Ampoule Labeling Machine:The Complete FAQ Guide In 2025

As one of the important equipment in industries such as pharmaceuticals, cosmetics, and food, the stability and efficiency of ampoule labeling machines directly affect the quality and production efficiency of products.

At present, there are various brands and models of ampoule labeling machines on the market which may be different in performance, efficiency, stability, and other aspects. Do you aspire to know any information about the definition, importance, main parts of ampoule labeling machines?

This article will provide you with the most comprehensive information about ampoule labeling machines. Let’s explore the complete FAQ guide of ampoule labeling machine together!

1.What Is the Ampoule Labeling Machine?

Ampoule Labeling Machine - Sourced: ima.it

The ampoule labeling machine represents a mechanical solution designed to efficiently and precisely affix labels onto ampoules. This automatic machine seamlessly handles the entire process, from measuring the dimensions of the ampoules and labels, to dispensing and applying the labels, all without the need for manual intervention.

2.Why Is the Ampoule Labeling MachineImportant?

The significance of ampoule labeling machines has been steadily growing in prominence, and it’s natural to wonder about the underlying reasons for this. Let’s delve into why their importance is on the rise.

(1)Improve production efficiency

Improve Production Efficiency - Sourced: yamatoscale

Automatic ampoule labeling machines can significantly improve production efficiency, reduce manual labeling time and labor intensity. They can complete labeling tasks at high speed and stability, ensuring the continuous operation of the production line.

(2)Ensure product quality and safety

Ampoule - Sourced: reagent

Ampoule labeling machine can detect liquid filling and foreign objects (such as glass shards, impurities, etc.) inside the bottle, and automatically remove defective products, thereby improving the detection accuracy and safety of the product.

Automated operations reduce direct contact between personnel and products, lowering the risk of cross contamination. Meanwhile, machines made of corrosion-resistant materials such as stainless steel also ensure the hygiene and safety of the production environment.

(3)Prevent forgery and tampering

Prevent Forgery and Tampering - Sourced: Freepik

Modern ampoule labeling machines can be equipped with anti-counterfeiting labels and traceability systems, which can enhance the anti-counterfeiting and traceability capabilities of products, thereby improving their safety and reliability.

3.What Are the Applied Industries of Ampoule Labeling Machine?

Have you seen ampoule in your daily life? Have you paid attention to their labels? Ampoule labeling machines are widely used in multiple industries, let’s explore them one by one.

(1)Pharmaceutical industry

Water For Injection Plastic Ampoule - Sourced: Lavoisier.Com

Ampoule labeling machine plays an important role in the pharmaceutical industry, mainly used for label pasting of drug packaging bottles, ampoule and other products. These labels typically contain important information such as drug name, specifications, production date, expiration date, which are crucial for drug identification, tracking, and management.

(2)Cosmetic industry

Radiance Ampoules - Sourced: toskani

Ampoule labeling machines are also widely used for packaging cosmetics, skincare products, and other products. These products usually have high requirements for packaging aesthetics and label clarity, and ampoule labeling machines can meet these needs.

(3)Food and beverage industry

Small Bottles for Beverage - Sourced: beveragedaily.com

Some special food and beverage products are also packaged in round containers. Ampoule labeling machines are used in this field to ensure clear and accurate information on labels.

(4)Chemical industry

Chemical Reagents - Sourced: Freepik

Some chemical reagents and laboratory liquids are also packaged in ampoules. The ampoule labeling machine can ensure that the label information of these products is correct and error free, so that laboratory personnel can accurately identify and use them.

(5)Health care industry

Vitamin C Concentrate - Sourced: nocheskincare

Some health care products such as nutritional supplements and therapeutic liquids may use ampoules. The ampoule labeling machine can provide relevant information such as nutritional content and usage instructions in these products.

4.What Are theMain Parts of Ampoule Labeling Machine?

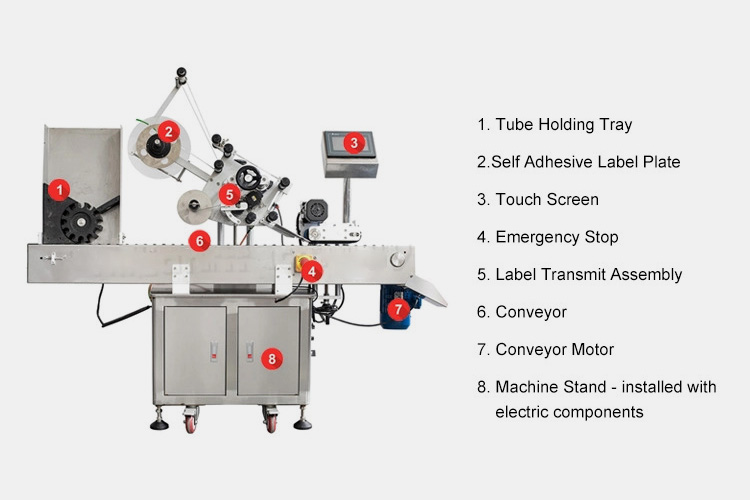

Main Parts of Ampoule Labeling Machine

Ampoule labeling machine contains a variety of parts that work together to complete the labeling task. However, due to differences in design and functionality among ampoule labeling machines from different manufacturers, the specific types and quantities of parts may also vary. But generally speaking, ampoule labeling machines may include the following main parts:

| Main Parts | Description |

| Tube holding tray | The tube holding tray is used to hold and arrange ampoules before processing. It ensures that the ampoules are in the appropriate position and sequence before entering the labeling machine. The rotating shaft on the tube holding tray is usually equipped with a motor and gear system to achieve smooth rotation and transportation of the bottles. |

| Self adhesive label plate | It is commonly used to extract self-adhesive labels from label scrolls. These labels are precisely attached to the ampoules with the help of a labeling machine. |

| Touch screen | The touch screen allows operators to set various parameters for labeling according to production needs, such as labeling speed, labeling position, labeling quantity, etc., to ensure the accuracy and efficiency of labeling. |

| Emergency stop | It ensures that equipment power can be quickly cut off in emergency situations to prevent accidents from occurring. |

| Label transmit assembly | It is responsible for transferring labels from the label supply system to the labeling location, ensuring that the labels can be accurately and stably attached to the ampoules. |

| Conveyor | The main function of the conveyor is to smoothly and continuously transport the ampoules to be labeled to the labeling position. |

| Conveyor motor | It can realize precise control over the speed and position of the conveyor belt to ensure the stability and accuracy of ampoules during the labeling process. |

| Machine stand - installed with electric components | Various electrical components that control the operation of the motor, such as contactors, relays, frequency converters, etc., are usually installed inside the motor cabinet for centralized control and management. |

5.What Can You Label through the Ampoule Labeling Machine?

The information that can be placed on the label of the ampoule labeling machine is diverse, depending on the characteristics of the product and the needs of the manufacturing enterprise. Here are some common information that can be placed on ampoule labels:

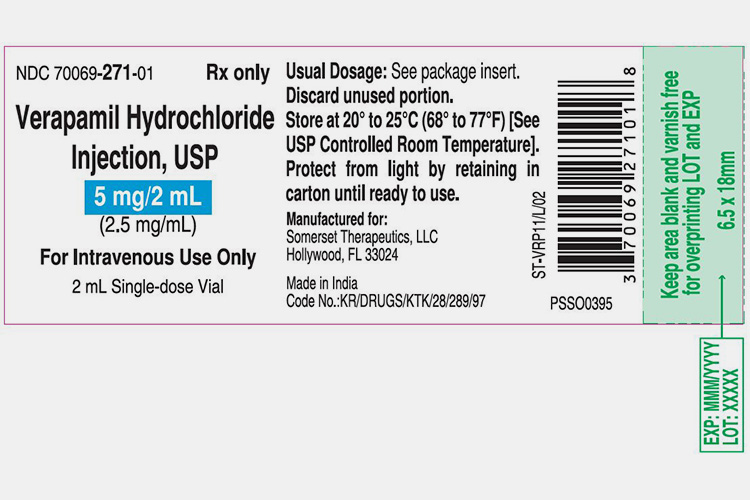

Ampoule Label Information - Sourced: DailyMed

(1) Product information:

Product Name: Clearly indicating the name of the drug or product.

Specification and Model: Indicating the product’s specifications, model, or capacity information.

Production date: Marking the production date of the product for traceability and understanding of its production time.

Validity/Shelf Life: Indicating the expiration date or shelf life of the product to ensure that consumers use it within the safe period.

(2) Manufacturer information:

Manufacturer Name: Indicating the name of the manufacturer that produced the product.

Production address: Providing the detailed address of the manufacturer can help consumers understand the source of the product.

(3) Instructions and warning for use:

Usage and dosage: Providing detailed instructions on the usage and dosage of the product.

Precautions: Listing the precautions to be taken when using the product, such as contraindications, side effects, etc.

Warning signs: such as flammable, explosive, toxic and other warning signs, reminding consumers to pay attention to safety during use.

(4) Other information:

Batch number: it is used to distinguish products from different batches for quality traceability.

Anti counterfeiting information: preventing the occurrence of counterfeit and inferior products through special markings or technologies.

Barcode: it is used for product identification, tracking, and inventory management.

6.What Quality Standards Should Ampoule Labeling MachineComply with?

In the design and manufacturing process of ampoule labeling machines, a series of international quality standards and quality guidelines are usually followed to ensure their quality, safety, and compliance.

ISO 9001

ISO 9001 - Sourced: pcilasercut

ISO 9001 is a quality management system standard developed by the International Organization for Standardization (ISO). This standard aims to assist organizations in establishing, implementing, maintaining, and improving quality management systems to ensure that the quality of products and services meets customer and regulatory requirements. For ampoule labeling machine manufacturers, following the ISO 9001 standard means:

Clear quality policies and objectives need to be established and integrated throughout the entire organization.

Ensuring the effective operation of the quality management system, including all aspects such as design, procurement, production, inspection, and after-sales service.

ISO 14001

ISO 14001 - Sourced: qassurance

ISO 14001 is an environmental management system standard that requires organizations to identify and manage environmental factors in their activities, products, and services to prevent pollution, reduce resource consumption, and continuously improve environmental performance.

Although ISO 14001 primarily focuses on environmental management, ampoule labeling machine manufacturers can also choose to follow this standard if they wish to demonstrate their commitment and performance in environmental protection. This helps to enhance the environmental image of the enterprise and may meet specific requirements of certain customers.

7.What Should You Consider When Choosing An Ampoule Labeling MachineManufacturer?

Choosing the right manufacturer is crucial for the smooth operation of a factory. What factors do you need to consider when choosing an ampoule labeling machine manufacturer? You can consider the following aspects:

(1) Product quality

Product Quality - Sourced: SAS blogs

You should understand the technical level of the manufacturer and the technical parameters of the ampoule labeling machine, including labeling accuracy, speed, stability. Besides, you should ensure that the labeling machine meets the specific requirements of ampoules, including bottle size, shape, and material.

(2) Manufacturer’s reputation

Manufacturer’s Reputation - Sourced: impactpr

You can refer to relevant customer evaluations, market feedback and the manufacturer’s past cases and successful experiences to understand the manufacturer’s reputation in the industry.

(3) After-sales service

After-sales service - Sourced: salesjob

You should understand the length of the warranty period for the ampoule labeling machine, including the main components and consumables. And you should check if timely technical support and maintenance services are provided, and if training services are available.

(4) Price and cost-effectiveness

Price and Cost-effectiveness - Sourced: edepoze.com

Everyone wants to buy products that are both good and affordable. When purchasing an ampoule labeling machine, you should compare quotes from different manufacturers, but don’t just rely on price as a determining factor, also consider cost-effectiveness.

Before selecting an ampoule machine manufacturer, on-site inspections can be arranged to personally check the actual operation of the production line and equipment, while communicating with existing customers to obtain genuine feedback on usage. These steps can help you make wiser choices.

8.What Additional Auxiliary Equipment Is Required To Work With The Ampoule Labeling Machine To Create a Complete Production Line?

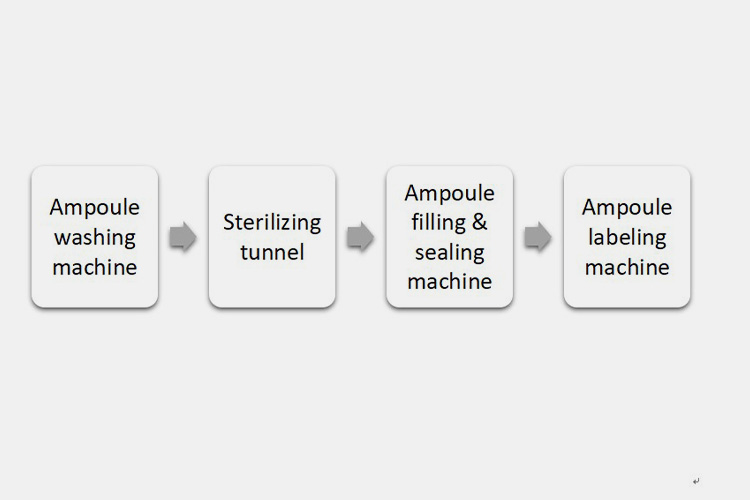

Ampoule Production Line

Do you know the entire ampoule production line? The operation process of the entire ampoule production line includes ampoule washing machine, sterilizing tunnel, ampoule filling & sealing machine, and ampoule labeling machine. next, let’s explore additional auxiliary equipment is required to work with the ampoule labeling machine to create a complete production line.

(1)Ampoule washing machine

AIPAK Ultrasonic Washing Machine

Function: It is used for thoroughly cleaning ampoules, removing impurities and dirt inside the bottle.

Type: Generally it is divided into ultrasonic cleaning machine and spray cleaning machine. The former uses ultrasonic vibration to clean the dirt inside and outside the bottle, while the latter uses high-pressure water jets to clean the bottle.

(2)Sterilizing tunnel

AIPAK Sterilizing Tunnel

Function: Sterilizing tunnel is used to sterilize the cleaned ampoules to ensure that they do not contain harmful microorganisms.

Type: Common sterilization methods include high-temperature steam sterilization (such as high-pressure steam sterilization pots) and dry heat sterilization. The choice of method depends on the material of the bottle and the production process requirements.

(3)Ampoule filling & sealing machine

AIPAK Aka Series Ampoule Filling And Sealing Machine

Function: Ampoule filling and sealing machine is used to accurately filling liquid drugs or other contents into ampoules and sealing the ampoules to ensure that the contents are not contaminated.

Types: The commonly used sealing methods include flame sealing and laser sealing. Flame sealing uses high-temperature flames to melt the bottle mouth to form a seal, while laser sealing uses laser technology to melt and seal the bottle mouth.

9.How to Troubleshoot Common Problems of Ampoule Labeling Machine?

The ampoule labeling machine may encounter some problems during use due to human or other reasons. The following is an introduction to common problems and countermeasures of ampoule labeling machine.

The Problems of Ampoule Labeling Machine - Sourced: Neftis

| Problems | Solutions |

| The label is not firmly attached | Adjust labeling pressure: If the labeling pressure is too low, increase the labeling pressure appropriately to improve adhesion.

Replace adhesive: Choose the appropriate type of adhesive for labeling to ensure its bonding effect. Control labeling speed: Labeling speed that is too fast or too slow may affect the adhesive effect of the label, and the labeling speed should be adjusted appropriately to achieve the best results. |

| Label misalignment or deviation | Label feeding adjustment: Check the adjustment of the label feeding system to ensure smooth and accurate label feeding.

Sensor position adjustment: Check the sensor position of the device to ensure that the sensor can accurately sense the label position. Label path inspection: Check the label labeling path to ensure that there are no obstacles in the path of the label during the labeling process. |

| The machine cannot start | Check power supply: Confirm that the device is connected to a power outlet and that the outlet is functioning properly.

Check the control system: You can try restarting the device or resetting the control system to solve the problem. Check sensors: If the device is equipped with sensors, the sensors should be checked for damage or looseness. |

10.How to Maintain Ampoule Labeling Machines?

In order to ensure the long-term operation of ampoule labeling machines, proper maintenance is also necessary.

(1) Cleaning work

Cleaning Work - Sourced: ajanitorsstory

Before and after the work of the ampoule labeling machine, the outer surface of the machine should be wiped with a soft cloth to remove dust and debris.

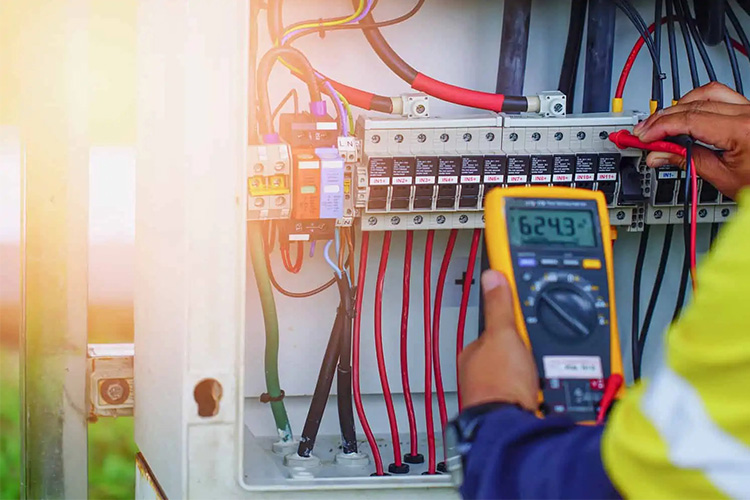

The workers should regularly use a vacuum cleaner or soft brush to remove dust inside the equipment, especially inside the electrical control box. Clean and dry compressed air can be used for dust removal (the main power supply of the equipment must be turned off during dust removal).

(2) Lubrication

Lubrication - Sourced:iselinc.com

The transmission part and key parts such as bearings of the ampoule labeling machine need to be lubricated regularly to reduce wear and friction. Recommended lubricating oil or grease should be used and lubricated according to the manufacturer’s recommendations.

For example, the transmission chain of the active labeling motor should be checked once a month and adjusted appropriately. After adjustment, lubricating oil should be added immediately to ensure rust prevention and lubrication.

(3) Regular inspection

Regular Inspection - Sourced: scottco.com

Before starting work, the power supply, label tape, sensors of the ampoule labeling machine should be checked to ensure that the equipment can operate normally. Regularly inspect the electrical system, including wires, cables, motors, and controllers, to ensure that they are in good working condition.

Conclusion

The ampoule labeling machine, owing to its myriad advantages, has found widespread adoption across numerous industries. Upon reading this article, you have gained valuable insights about ampoule labeling machine. If you require further clarification, please do not hesitate to reach out to Allpack at your earliest convenience.

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide