Cap Torque Tester:The Complete Buying Guide In 2025

Are you curious about how manufactures ensure the safety and quality of the product packaging? The cap torque tester plays an important role. With its high precision and stability, the cap torque tester has become increasing popular in many industries.

Have you seen how the cap torque tester accurately measures the torque value? Do you have any doubts about the definition, applied industry, types, main parts and other related elements of cap torque tester?

Next, I will provide you with the most complete buying guide for cap torque tester.

1.What Is the Cap Torque Tester?

Cap Torque Tester - Sourced: crane-electronics.com

The cap torque tester refers to a device that carefully measure the torque values of the bottle caps. This device is also called as bottle cap torque tester, which involves many packaging products, including bottles, and beverage containers.

This device can also meet the requirements of pressure type bottle cap locking and opening force testing.

2.What Are the Features of the Cap Torque Tester?

Why choose a cap torque tester? What are the features of this machine? The following reveals the features of this device.

(1)High precision measurement

The cap torque tester can get high precision, duet to its sensor. You can use it to ensure the quality of your products.

(2)Adjustable

The grips and fixtures of the cap torque tester can be adjustable, so it can be adjustable to different bottle caps.

(3)Good stability

Good stability - Sourced: Pix4free

Through stable fixing devices and advanced measurement technology, the cap torque tester ensures good repeatability and stability of testing over a long period of time.

3.What Are the Applied Industries of Cap Torque Tester?

Do you know which industry can cap torque tester apply? This high-precision cap torque tester plays an important role in multiple industries. Next, let’s explore the main industries in which it is applied together:

(1)Pharmaceutical industry

Drug - Sourced: SKS Bottle

Many pharmaceutical industries use cap torque testers to detect the safety of the products. I believe everyone has taken drugs, so you must know that lots of drugs are packaged by various bottles. The sealing of drug bottle is related to the quality of the drug, and even related to the people’s health.

(2)Food and beverage industry

Beverage - Sourced: SKS Bottle

As you known, the cap is related to the quality of the products. And now, bottle packaging is widely used in the food & beverage industry.. Therefore, the cap torque tester is also used in this industry to avoid leaking during transportation.

(3)Cosmetic industry

Cosmetic - Sourced: Sphere Resources

Cap torque tester is also used in the cosmetics industry to test the torque value of packaging bottle caps. As you can see, many cosmetics are used in the bottles, which need good sealing.

If the cosmetics bottle leak, the liquid will get worse and unable to use, so it will affect the customer’s buying experience.

In a word, cap torque testers are widely applied in these industries to ensure these products in good sealing and good quality.

4.What Arethe Benefits of Cap Torque Tester?

Why use a cap torque tester? Do you know what benefits it has? The benefits mainly manifest in the following aspects:

(1)Avoiding air leakage issues

Air Leakage Issues - Sourced: Alltopbargains

Leakage issues can affect product quality, customer shopping experience, and more. Cap torque tester is widely used in various products, effectively avoiding air leakage and oxidation problems, and maintaining product safety.

Saving cost

The cap torque testers contribute significantly to cost savings by minimizing wasteful product loss and diminishing the necessity for rework, thereby optimizing production efficiency, and reducing overall expenses.

Improving product quality

Improving Product Quality - Sourced: solidworks.com

The cap torque tester can accurately improve product quality and increase product qualification rate. For products that fail the inspection, they will be removed to ultimately ensure the safety of the products in the hands of customers.

5.How Many Types of Cap Torque Testers?

Have you seen different types of cap torque testers? Do you know how many types of this device? Next, I will introduce two main types.

(1)Handheld cap torque testers

Handheld Cap Torque Tester - Sourced: mark-10.com

Handheld cap torque testers are small than other kinds of testers, so it is convenient to carry. This kind devices are mainly used to measure the tightness of bottles.

As showed in the above picture, handheld cap torque testers are equipped with a digital indicator, which can clearly show the test results. This device can detect samples of various sizes and shapes.

(2)Desktop cap torque testers

Desktop Cap Torque Tester - Sourced: sotax

Desktop cap torque tester is suitable for measuring PET bottles and other materials, and is often found in scientific research in laboratories. It has higher measurement accuracy and stability.

The desktop cap torque tester can also be suitable for products of various sizes, mainly for occasions that require high testing accuracy

6.What Are the Main Parts of Cap Torque Testers?

Although the cap torque tester is relatively compact, it also has many complex components. The cap torque tester is mainly made up of four parts. Well, let’s explore the main parts of cap torque tester together.

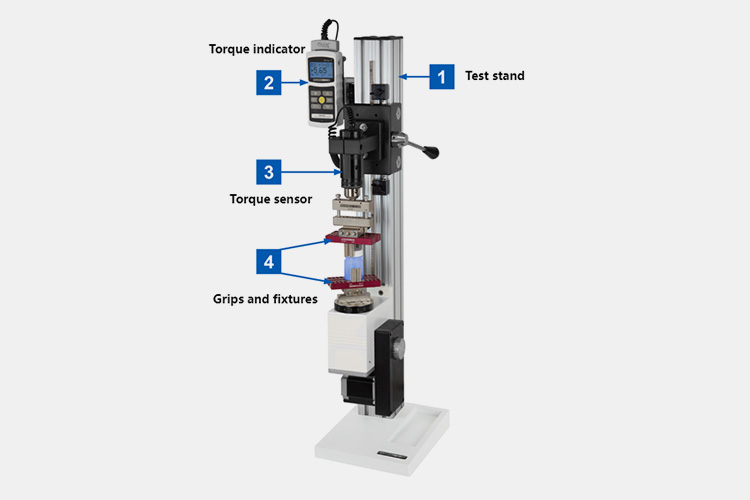

Main Parts of Cap Torque Testers - Sourced mark-10.com

Test stand

The test stand is the supporting part of the entire machine. So, the test stand is stable and durable to hold the whole device, which can ensure the normal running of the equipment and keep the accuracy.

Torque indicator

The torque indicator is also very important, which is used to display the torque value to operators. With the development of the technology, many torque indicators often use digital indicator, which are clear for operators.

Torque sensor

The torque sensor is the key part of the cap torque tester, and this device is used to accurately measure the torque value.

Grips and fixtures

Grips and fixtures are used to keep bottle caps do not slide or shift during the testing process. To cater different types and sizes of bottle caps, the grips and fixtures should be designed to adapt to them.

The four parts are the core parts of the cap torque tester, to be honest, there are also many other small parts in this device.

7.What Is the Working Principle of theCap Torque Tester?

Working Principle of The Cap Torque Tester - Sourced: mqs

Have seen how the cap torque tester work? Are you curious about its workflow? The working principle of the cap torque tester is mainly based on torque sensor technology. The workflow of the cap torque tester will experience four steps:

Step1: Preparing the sample

You should prepare a sample bottle and fix the it on the grips and fixtures of the cap torque tester, and the bottle should be kept stable.

Step2: Setting test parameters

After placing the bottle, you should set the required parameters for testing through the control system, including rotation direction and rotation speed.

Step3: Starting the device

Start the cap torque tester, and torque sensor will lead the cap to rotate. During the process, the torque sensor will monitor and record the torque value required for the bottle cap to rotate.

Step4: Outputting the result

The torque indicator will show real-time torque values. You can refer to the date and check it.

8.What Quality Standards Should A Cap Torque TesterMeet With?

Cap torque tester also need strictly follow the quality standards. Do you know what are they? Here is an overview of some major ASTM Standards and ISO Standards:

(1)ASTM D7860-14

ASTM Standards - Sourced: Nimonik

ASTM International is a standard about the products, service, and others. The ASTM D7860-14 standard is used for packaging of child resistant containers, specifying the testing method for cap torque testers to ensure packaging safety, and keep it use easily for children.

(2)ASTM D3474

ASTM D3474 also belongs to the ASTM Standard. This kind standard categorizes child-resistant packaging as a vital measure to safeguard products from unintended access by children, thereby mitigating the hazards of accidental ingestion or exposure to potentially dangerous materials.

(3)ISO 17025

ISO Standards - Sourced: GenomSys

ISO, as a national standards body in the world, has also developed a standard about torque testing. As a part of ISO Standard, ISO 17025 standard ensures accuracy of testing results of testing and calibration in laboratories.

The operators should strictly adhere to ISO 17025 standard, because it serves as a test to their quality management systems.

9.What Should You Consider When Choosing A Cap Torque Tester?

Do you want to purchase a cap torque tester? When choosing this device, you need to consider multiple factors.

(1)Ease of use

When purchasing a cap torque tester, you need to choose a machine that is easy to operate, such as a clear interface and simple operation process, which can improve your work efficiency.

(2)Accuracy

Measurement Accuracy - Sourced: Adobe Stock

Accuracy is closely related to the quality of the product. Therefore, you should choose a high-precision cap torque tester, which is crucial for the accuracy measurement results.

(3)Capacity

It is very important to ensure that the cap torque tester’s measurement range aligns with the specific torque testing demands of the bottle caps. Given the potential variation in torque values among bottle caps for different products, selecting an appropriate measurement range tailored to the actual application is crucial.

(4)Device with good brand

Brand - Sourced: Adobe Stock

As the saying goes, the fragrance of wine is not afraid of deep alleys. Products with good reputation and brands have a certain quality guarantee. Therefore, when choosing a cap torque tester with a good reputation, you will get reliable product quality and after-sales service.

10.What Are the Common Issues and Solutions for Cap Torque Tester?

During the use of the machine, problems are inevitable. The cap torque tester may encounter some problems during use, and we can solve simple problems ourselves. Therefore, it is very important to understand the common problems and countermeasures of cap torque testers.

| Common Issues | Solutions |

| Power supply | When meeting this issue, you should check the power plug. And then, you should check the situation of the power switch and ensure if it is damaged. |

| Inaccurate reading or data loss | When you read the measurement results are not accurate or you find the situation of date loss, you should check the power connection of the torque sensor and the quality of the torque sensor. If the torque sensor is damage, you should change it. |

| Mechanical alignment | Mechanical issues may affect measurement accuracy. You should pay attention to the cap torque tester to see whether it keeps in suitable place. |

| The torque indicator doesn’t show the result | If you have seen the torque indicator doesn’t show the result, you should check the power connection of the torque indicator. If the device cannot run normally, you should change it. |

11.How to Maintain the Cap Torque Testerfor Effective Work?

Things need maintenance in order to last, and machines are no exception. Therefore, you need to maintain the cap torque tester to ensure its accuracy. Here are some specific maintenance solutions:

(1)Cleaning

Cleaning - Sourced: CLH Healthcare

Device need clear regularly, so does cap torque tester. When the cap torque tester stores for a long time, it will generate dust and other debris. You should wipe it with a soft cloth and avoid using hard objects for cleaning. Special attention should be paid to sensors and their connection points.

(2)Calibrating

Calibration - Sourced: eleymet.com

If you do not calibrate the machine, it may cause error during the measurement progress. So, you should regularly calibrate the cap torque tester according to usage frequency and accuracy requirements to ensure its measurement accuracy.

(3)Replacing worn parts

For severely worn components, you should replace them in a timely manner to ensure the overall performance of the cap torque.

12.What Is the Future Trend of the Cap Torque Tester?

As a key equipment in packaging quality control, what is the future of the cap torque tester? Are you curious? Let’s explore its future trend together.

(1)Higher precision

Higher Precision - Sourced: thoughtco.com

With the continuous advancement of sensor technology, the cap torque tester will adopt higher precision torque sensors. In addition, it will adopt more advanced data analysis systems to ensure the accuracy and stability of measurement results.

(2)More Adaptable

Artificial Intelligence - Sourced: DigitalMara

With the development of artificial intelligence, the cap torque tester in the future will use AI to achieve more accurate measurement. Therefore, this device can be adjustable to more types of bottle mouths, and meet the needs of more customers.

Conclusion

The cap torque tester serves as a significant part in packaging quality control in industries such as food, beverage, and pharmaceutical due to its advantages. This article introduces a series of buying guide of the cap torque tester in the hope of providing assistance to you. If you want to know more, feel free to contact Allpack at any time.

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide