Chlorine Tablet Press Machine: The Complete Buying Guide In 2025

Wait a second! Are you in search of a guide that gives you whole information about chlorine tablet press machine? Here you got it! This ‘Chlorine Tablet Press Machine: The Complete Buying Guide In 2024’ will cover every aspect of the main theme. Starting from its introduction, it will tell you its benefits, applications, elements, operation method, maintenance and important factors that you should consider before buying this machine.

Let me tell you the questions this guide will deal with:

1.What is a chlorine tablet?

Chlorine Tablets Use for Pools

A chlorine tablet is a compact form of chlorine gas prepared in tablet form for suitable dosage. It is used for removal or putting an end to the presence of microorganisms in water.

Chlorine tablets are made for the purpose of cleaning water or any other liquid. It functions best for the disinfection of water which works in the release of chlorine from water from time to time. Its composition involves dichloroisocyanuric acid and trichloroisocyanuric acid which implies that it contains chlorine in abundance i.e. 90-95%.

2.What is a chlorine tablet press machine?

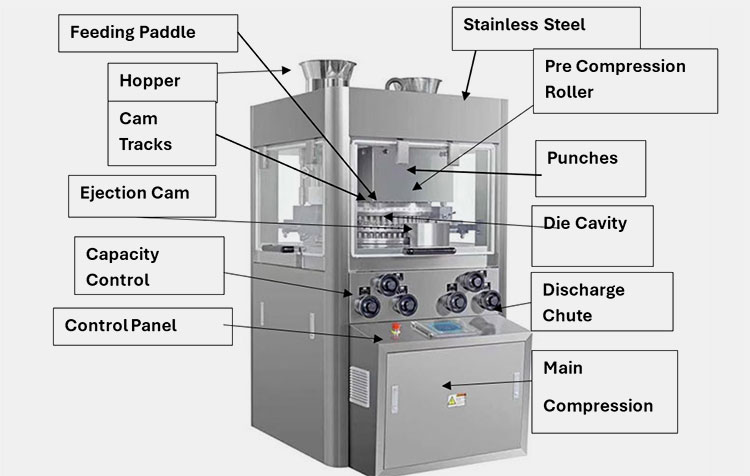

Tablet press machine: Picture Courtesy: AIPAK

A chlorine tablet press machine is also termed a ‘ chlorine tablet punching machine’. It is a highly specialized machine that makes the task of making chlorine tablets easy as well as automated. Hence it automatically compressed the dosage powder into compact form of tablets having well-proportioned size and uniform dimensions.

Basically, it helps in pressing the granular substances or tablet dose which is in powdered form. In this way, the powder or grainy substance has its solid shape and compact size. Moreover, this innovative machinery designs hollow containers that is called mold and utilizes it to give specific shape and size to the chlorine tablets.

3.How does a chlorine tablet press machine benefit you?

The chlorine tablet press machine has all your desired features to benefit you in many ways;

Topmost Efficiency

Highly Efficient Chlorine Tablet

Manual methods which were used for pressing tablets is very time as well as energy-consuming. Moreover, these traditional methods are more likely to be erroneous. But presently, chlorine tablet press machine makes this task trouble free and effortless. It works smoothly along with topmost efficiency.

Operational Consistency

Consistency in Process

With a PLC control device installed in the chlorine tablet press machine, it enables the operation to be done more competently. Hence you won’t face any inconsistency in tablet dose during the whole process.

Maximum Degree of Precision

Error-Free Chlorine Tablet Production

Its automated operation make certain the process is aligned with maximum degree of accuracy and precision. It has an automatic system of detecting missing doses to keep the tablet dosage uniform throughout the process.

High Quality Production

Greater Production

Chlorine tablet press machines is economical for small enterprises as well as big companies because it can be installed in less space as compared to other heavy machinery. Hence giving its owner more benefit with its high production capacity in a short period of time.

Alternativeness in Dimensions

Variety of Products

Moreover, industries can reap financial rewards from chlorine tablet press machine because they can deal with a variety of materials to be pressed. This variation gives them the opportunity to enter into various businesses with this single advanced machine.

