for the whole batch. |

| Horizontal Sealing | This section is responsible for inducing sealing with a horizontal position. |

| Finished Cutting | After filling the pouches, the finished cutter comes into the picture; it cuts each pouch from the continuous roll with very accurate precision. Here are all the pouches neatly separated and ready for use. |

| Touch Screen | You are totally in control of everything with the friendly touch screen. Now, with a few taps to set up settings, view progress in real-time, or debug any issues then you're sure the machine will operate just as planned. |

| Electricity Box | All main electrical components are stored in a chamber for the user’s safety known as an electricity box. |

| Stainless Steel Structure | Finally, the stainless-steel body gives the machine a robust and clean outlook. It is capable of handling long hours without losing the freshness-hygiene easily accommodated in a product like nicotine pouches. |

6.What are the major classifications of nicotine pouch packaging machines?

Classification of Nicotine Pouch Packing Machine

The packaging machines for nicotine pouches can be grouped in various ways. Consider their differences in functionality. For instance, the degree of automation: do you want an absolutely automated machine or one where there is a higher involvement of human effort? How many pouches can be processed at a time on a production run? Consider the difference in efficiency based on that number! Understanding these categories will help guide your decision in making the best choice for your packaging needs.

Fully Automatic Machines

Fully Automatic Nicotine Pouch Packing Machine

All the operations from feeding to forming, filling and sealing, cutting to labeling are performed by totally automatic machines. How cool it would have been if everything were done by an entirely automatic machine? Do you think these have any implications on mass production? These machines require a minimal presence of man for mass output.

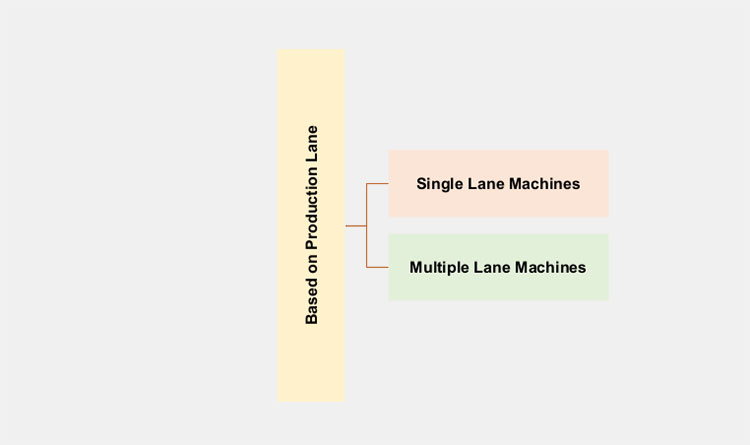

Based on Production Lane

Single Lane Machine

Single Lane Machine

Single lane machines work with one pouch at a time, which makes them slower but significantly more precise. The machines are also less expensive, making them perfect for smaller or niche products. Do you have an impression about how easily you might be able to adjust for different pouch sizes or product variations? This flexibility makes single lane machines an extremely versatile offering for manufacturers, which can be used in fine-tuning.

Multiple Lane Machine

Multiple Lane Machine

Multiple-lane machines can process dozens of pouches all at one time, so production is much faster. How do you feel this speed would affect mass production? While these machines are more expensive, they are designed to anticipate high-volume manufacturing. It is paying for a higher level of output and reduced flexibility with large-scale production. Although they will offer the least number of customization, their productivity makes them fit best for mass production.

7.What is the production line of nicotine pouch packing machine?

Production Line

When a nicotine pouch packing machine is coupled various units in the production line assumes a sleek operation that involve five important machines. This is assured to be efficient, given the high-volume packaging operations. Here is how it works:

For packaging nicotine pouches, the bottle unscrambler machine is required which is the most important piece of equipment. It makes sure that empty cans are aligned and oriented properly for what comes next. Pouches are conveyed and sorted to be loaded into these cans. No intervention is needed prior to packaging; they are ready for canning.

Nicotine Pouch Packing Machine

The process starts with the nicotine pouch machine, forming into pouches filled with nicotine material and sealing pouches for retention of freshness. In this automatic system, each pouch will be correctly filled.

Nicotine Pouch Capping Machine

The integrated system loads the cans with nicotine pouches. The nicotine pouches are filled in all cans get the correct number of nicotine pouches are firmly secure by twisting of caps over them.

This is an automatic process offering high productivity. Once these cans are filled, they will be taken through induction sealing machine for further protection of products.

Induction Sealing Machine

An electromagnetic radiation is emitted which induces the melting of cap layers that forms are strong sealing upon cooling to produce a tamper evident packaging.

Labelling and Packaging Machine

Lastly, the cans are branded and labeled with product details are labeled by using labeling machine prior to distribution, which marks the final step in the production cycle.

8.What Other Products can be filled in a nicotine pouch packing machine?

Apart from nicotine, there are wide range of other materials can be filled with using the same category machine that gives you tremendous results. Yes, this is the only nicotine pouch packing machine that is designed to help your problem in the lowest possible expenditure so you can enjoy dealing versatile materials packaging with this unit. You can read more about types of materials in this discussion.

Chewing Tobacco

Tobacco- Picture Courtesy: Dazed

Have you heard about snus? This is the kind of tobacco you can chew. You can fill them in the production facility when you have access to the nicotine pouch packing machine. For that, you don’t need special training in treatment. You load your product in the hopper and put protocol to facilitate true and reliable packaging.

Herbal Snuff

Herbal Snuff

This is mainly used among those people who want to get rid of daily smoking habits. It is known as a tobacco free solution and can be packed in a similar fashion as nicotine pouch packing. Therefore, it is recommended in the production units of herbal snuff manufacturing.

Flavor Candies and Chewing Gums

Flavor chewing gum- Picture Courtesy: Candy Mail

Various eatables you have in your bags, office desk, and home are small in size and packed in kind of nicotine pouches. The machine design is not only user friendly but also your business which can be filled and sealed your various products in the easiest way.

Coffee Powder

Coffee Powder

You can fill and seal your single serving coffee powders in a small proportion of pouches by using a nicotine pouch packing machine. It is suitable for filling ground as well as raw coffee materials in each pouch.

Spice, Condiment, and foods items

Spices or Condiments, foods items

The broad range of spices and condiments are filled and sealed using the machine that is mainly used for parties, traveling, or picnic purposes. It can give you a pre-determined portion of products accurately in each pouch.

9.What are common issues related to a nicotine pouch packing machine? How to solve these?

Troubleshooting

It is natural that after working for a while, machines can have defects that should be resolved. There are some common problems that may happen to your nicotine pouch packing machine, and here are some useful suggestions for you on what to do if you face any of the problems given below.

Some common issues and their solutions:

Inconsistent Sealing

Inconsistent sealing- Picture Courtesy: Nic Pouch UK

Causes

This may be associated with old rubber sealing parts or inappropriate temperature or pressure at the time of sealing.

Solutions

Check the seals first. If they are worn out, replace them. Check the machine's temperature and pressure settings. This will ensure that the seal lasts because monitoring these two aspects at times ensures no repeated malfunction.

Variation in Packing

Packing Variation

Causes

Inaccurate calibration, software malfunctions, or worn-out parts that could be the cause of variations in pouch weight or content distribution. Faulty packaging may result from malfunctioning due to misalignment of the machine parts

Solution

Reset the machine calibration setting. When necessary, update the software. Replace with parts that have wear and tear to ensure constancy. Reline components for packaging carefully considering the fact that all the parts should be in line.

Unexpected Machine Downtime

Prevent overheating- Picture Courtesy: GloryTech

Causes

Sensor malfunctions, overheating, and mechanical failures are the principal causes of sudden stops.

Solution

Stable power supply; ventilation; regular mechanical check-ups; and stocks of critical spare parts on hand for quick replacement.

Product jamming

Picture Courtesy: promotorzy.pl

Causes

Sometimes the accumulation of dirt in the hopper or nozzle leads to jamming of products. This problem you may encounter due to the large size of ingredients, which make the products jam.

Solution

You can eliminate this problem by having the right and suitable machine according to your ingredient size. Also keep your machine clean. And try to keep it dirt- and debris-free.

Pouch formation problem

Causes

The incorrect position of the film roll, and incomplete pulling of film can create pouch-forming issues.

Solution

By having a check on the film pulling station, accurate and appropriate positions of the film roll can be used as tools to eradicate this problem.

10.What are the key factors you should reflect on when buying a nicotine pouch packing machine?

Here are the key factors on which you should reflect while buying a nicotine pouch packing machine that is suitable for your required tasks. You should consider the given key factors.

Material nature

White Nicotine Pouch Packing Machine

The nature of packing material (solid or liquid) for which the pouch packing machine is to be bought should be taken into consideration first. It will help you to choose the right one for your business. It will aid the dealer in suggesting the best machine for the type of material nature.

Reasonable price

Pouch Packing Machine: Picture Courtesy: Trade Bird India

Machines can be of various prices; some may be that expensive because of their efficient working and time-saving qualities, and also some may be cheap because they do not make the task as convenient as compared to the expensive one. But the one with the best qualities and an affordable price should be chosen according to your budget.

Capacity and Speed

Nicotine Pouches : Picture Courtesy: NPR

The rate per hour of the nicotine pouch packing machine is an important factor that you should have to look at before it’s purchased. The most effective is the one whose working rate per hour is higher. It will reduce the time and increase the production. The rate of production also depends on the capacity of the machine, so it is also a key factor to be checked. The higher the capacity, the more will be the production.

Quality and warranty

Nicotine Pouches Packing Machine: Picture Courtesy: loyal

The most basic factor that you must check before buying the nicotine pouch packing machine is the quality of the machine. The greater warranty reflects the best quality of machine. For your satisfaction, you can check the machine’s working quality and warranty policy.

Conclusion

Now you got the idea that a nicotine pouch packing machine can benefit your business in bringing it to a higher level with its high efficiency, greater production and multiple functions. This machine is not only capable of carrying of nicotine pouch packing but you can get benefits of other packaging tasks too. What are those? How the machine benefits you? If you are interested in buying a nicotine pouch packing machine, you can find its different varieties from Allpack. Their deals will suit your requirements. You can contact us if you want further information.

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide

Tell us your material or budget, we'll reply you ASAP within 24 hours