Your Superior Pharmaceutical Vacuum Degassing Machine Supplier

Vacuum Degassing Machine

Allpack vacuum degassing machine uses heating, circulation and vacuuming to degas distilled water and deionized water. Compared with the boiling method, it has the advantages of safety and time saving.The vacuum degassing machine can accurately control the temperature of the dissolution medium and the vacuum degree of the container where the dissolution medium is located to achieve the ideal degassing effect. It can be used with the dissolution instrument and is fully in line with the Chinese Pharmacopoeia.It is suitable for degassing distilled water and deionized water in the pharmaceutical research, pharmaceutical, chemical and other industries.

Allpack Vacuum Degassing Machine

Vacuum Degassing Machine

Allpack vacuum degassing machine is a new generation of vacuum membrane degassing device developed and produced to meet the demand for short time, large quantity and continuous degassing treatment. The vacuum degassing machine can effectively degas all kinds of solvent media like distilled water, deionized water, and other purified water to ensure the accuracy of downstream experimental results. When working, the dissolved medium passes through the degassing membrane fibre under the pressure, while outside under the action of the vacuum pump the gas is continuously pumped away and negative pressure is formed.

High degassing efficiency

Color touch screen, clear parameters, easy to operate

Automatic quantitative liquid inlet, preheating, degassing and quantitative liquid discharge

The Buyer's Guide

Vacuum Degassing Machine: The Complete Buying Guide In 2025

Safety and quality are the two fundamental facets in the manufacturing sector and are built into every attribute of business because poor quality and safety have tons of negative consequences such as loss of revenue costs, discontented customers, tarnished reputation, wasted resources, harm to individuals and environment, and product liability claims.

Nowadays, businesses have been using specific devices to meet specific quality and safety standards and the vacuum degassing machine is the most important of all these instruments. It significantly improves the shelf-life and quality of products by removing undesired gases from the products. Industries utilizing this machine gain a trusty reputation, save resources, and keep the environment and people safe.

So, readers, this buying guide is penned to improve your knowledge about the vacuum degassing machine and to communicate its unconventional features. This will help care for and maintain the vacuum degassing machine. Let’s begin our interesting read.

1.What is a Vacuum Degassing Machine?

Vacuum Degassing Machine- Picture Courtesy: RealEasy

A vacuum degassing machine is a sophisticated solution in the developmental sector, offering means for removing various soluble or dissolved gases, for instance, oxygen, hydrogen, and nitrogen from liquid, molten, or pasty material. The gases, vapors, and other watery content are eliminated from the processing material under a low-pressure environment using a vacuum.

The degassing operation is performed by reducing the pressure within the vessel, which in turn decreases the solubility of gases, consequently resulting in their escape from liquid material.

It is a safe and accurate tool for improving the quality of material, as suspended gases can have adverse effects on the quality of the end product. Owing to, its simple architecture and effective outcome, it is considered an integral device in the processing industries.

2.Why Manufacturing Sector Require a Vacuum Degassing Machine?

The vacuum degassing machine is an excellent addition to the production field, providing a multitude of advantages like consistent and precise results. Here are some extraordinary benefits due to which the vacuum degassing machine has gained traction in industries:

Boosting Material Quality

Boosting Material Quality- Picture Courtesy: Bruker

The dissolved gases influence both the mechanical and physical features of materials or products. It causes blistering, brittleness, and oxidation of liquids. It also results in severe damage, rendering the final product unusable. Therefore, to obtain high-quality and damage-free products that fulfill quality regulations, vacuum degassing machine is a must in industries.

No Structural Imperfection

No Structural Imperfection- Picture Courtesy: GMK Center

A vacuum degassing machine is a part of routine casting and molding procedures because trapped gases can lead to the creation of air spaces or pockets in materials like steel, resulting in the porosity of the end product. Consequently, it is essential to extract these gases before materials are solidified, this improves the structural strength and consistency of products.

Precision in Manufacturing Sector

Precision in Manufacturing Sector- Picture Courtesy: AVT Sealing Solutions

The existence of gases can severely impact the functionality of products in the manufacturing sector, where due importance is given to extreme precision and high performance. Thus, vacuum degassing is a multifaceted tool in these industries, as it removes gases from steel and metal components, making engine, electric, and other alloy parts fit for use and ensuring that they fulfill recommended standards.

Better Aesthetics

Better Aesthetics- Picture Courtesy: Package Inspiration

Other major reasons why vacuum degassing machine is employed in production are better product appearance and improved surface finish. In plastic and polymer fabrication units, a vacuum degassing machine is significant in allowing materials to have an even surface finish and reduce cosmetic flaws, for instance, air bubbles or non-uniform texture.

Extend Shelf-life

Extend Shelf-life- Picture Courtesy: Sun Chemical

A vacuum degassing machine is needed in mass-produced industries since it has a beneficial part in extending the shelf-life of the goods by removing gases that can cause oxidation and other chemical reactions in the materials. Failure to do so would spoil and reduce the expiry period.

Higher Chemical Reactivity

Higher Chemical Reactivity- Picture Courtesy: Tu Dortmund

Unwanted gases in the materials result in undesired chemical reactions in the materials, decreased solubility of solutes, and affect the product yields. Hence, a vacuum degassing machine is employed to obtain a purer formulation and faster reactions.

Waste Reduction

Waste Reduction- Picture Courtesy: Water Corporation

A vacuum degassing machine helps in minimizing the necessity of reworking, scrap materials, and product defects. This is because it removes product defects by drawing out the trapped gases. Hence, by using this machine, manufacturers achieve higher manufacturing efficiency and significantly lower operational costs.

3.What is the Operating Mechanism of a Vacuum Degassing Machine? What are Its Working Stages?

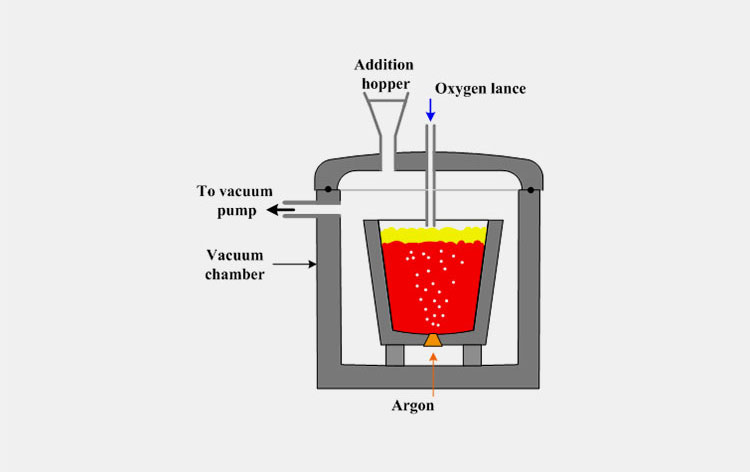

The operating mechanism of the vacuum degassing machine is dependent on the formation of low-pressure environment due to the vacuum system. This decreases the solubility of gases, leading to their extraction from material.

The working stages of the vacuum degassing machine are penned below:

Loading of Materials

Loading of Materials- Picture Courtesy: Easy Composites

At the beginning of the operation run, the raw materials, such as molten metals, pastes, liquids, and others are loaded into the vacuum chamber of the vacuum degassing machine. Afterward, the sealing of the chamber takes place to produce an airtight environment. This prevents the entry of gases inside the chamber.

Vacuum Formation

Vacuum Formation- Picture Courtesy: Essy Composites

Immediately after the sealing of the special chamber, the vacuum pump is turned on to establish low-pressure conditions inside the chamber. This results in a reduction of the partial pressure of gases entrapped in the material. The application of vacuum level is based on material properties and quantity of gas present in the material.

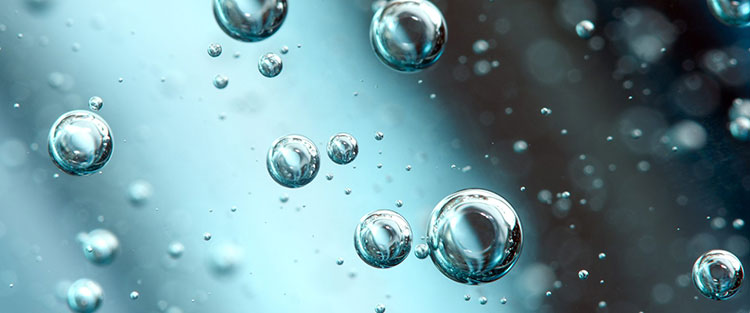

Degassing

Degassing- Picture Courtesy: Niroo Namad Youtube Channel

It is the central stage in the working of a vacuum degassing machine. With the decrease in pressure, the gases are forced to leave the vacuum chamber. They go up towards the surface of the material and form bubbles, thereby diffusing out of the feed.

Stirring or agitation is applied at this stage so that gases consistently escape from every part of the feed. Argon is used in certain cases to promote the removal of gases.

Gase Collection

Gas Collection- Picture Courtesy: Industrial Sonomechanics

The gases are evacuated from the chamber and are collected into an exhaust system connected to the vacuum degassing machine. Any hazardous vapor or containments are trapped and filtered out to maintain a safe environment.

Pressure Release and Material Discharge

Pressure Release and Material Discharge- Picture Courtesy: Easy Composites

Once the entire gaseous material is vented out, the vacuum system is turned off and pressure in the chamber is reverted to standard value. The gas-free material is cooled and loaded into molds or transferred to the next processing stage.

4.What Industries Need Vacuum Degassing Machine?

Vacuum degassing machines have immense popularity in several manufacturing areas and their applications are far-ranging- from food to metal industries. It aims to enhance quality standards, resulting in better outcomes. Let’s go into the details of industrial applications of this handy equipment.

Metallurgy and Steel Industry

Secondary Metallurgy- Picture Courtesy: Pfeiffer Vacuum

A vacuum degassing machine is known for its use in the manufacturing of steel and other alloys. Dissolved gases in molten steel led to high porosity, blistering, and reduced tensile strength. Therefore, during the secondary steel-producing process, these gases are extracted to create better and purer steel and other metal alloys.

Plastic and Polymer Industry

Plastic Manufacturing- Picture Courtesy: Flying Tiger KJ

In the plastic and polymer industry, a vacuum degassing machine is utilized in the plastic extrusion process. By degassing molten plastic, unwanted impurities, gases, and volatile materials are eliminated and it significantly boosts the appearance and finish of end products.

Electronic Industry

Electronic Manufacturing- Picture Courtesy: Siemen Blog

Due to the beneficial use of a vacuum degassing machine in semiconductor processing, it is widely utilized to produce electronic components like microchips, circuit panels, capacitors, and electric sensors.

Chemical Industry

Chemical Processing- Picture Courtesy: Manufacturing Tomorrow

This machine is involved in the purification of solvents in the chemical industry, as it extracts undesired suspended gases from the chemical materials that can interfere with chemical reactivity, resulting in loss of yield.

Pharmaceutical Industry

Pharmaceutical Processing- Picture Courtesy: EZO

In the pharmaceutical industry, huge importance is given to the purity and stability of medicinal compounds, as they directly impact the health of patients. Therefore, a vacuum degassing machine helps in formulating pure and sterile materials e.g., active pharmaceutical ingredients and specialty compounds.

Food and Beverage Industry

Beverage Packaging- Picture Courtesy: Roetell

It has a major role in the food and beverage sector since it removes oxygen from food and beverage products like juices, carbonated drinks, wines, dairy food, etc., leading to decreased oxidation, cloudiness, and spoilage of consumable products and improved clarity, taste, and stability.

Medical Sector

Medical Instruments- Picture Courtesy: Shortly

Medical instruments, especially those created from plastics or rubber needed to be degas to improve their safety. Therefore, the vacuum degassing machine in the medical sector improves the sterility of medical devices and reduces their microbial contamination.

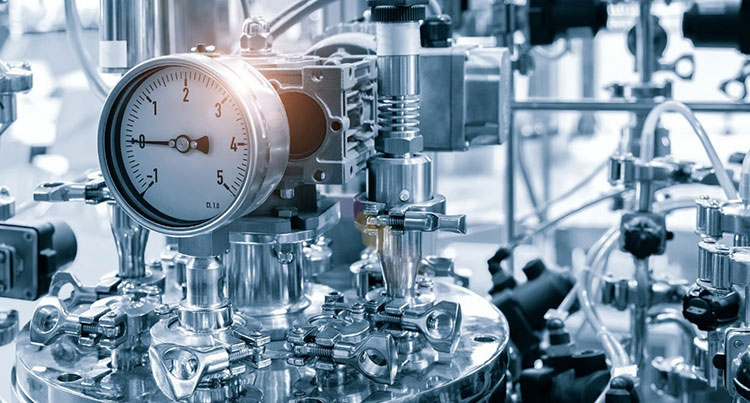

5.What are the Components of a Vacuum Degassing Machine?

The vacuum degassing machine has a simple construction, comprising various parts, each maintaining process harmony. We have included the diagram having labeled part with discussion for your understanding.

Parts of Vacuum Degassing Machine

| Material Inlet | It introduces the material in the chamber smoothly and is sealed to prevent gas leakage and entry into the vacuum chamber. |

| Viewing Window | It is a key component that allows real-time monitoring of the gas extraction process. It is used by operators to check the degassing status and verify the uninterrupted workflow. |

| Support | It is a structural part that sustains the apparatus and keeps it stabilized during processing. It features a frame and mounting stands that hold the weight and decrease vibrations during the run. |

| Product Outlet | The degassed products are transferred out of the camber via the product outlet. It safely removes them without reintroducing impurities and air. |

| Transfer Pump | This type of pump in the vacuum degassing machine is used for transferring products like degassed liquids out of the chamber. |

| Vacuum Pipe | This is a vital part of the machine and connects the main chamber to the vacuum pump. It aids in forming and maintaining low-pressure settings in the vacuum chamber. |

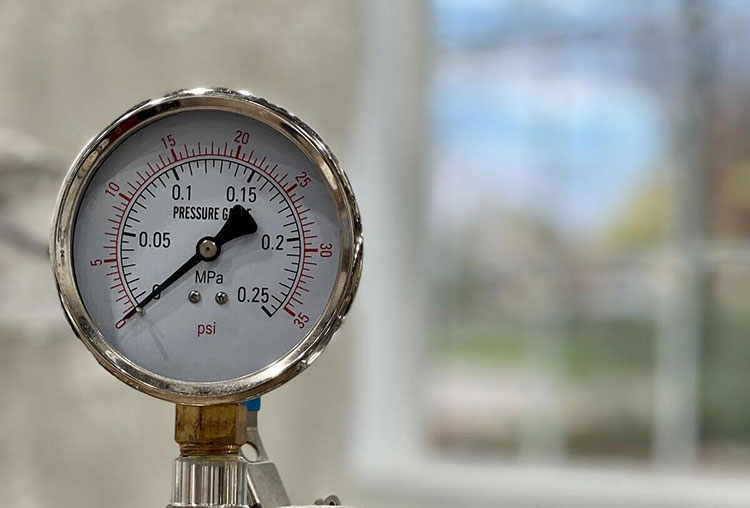

| Pressure Gauge | It is a device employed for detecting and gauging the pressure level inside the vacuum compartment. It is essential for keeping the vacuum level under the required range. It also notifies the technicians if the vacuum range decreases below the standard threshold. |

| Control Panel | To control the operativity of the vacuum degassing machine, an interface or computerized panel is fitted with the machine. It consists of different controllers and software for adjusting different parameters, such as pressure, temperature, vacuum value, and others. It maintains the functionality of vacuum pumps, heaters, and agitators. It also has a data logging feature. |

| Chamber Body | It is a main component of the machine in which material is fed for gas removal. It is manufactured using heat-resistant and high-tensile strength materials, such as stainless steel. |

| One-way Valve | It is installed in the vacuum pipe for safety purposes. It reduces the chances of over-pressurization in the pipe and vacuum failure. |

| Vacuum Pump | The job of the vacuum pump is to generate a vacuum inside the compartment by decreasing the pressure level. There are different types of pumps, for example, rotary vane pumps, root blowers, and diffusion pumps. |

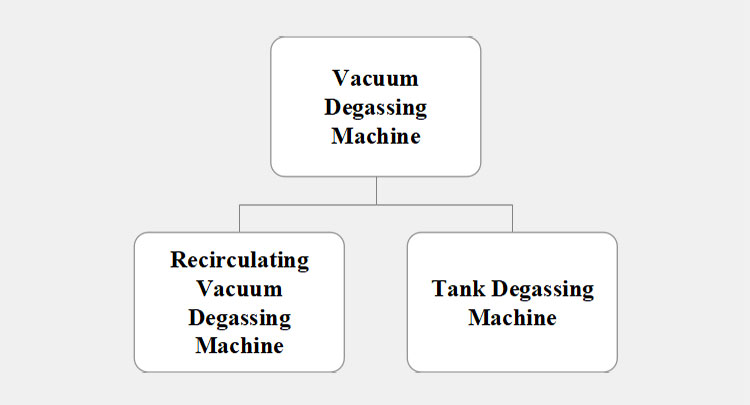

6.What are the Types of Vacuum Degassing Machines?

A vacuum degassing machine falls into two main groups, which are:

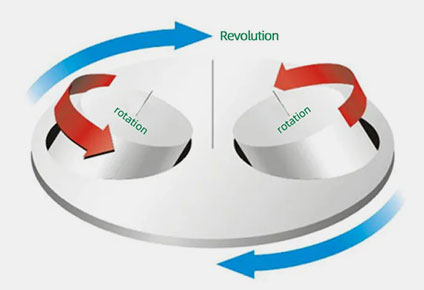

Recirculating Vacuum Degassing Machine

Recirculation Vacuum Degassing Machine-Picture Courtesy: Substech

It is a dedicated kind of vacuum degassing machine, engineered to consistently circulate a feed in the vacuum chamber. It usually has two entry and discharge vents (snorkels and legs) through which material is entered and unloaded from the machine, respectively. These points are sealed to avoid contamination.

Material is repeatedly passed to and recirculated into the chamber that allows continuous exposure of materials, leading to thorough degassing, and producing high-quality and high-purity products. This device is more suited to batch processing, promoting quick degassing jobs.

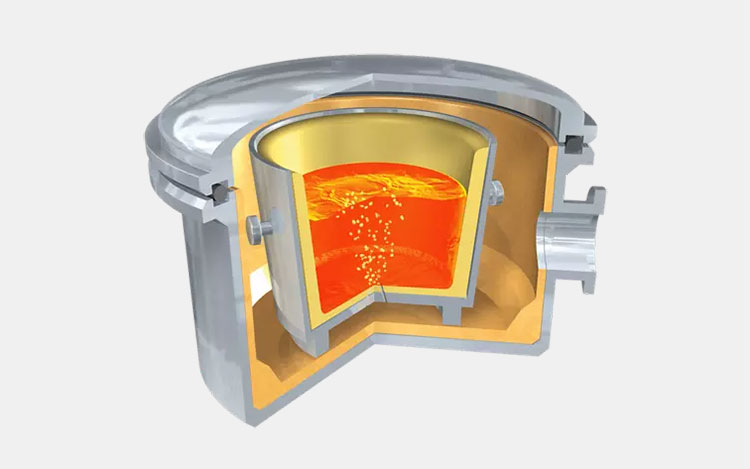

Tank Vacuum Degassing Machine

Tank Vacuum Degassing Machine- Picture Courtesy: Substech

It is a device in which a large tank accommodates the materials for degassing. This vessel is featured with vacuum pumping systems and stirring mechanisms that mix the materials. Usually, inert gases, such as argon are injected into the holding chamber to facilitate the gas extraction process.

These gases aid in the stirring and agitation of molten materials, promoting the release of entrapped gases. The use of argon helps in attaining greater degassing levels.

It is a flexible device and is typically used for batch processing of both smaller and mass-scale batches.

7.What is the Typical Vacuum Level in a Vacuum Degassing Machine?

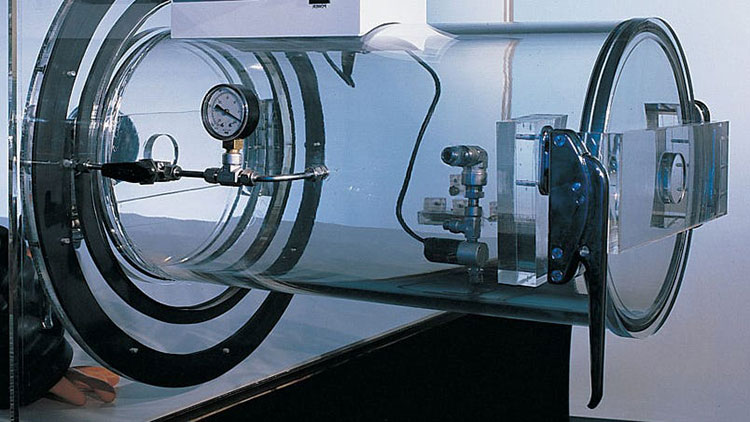

Vacuum Level in Vacuum Degassing Machine- Picture Courtesy: Terra Universal

It should be noted that the typical vacuum level differs with the properties of starting material, and the type and quantity of gas present in the material. If a high level of degassing is required, then it is recommended to maintain low pressure in the vacuum chamber of the vacuum degassing machine.

However, if there is a reduced quantity of gases in the material, then you may set higher pressure in the vacuum chamber. Moreover, it is observed that rapid extraction of gases needs a low-pressure vacuum level.

For steel degassing in metallurgy, about 0.67 to 13.33 mbar vacuum level is employed. It is low to medium vacuum level and is suitable for drawing out suspended gases in molten steel. A 10-100 mbar vacuum range is applied in food and beverage industries to remove air. The vacuum level of a vacuum degassing machine for plastic and polymer manufacturing is about 10-100 mbar.

8.How to Prolong the Operational Life of Vacuum Degassing Machine?

Vacuum Degassing Machine- Picture Courtesy: BrightWay

Every manufacturer wants to attain maximum benefit from their investment and for that, they want to extend the operational life of a vacuum degassing machine. This is easily done by regularly maintaining and properly operating the machine. Here are some tips for you to extend the working life of a vacuum degassing machine.

| Use of Protective Systems | Fitting overload protection systems such as fuses, circuit breakers, and load sensors in machines for critical parts like vacuum and transfer pumps protect them from power surges and electrical overloading. Vibration damping is also offered with vacuum pumps to avoid wear and tear due to vibrations. |

| Regular Cleaning | It is a must practice to extend the life of the machine, as failure to clean equipment after every machine can result in material buildup, which degrades parts and decreases performance. Use approved cleaning agents to clean the instrument from top to bottom. |

| Preventive Maintenance | Lubricate motors, pumps, and agitators to decrease frictional wear and tear. Also, clean and replace the filter to avoid clogging. Inspect defects in seals and gaskets to prevent vacuum leaks. |

| Check Vacuum Pump Health | The vacuum pump is the central part of the vacuum degassing machine, so, it should be regularly inspected to check its working status and health. Check its operating temperature, pressure range, and noise level to detect its functioning. It should be oiled and its parts should be replaced according to schedule. |

9.How to Troubleshoot Vacuum Degassing Machine?

In the troubleshooting process of a vacuum degassing machine, you detect and diagnose common technical failures in the machine that contribute to poor machine efficiency and functionality. To aid you in troubleshooting, we are mentioning some potential problems and their solutions.

Inconsistency in Vacuum Levels

Inconsistency in Vacuum Levels- Picture Courtesy: Digivac

Sometimes, it is difficult for the machine to achieve the required vacuum level or it deviates from the set range.

Cause

Many factors cause this problem, for instance, seals are gaskets are not secured properly or they are damaged. Vacuum pumps may be old, unlubricated, or uncontaminated. Air filters are clogged, keeping the pump from attaining the needed vacuum level. Vacuum sensors are defective and detect inaccurate readings.

Solution

To prevent this issue, it is a must to inspect seals and gaskets and replace them if they look cracked, old, or defective. For the efficient working of the vacuum pump, make sure it is clean lubricated, and damage-free. Replace clogged filters for smooth vacuum functionality. Check and calibrate sensors to have accurate readings.

Excessive Degassing Time

Excessive Degassing Time- Picture Courtesy: Vacuum-Degassing

Now and then, it is observed that the equipment takes more time to remove gases from material or has insufficient gas removal.

Causes

It is due to an insufficient vacuum level that leads to a longer degassing rate. The stirring system of the machine is not working accurately, decreasing the effectivity of degassing. There is a heavier material load in the vacuum chamber, causing a reduction in degassing speed.

Solutions

To resolve this problem, you should check the required working pressure of the vacuum system. Also, inspect the vacuum pump for leaks. It must be ensured that the stirring mechanism is operating correctly and is in continuous contact with the feed. Unload the material from the machine to prevent its overburdening.

Material Contamination

Material Contamination- Picture Courtesy: Ruptured FX Youtube Channel

Foreign objects or other physical contaminants in the final product are detected in the material. Sometimes, there are undesired residues in the vacuum chamber.

Causes

Failure to clean the machine after every batch can contaminate the current feed. If the material inlet is dirty or defective, it can result in the entry of external objects or impurities into the vacuum chamber. Improper loading of feed can bring foreign objects into the vacuum chamber.

Solution

It is suggested to routinely perform cleaning of the vacuum chamber to avoid contamination from earlier batches. Examine the material inlet to verify that it is clean and intact. Proper material loading protocols must be followed to avoid contamination risk.

Pump Overheating

Pump Overheating

In some cases, the vacuum pump overheats during the run, leading to machine shutdown or underperformance.

Cause

It is due to numerous reasons, for instance, inadequate lubrication of mobile components, clogged cooling system, poor air circulation in the machine, and running pump at maximum capacity for extended duration.

Solution

To prevent overheating, it is advised to maintain the appropriate lubrication status of the pump and other related parts. Examine and clean the cooling system and its components like fans, cooling channels, and heat exchangers. Refrain from operating the pump at maximum capacity for lengthy durations.

10.What are the Consideration Points for Purchasing a Vacuum Degassing Machine?

To buy a machine that exceeds your expectations and improves seamlessness of operativity, it is suggested to ponder on consideration points related to system requirements. Several key factors are written below to assist you in purchasing an excellent vacuum degassing machine.

Type of Material

Type of Material

First, you must decide on the type of material that you will be degassing like metals, plastics, food, and others. Study the properties of the materials, such as their viscosity, density, etc. You will also have to identify the gases that you will be extracting. Select the machines that match your material characteristics and degassing needs.

Vacuum Level

Vacuum Level- Picture Courtesy: Poppe + Potthoff Maschinenbau

It is imperative to determine the suitable vacuum level for your particular operation because materials require varying vacuum pressures- high, low, and medium- for their effective degassing. Your potential machine should be able to attain and maintain the required pressure.

Vacuum Chamber Capacity

Vacuum Chamber Capacity

The design and capacity of the vacuum degassing machine largely impact its working status and production volume. The vacuum chamber is manufactured in a variety of sizes, so if you require higher throughput, go for a heavy-duty vacuum degassing machine.

Maintenance and Support

Maintenance and Support-Picture Courtesy: RIB Software

Experts recommend contemplating service contracts, spare parts inventory, and technical support of the manufacturer when purchasing the machine. Support from manufacturers like maintenance plans and accessibility of spare parts at short notice is necessary for increasing uptimes and reducing chances of operational disruptions.

Budget

Budget- Picture Courtesy: NJ.com

Calculate and compare the upfront cost of the machine with its life expectancy, durability, and operational level. Also, access the total cost of ownership, counting energy usage, maintenance charges, and spare part replacement costs. Machines having better work productivity, durability, and lower energy consumption save money down the line.

Conclusion

In summary, a vacuum degassing machine is an indispensable tool that offers valuable services in various industries. It comes with extraordinary advantages, such as efficient degassing, and boosts product quality and aesthetics. Its limitless potential contributes to the continuous evolution and growth of business. There are several amazing series of vacuum degassing machines in the market and selecting the right one is a challenging task. Therefore, Allpack is ever ready to help you in this task by offering you valuable guidance and support. So, get in touch with us through email or messaging service.

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp:+86 18171018586