4.What is the industrial use of a chlorine tablet press machine?

Today’s era is the age of seeking multitasking machines so you may get multiple advantages. The same is the case for machines, one searches to get solutions offering less human intervention, and giving more production together with producing varieties.

Many industries are searching for the type of automatic machinery that can be used for different purposes or in different industries. You can invest in chlorine tablet press machine for various commercial applications. Let’s see which businesses can use this machinery;

Pharma Industry

Pharmacy Drug Health Tablets

Pharma-corporations deal with the production of medicines, and they provide these medications with safe packaging. As this is concerned with the patient’s health and people’s life, it is a very delicate business to deal with.

A tiny defect in dose can lead to adverse effects on patients’ s physiology and affect the reputation of the industry.

But a chlorine tablet press machine is a quick fix for these issues. It can press the tablets in bulk meanwhile maintaining the quality standards, dose, and consistency of your product with its highly efficient devices.

Nutraceutical Industry

Nutrients Supplement

The Nutraceutical industry needs chlorine tablet press machine for preparing supplements of fruits, vegetables, or other nutrients in this form.

The chlorine tablet press machine is useful in this sector to produce nutrient supplements from a mixture of different things such as minerals, vitamins, phytochemicals, plant extracts, or botanical compounds etc.

Chemical Sector

Tablets Use as Fertilizer

The chemical sector has its own applications from chlorine tablet press machines. The industry uses varieties of pesticides, antiseptics, and decontaminating agents including phenyl, fertilizers etc. These all items are converted into tablet shapes having different sizes for more convenient use. So, chemical industries can install this machine for the usage of these products in tablet form so that an appropriate amount of dose is taken.

Food industry

Food Wash Cleaning Tablets

These machines are useful for making food goods that are generally used in compact form. Therefore, it is widely spread throughout the globe in the food processing or also catering industries. It is highly recommended to use for making compact food products such as mint, confectioneries snacks etc.

5.Does a chlorine tablet press machine deal with other items?

Chlorine tablet press machine can deal with a variety of substances and transform them into tablet form but be aware! It can not convert all your powdered items into compact form such as tablets.

The automatic chlorine tablet press machine is capable of providing a compact shape to the powdered substances efficiently. Moreover, granules can also be pressed together to form a tightly packed tablet dose.

Loose Particles

Picture Courtesy: mcePharma a.s

Many items are needed in specific doses that are basically in powdered form or in loose particle shape. These loose particles are present in different sizes and shapes. The chlorine tablet press machine helps in pressing this powdered form into a compact structure called a tablet.

A tablet is a suitable form for powder because it contains the appropriate amount of dosage needed for any purpose.

Granules

Nutrient Supplements

Granules are also particles in nature but their size is smaller than a pebble or bigger than a sand particle. But this machine with all its latest technology, can turn granules into tablets with much ease and comfort.

6.What are the major parts of a chlorine tablet press machine?

A chlorine tablet press machine is composed of various components featured with innovative traits. These components are listed below;

Components of Chlorine Tablet Press Machine: Picture Courtesy: AIPAK

Hopper

The material is loaded into the hopper of the feeding system present in a chlorine tablet press machine. An optimum amount of raw material is used to fill the hopper making certain uniformity in the whole manufacturing process of chlorine tablets.

Die Cavity

This is one of the most significant components due to its vital role of compressing the powder into compact shaped tablets. The die cavity is designed in such a way that makes it compatible with shape or size of tablets, its diameter or thickness etc.

Feeding Paddle

The feeding paddle is the component that feeds chlorine powder into die cavity. Meanwhile, it ensures the required weight or dimensions of a tablet along with its quick rotation.

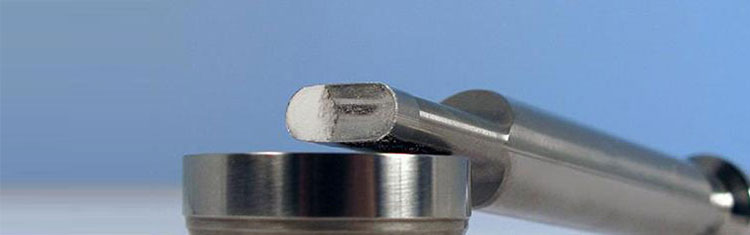

Punches

Punches are primarily inserted to press the powder into tablet form. The chlorine tablet press machine consists of two punches named upper punch and lower punch. Both have their own function. The upper punch moves in a downward direction to press the powder and give it a compact shape. While the lower punch moves in an upward direction to throw out the compressed tablet.

Cam Tracks

Cam tracks are induced into the chlorine tablet press machine to guarantee that both the upper and lower punches are functioning in a normal state.

Ejection Cam:

Ejection Cam is the component that becomes functional when the powder is pressed by the punches and the chlorine tablet is ready in a compact design. It moves the prepared tablet in upward direction by guiding the lower punch. In this way, it ejects the chlorine tablet from the die cavity.

Capacity Control

Capacity control is induced to keep the tablet in the die cavity till the time it is compressed by the punches.

Pre-Compression Roller

Pre-compression roller are there to release the surplus air captured in the die cavity. It performs this function by providing these with the compression force during the process.

Main Compression

Now, this is the component that ensures the chlorine tablets’ firmness, density, or its endurance ability. It gives the finishing compression force to give it high stability or durability.

Discharge Chute

The primary function of the discharge chute in a chlorine tablet press machine is to convey the prepared and compressed tablets from the main compression towards the tablet collection centre.

Operational Panel

This is the control centre of a chlorine tablet press machine which is used to set various parameters such as; diameter, pressure level, or thickness of the product.

7.How does a chlorine tablet press machine work?

The chlorine tablet press machine’s working principles depend on the type or model of the machine. But here you will study the general mechanism in which it works.

There are four (4) fundamental stages involved in this process.

Filling

Picture Courtesy: Shanghai Tablet Press Mechanics

It is the first step to initiate the process of chlorine tablet compression. The hopper is filled with the powder which uses free paddles to transfer it to the die cavity. The powder is distributed evenly or uniformly into each die.

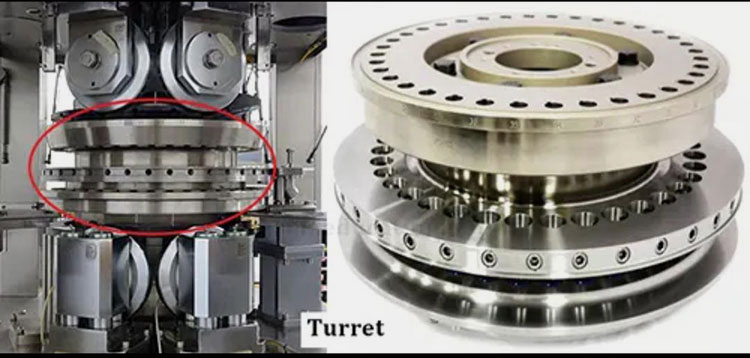

Metering

Picture Courtesy: Herun Machinery

This is the second phase of the chlorine tablet pressing process. This step is significant because it is concerned with the discharge of extra powder from turret. In this way it controls the quantity of powder as to ensure right quantity. Metering, basically allows the correct dose for chlorine tablet pressing.

Compression

Picture Courtesy: LinkedIn

Compression is completed in two phases;

Pre-Compression Phase

This phase is subjected to lowering the upper punch due to which the ingredients present in the die cavity are applied with tolerable pressure. This aims to form a compressed mass from powder called slug.

Slug helps in removing extra air gaps from the powder which is base for pre-compression phase.

Main-Compression Phase

This phase is characterized by applying additional pressure over the slug by upper punch. It results in the additional compression of the powder and finally in this phase the powder is changed into a compact form i.e. tablet. In simple words, it gives final shape to the powder and transformed the powder into tablet form.

Ejection

Picture Courtesy: Wanbin Ren

Once you are done with the compression phase, tablets now enter into the next phase which is ejection. For this purpose, the lower punch moves upward and let out the prepared chlorine tablet from die pocket. Lubricants are applied for smooth ejection of the tablet from die cavity which helps in preventing the process from stopping or the tablets from jamming or clogging.

8.What are the various types of chlorine tablet press machine?

You can find a wide range of chlorine tablet press machine according to your production requirements. These are different from each other in terms of their structural design, capacity for production, speed, tablet structure or shape etc. Lets learn the most important chlorine tablet press machine with its brief description.

Single Punch Chlorine Tablet Press Machine

Allpack Single-Punch Automatic Tablet Press Machine

Single automatic chlorine tablet press machine is the machine which has simplest configuration or design. It is suitable for the small- scale businesses whose production capacity is limited.

It is very simple to operate as it has a set of two dies and a punch that performs the function of pressing the powder into compact tablets in uniform manner. This machine has the options for you to get different tablets by just changing its parameters of punch or dies.

It works in the following way:

- Set the dies and punch with required parameters.

- The powder moves through feeding hopper.

- After that, dies fill with powder.

- Here in the dies, the powder will be applied with necessary pressure from punches.

- And pressure turns the powder into tablet.

- Finally, the tablet is ejected in the form of compact chlorine tablet.

Rotary Automatic Chlorine Tablet Press Machine

Rotary Automatic Chlorine Tablet Press Machine: Picture Courtesy: AIPAK

Rotary automatic tablet press machine is available in many varieties from basic to most advanced one. These variants are different from each other with regard to its level of automation and the process flow rate.

The machine has applications in a wide range of industries due to its expeditious speed and unfailing net results. It is its high-efficiency that make it able to deal with millions of tablets in a single hour meanwhile retaining the tablet quality.

Let’s learn how it works:

- It starts with the filling of powder into the hopper where it undergoes wet granulation procedure.

- In the second step, the required amount of powder is poured into the cavity.

- In third step, the basic process of compression occurs where required amount of pressure is exerted onto the powder and it turns into tablet.

- The fourth step is related to the discharge of the prepared tablet when lower punch rises in upward direction.

Bilayer Tablet Compression Machine

Bilayer Tablet Compression Machine- Picture Courtesy: deepujpharmamachinery

Now this machine has got some interesting features and it is specially designed for making bilayer chlorine tablets. It makes bilayer tablets by contraction or pressing of two formulations in each separate tablet. Pharmaceutical, nutrient-specific businesses, or food sector are using this machine for large-scale production due to its innovative technology.

Its working procedure is discussed below:

- At first the die cavities are filled with first formulation and here it is compressed with punches.

- Now, these die cavities are moved with turret and loaded with second formulation.

- Here the function of main compression begins which exerts pressure over these formulations and give them a compact shape i.e. bilayer tablets.

- After the formation of tablets, these are ejected one by one from the die cavities.

Multilayer Chlorine Tablet Press Machine

Multi Layer Chlorine Tablet Press Machine: Picture Courtesy: deepujpharmamachinery

If you want one of the most modern chlorine tablet press machine featured with innovative traits, here is multi-layer chlorine tablet press machine. It has unique capability of making three-layered chlorine tablets where each layers’ dose is formed with high precision. It ensures this high-precision dosage with the help of its weighing or checking features.

The operative steps of this machine are the following:

- The die cavities are loaded with first kind of powder to be compressed by punches.

- After pressing the first powder, the turret brings second powder into the feeding cavities and pressed with the help of punches.

- Once second powder is pressed uniformly, two layer are made.

- Now, third powder is filled in these same die cavities and compressed altogether with other two powder layers.

- In this way three-layer chlorine tablet is produced and then discharged through the discharge chute.

9.Which maintenance techniques are necessary for a chlorine tablet press machine?

The following maintenance techniques help you in decreasing the chances for malfunctioning of the machine during the production procedure. These techniques can be exercised on daily, weekly or monthly basis.

Regular Clean-up

Picture Courtesy: Shang Hai Shi

Cleaning the machine regularly and dusting it, ensures its efficiency for a longer period of time. It is very important to clean or dust all the components including hopper, punches dies to prevent any trouble during compression tablets.

Lubrication

Apply good lubricants over the parts such as rollers, punches, or other movable parts. It will guarantee the process to be completed in a uniform manner.

Look for Wear and Tear Parts

Picture Courtesy: Pharma Efucat.Net

It is better to keep a check on the machine regularly and look for its damaged or non-functional components. If you find any, replace them with the new ones to keep it working smoothly. Moreover, in this way, you will prevent further damage to the machine.

10.How to troubleshoot the problems with the chlorine tablet press machine?

While working with a chlorine tablet press machine, you might encounter some unfortunate incidents that could stop the manufacturing process or slow it down. But do not worry about this as every problem has its solution. Some are very common troubles related to these machines that have easy solutions, so let’s learn about it.

Chlorine Tablet Capping

Picture Courtesy: Romaco

Chlorine tablet capping refers to the breakdown of the layers of the tablet during the production process. Its main cause is the entrapment of air in the powder. When excessive air is unable to get out during the compression of the powder, this situation arises.

Solution

By increasing the time of stay during the compression stage helps the powder to release extra air which otherwise causes chlorine tablet capping. The resetting of punches, or dusting or cleaning of dies will also be helpful in tackling this issue.

Powder Sticking

Powder Sticking: Picture Courtesy: Scientist Live

Sometimes you find the powder particles to adhere with the heads of the upper or lower punches. It's quite irritating as it slows down the process of compression of tablets. It may be caused by to presence of moisture in the powder particles. While it may cause the other way round, for punches heads or tips may also catch the particles.

Solution

The solution for this problem is to dry the powder adequately or to increase the time for compression following its wet granulation. Additionally, it is recommended to polish the punching tools frequently. It will minimize risk of sticking of powder with punches’ tips.

Production of Attached Chlorine Tablet

Chlorine Tablets

This is the condition when tablets are tightly attached to each other and unable to get separated. It happens due to the overuse of binding agents, as it results in attaching the sides of tablets to each other.

Solution

The best solution for this issue is to use the appropriate quantity of binding agents. Reducing the lubrication is also a good thought to avoid this condition.

Tablets’ Fragility

Non- Fragile Chlorine Tablet: Picture Courtesy: Freepik

Fragile tablets are a big challenge for the packaging or filling industries. The fragile condition of tablets makes them more vulnerable to breaking during their coating or delivery. It has three major reasons. These include:

Limited binders.

Compression speed goes beyond the normal degree.

Particles having relatively larger size than normal i.e. powder isn’t in its finest state.

Solution

Don’t worry! It has its own tactics such as: apply binders in the ingredients in required amount, bringing the pressure to optimum level, and check the granules’ size. This will solve your problem and the production process won’t get stopped.

11.Enumerate a list of relevant factors that should be considered while purchasing a chlorine tablet press machine?

There are a number of factors you should consider before buying a chlorine tablet press machine. Lets discuss it one by one.

Production Capacity

Greater Productivity

Go for checking the production capacity of the chlorine tablet press machine first and then decide which one to buy. It is a very crucial factor as it directly affects the profit outcome of your business.

Efficiency

Efficient Chlorine Tablet Production: Picture Courtesy: Easy Pooling.com

If you want to achieve your manufacturing demands on time in fact in a short period of time, you should consider the efficiency of the machine. It is important to have knowledge about the speed of the machine and its durability.

Construction Material

When buying a chlorine tablet press machine, you should select a machine with highly strong structural features. For example, a machine made up of stainless steel will be highly resistant to heat or corrosion. Therefore, to avoid loss of time, energy, and investment, it is better to select a machine constructed with high-quality material.

Expert’s opinion

Chlorine Tablets: Experts Choice

If you are a beginner in this area of business, you should give a thought to ask a consultant or expert of the machine for a better choice.

Conclusion

In a nutshell, buying a chlorine tablet press machine will be beneficial for you and it will open the door of success for you in many related industries. As its application shows its multi-functioning capabilities ranging from pharmaceutical industries to food and chemical corporations, now you can opt for the best one that meets your demands. If you are interested in purchasing this machine, AllPack has all the varieties of this machine. Allpack has modelled such innovative chlorine tablet press machines that have all important and useful features. If you are left with any questions in your mind then we are here to assist you. Feel free to contact us.

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide