Your Significant Pharmaceutical Tablet Hardness Supplier

- High Precision&Reliability In Measuring

- Adaptability For Larger Diameters &Higher Pressure

- Improved Safety and Reliability

Tablet Hardness Tester

Allpack Tablet hardness tester is instrument for detecting breaking hardness of tablet, it is a necessary instrument for testing the hardness value of tablets.Test data is displayed and locked automatically, so can test be reset and cycled.It can deal with and print out such data as: hardness of each tablet, the maximum value, the minimal value, the average value and the number of tablets. The tablet hardness tester has been widely used in pharmaceutical factory, laboratory and scientific research. For automatic continuous tests, the tablet hardness tester will provide the function of querying the results of previous tests.It can realize automatic tablet compression, automatic display, automatic latching, automatic reset, automatic cycle test, automatic linear error correction and automatic fault diagnosis.

Allpack Tablet Hardness Tester

APK-350N Intelligent Tablet Hardness Tester Tablet Hardness Apparatus

Allpack APK-350N Intelligent tablet hardness tester is a special instrument for measuring the hardness of tablet drugs. It adopts international advanced design concept and manufacturing technology. The shape is smooth, beautiful, compact and stable, and it is highly reliable and easy to operate. This tablet hardness tester is widely used in pharmaceutical factories, medical research, teaching and research and drug inspection departments.Built-in user management, data management system, and long-term storage of test data.It can be tested continuously for 1000 times, and the user can adjust the continuous test interval.

Smaller size, higher precision, more complete

Simple and user-friendly interface and method

Weak current working voltage is safer

APK-200C High Efficiency Laboratory Digital Tablet Hardness Tester with Printer

Allpack APK-200C tablet hardness tester is suitable to making trial of tablet's hardness in each of medicine factories, education and research of medicine, and medicine examining departments; Equipped with advanced transducer's circuit installation of taking in and taking off with motor for automatic measure, operation convenient, measuring accuracy high and good intuition of measuring value displaying with digital tube in this instrument regarding being master of laboratory's datum relative to medicine tablet's hardness reliability how to effect on coating, packing and transportation as well as to degrees of cracking relief and dissolution of medicine tablet's measured hardness, essential to be offered.

LCD Display

High-precision pressure sensor ensures the precision and reproducibility of test.

Easy operation

The Buyer's Guide

Tablet Hardness Tester: The Complete Buying Guide In 2025

Do you want to make your tablets quality testing more strict? That's great! A successful pharmaceutical manufacturer must always have a priority to know the properties of compressed tablets in order to avoid inconsistencies. In this way, tablet hardness tester is an ideal solution to check the tablet breaking force.

This innovative solution allows you to conduct a safe and convenient testing for your tablets, so, their hardness can be easily found. Whether you want to discover the calibration, working process or troubleshooting of a tablet hardness tester, this buying guide is going to be the best partner of yours. So, be ready to explore it!

1.What Is Meant By Tablet Hardness?

Holding tablet in fingers

Tablet hardness simply refers to the strength of a compressed tablet to resist breakage. It means the higher the tablet hardness the stronger it will be to endure force while as the lower tablet hardness will require little force for cracking.

Now, the question is why is it important to find the tablet hardness? So, the answer is simple! Because tablet hardness influence the drug release timing and its potential effects which are considered paramount in pharmaceutical industry.

Therefore, a tablet hardness tester is used to know the hardness of compressed tablets, so, the quality of tablets can be found and best practices may be adopted to produced consistent and effective tablets.

2.Define A Tablet Hardness Tester?

Allpack- APK-200C Tablet Hardness Tester

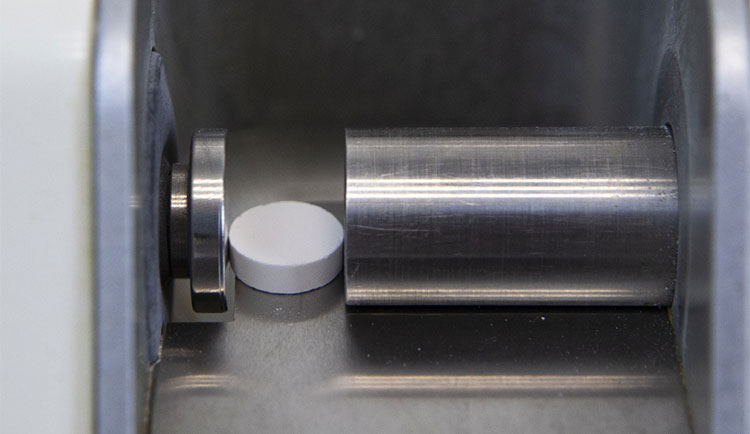

Tablet hardness tester is a specialized equipment tailored with wonderful specifications to find out the hardness of tablets. It uses platens or stainless steel jars for testing tablets hardness. The tablet is simply placed between the parallel jaws and force is applied to squeeze the tablet. The applied force is then recorded in the tester in newtons which becomes the tablet hardness value.

This tablet hardness tester is best suitable to process any kind of small to large or sensitive to hard tablets. Similarly, with small footprint and range of models it is quite easy to operate the tester. Hence, its importance can be seen in industries producing compressed tablets encompassing pharmaceutical, nutraceucal, and veterinary sector.

3.What Are The Benefits Of A Tablet Hardness Tester?

The use of a tablet hardness tester is beneficial for various reasons such as it helps in maintaining the integrity of tablets, controlling their solubility, and enhancing compliance. These advantages can be easily understand by reviewing the underlying explanation:

Portable Design

Allpack- Portable APK-350N Tablet Hardness Tester

The first benefit of a tablet hardness tester is associated with its structure which is easily portable. It is just comprised of few components, thus, no space is taken by it and you can simply place it anywhere in your production facility, laboratory, or office.

Assessing Accuracy

Tablets in hand- Picture Courtesy: soona.co

Tablet hardness tester uses latest measuring techniques to record the force frequency. It notice the minute change that take place during testing. Thus, you will be provide with accurate data upon which you may rely for successfully manufacturing quality tablets.

Quality Maintenance

Quality maintenance of tablets icon- Picture Courtesy: worldpharmatoday.com

A tablet hardness tester can greatly help you in maintaining the drug quality control and enhancing its compliance to the regulatory standards. Thus, you will be able to produce tablets with desired specifications.

Flexible

Various types of tablets- Picture Courtesy: stock.adobe.com

Another most interesting fact about a tablet hardness tester is its flexibility to test all kinds of tablets regardless of the shape, size, and structural integrity. Therefore, it has wide application for all types of tablets.

Provide Information

Tablet hardness tester provide essential information regarding the tablets which are helpful for choosing the right technique for packaging, handling, and transportation. Moreover, it enable you to control the changes like tablets friability, dissolution, and disintegration rate.

4.What Type Of Tablets Can Be Tested By A Tablet Hardness Tester?

A tablet hardness tester can deal with any kind of tablet. These include:

Coated Tablets

Coated tablets- Picture Courtesy: pharmamachinery.co.uk

Mostly, compressed tablets are coated to cover their unpalatable taste, odor and maintain their structural integrity. This coating vary from simple thin coating to enteric coating which solidify the tablets. However, you can simply test the hardness of such tablets by using a tablet hardness tester.

Uncoated Tablets

Uncoated tablets- Picture Courtesy: lfatabletpresses.com

Compresesed tablets without coating like buccal tablets, effervescent tablets, sublingual tablets, and other regular tablets are also eligible to be tested by a tablet hardness tester.

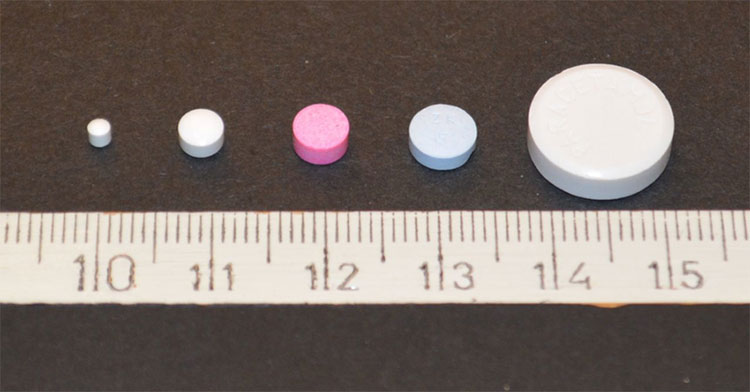

Different Size Tablets

Different sizes of tablets- Picture: researchgate.net

Tablets are produced in small to large size to facilitate certain dosage requirements. Keeping this in view, a tablet hardness tester is designed in such a way that it supports the handling of all sizes tablets.

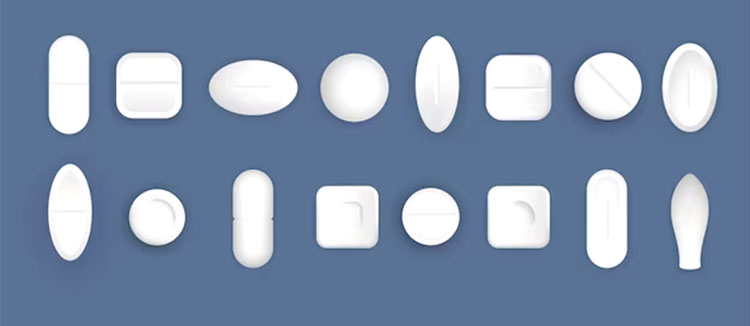

Different Shape Tablets

Various shapes of tablets- Picture Courtesy: Freepik

Similar to size, the shapes of tablets also vary including oval, oblong, triangle, round, pentagon, and heart etc. Simply, these all are testable with same kind of a tablet hardness tester.

5.How To Operate A Tablet Hardness Tester?

Operating a tablet hardness tester is a piece of cake. You just need to understand the working mechanism of the tester and employ it for tablet hardness testing. It will include the following steps:

Tester Setting

Tablet hardness tester setting

Pick up your tablet hardness tester and place it on flat surface. Now, set it properly by adjusting the bars and functional parameters. It is important to apply pressure on tablets in accordance with their manufacturing parameters to avoid harm to tablets and recording false data.

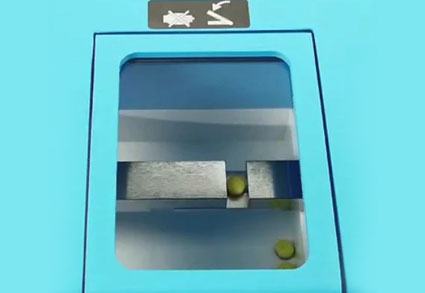

Tablet Positioning

Once you have done the setting, just feed the desired tablet to the tester by placing it between the indenter. Make sure to position the tablet in right way especially when testing irregular shape tablets like pentagon and triangular tablets.

Force Application

Tablet hardness tester applying force to tablet- Picture Courtesy: merlin-pc.com

Press the power button to start testing. The tester will initiate applying force to the tablet from either single or double sides. This phenomenon is considered a key step in tablet hardness testing.

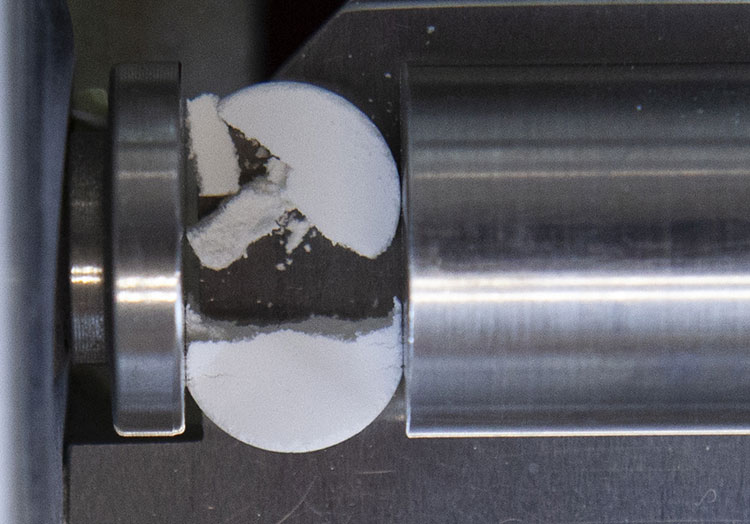

Hardness Measurement

During the application of pressure to tablet, the tester will measure tablet hardness by one of the two ways: either by measuring the depth of jaw penetration or by measuring the size of impression left by the jaw. This calculation is recorded in the tester digital screen which allows you to know the breaking point and sturdiness of a tablet.

Tablet Discharging

Once the tablet is tested, you can pick it up or push it towards the collection container. In case of tablet breakage during testing, keep it separate from the rest one.

6.Describe The Structure Of A Tablet Hardness Tester?

The structure of a tablet hardness tester is extremely precise and portable which is only composed of few components including:

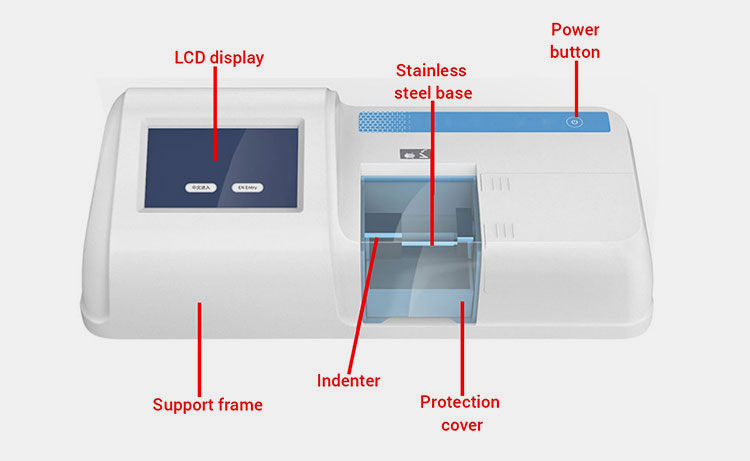

Structure of Allpack's APK-200C Tablet Hardness Tester

LCD Display

Tablet hardness tester has an intuitive LCD display with touch screen interface. It is located on the front side of tester which can be easily used for adjusting the parameters like depth and size of indenter for penetration. It display information through points under multiple titles such as number of tablet, thickness, diameter, and hardness etc.

Support Frame

The support frame refers to the overall body of a tablet hardness tester which support other parts to be united.

Stainless Steel Base

Stainless steel base refers to the area where tablet is placed for hardness tester. It is located between two bars.

Indenter

Indenter is a metallic tool which is used to apply force to the tablet.

Protection Window

Tablet hardness tester has a protection window over testing area which helps in providing enclosed room for tablets testing while at the same time allows user to visually observe the tablet hardness testing mechanism.

Power Button

Power button is situated on the top front side of tablet hardness tester. It is used to switch on the tester for working.

Other Parts

Tablet hardness tester has other parts as well such as power system which supply adequate voltage to the tester. Apart from this, it supports USB connection for printing data.

7.What Are The Types Of A Tablet Hardness Tester?

Tablet hardness tester is available in different types. Depending upon your needs, you can opt for the relevant one. Although, the design, automation, and specification of each type may vary, however, all of them are used for the same task of testing tablet hardness. For clear understanding, look into the explanation below:

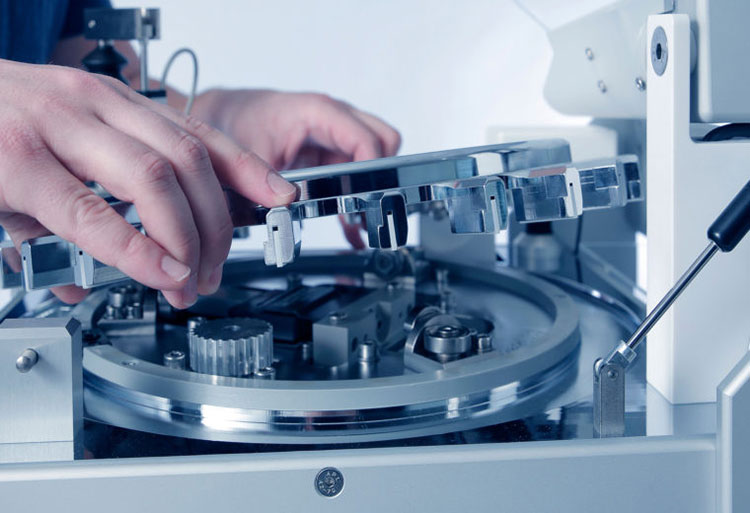

Automatic Tablet Hardness Tester

Allpack- APK-350N Tablet Hardness Tester

Automatic tablet hardness tester is an electrically run equipment. It has a precise body with various features for attaching USB for printing, intuitive LCD display, an enclosed chamber for tablet testing, and power system. It works automatically once tablet is placed inside the testing unit from where the tablet can be discharged into a collection bin. Such type of tester allow for convenient and contamination free testing. However, it is a bit expensive which makes it favorable for large research and laboratory centers.

Digital Tablet Hardness Tester

Digital tablet hardness tester- Picture Courtesy: hoverlabsonline.com

Digital tablet hardness tester is a compact size device which is easily portable. It consists of an LCD with backlist display, glass safety cover, metallic base, and testing chamber. This tablet hardness tester can deal with tablets size from 2mm to 28 mm. You can simply operate it by placing the tablet between bars and twisting the push unit to apply pressure.

The digital display will keep measuring force applied till the point of tablet breakage or hardness is found. It is suitable for small to medium testing laboratories as hygiene of the tablets is well preserved.

Manual Tablet Hardness Tester

Manual monsanto tablet hardness tester

Manual tablet hardness tester is a small size tool which is solely dependent upon user for testing tablets. The entire structure is made up of quality material to retain the quality of tablets. It mainly consists of a screwing device on one end while as the tablet testing unit on the other end. In middle, there is an indicator under a scale whose movement show the hardness of tablet. It can be brought into operation by placing tablet in the jaw and twisting the screw. It is good for insensitive tablets like food and chemical tablets.

8.Differentiate Between Tablet Hardness Tester And Tablet Friability Tester?

Tablet hardness tester and tablet friability tester are two important equipment employed to conduct a thorough tablet testing. However, both are different from one another due to several reasons. It is important to know these differences as shown in the table below:

| No | Aspects | Tablet Hardness Tester | Tablet Friability Tester |

| 1 | Purpose | Tablet hardness tester is used for the purpose of determining tablet cracking point. | On the other hand, tablet friability tester is employed for knowing the fragility or tablets. |

| 2 | Testing technique | It measures the hardness by checking the applied mechanical force or measuring the length of impression left by the jaw during testing. | In contrast, it calculates the weight loss after tablets undergo testing. |

| 3 | Process | The tester apply pressure to tablets by holding between two jaws. | While as, it exposes the tablets to shaking and vibration in drums for determining their friability. |

| 4 | Accuracy level | Its accuracy rate should prevail between ±0.25kg or ±0.1kg. | Contrary to that, tablet friability tester must have accuracy of about ± 1 rpm. |

| 5 | Picture |

Allpack- APK-350N Tablet Hardness Tester |

Allpack- APK-300E Tablet Friability Tester |

9.Where You Can Use A Tablet Hardness Tester?

A tablet hardness tester is applicable to every industry where there is manufacturing and processing of tablets. It is primary used for maintaining the quality control of tablets in various fields such as:

Pharmaceutical Industry

Various tablets & capsules- Picture Courtesy: cargill.com

Tablets are abundantly produced in pharmaceutical industry to deliver therapeutic drugs. As medicated tablets are made with immense care to deliver effective benefits and reducing possible side effects, their quality testing is very important in which tablet hardness is of core importance. Thus, a tablet hardness tester is a must have equipment to provide a safe and hygienic way for the testing of tablets.

Nutraceutical Industry

Nutraceutical tablets- Picture Courtesy: nutraceuticalsworld.com

Tablets containing vitamins, minerals, and protein come under the pharmaceutical category. These tablets like pharmaceuticals also hold active ingredients and excipients. Therefore, it is crucial to maintain the balance and determine overall quality of tablets for which tablet hardness tester can be used.

Animal Care Industry

Dog tablets- Picture Courtesy: https://www.msd-animal-health-hub.co.uk

As veterinary industry is associated with the management of animal healthcare, manufacturing of tablets as a drug form is a must have practice. Thus, in order to fulfill the essential requirements for effective tablets, a tablet hardness tester is used in this field.

Confectionery Industry

Milk tablets- Picture Courtesy: medimexsingapore.com

Manufacturing of tablets is not confined to medical industry only, rather we also found it in other field like food and confectionery where certain ingredients are transformed into tablets. The common examples include milk tablets and chocolate tablets for which this tablet hardness tester can be used.

Daily Chemical Industry

Dishwasher tablets- Picture Courtesy: fominsoap.com

You may not be unfamiliar to the tablets processing being carried out in chemical industry for disinfecting and washing purposes such as chlorine tablets, detergent tablets, and pesticides tablets. These tablets also require tablets hardness testing during for maintaining consistency. Hence, a tablet hardness tester is applicable here.

10.What Quality Standards Should A Tablet Hardness Tester Comply To?

As tablet hardness tester is meant to test sensitive pharmaceutical as well as other tablets, it must comply to certain quality standards in order to be called as quality equipment. For this purpose, some prominent regulatory standards are established and recognized worldwide. If a tablet hardness tester is certified by the underlying mentioned standards it means that it is made up of quality material:

Quality Standard checking icon- Picture Courtesy: Freepik

International Organization for Standardization (ISO)

Food and Drugs Administration (FDA)

Good Manufacturing Practices (GMP)

Conformate European (CE)

IQ Compliance

OQ Compliance

11.How To Maintain A Tablet Hardness Tester?

Maintaining your tablet hardness tester can help in prolonging its working lifespan and performance. In this way, considering below mentioned guidelines can be useful:

User maintaining tablet hardness tester- Picture Courtesy: ischi.com

Calibration:Calibrate your tablet hardness tester with right tools to enhance its measurement accuracy level.

Cleaning:Make sure to clean the tester after use to avoid the possible buildup of contamination that may affect the quality of tablets and testing results. Use recommended cleaning agent for safe cleaning.

Inspection:Conduct regular inspection for your tablet hardness tester especially during operation to take note of abnormalities and make time corrections.

Servicing:Carry out the servicing of your tablet hardness tester on daily basis and check for damaged parts. If there is need of parts repairing or replacement, do it immediately.

12.What Factors Influence The Hardness Of Tablets?

There are several factors that influence the hardness of tablets. These include:

Tablet breakage during testing- Picture Courtesy: merlin-pc.com

Binder Properties

Apart from active pharmaceutical ingredients, excipients are also used in tablets making among which binders are of prime importance. Now, the type of binder and its ratio greatly affect the hardness of tablets. In addition, use of potent binder may harden the tablet and vise versa.

Compression Force

Tablet hardness is also influenced by the applied compression force. For instance, the greater the pressure applied during compression the harder will be tablet. In contrast, low compression force often give you easily breakable tablets.

Granulation Method

Granulation method is another important factor for affecting the hardness of tablets. In this way two popular granulation methods are used naming Wet granulation and dry granulation. The former produce strong tablets, while as, the tablets formed through dry granulation are often soft.

Coating Type

Type of coating employed for tablets may also modify the hardness of tablets as like enteric coating and film coating help in solidifying the tablet hardness. In contrast, the use of sugar coating produce soft tablets.

13.How To Select The Best Tablet Hardness Tester?

When choosing a tablet hardness tester for your business, keep in mind few factors to get the most compatible one. These are enlisted below:

Tester Specifications

Specifications of tablet hardness tester PLC- Picture Courtesy: ischi.com

Check the parameters and specifications of machine because each tablet hardness tester come with distinct features. So, you should keep in mind the parameters which you are looking for. For instance, whether the tester only provide hardness information or additional information like tablets diameter and integrity etc.

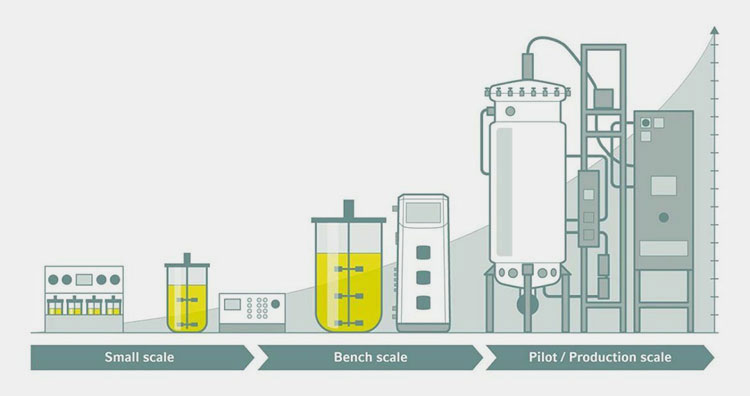

Production Scale

Different production scales- Picture Courtesy: akronbiotech.com

Another important aspect to look for is whether you need an automatic tablet hardness tester or manual tablet hardness tester. This question is directly associated with your production scale. If you are running low volume of manufacturing then manual or digital tablet hardness tester is a good choice on the other hand only automatic tester is suitable for large production.

Accuracy Level

Accuracy and precision are what tablet hardness tester is used for. So, you should check the accuracy level of the tablet hardness tester before purchasing. For this, you may ask the vendor to conduct a sample testing.

Quality Compliance

Compliance principles icon- Picture Courtesy: pharmatechassociates.com

Tablet hardness tester is the key equipment to ensure that tablets are made in accordance with the established quality control requirements. In such a case, it is obligatory for the device itself to comply quality standards and their guidelines.

Conclusion

To put in a nutshell, Tablet Hardness Tester is an innovative equipment that can help you find the exact tablet hardness for ensuring the quality of tablets. Not only is it obligatory for the quality control of tablets but also beneficial for making your drugs more effective, so, they can be useful for patients. In addition to it, the portable design, convenient usage, and simple maintenance makes the tablet hardness tester more attractive for tablets manufacturers. So, if you are looking for a top-notch tablet hardness tester then leave us a message. We will contact you ASAP!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp:+86 18171018586